High-heat-insulation ultralow-heat-conductivity-coefficient composite heat preservation material with fireproof function

A composite thermal insulation material and thermal conductivity technology, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve the problems of thermal insulation composite thermal insulation materials without fire resistance, low thermal conductivity, and low thermal insulation of composite thermal insulation materials. , to achieve the effect of excellent chemical stability, good fire resistance and improved use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

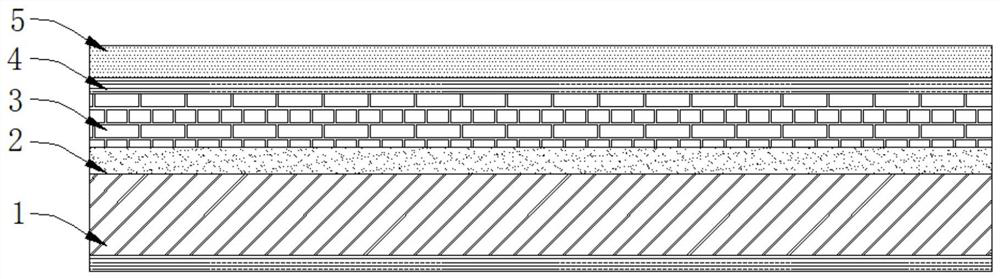

[0028] see figure 1 , the present invention provides a technical solution: a composite insulation material with high heat insulation and ultra-low thermal conductivity with fireproof function, comprising an aluminum silicate fiber base layer 1 and a waterproof coating 4, and one side of the aluminum silicate fiber base layer 1 is set There is a barrier layer 2, and the other side of the barrier layer 2 is provided with a heat insulation layer 3, the other side of the heat insulation layer 3 is provided with a waterproof coating 4, and the fireproof layer 5 is provided on the other side of the waterproof coating 4;

[0029] The specific operation is as follows. The composite thermal insulation material with high heat insulation and ultra-low thermal conductivity with fireproof function has excellent chemical stability, thermal stability, tensile strength, low heat capacity and low thermal conductivity, so as to avoid external force during actual use. The pulling of the composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com