Fireproof inhaul cable and manufacturing method thereof

A manufacturing method and cable technology, applied in the cable field, can solve the problems of complicated zinc coating process, high material cost and high cost, and achieve the advantages of improving fire resistance and service time, simple and easy process, and good construction performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

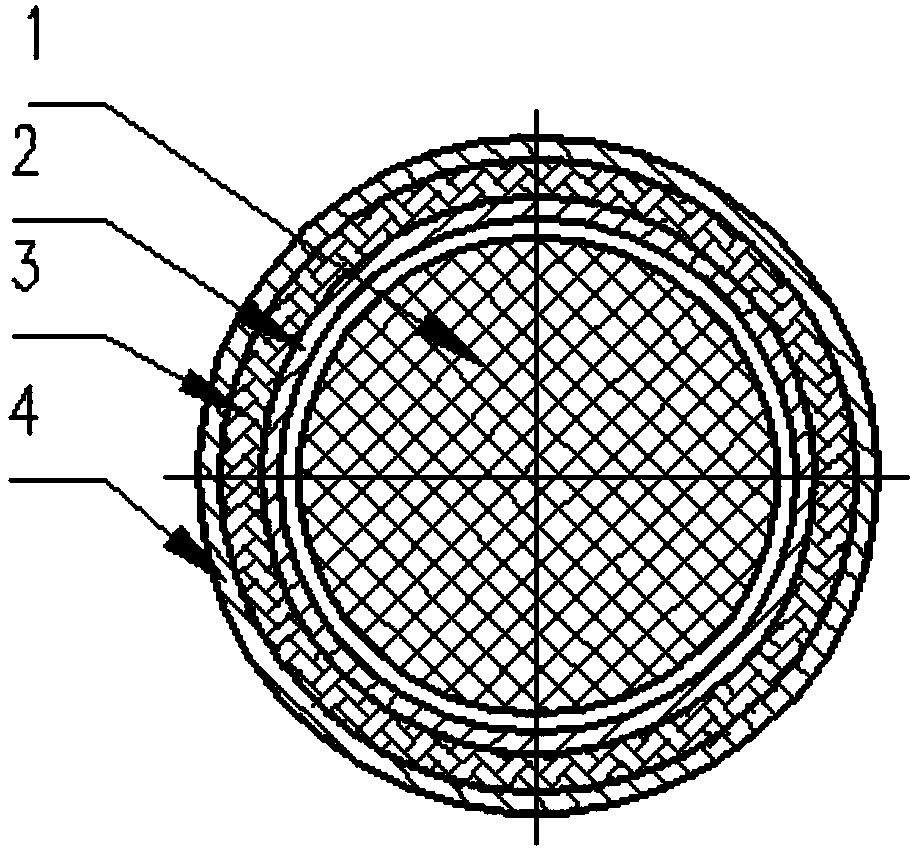

[0036] as attached figure 1 and attached figure 2 As shown, a fireproof cable, including cable (1), inner liner (2), fireproof layer (3) and outer liner (4), is characterized in that, the inner liner (2) is nested On the outside of the cable (1), the outer liner (4) is nested outside the inner liner (2), between the inner liner (2) and the outer liner (4) The fireproof layer (3).

[0037] The inner lining pipe (2) and the outer lining pipe (4) are one of high-density polyethylene pipes or steel casing pipes.

[0038] The fireproof layer (3) is a filled fireproof material (3a), such as aluminum silicate fiber cotton, perlite and the like. Aluminum silicate fiber cotton and perlite have good fire resistance.

[0039] A method for making a fireproof cable, comprising the following steps,

[0040] Step 1, making inner and outer lining pipes according to the diameter of the dragline, the diameter of the inner lining pipe is greater than or equal to the diameter of the draglin...

