Automatic compensation butterfly valve

An automatic compensation and butterfly valve technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of unsealed valves, increased opening torque, and valve stem damage, so as to achieve reliable sealing performance, reduce opening torque, and increase service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

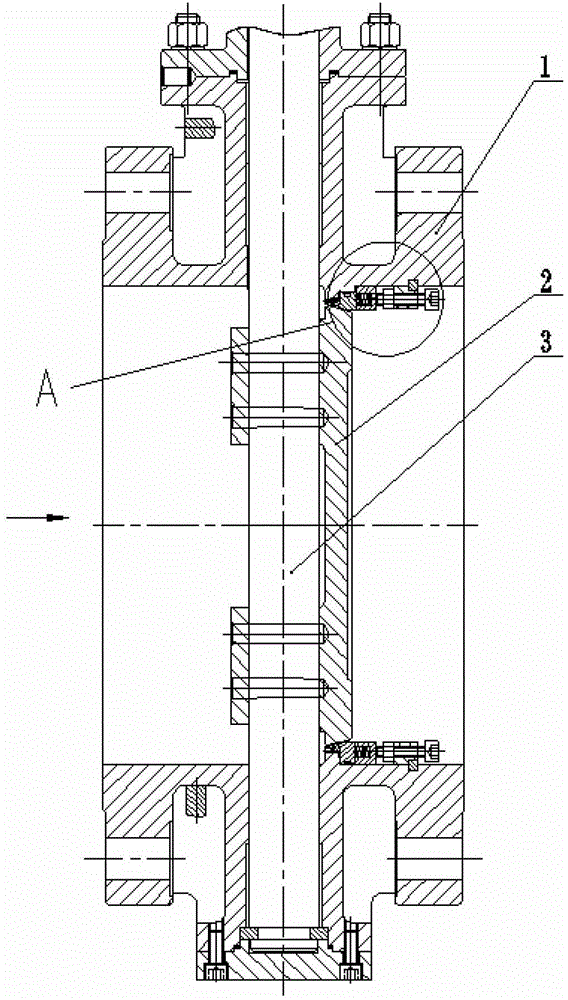

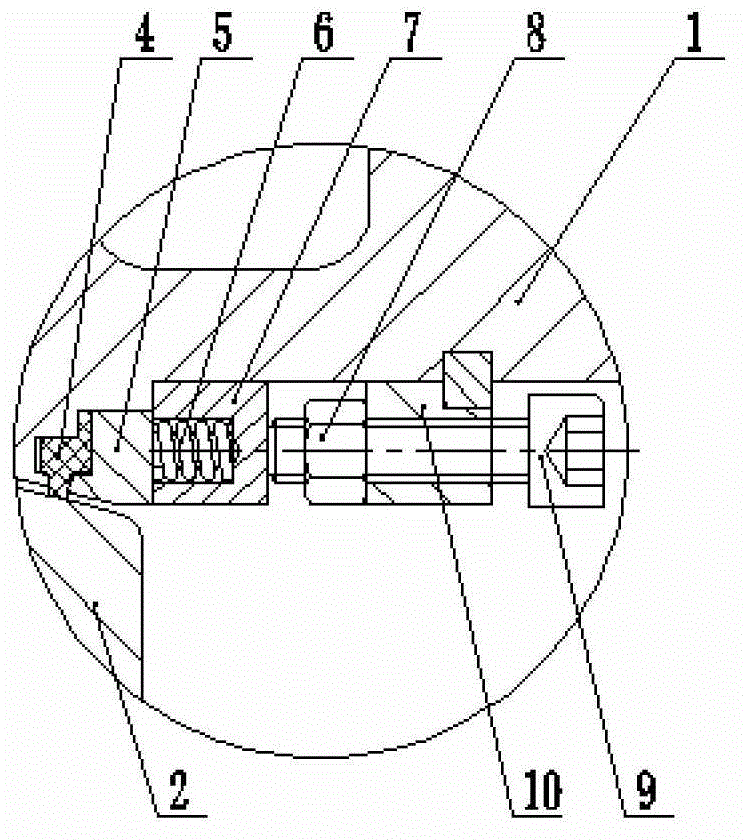

[0016] An automatic compensation butterfly valve, including a valve body 1, a valve stem 3, a butterfly plate 2 and a valve seat sealing ring 4, as attached figure 1 The valve body shown in the figure has a horizontal medium channel, and the arrow in the attached drawing shows the flow direction of the medium. The butterfly plate controls the closing and opening of the medium channel in the valve body; a valve seat sealing ring is coaxially installed on the inner wall of the medium channel of the valve body on the side where the butterfly plate is installed, and the valve seat sealing ring is frictionally sealed with the butterfly plate, and the valve seat sealing ring The material is fluorine plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com