Patents

Literature

32results about How to "Small opening torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

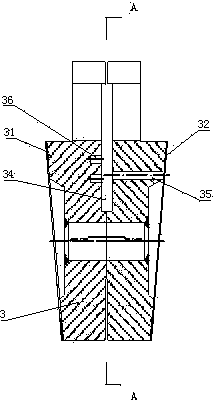

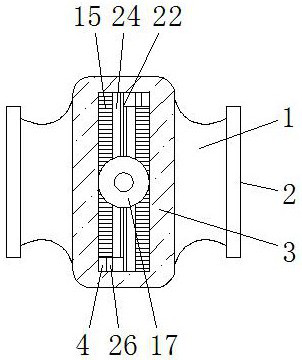

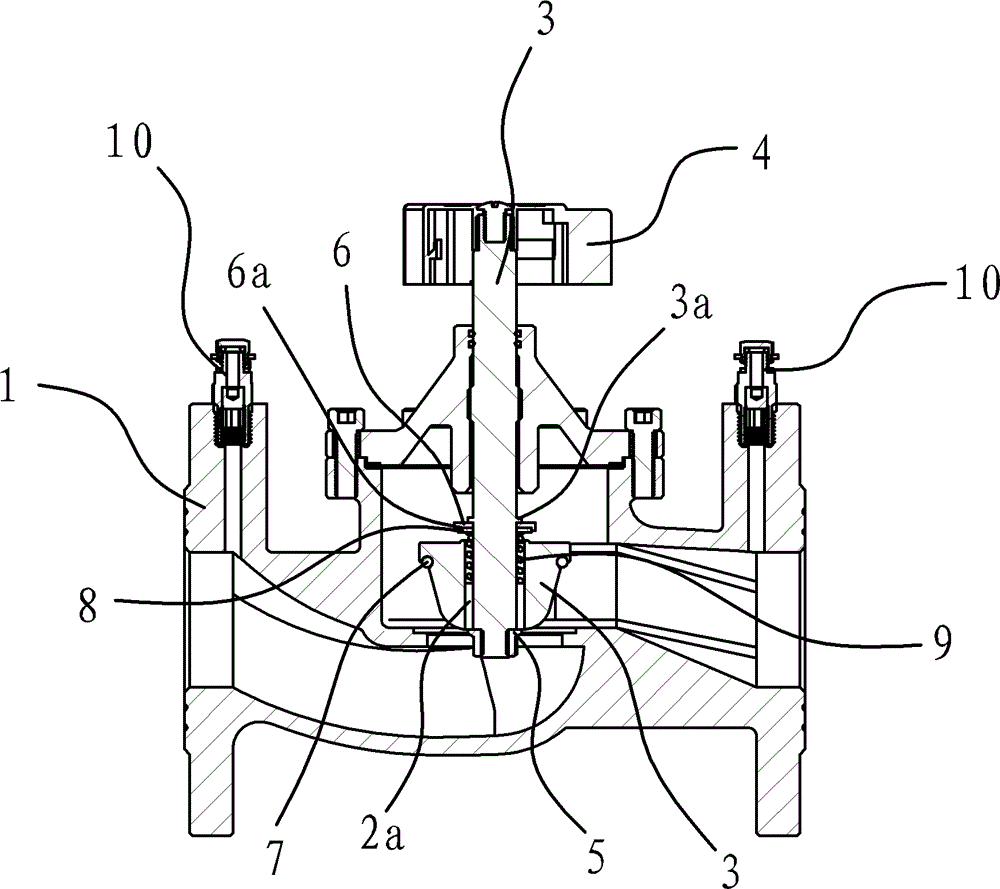

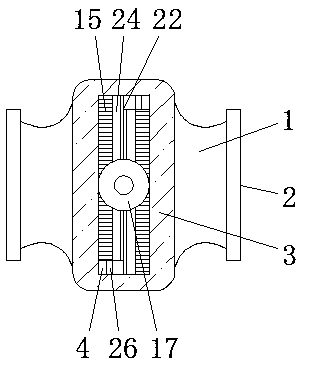

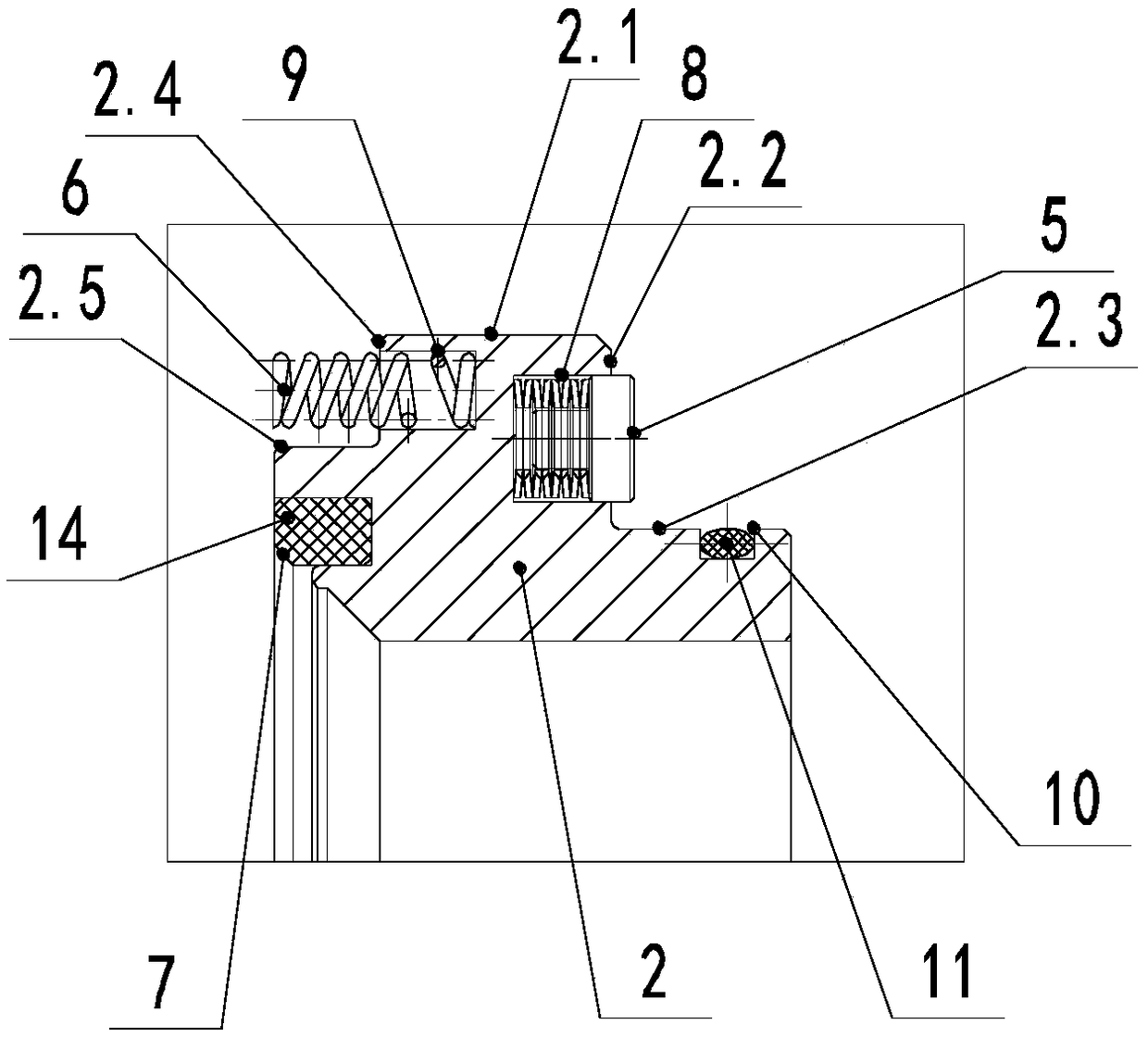

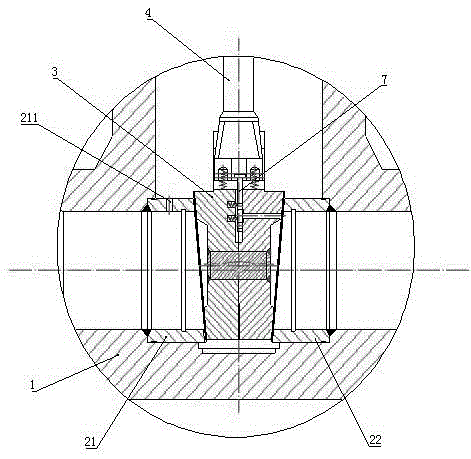

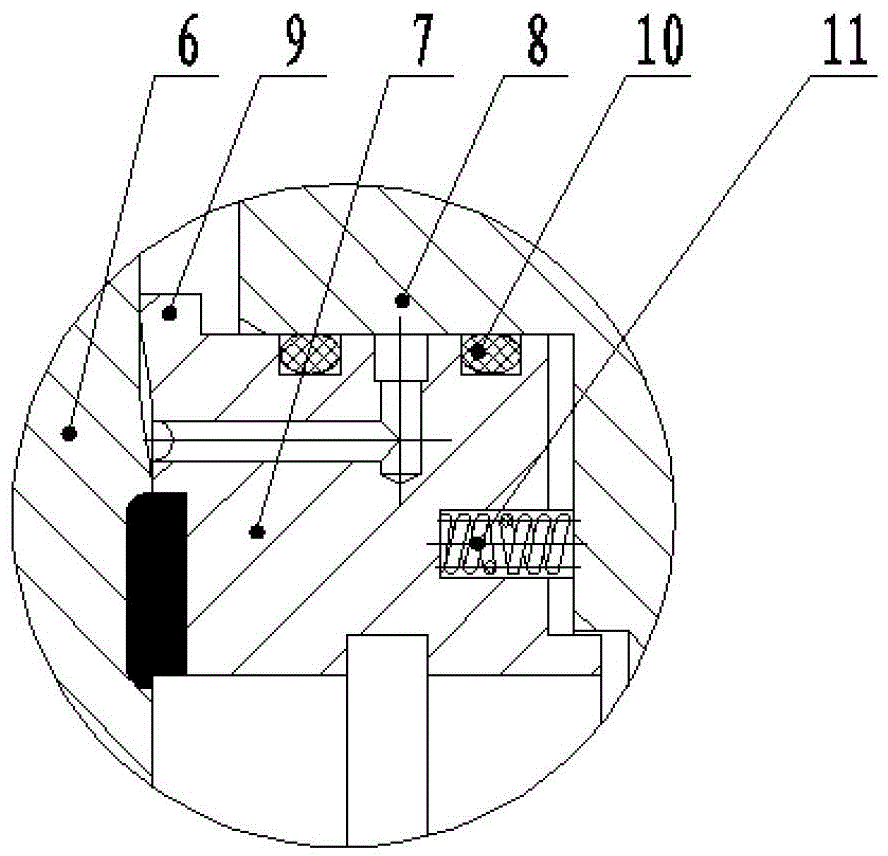

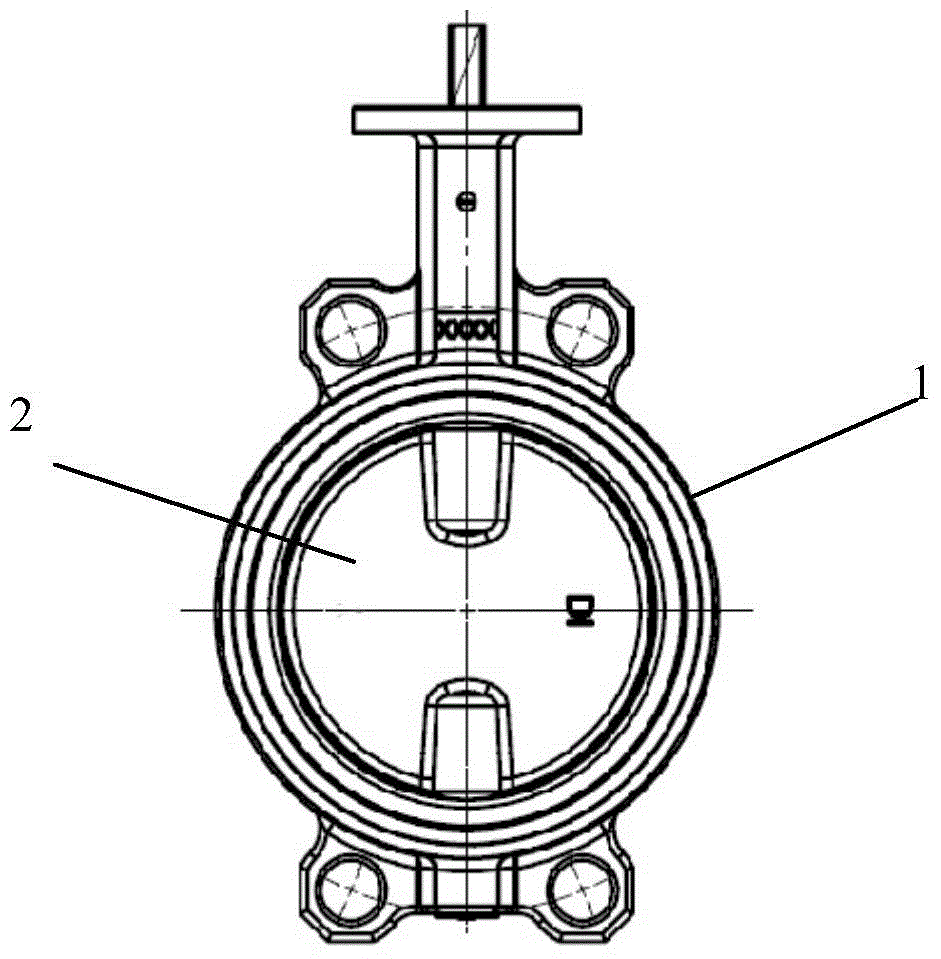

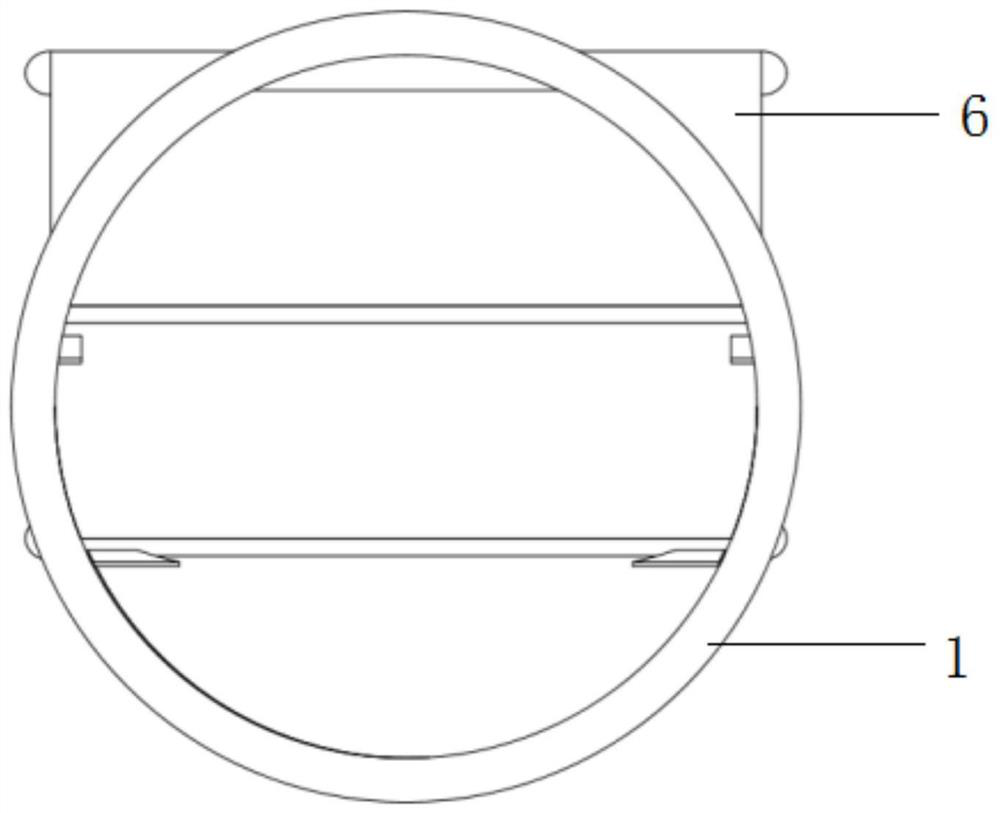

Automatic compensation butterfly valve

The invention relates to an automatic compensation butterfly valve which comprises a valve body, a valve rod, a butterfly plate and a valve seat sealing ring. A horizontal medium channel is arranged in the valve body, the valve rod is longitudinally arranged in the valve body, and one side of the valve rod in the valve body is fixedly provided with the butterfly plate which rotates under the driving of the valve rod. The valve seat sealing ring is coaxially arranged on the inner wall of the medium channel on one side, where the butterfly plate is arranged, of the valve body, and the valve seat sealing ring is sealed with the butterfly plate in a rubbing mode. The valve seat sealing ring is arranged on the valve body through an elastic compensation device, fixing seats are fixedly arranged between the inner wall of the valve body on the valve seat sealing ring side and the valve seat sealing ring horizontally at intervals. The fixing seats are horizontally provided with screws which are arranged on the fixing seats through guide regulation by nuts, the screws butt against a spring seat horizontally, and the spring seat butts against a pressing ring horizontally. The pressing ring horizontally butts against the valve seat sealing ring. The automatic compensation butterfly valve is simple in structure, scientific in design, reliable in sealing performance, long in service life, small in opening torque, and suitable for various occasions.