Embodiment 2

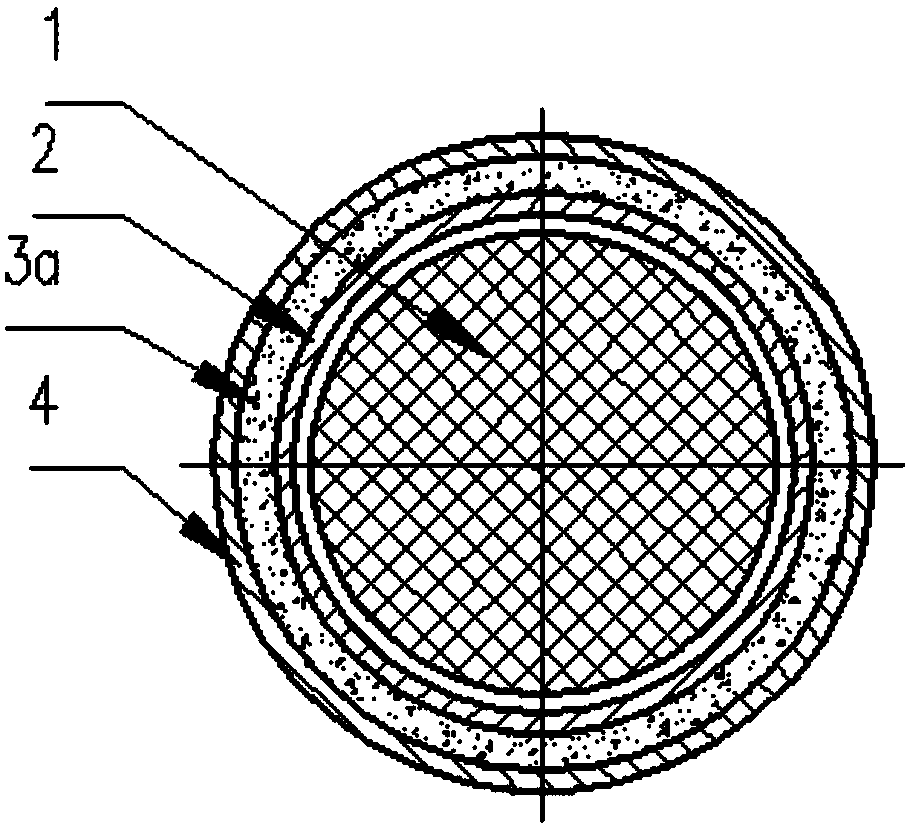

[0045] as attached image 3 As shown, a fireproof cable, including cable (1), inner liner (2), fireproof layer (3) and outer liner (4), is characterized in that, the inner liner (2) is nested On the outside of the cable (1), the outer liner (4) is nested outside the inner liner (2), between the inner liner (2) and the outer liner (4) The fireproof layer (3).

[0046] The inner lining pipe (2) and the outer lining pipe (4) are one of high-density polyethylene pipes or steel casing pipes.

[0047] The fireproof layer (3) is a wrapping fireproof filler (3b), such as one of fireproof cotton, fireproof blanket, fireproof cloth and the like.

[0048] A method for making a fireproof cable, comprising the following steps,

[0049] Step 1, making inner and outer lining pipes according to the diameter of the dragline, the diameter of the inner lining pipe is greater than or equal to the diameter of the dragline, and the diameter of the outer lining pipe is larger than the diameter of...

Embodiment 3

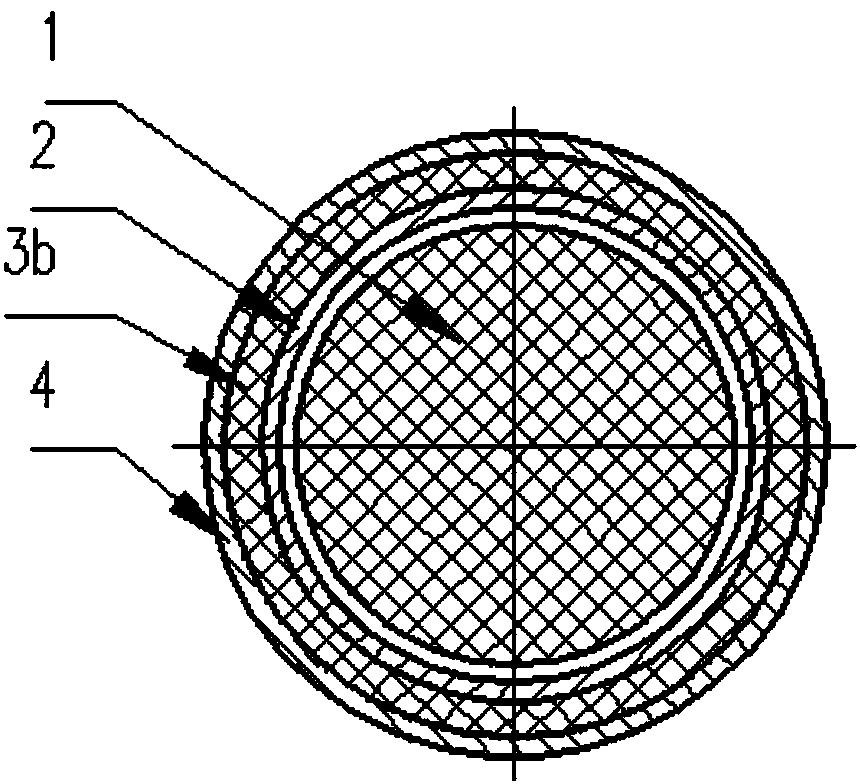

[0054] as attached Figure 4 As shown, a fireproof cable, including cable (1), inner liner (2), fireproof layer (3) and outer liner (4), is characterized in that, the inner liner (2) is nested On the outside of the cable (1), the outer liner (4) is nested outside the inner liner (2), between the inner liner (2) and the outer liner (4) The fireproof layer (3).

[0055] The inner lining pipe (2) and the outer lining pipe (4) are one of high-density polyethylene pipes or steel casing pipes.

[0056] The fireproof layer (3) is a fireproof paint (3c) painted outside the lining pipe (2).

[0057] A method for making a fireproof cable, comprising the following steps,

[0058] Step 1, making inner and outer lining pipes according to the diameter of the dragline, the diameter of the inner lining pipe is greater than or equal to the diameter of the dragline, and the diameter of the outer lining pipe is larger than the diameter of the inner lining pipe;

[0059] Step 2, the inner lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com