Efficient and environment-friendly mechanical draft cooling tower

A ventilation cooling and environment-friendly technology, applied in the field of cooling towers, can solve problems such as difficulty in eliminating low-frequency noise, achieve the effects of reducing resistance, reducing emissions, and facilitating construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

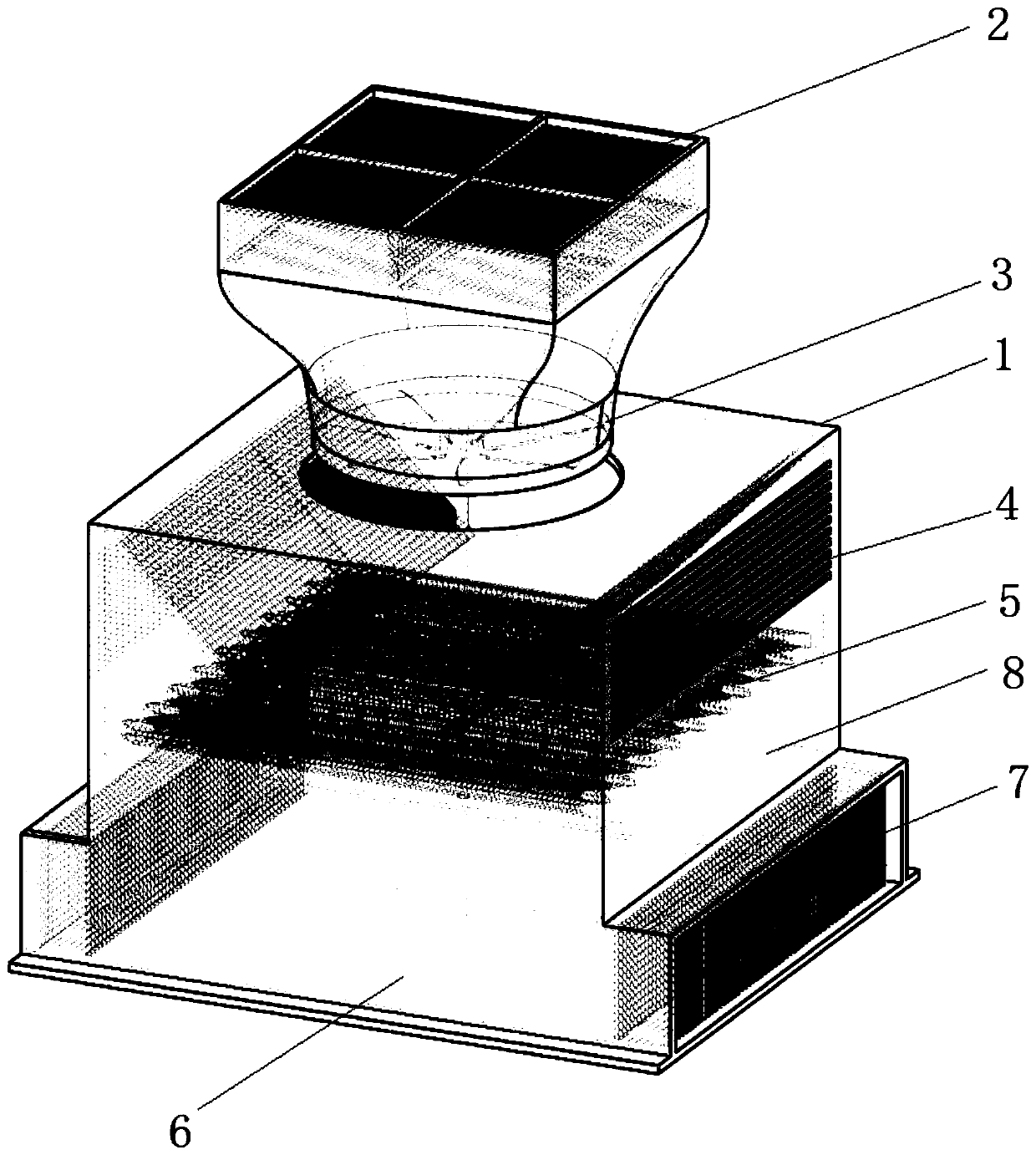

Embodiment 1

[0033] Embodiment 1 of the present invention: a high-efficiency and environment-friendly mechanical ventilation cooling tower, including a tower body 1 and a noise reduction structure, the noise reduction structure includes an exhaust muffler 2 arranged at the top of the tower body 1 and an exhaust muffler 2 arranged at the bottom of the tower body 1 The air inlet muffler 7; also includes the sound insulation guide tube 3 arranged under the exhaust muffler 2, the noise reduction demister 4 arranged under the sound insulation guide tube 3, and the noise reduction demister 4 arranged under the noise reduction demister The water device 5 is arranged in the water distribution filling area 8 below the water eliminator 5 , and the falling water noise reduction device 6 is arranged under the water distribution filling area 8 . Wherein, the exhaust muffler 2 and the air inlet muffler 7 both include a muffler chamber 9 and a muffler plate 10 or a pointed muffler 11 , and the muffler pla...