Owner:TIANJIN BAILIZHANFA GRP

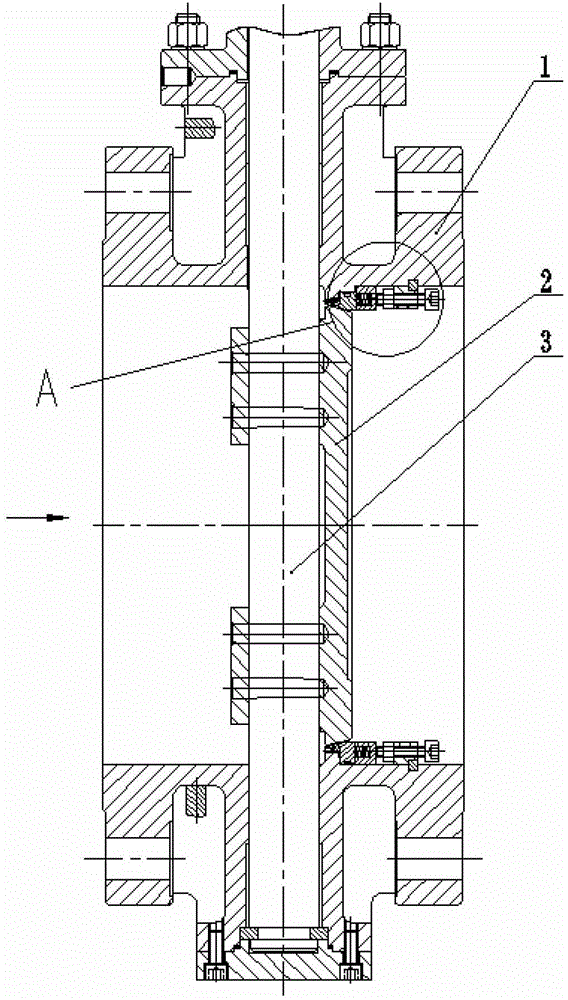

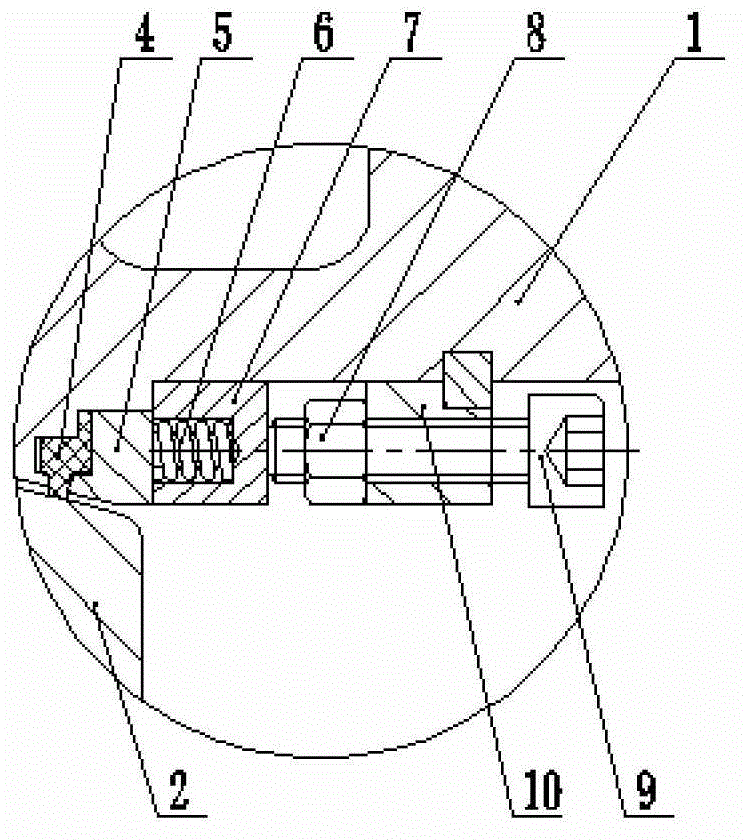

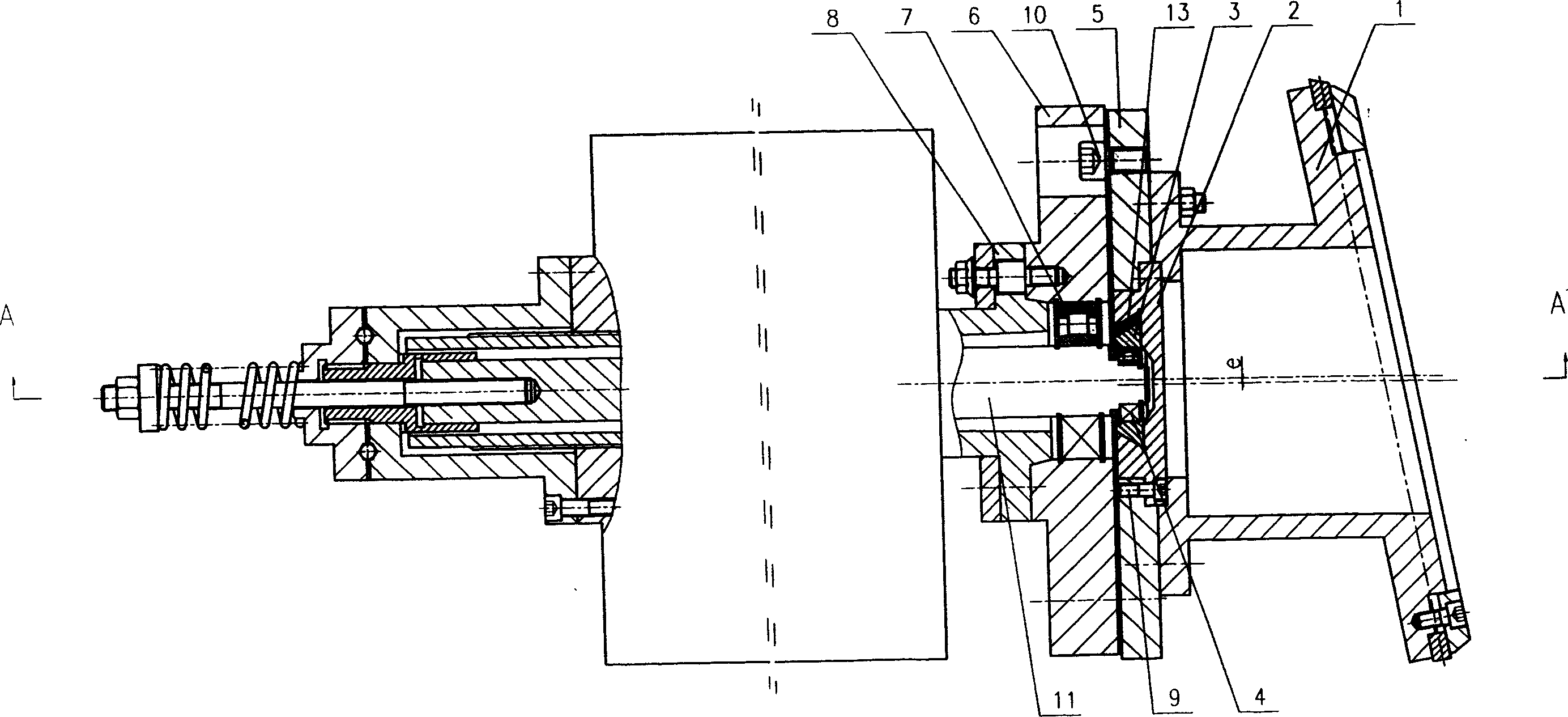

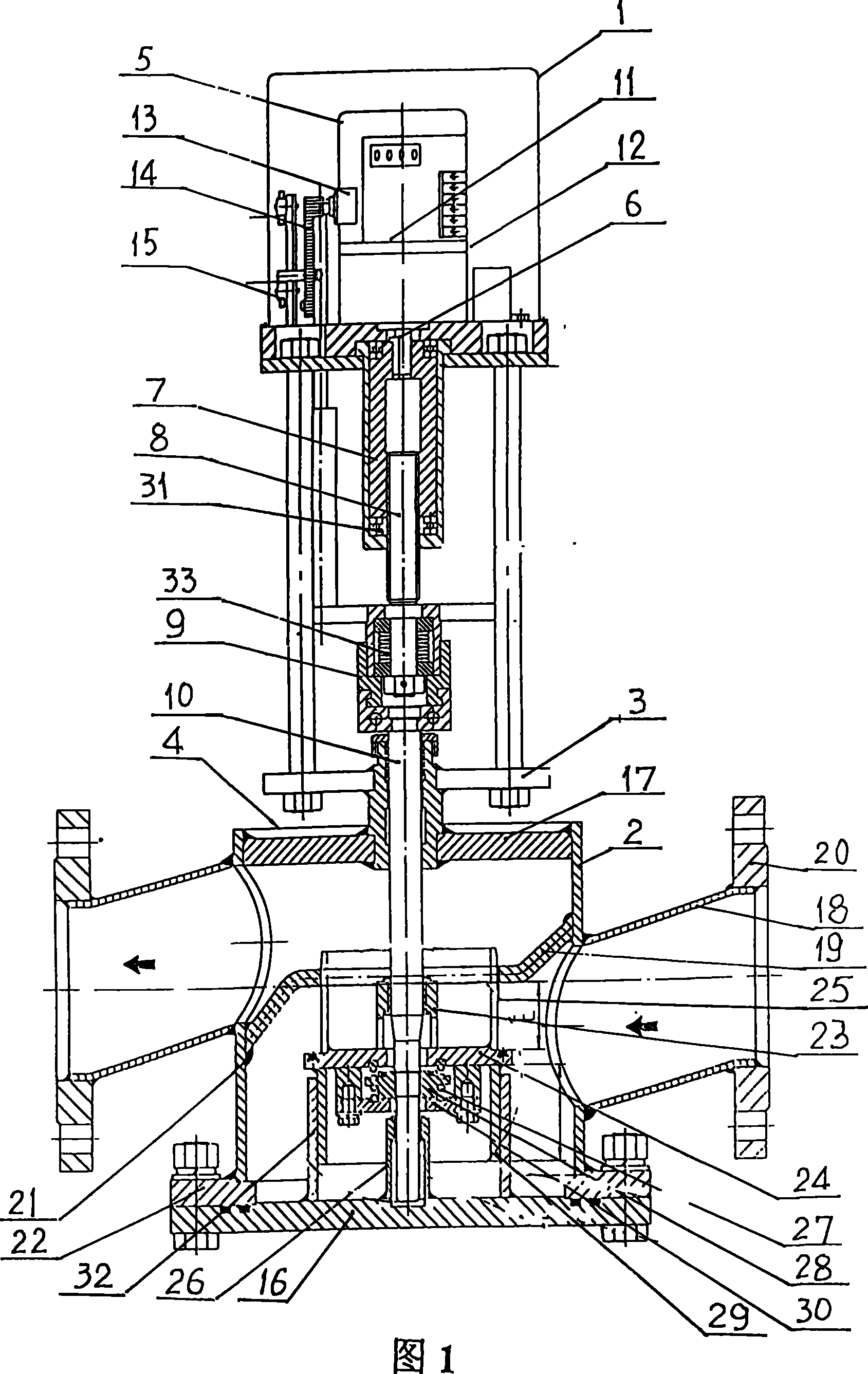

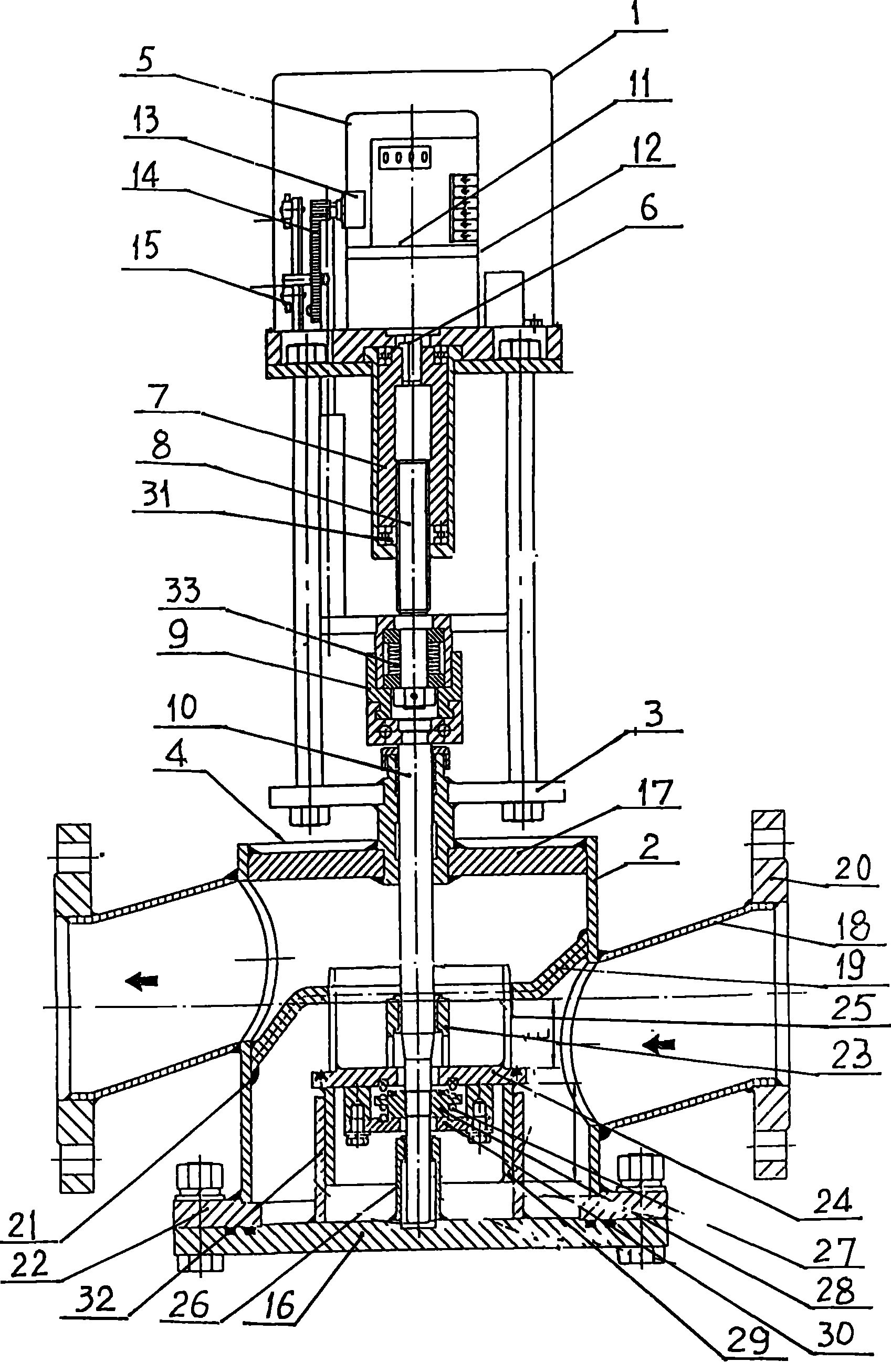

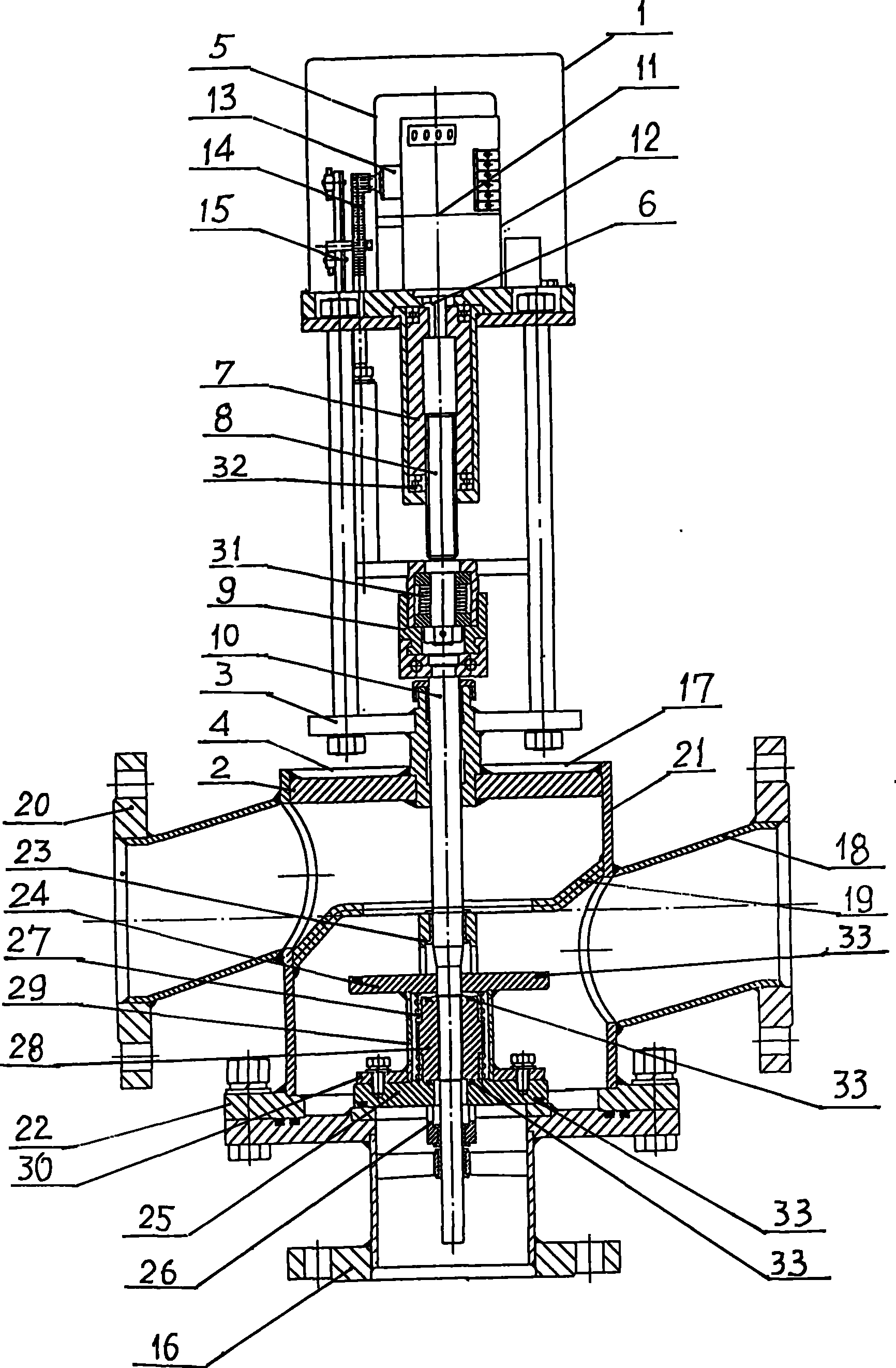

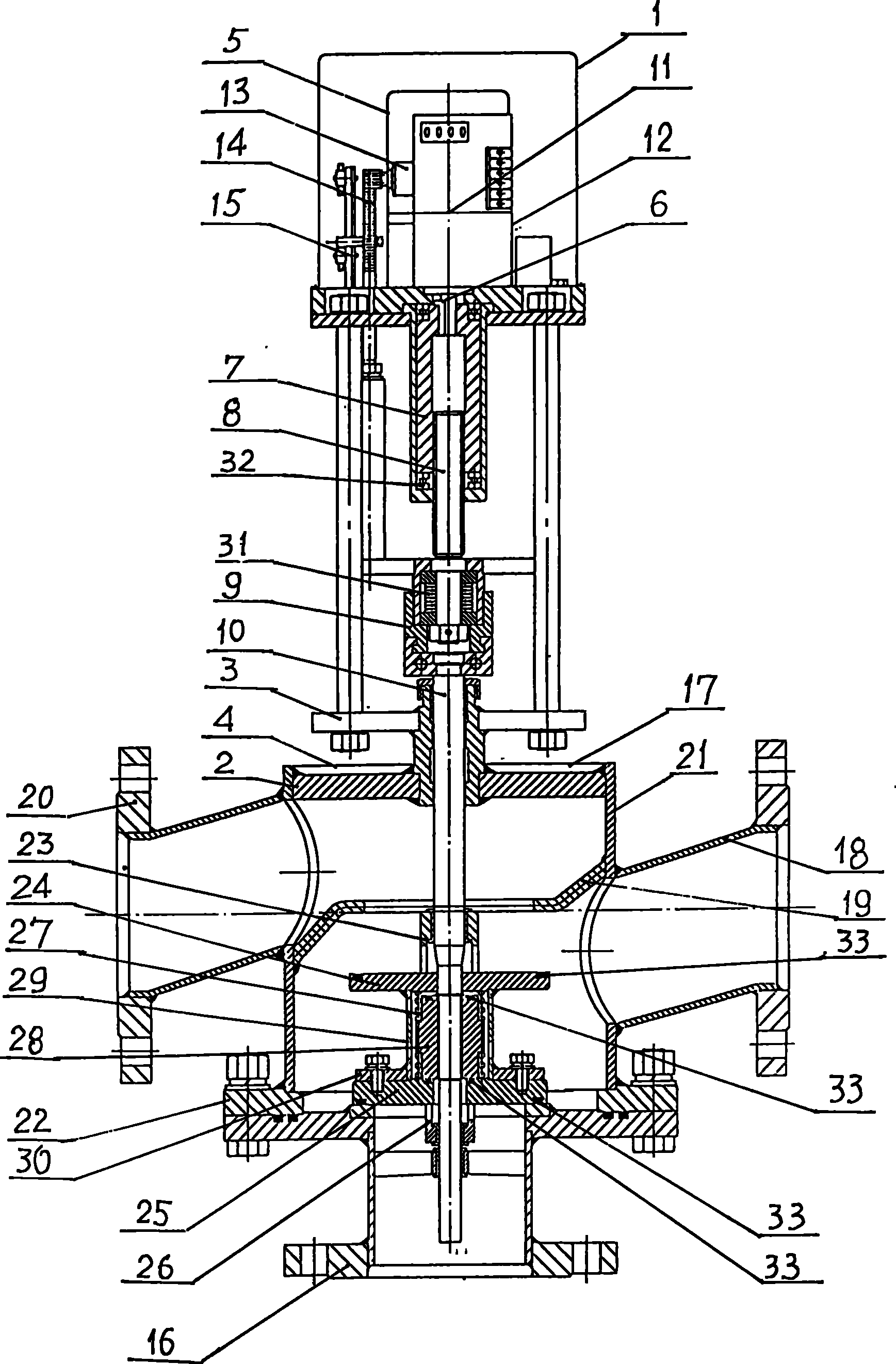

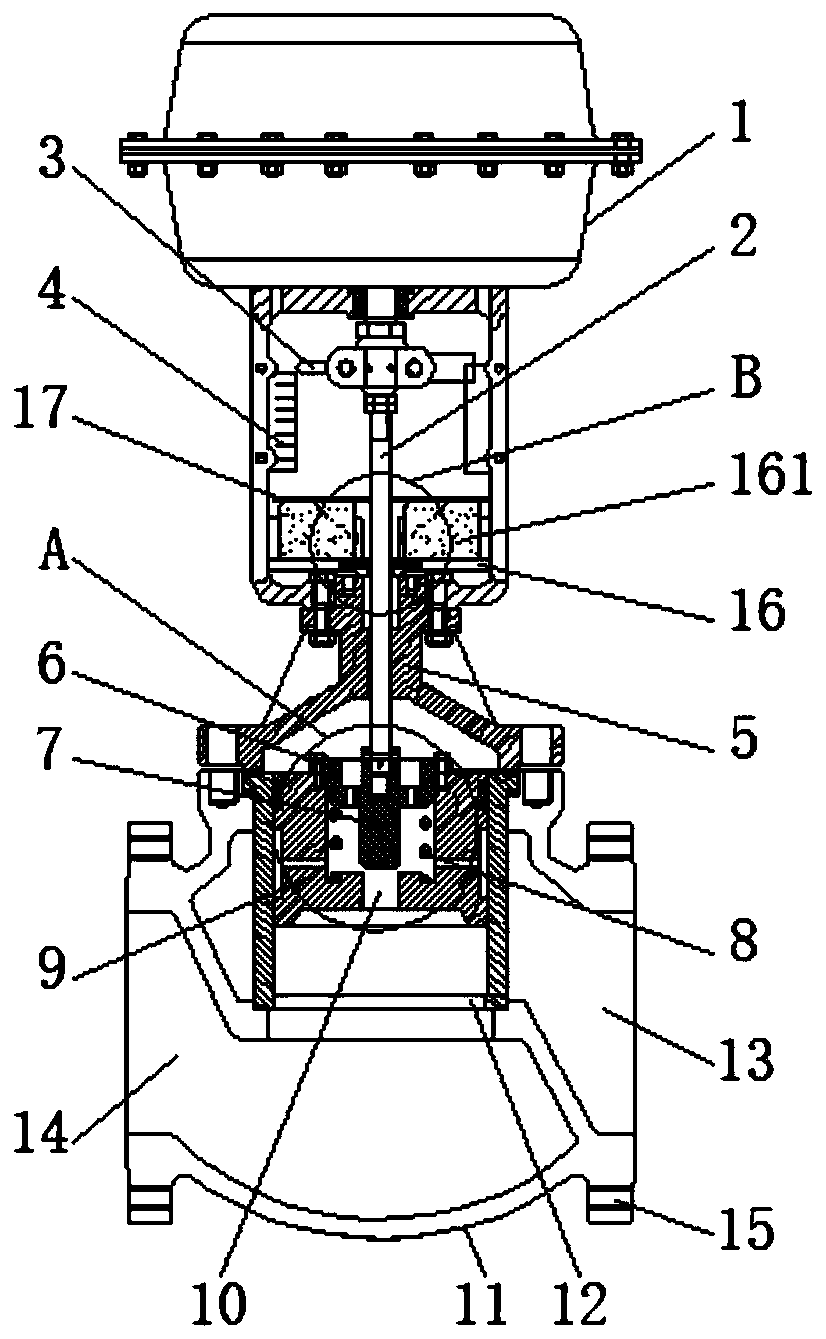

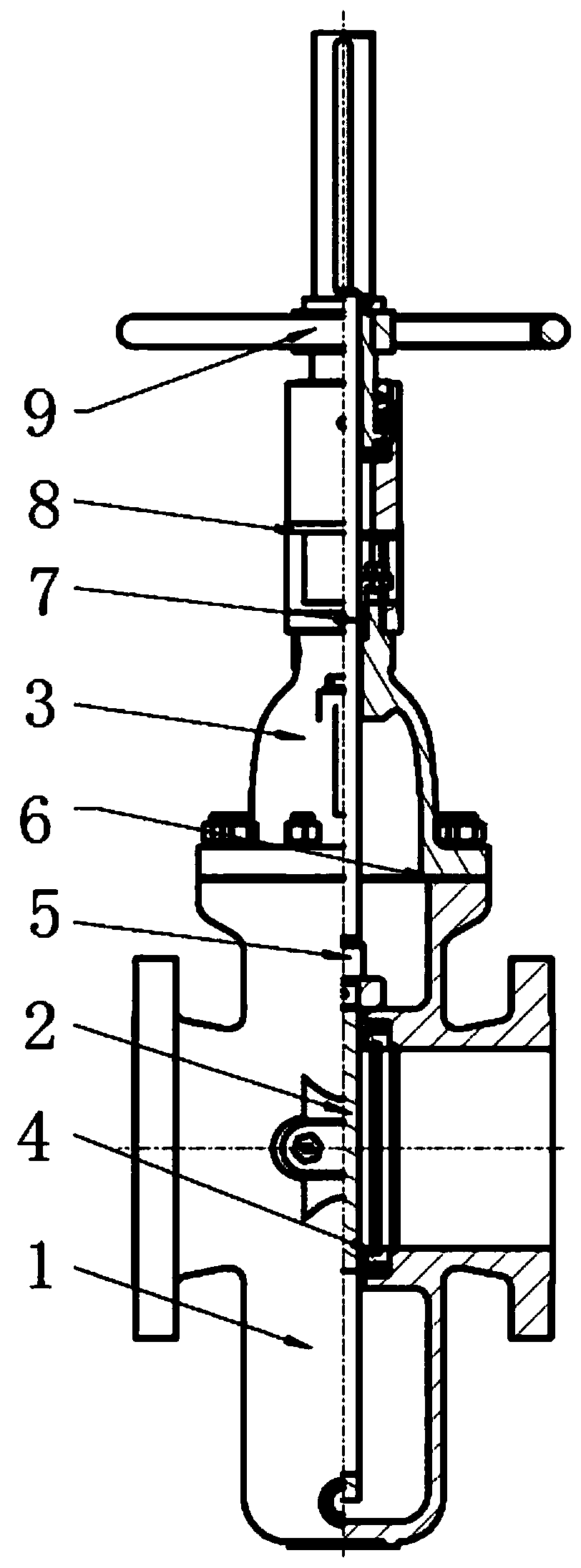

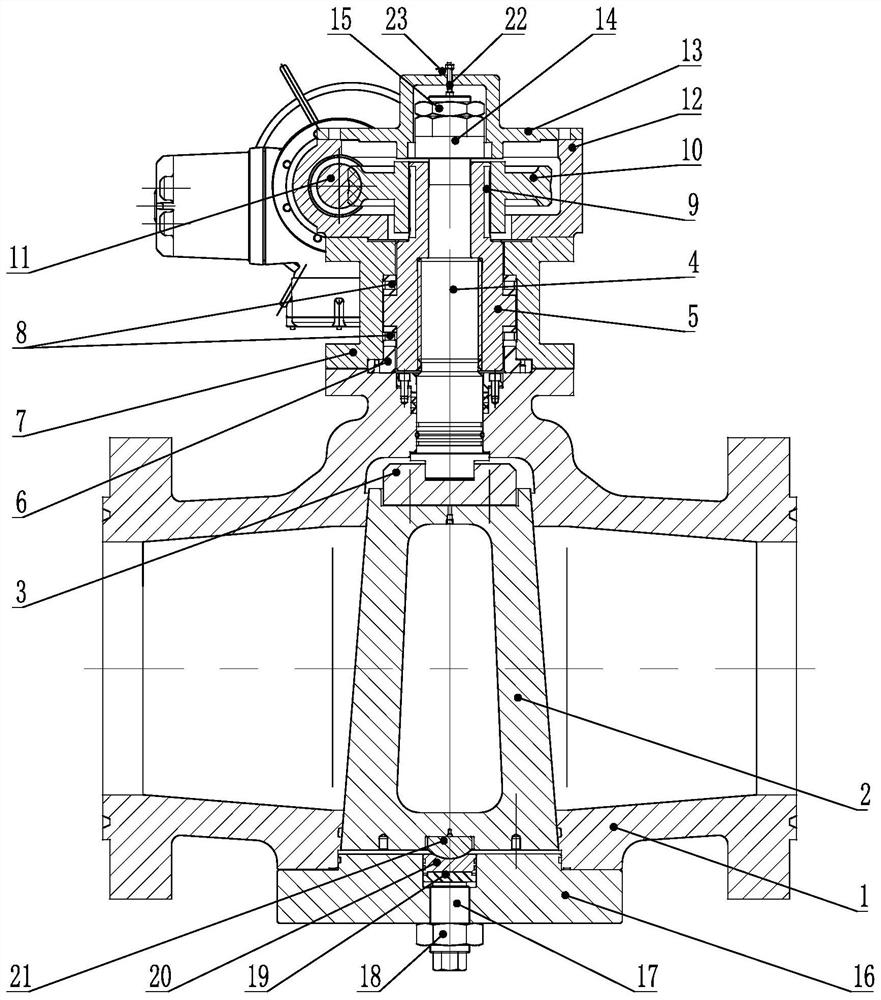

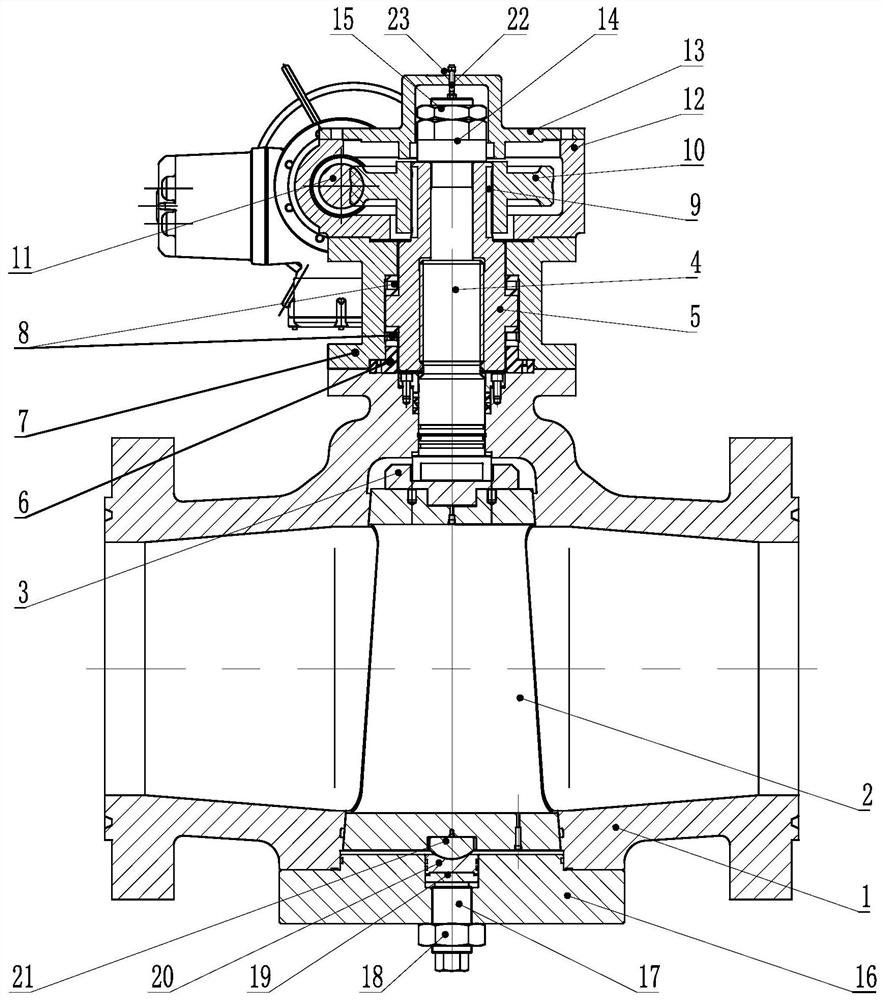

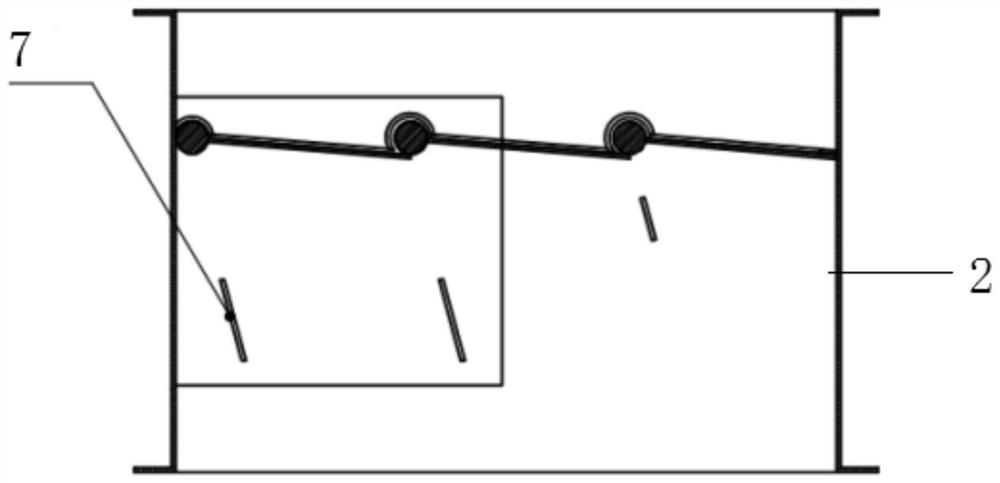

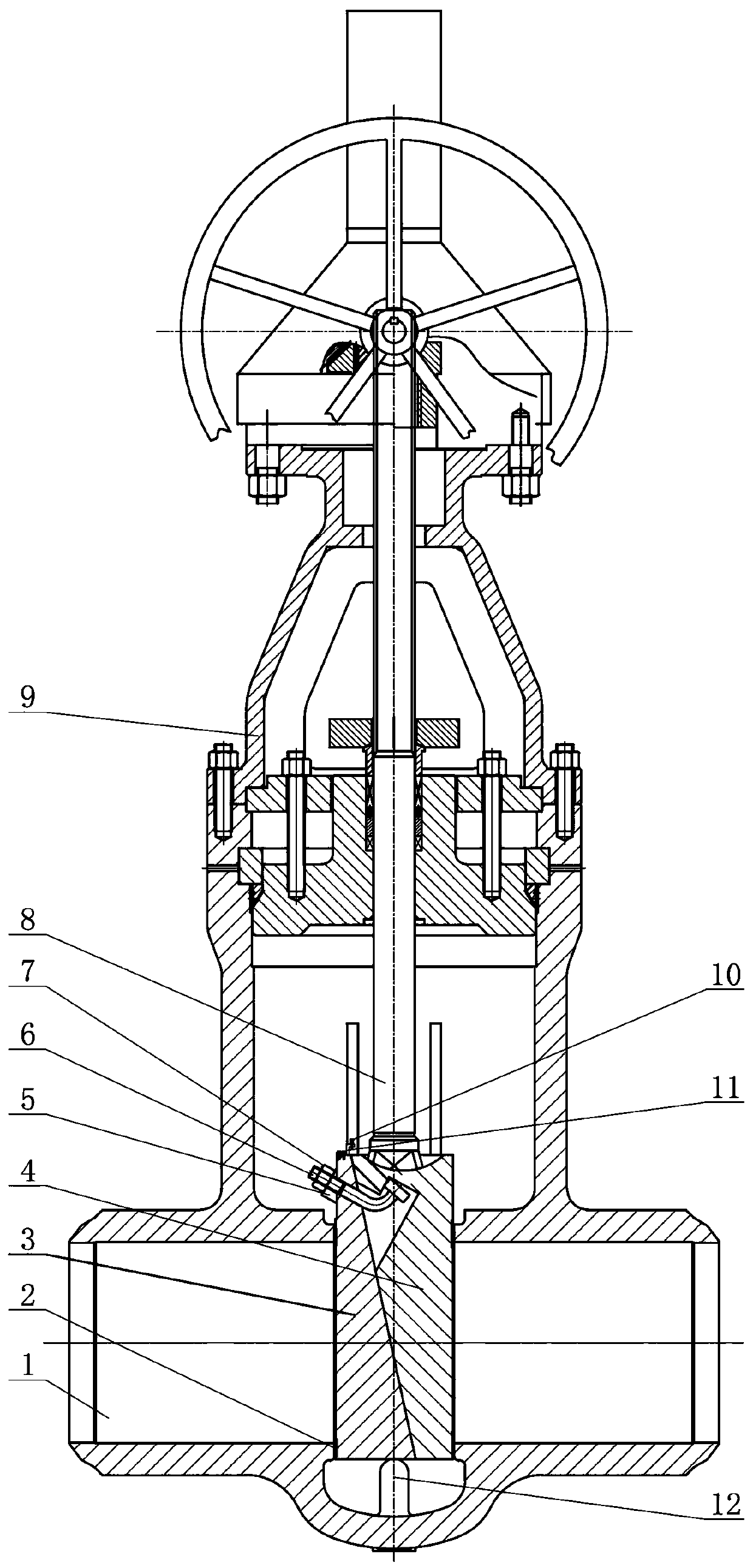

Pilot plant sluice valve

ActiveCN103925382ASmall opening torqueAvoid increased frictionSlide valveBiologyEnvironmental geology

The invention relates to a pilot plant sluice valve. The pilot plant sluice valve is characterized by comprising a pair of valve seats, a flashboard, a valve rod and an auxiliary flashboard; a pressure releasing hole A communicating a flow channel liquid feeding side and the cavity of a valve body is formed in the liquid feeding side of the valve seats; an auxiliary flashboard accommodating groove is formed at the center of a T-shaped groove at the top of the flashboard, and a pressure releasing hole C is formed in a sealing face B of the liquid discharging side of the side of the auxiliary flashboard accommodating groove; the lower end of the valve rod can move for a certain distance in the T-shaped groove; the auxiliary flashboard is mounted at the lower end of the valve rod and is embedded into the auxiliary