Noise reduction interior trim system for special vehicle cab

A technology for special vehicles and cabs, which is applied to vehicle components, superstructures, and subassemblies of superstructures, etc. It can solve problems such as less research on NVH performance of special vehicles, restlessness and attention, and mental stress of the occupants, and achieves a simple structure , strong adaptability, and the effect of widening the noise reduction frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

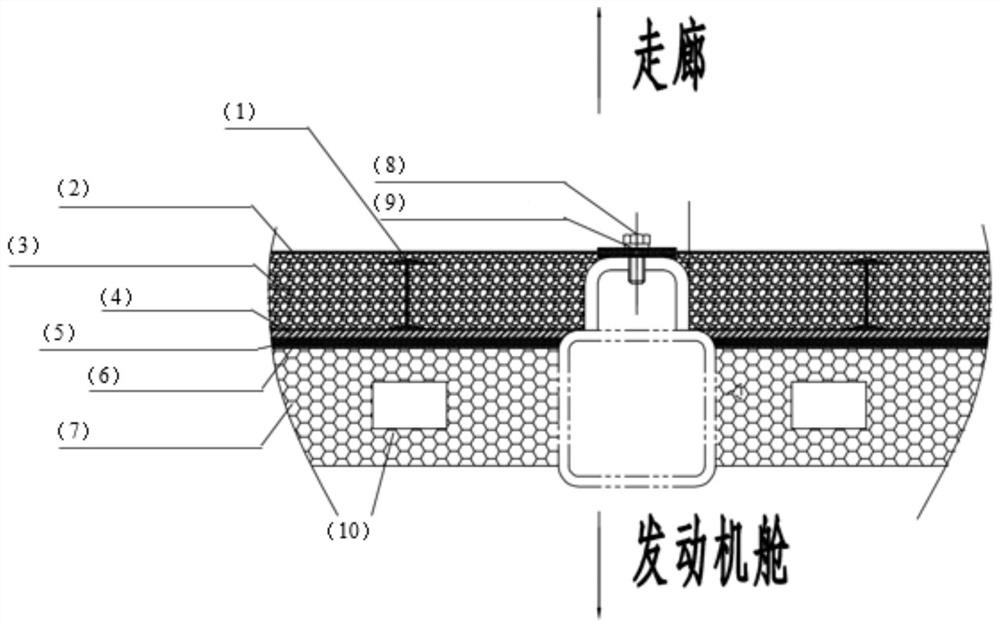

[0032] A noise-reducing interior trim system for a cab of a special vehicle, the system includes any one or a combination of any one or more of a sound-absorbing structure interior, a high-strength multi-layer composite floor, and an engine compartment sound-absorbing and insulating structure interior;

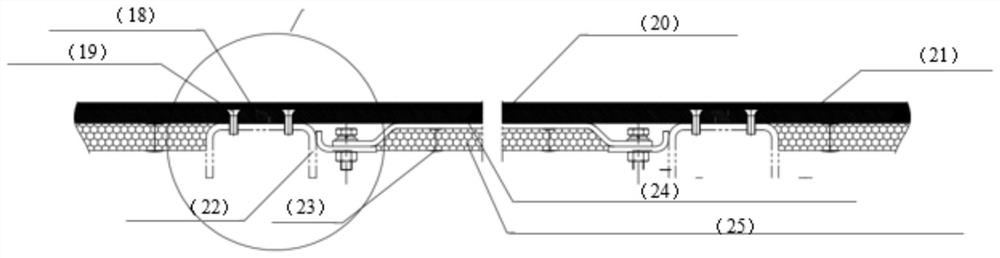

[0033] The interior of the sound-absorbing structure includes the first sound-absorbing material and the first armor layer in sequence from the inside to the outside, and the first sound-absorbing material is attached to the wall of the cab;

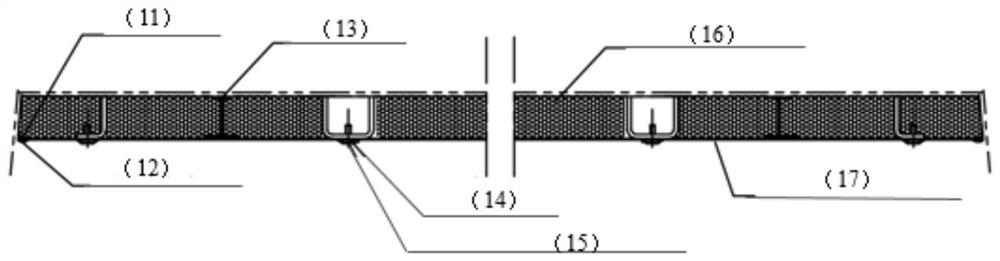

[0034] The high-strength multi-layer composite floor includes floor leather, damping composite interlayer floor, and second sound-absorbing material from top to bottom, and the second sound-absorbing material is set close to the ground;

[0035] The interior decoration of the sound-absorbing and insulating structure of the engine compartment includes the third sound-absorbing material, the damping steel plate, the fourth sound-absorbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com