Embodiment 2

[0034] Embodiment 2 of the present invention: a high-efficiency and environment-friendly mechanical ventilation cooling tower, including a tower body 1 and a noise reduction structure, the noise reduction structure includes an exhaust muffler 2 arranged on the top of the tower body 1 and an exhaust muffler 2 arranged at the bottom of the tower body 1 The air inlet muffler 7; also includes the sound insulation guide tube 3 arranged under the exhaust muffler 2, the noise reduction demister 4 arranged under the sound insulation guide tube 3, and the noise reduction demister 4 arranged under the noise reduction demister The water device 5 is arranged in the water distribution filling area 8 below the water eliminator 5 , and the falling water noise reduction device 6 is arranged under the water distribution filling area 8 . Wherein, both the exhaust muffler 2 and the air inlet muffler 7 include a muffler cavity 9 and a plurality of muffler plates 10 arranged in parallel, and the mu...

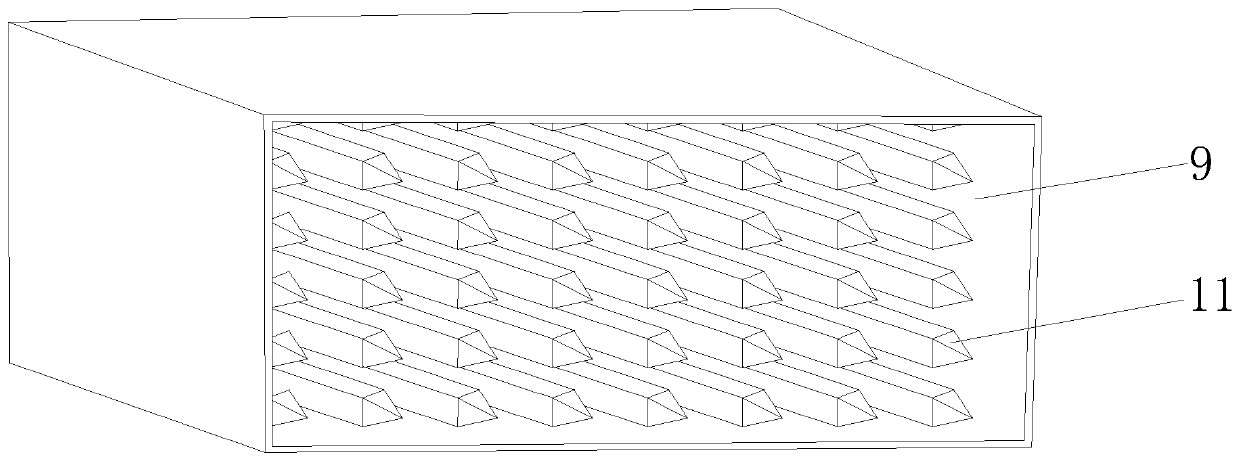

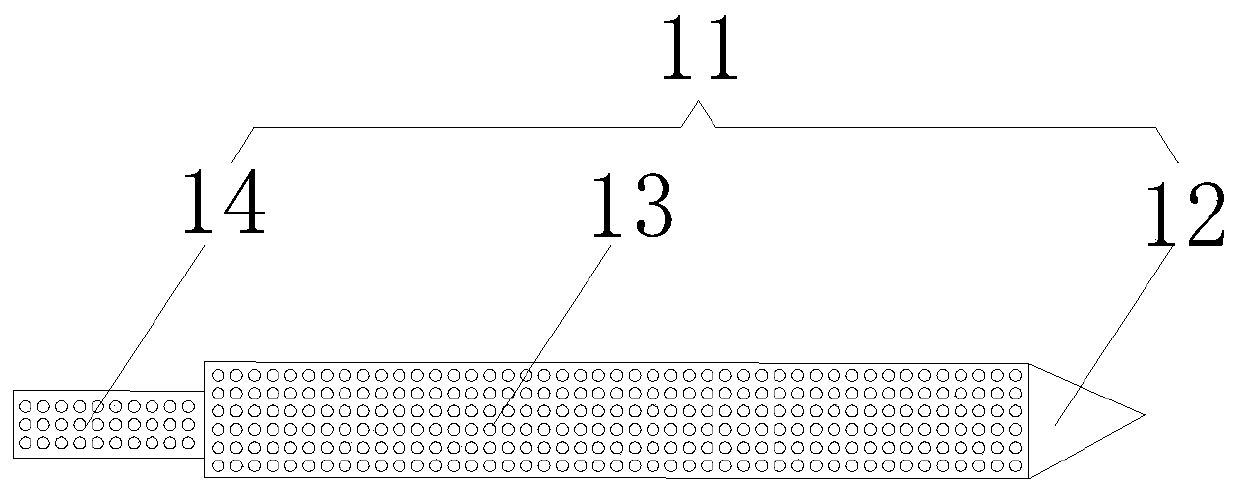

Embodiment 3

[0035]Embodiment 3 of the present invention: a high-efficiency and environment-friendly mechanical ventilation cooling tower, including a tower body 1 and a noise reduction structure, the noise reduction structure includes an exhaust muffler 2 arranged at the top of the tower body 1 and an exhaust muffler 2 arranged at the bottom of the tower body 1 The air inlet muffler 7; also includes the sound insulation guide tube 3 arranged under the exhaust muffler 2, the noise reduction demister 4 arranged under the sound insulation guide tube 3, and the noise reduction demister 4 arranged under the noise reduction demister The water device 5 is arranged in the water distribution filling area 8 below the water eliminator 5 , and the falling water noise reduction device 6 is arranged under the water distribution filling area 8 . Wherein, the exhaust muffler 2 and the air inlet muffler 7 both include a muffler chamber 9 and a pointed muffler body 11 , and the muffler body 11 is built in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com