flashboard accommodating groove, and is provided with a sealing face C, a pressure releasing hole B and a pressure releasing hole D. The pilot plant sluice valve has the advantages that when the valve is opened and closed, the initial valve rod is utilized to drive the auxiliary flashboard to move so as to allow the pressure releasing holes A, B, C and D to form a pressure releasing channel, the pressures on the liquid feeding side and the liquid discharging side are balanced, the opening torque is reduced accordingly, wearing caused by sealing face friction increasing is avoided, and service life is prolonged.

Owner:NANTONG POWER STATION VALVE

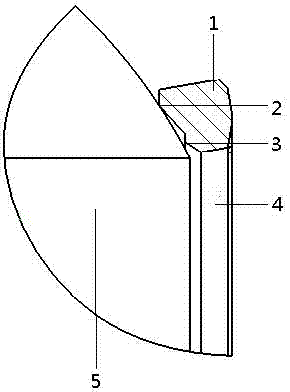

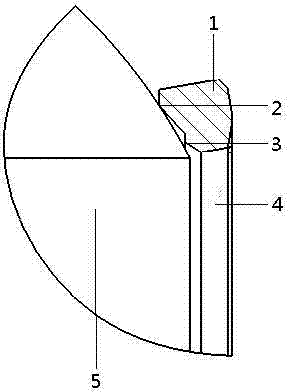

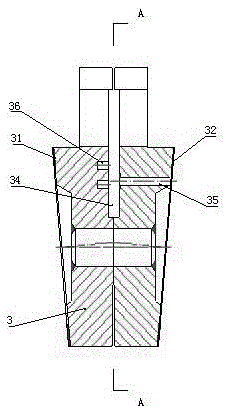

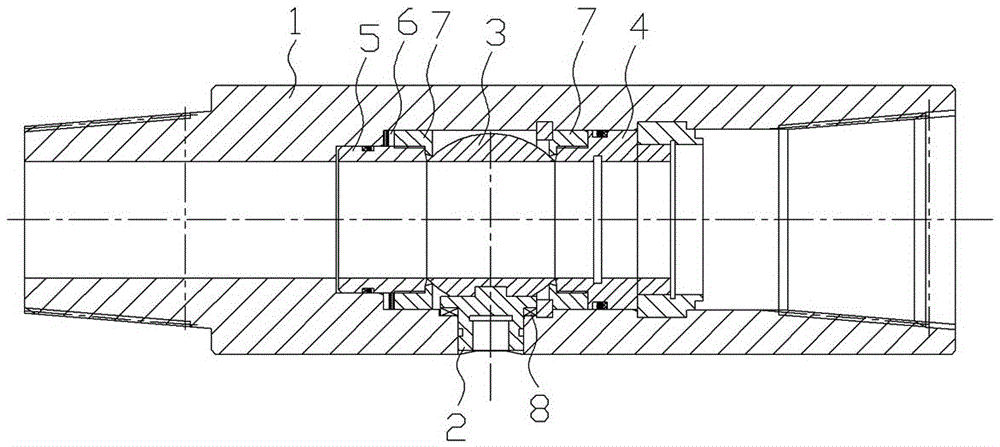

Butterfly plate of butterfly valve and Process tools

InactiveCN1540193AIncrease the eccentricityImprove sealingLift valvePositioning apparatusRadial planeEngineering

A butterfly plate for butterfly valve features that the profile curve of the radial plane of said butterfly plate with conic sealing curved surface is a circle. A fixture for manufacturing said butterfly plate features that an eccentrical value absorbing unit is arranged between inclined-surface fixture and the mainshaft flange of lathe by use of the eccentrical connection between fixing axle and dovetail slide block and the mutually perpendicular dovetail slots driving structure. Its advantage is high sealing reliability.

Owner:YONGYI VALVE

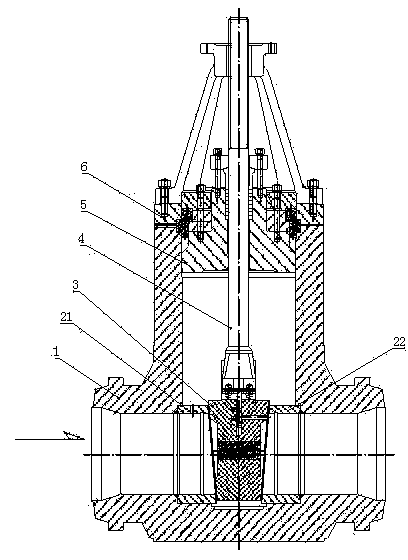

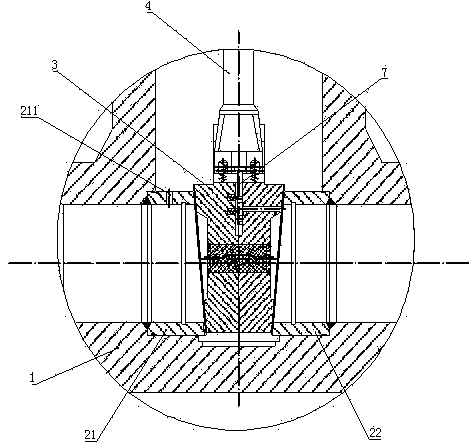

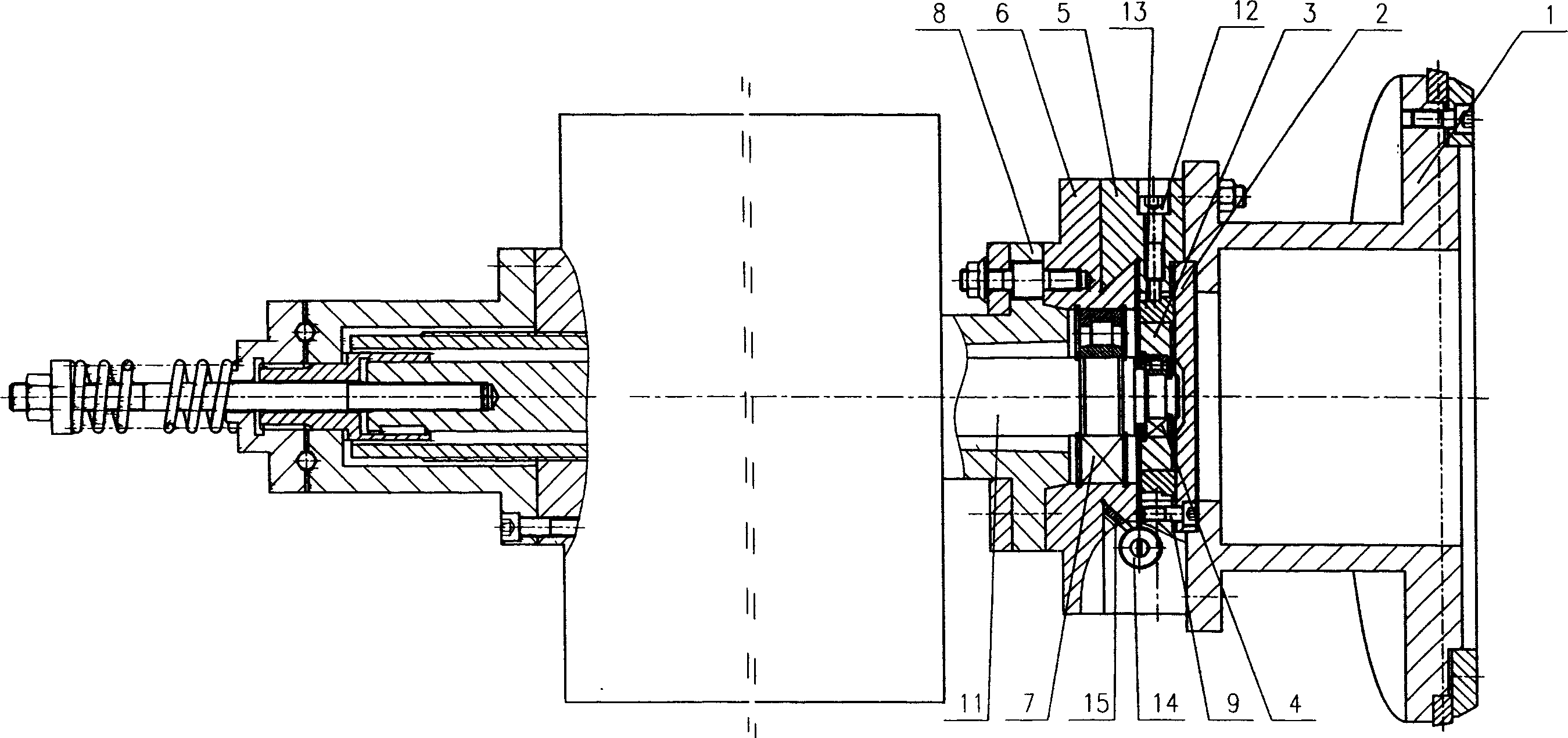

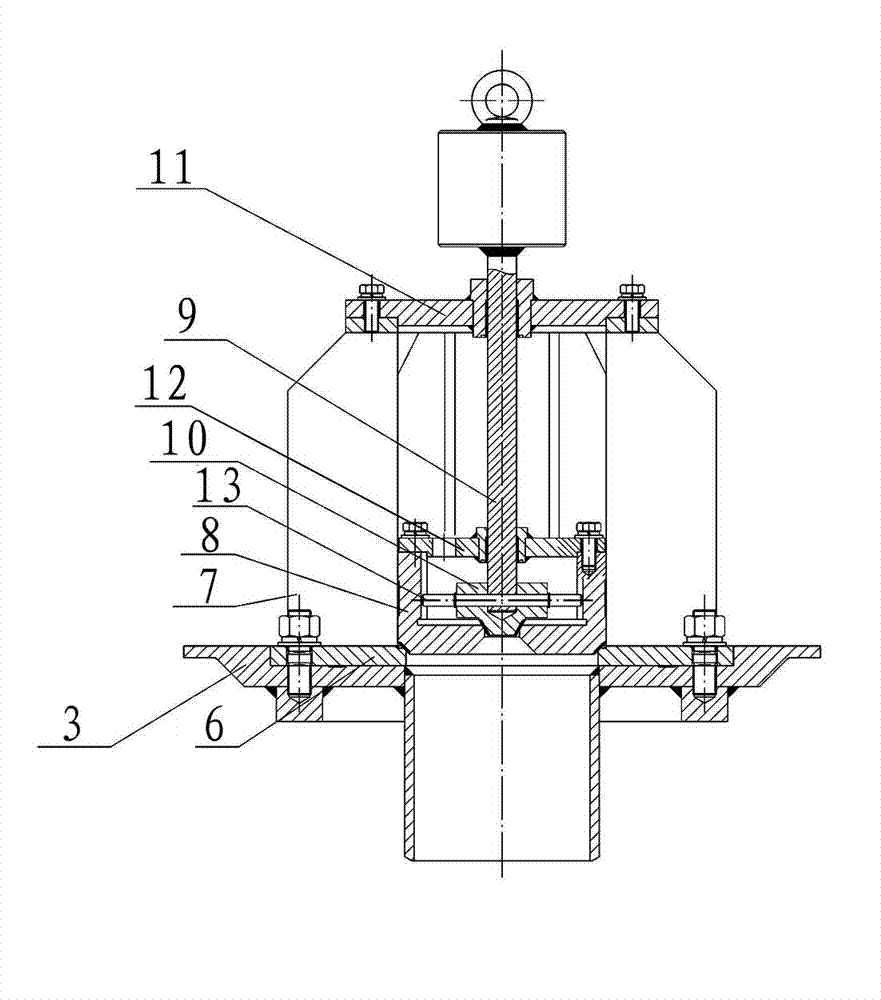

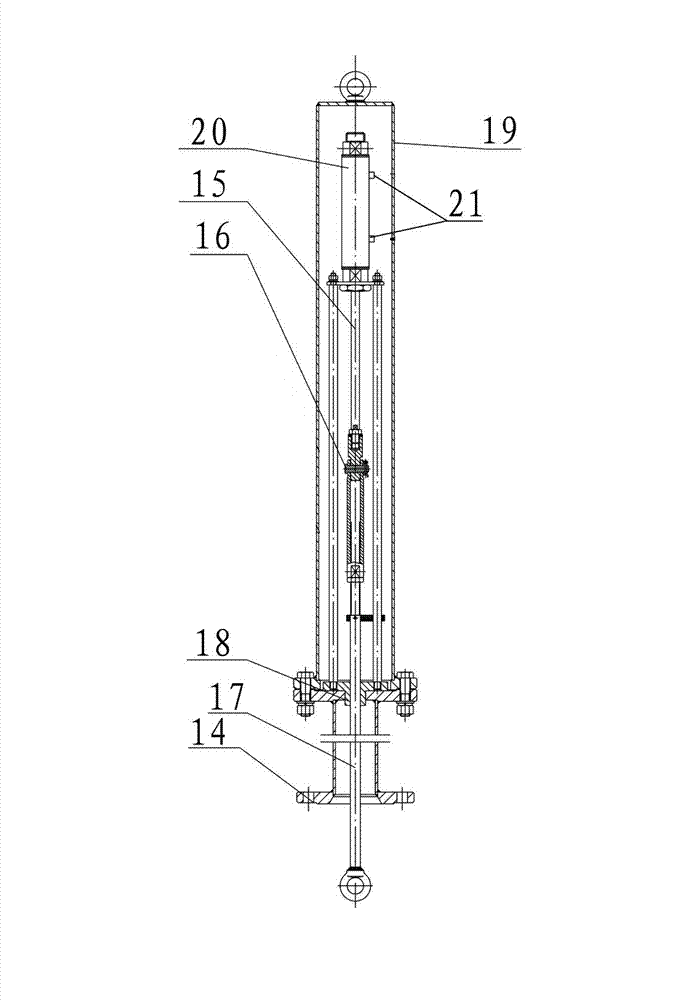

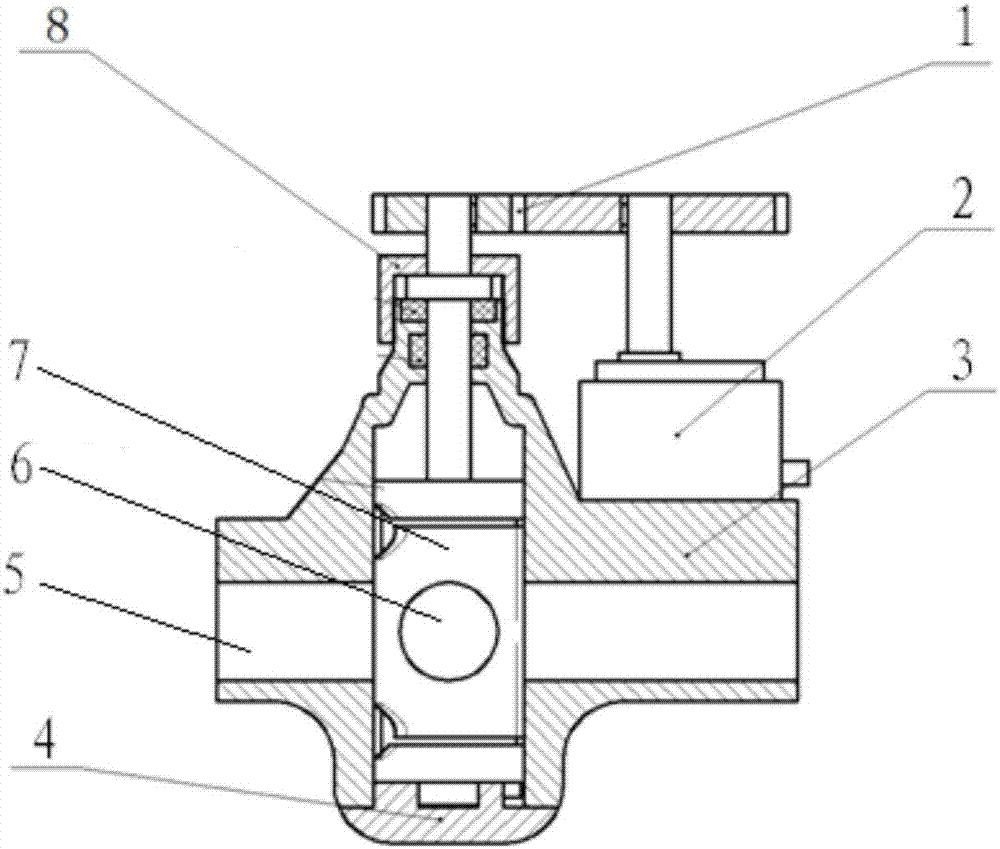

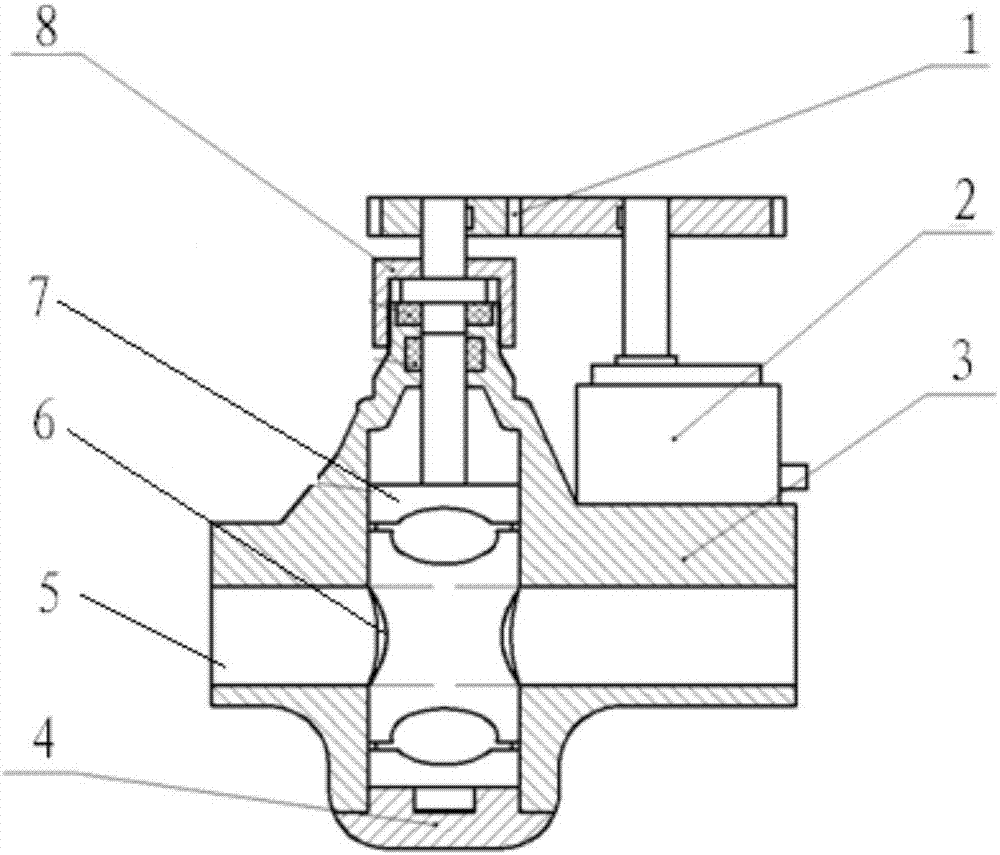

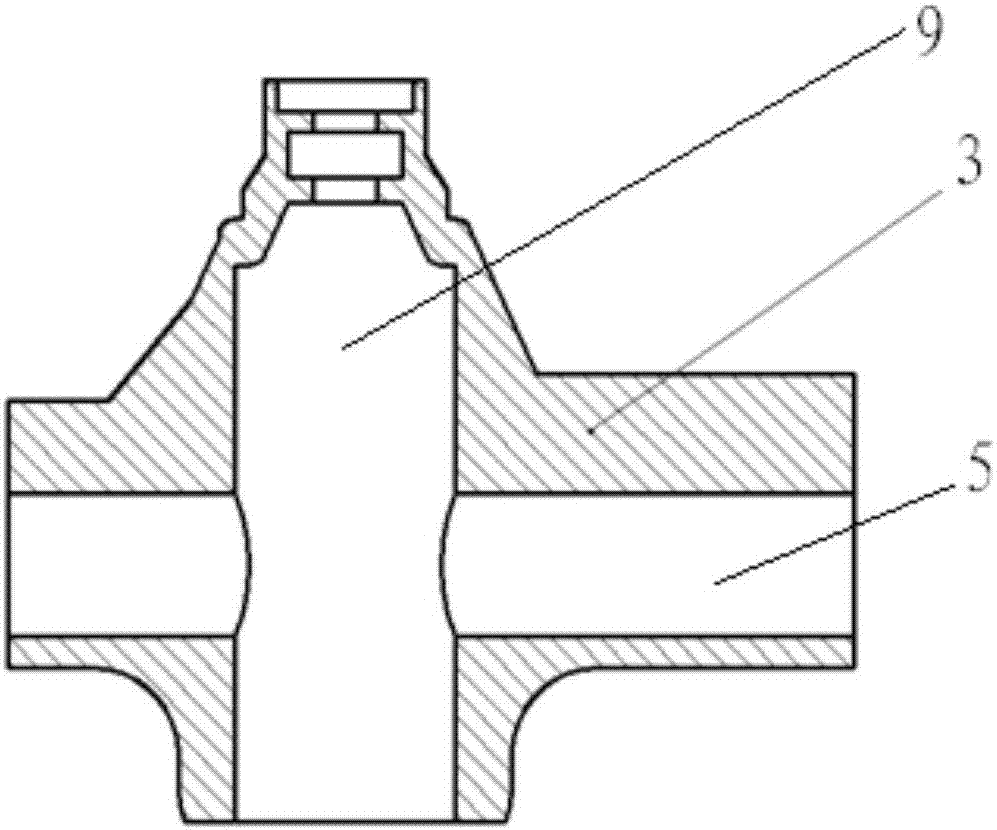

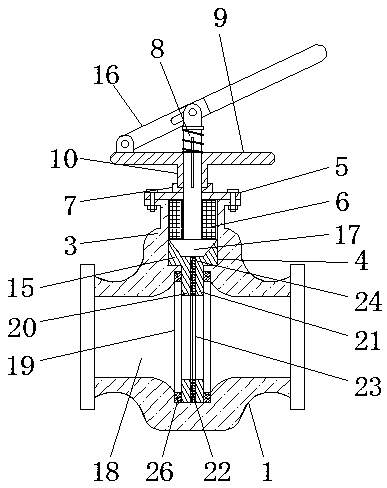

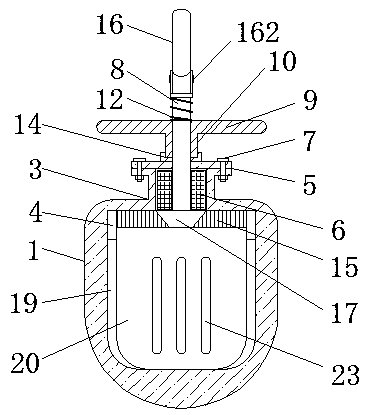

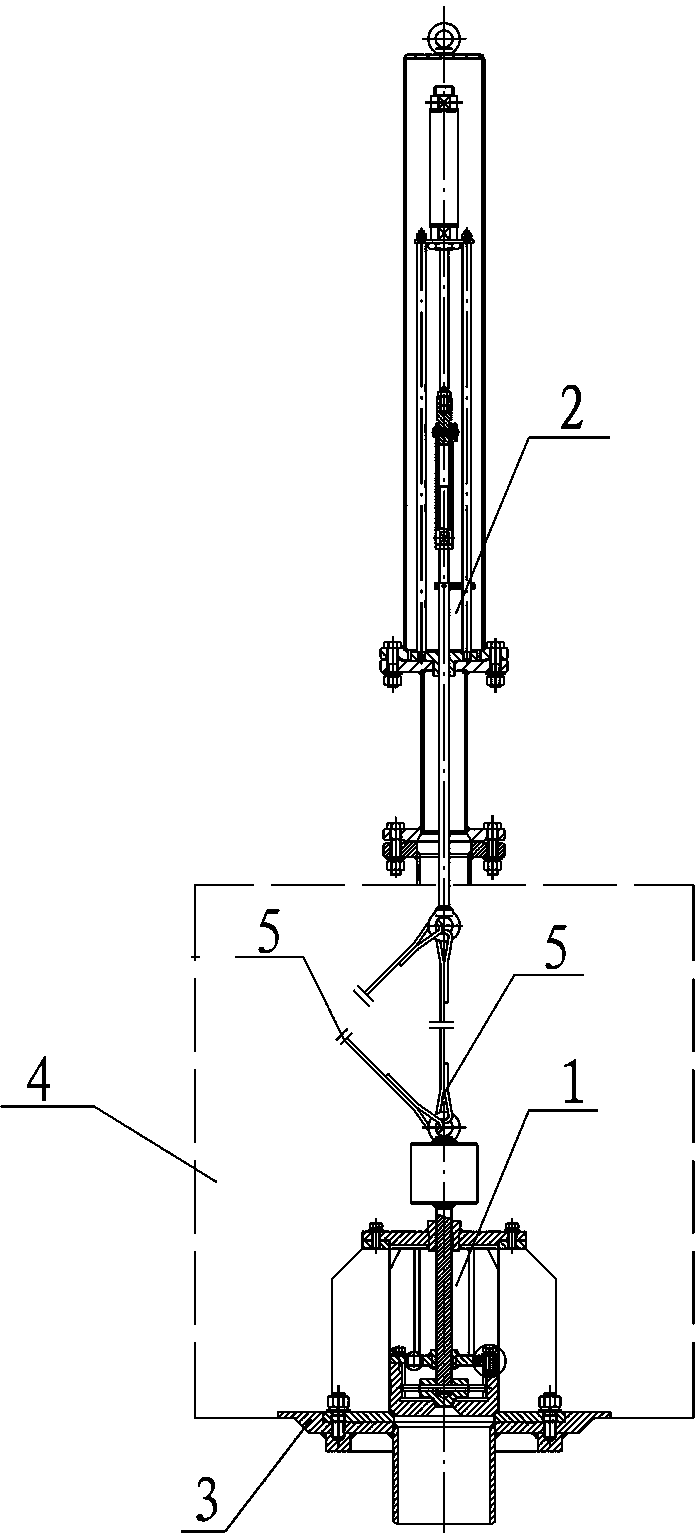

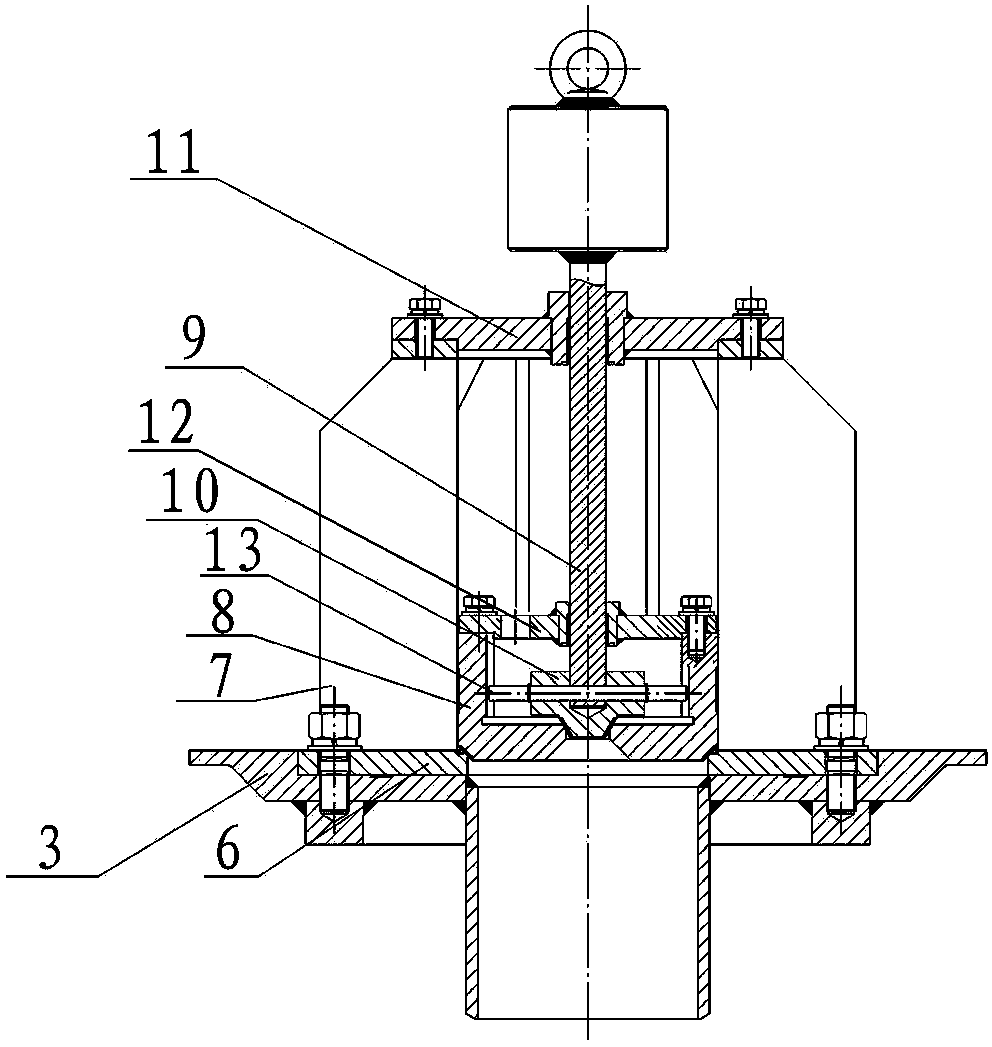

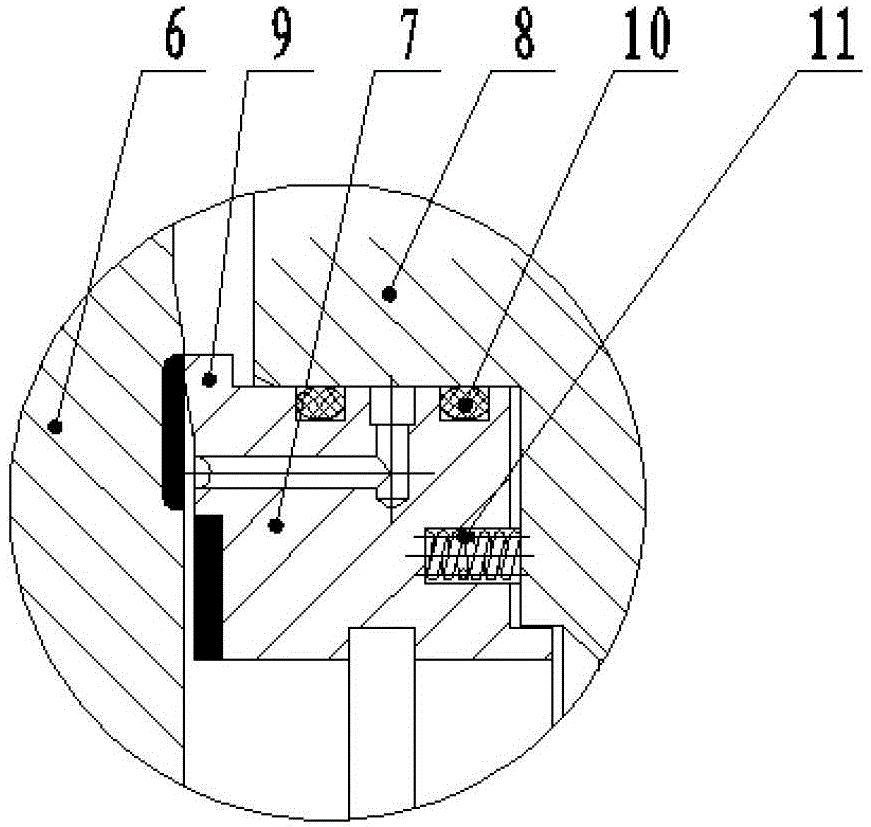

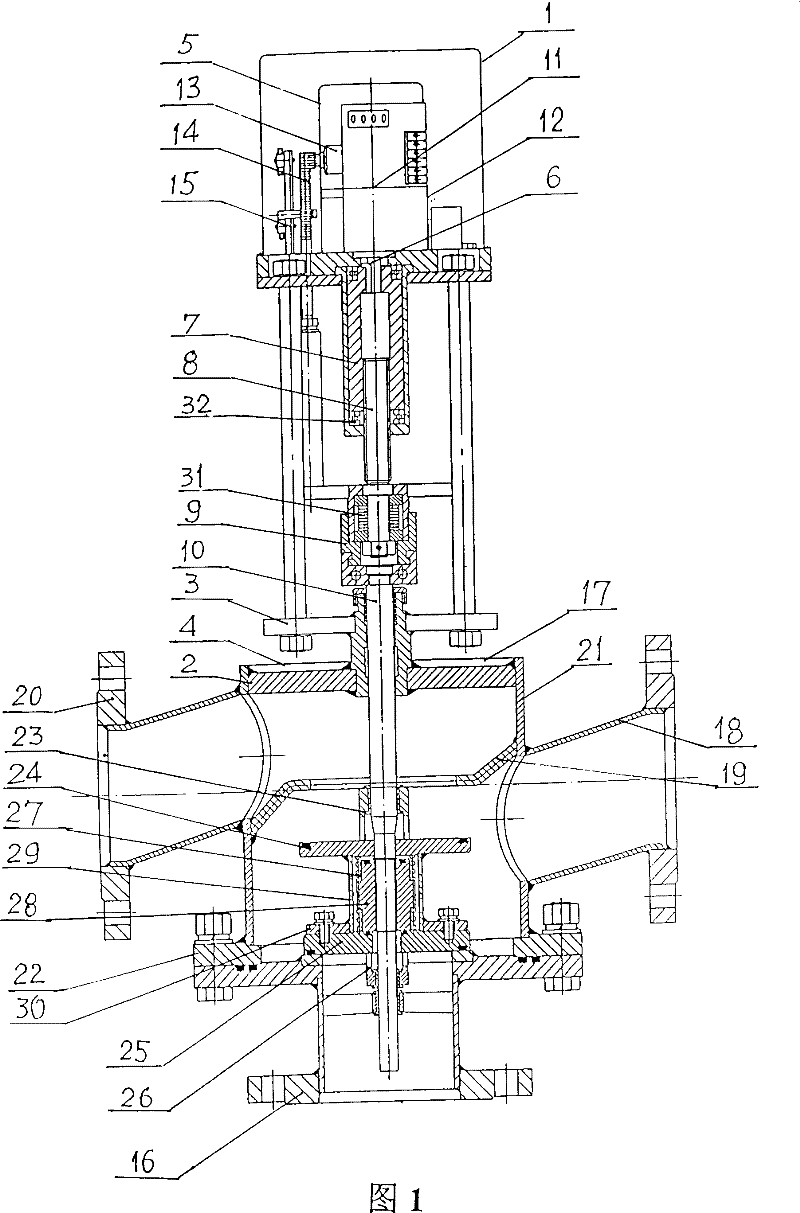

Emergency cut-off valve at bottom of built-in tank in low-temperature liquid storage tank

ActiveCN102927293ASmall opening torqueGuaranteed zero leakage sealing performanceOperating means/releasing devices for valvesLift valveLiquid storage tankEngineering

Disclosed is an emergency cut-off valve of at the bottom of a built-in tank in a low-temperature liquid storage tank. The emergency cut-off valve mainly comprises a main valve portion and a driving portion, the main valve portion is welded to the bottom of the low-temperature liquid storage tank through a bottom plate; the driving portion is placed at the top of the low-temperature liquid storage tank, and the main valve portion and the driving portion are connected through two stainless steel ropes, wherein one rope is a work rope, and the other rope is an emergency rope; a valve seat is fixed on the bottom plate of the main valve portion and connected with a guide frame, and a large valve clack which is capable of vertically moving and is matched with the valve seat to form a large sealing pair is built in the guide frame; and a small valve clack which is capable of vertically moving and is matched with a centre valve hole of the large valve clack to form a small sealing pair is arranged above the large valve clack through a valve rod. Compared with ordinary emergency cut-off valves, the emergency cut-off valve is small in executing mechanism, reasonable and compact in structure and good in using effects.

Owner:HANGZHOU HANGYANG KOSO PUMP & VALVE

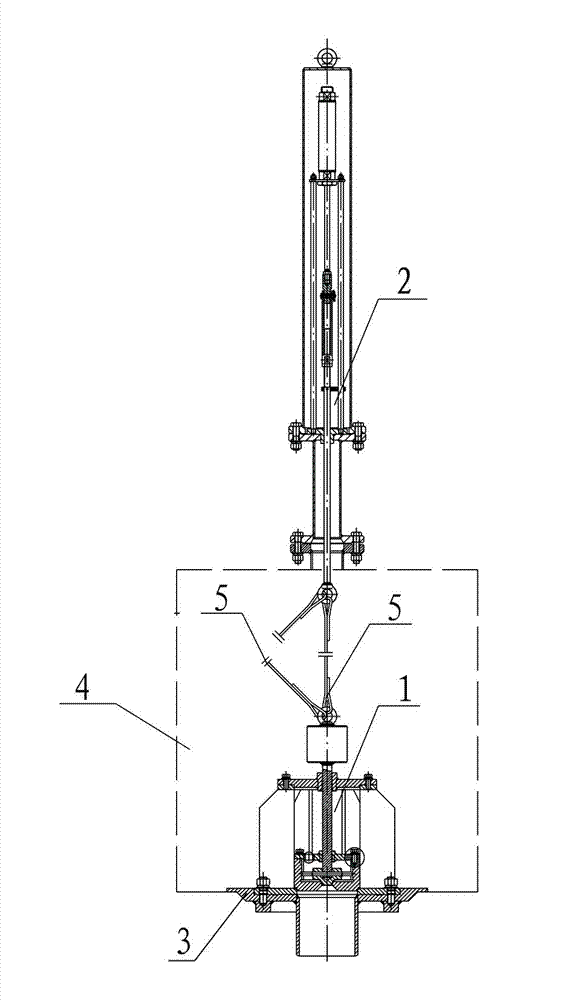

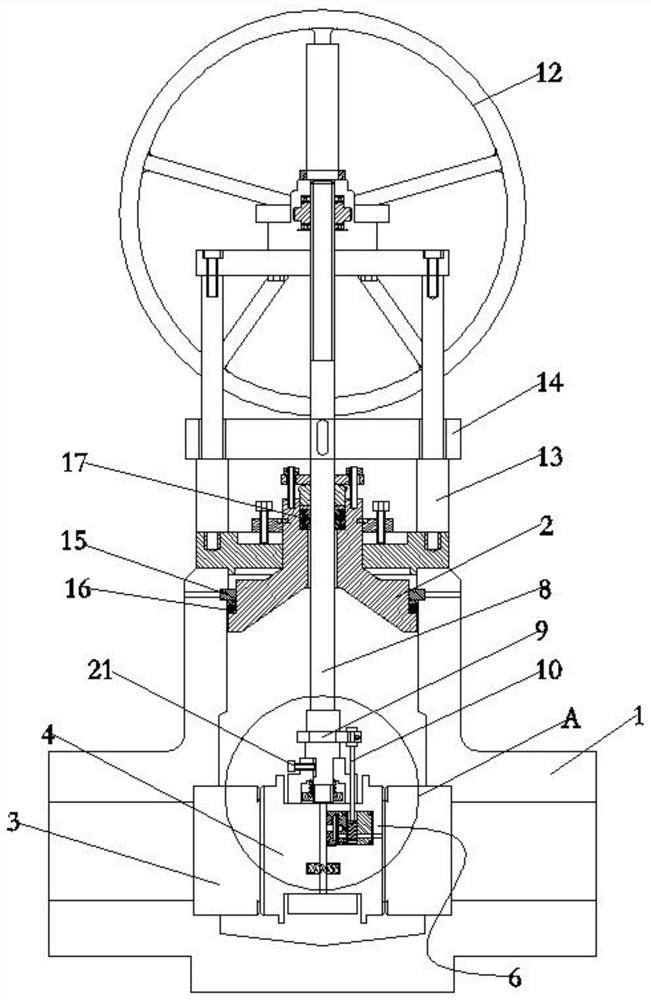

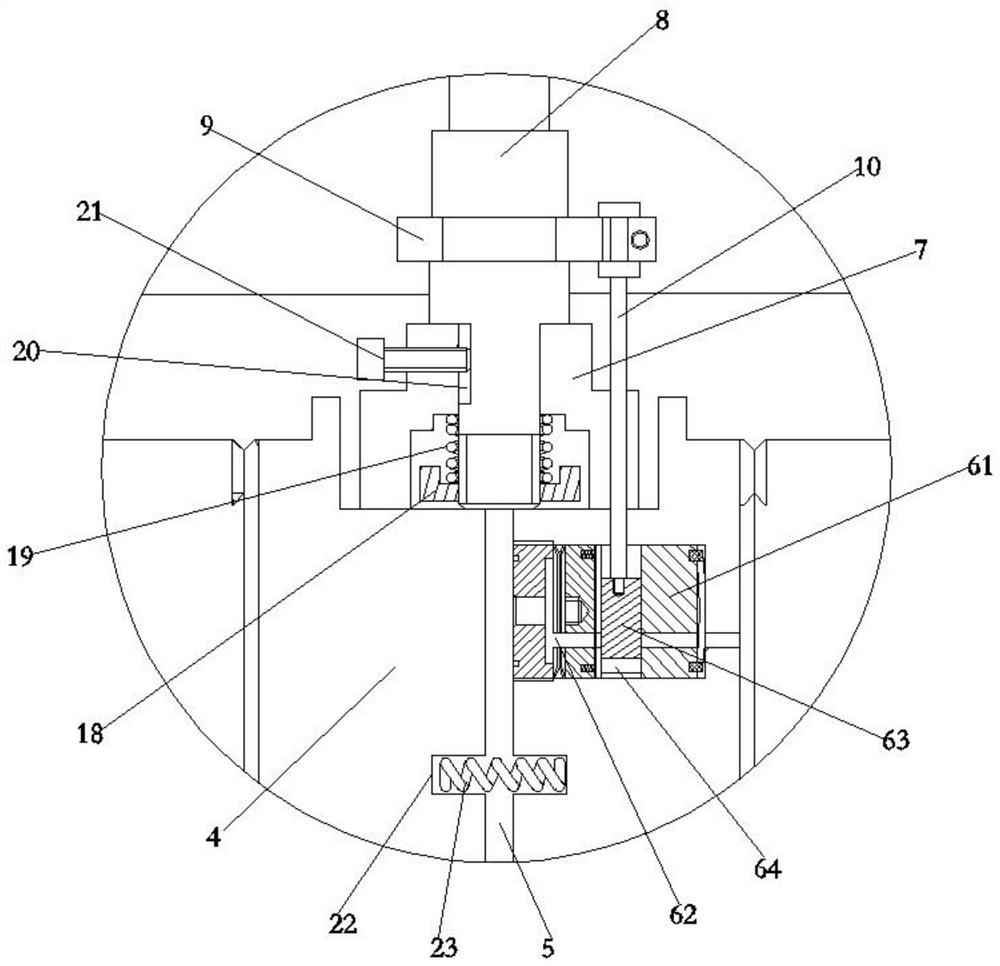

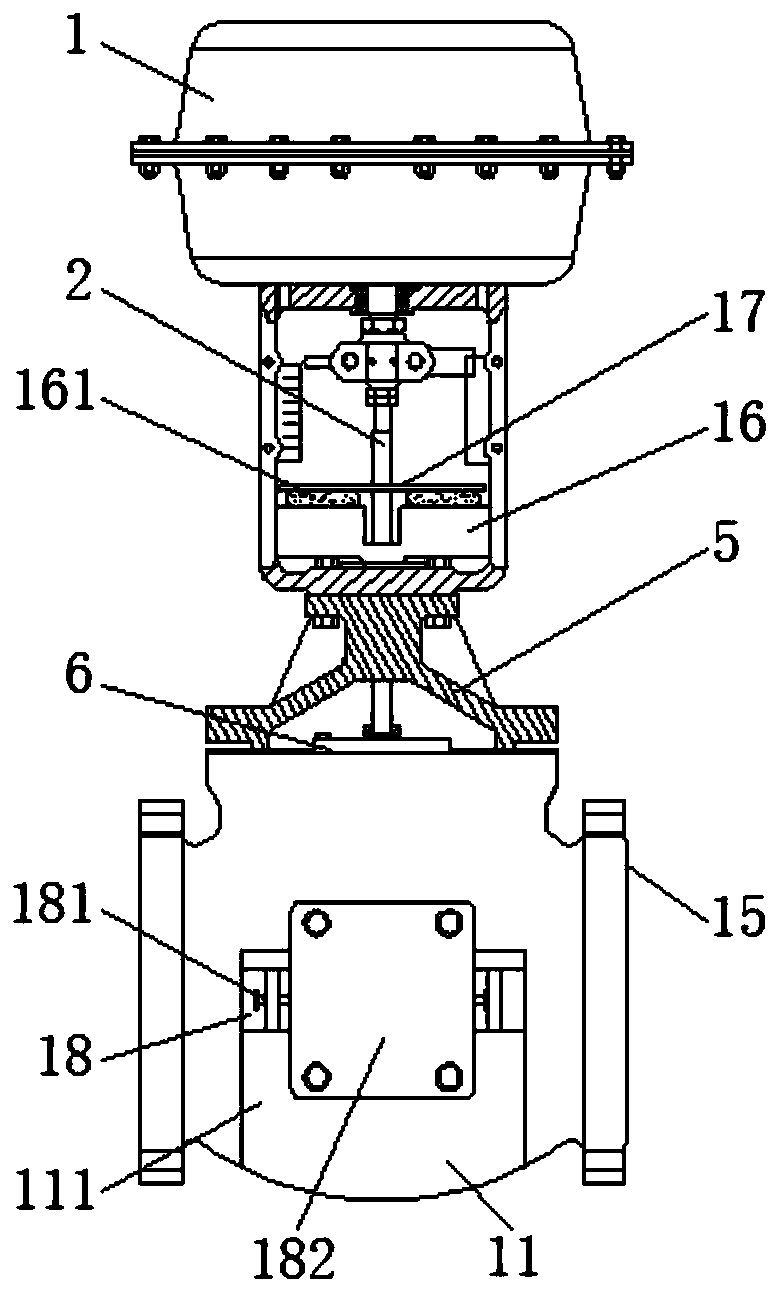

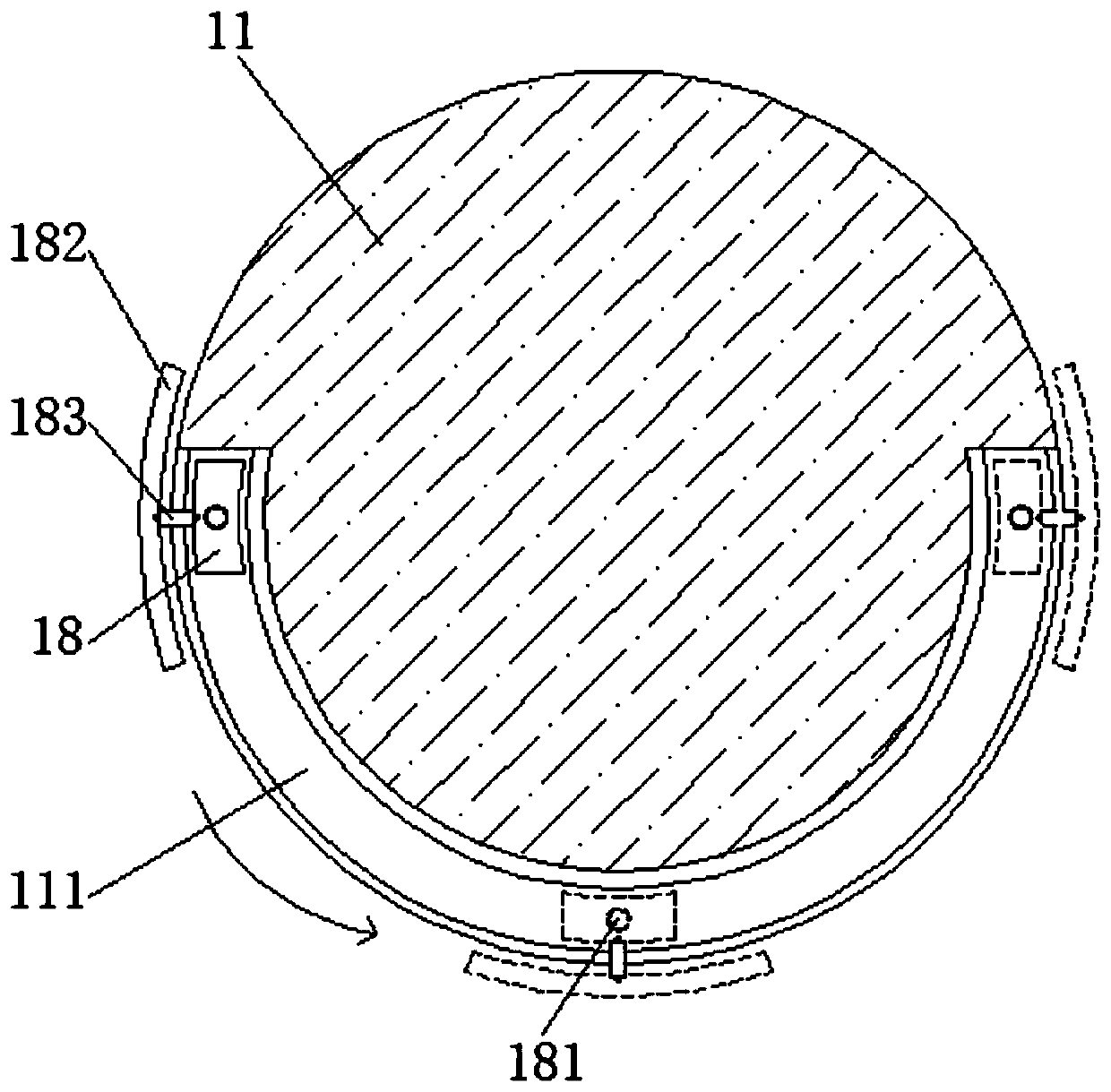

A fast opening and closing gate valve with pendulum type in the middle cavity

ActiveCN110056665BFlexible adjustment performanceFlexible operationSpindle sealingsOperating means/releasing devices for valvesEngineeringValve stem

The invention discloses a fast opening and closing gate valve with pendulum in the middle chamber, which comprises a gate valve body, a gate valve cover, a driving valve rod and a gate valve middle chamber. The drive valve rod runs through the gate valve cover, the middle part of the inside of the runner is provided with a movable connection sleeve, the lower end of the movable connection sleeve is evenly distributed with limited blocks, and the lower part of the gate valve cover is provided with Connecting the tooth groove, the right side of the first movable shutter is provided with a second movable shutter, and the side of the second movable shutter is provided with a flexible graphite sealing gasket. The pendulum-type fast opening and closing gate valve in the middle cavity is equipped with a first movable gate and a second movable gate for synchronous parallel swing opening and closing. The limit block of the movable connection sleeve can facilitate the flexible limit of the device and improve the practicability of the device.

Owner:TANGSHAN WEIDE MARINE EQUIP CO LTD

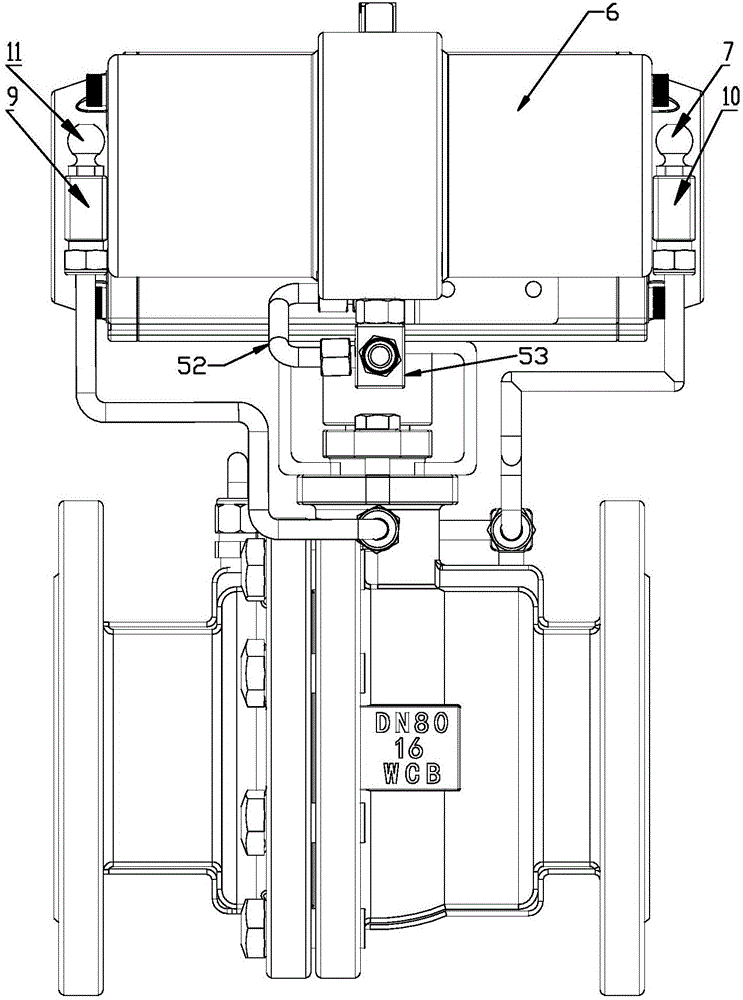

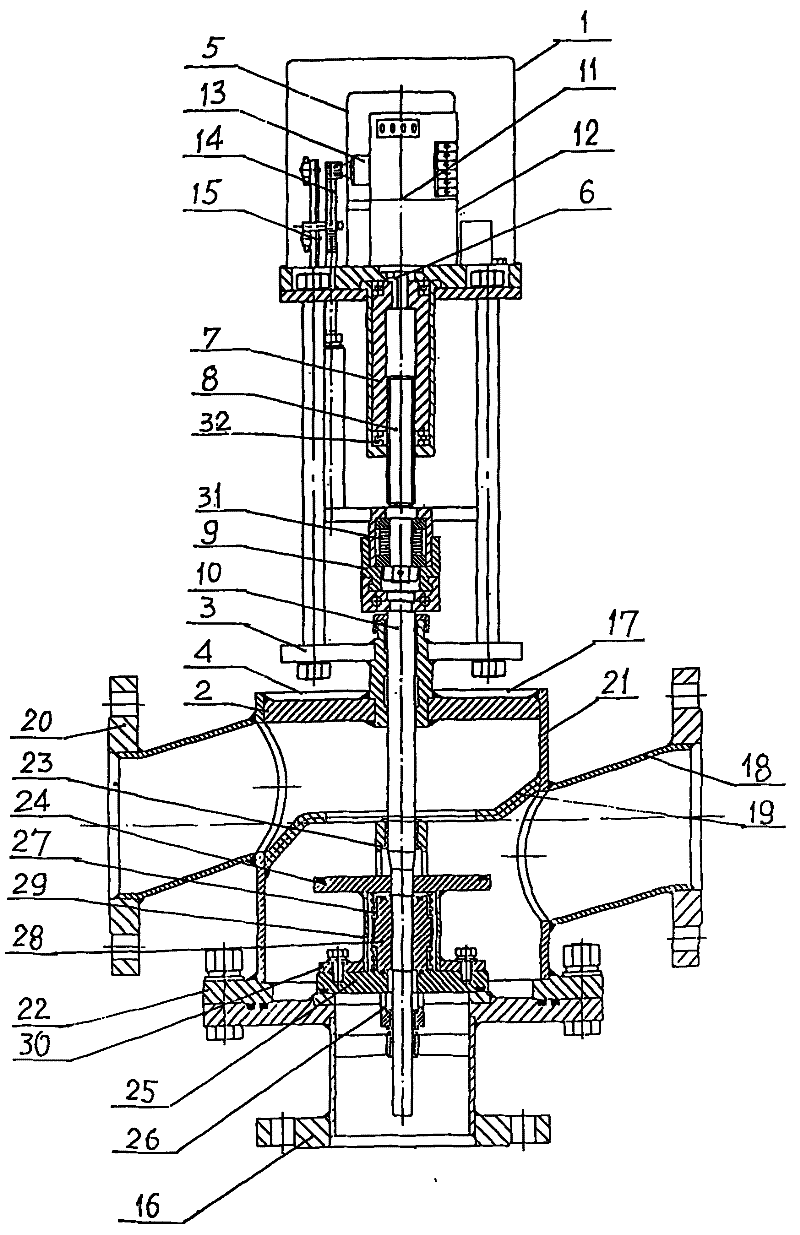

Cut-off type power-off reset electric valve

InactiveCN101354080BAutomatically cut off the medium flow directionIncrease pressureOperating means/releasing devices for valvesLift valveRestoration deviceCoupling

The invention relates to a turn-off type power failure restoration electric valve which is formed by the connection of an executing mechanism and a valve body; a drive motor, a transmission nut, a transmission screw, a coupling and a valve shaft are connected in sequence for transmission; a position signal feedback device, an analog quantity controller and a power failure restoration device are also installed in the executing mechanism; a pilot valve plate and a spool spring are installed in the middle of an upper valve plate and a lower valve plate; seal rings of polypropylene substrate material are installed on the valve plates; two ends of the transmission nut are additionally installed with a bearing; a butterfly spring is installed in the coupling. The valve has no leakage and can automatically restore when the power fails, thus saving energy and reducing consumption; the valve has easy and labor-saving opening and closing, advanced technology and excellent performance.

Owner:张跃

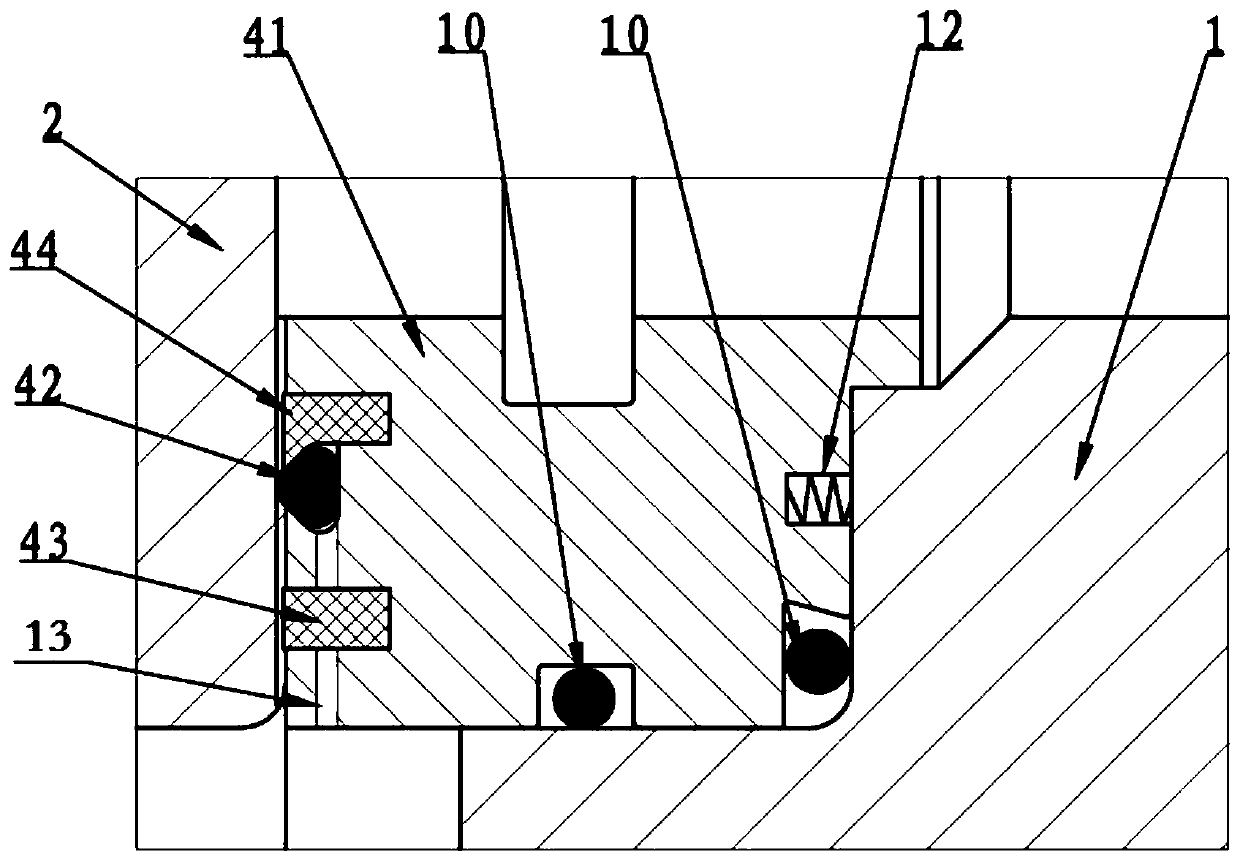

Valve oil film sealing structure and valve with oil film sealing structure

The invention discloses a valve oil film sealing structure. The valve oil film sealing structure comprises a valve seat arranged on a valve body and a valve element surface arranged in the valve body and corresponding to the valve seat. A gap is reserved between the valve seat and the valve element surface and is filled with sealing paste. The sealing paste is located between the valve seat and the valve element surface to form an oil-film-shaped sealing face. The end face, facing the valve element surface, of the valve seat is provided with a storage groove filled with the sealing paste. The valve seat is provided with a feeding channel, the inlet end of the feeding channel extends to the position of a sealing paste feeding port of the valve body, and the outlet end of the feeding channel communicates with the storage groove. The valve oil film sealing structure has the beneficial effects of being good in closing performance, resistant to abrasion, stable in performance and long in service life.

Owner:开立基业(北京)阀门制造有限公司

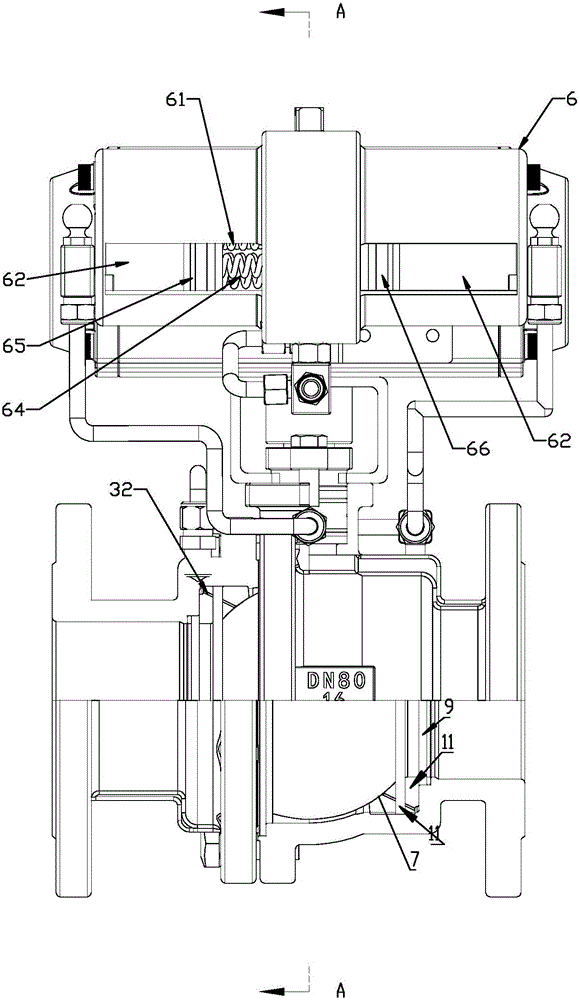

Middle open type translation double-sealed rectangular gate valve

The invention relates to a middle open type translation double-sealed rectangular gate valve. A right valve plate and a left valve plate which are opened or closed through rectangular frames are installed in a rectangular valve body, and the right and left valve plates are driven to move by a driving device installed on the valve body, and limited by shifting forks at the tops and bottoms of the right and left valve plates and limit rollers; and flow channel compensation is performed by virtue of a flow channel compensation device installed on the edge of an inner cavity of the valve body and flow channel compensation pieces connected to the flow compensation device, while a front sealing ring and a rear sealing ring of the inner cavity of the valve body as well as the front and rear sealing rings in the closure position of the right and left valve plates constitute bidirectional sealing. The rectangular gate valve provided by the invention is a valve with large size and zero leakage, the flow channel clearance is smaller than 5 mm, and the valve is applicable for working conditions of high flow rate and strong vibration.

Owner:HUBEI HONGCHENG GENERAL MACHINERY

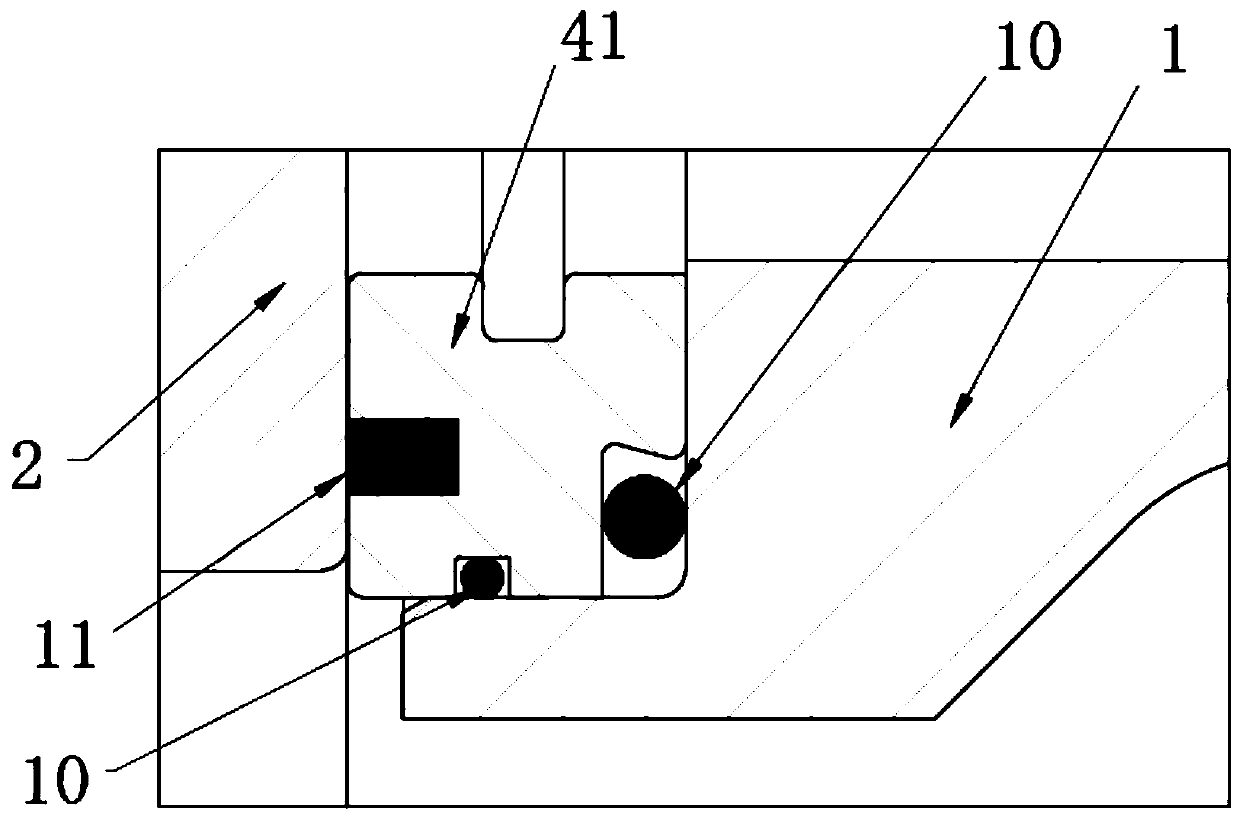

Hydraulic stop valve and application method

PendingCN107514473AExtended service lifeSmall opening torquePlug valvesOperating means/releasing devices for valvesPhysicsEngineering

The invention discloses a hydraulic stop valve and an application method. The hydraulic stop valve comprises a valve body, a valve element, a base and a steering engine; the valve body is provided with a transverse liquid channel and a longitudinal valve element cavity; the valve element is embedded in the valve element cavity of the valve body; a transverse through hole for enabling liquid to circulate is formed in the middle part of the valve element body; the valve element body is provided with an annular guide groove, a longitudinal guide groove and a communicating balance groove; a projected eccentric positioning block is arranged at the bottom of the valve element body, and is matched with the base; the steering engine is fixed on the valve body; an output shaft of the steering engine is connected with a valve element shaft at the upper end of the valve element through a transmission gear; the hydraulic stop valve is connected to a liquid pipeline; the steering engine is connected with a remote control system; and the remote control system controls the rotating speed and the rotating angle of the steering engine through electric signals.

Owner:XIAN AIRCRAFT IND GROUP

Double-seal valve seat

The invention provides a double-seal valve seat. Two seal rings are arranged on a seal body on the valve seat, a lower seal ring and the valve seat form an inclined angle of 5-10 degrees in the vertical direction, and an upper seal ring and the valve seat form an inclined angle of 15-25 degrees in the vertical direction. Traditional single-line seal is replaced by double-line seal, simultaneously the characteristic of elastic deformation of a teflon material is fully utilized, and good sealing effect is achieved. Compared with an ordinary type valve seat, the double-seal valve seat adopts the double-line seal and is small in opening force moment and good in sealing effect.

Owner:山东沃克控制阀有限公司

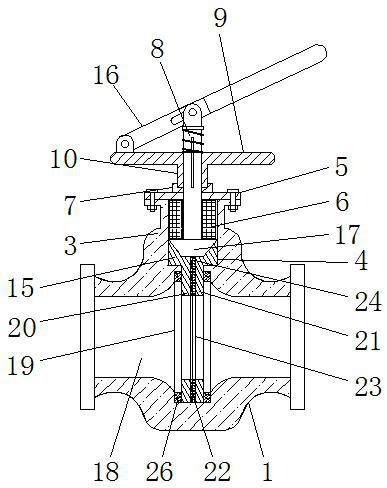

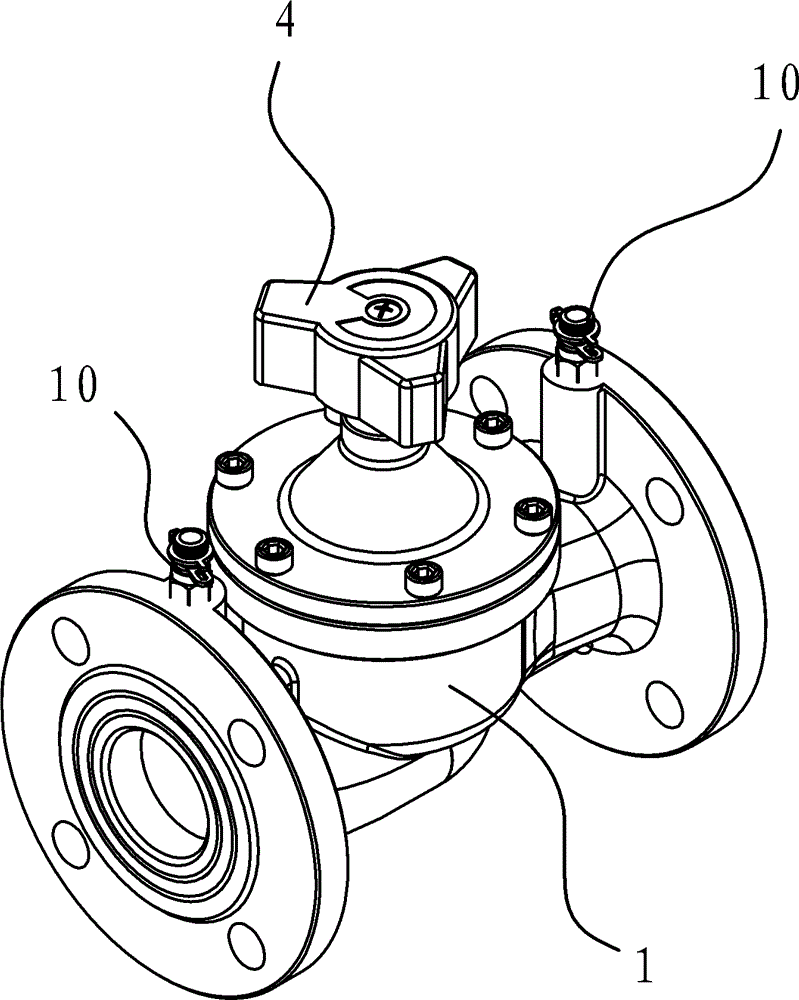

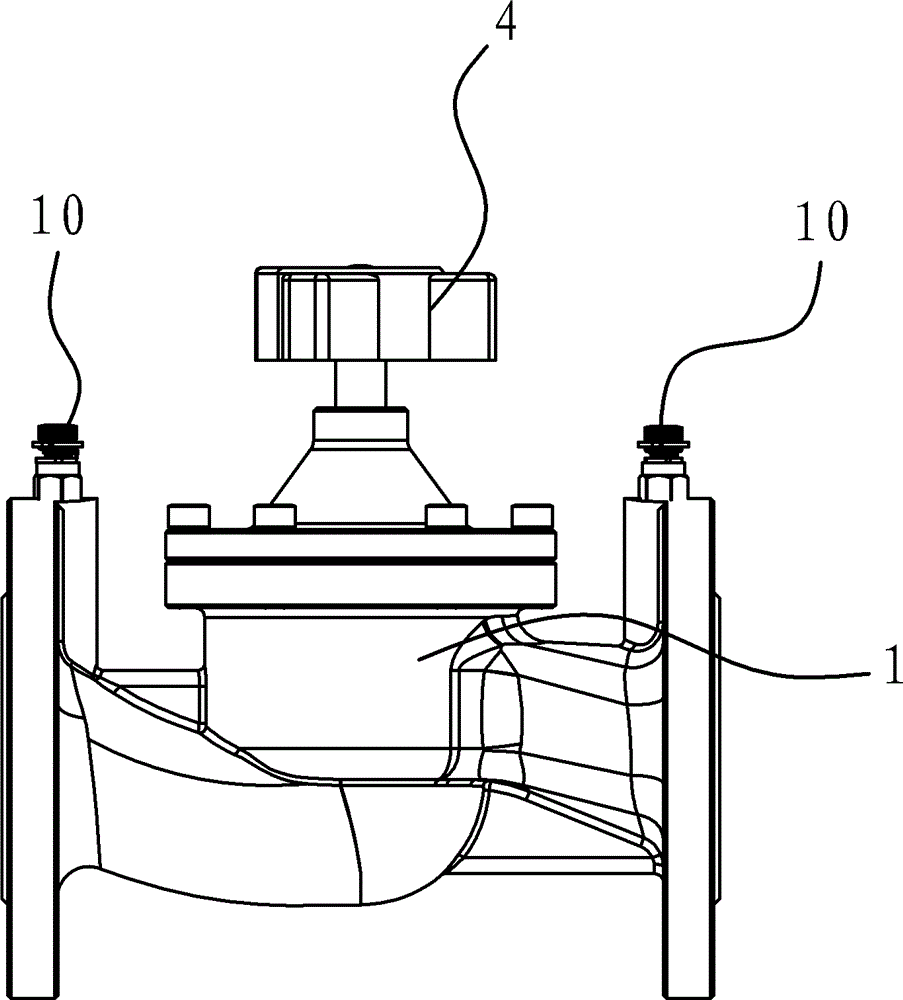

Pilot type control valve

InactiveCN102628523BKnow the actual medium pressureOpen smoothlyPressure relieving devices on sealing facesEngineeringControl valves

The invention provides a pilot type control valve which belongs to the field of mechanical technology and solves the problem that the existing pilot type safety valve is not applicable to a control valve. The pilot type control valve comprises a valve body, a valve core, a valve rod and a handle. The valve core is located inside the valve body and an inner end of the valve rod is connected with the valve core. An outer end of the valve rod extends out of the valve body to be connected with the handle. The valve core with a cylindrical shape is sheathed on the valve rod. The valve rod is provided with a nut and a small valve core, wherein the nut can abut against a bottom port of the valve core and the small valve core can abut against a top port of the valve core. The valve core is located between the nut and the small valve core and can move between them. There is a channel for fluid medium to pass through between the valve core and the valve rod. There is a sealing structure which can realize a seal between the small valve core and the top port of the valve core when the small valve core and the top port of the valve core contact each other. The pilot type control valve has the advantages of smooth opening, simple operationand the like.

Owner:卓旦春

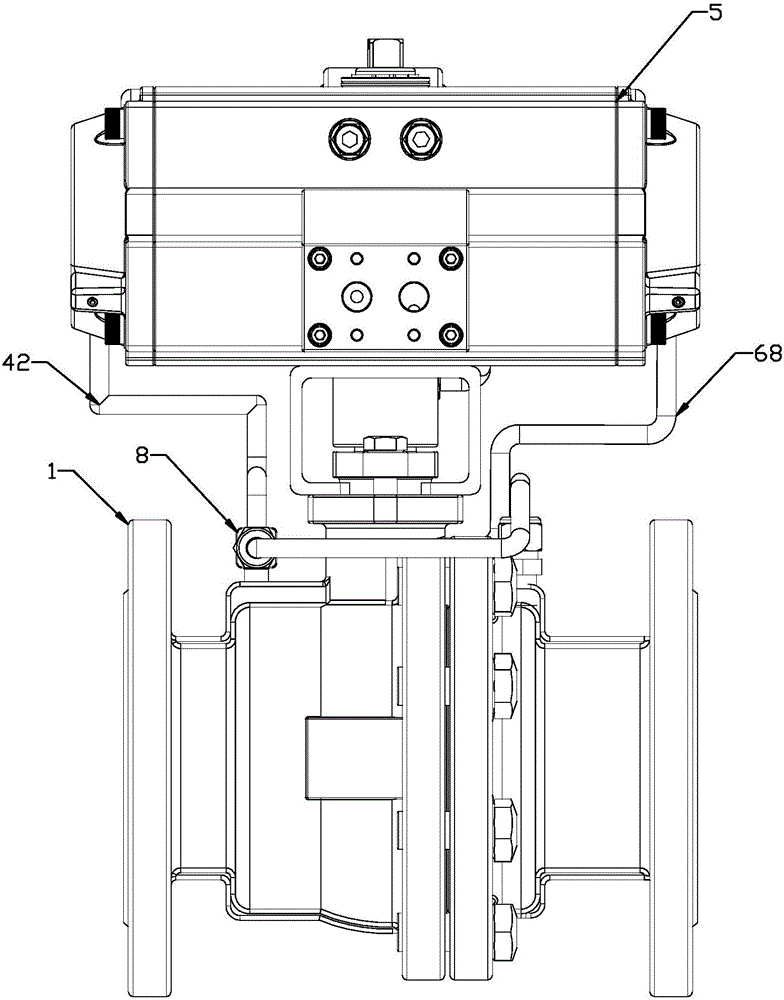

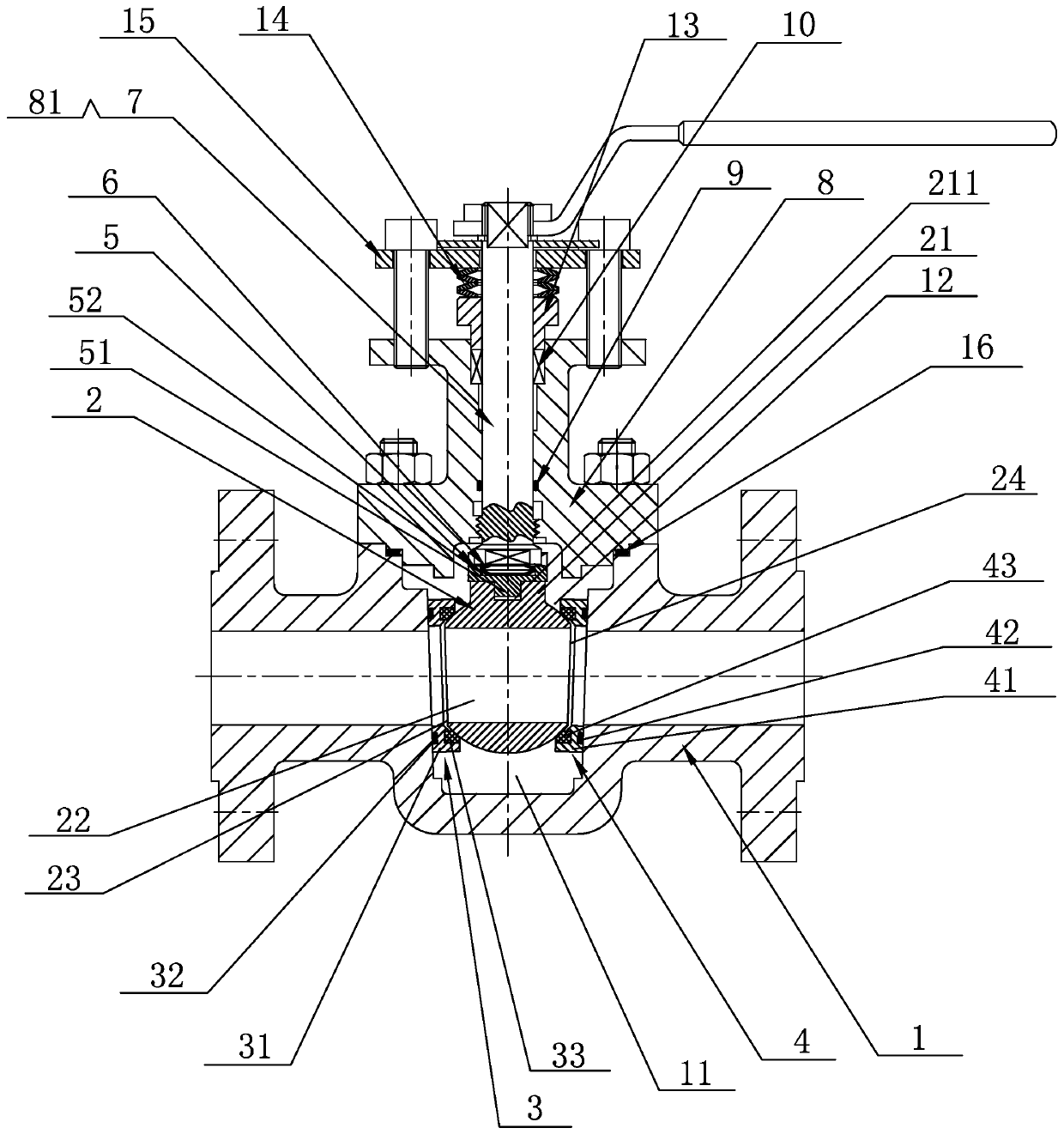

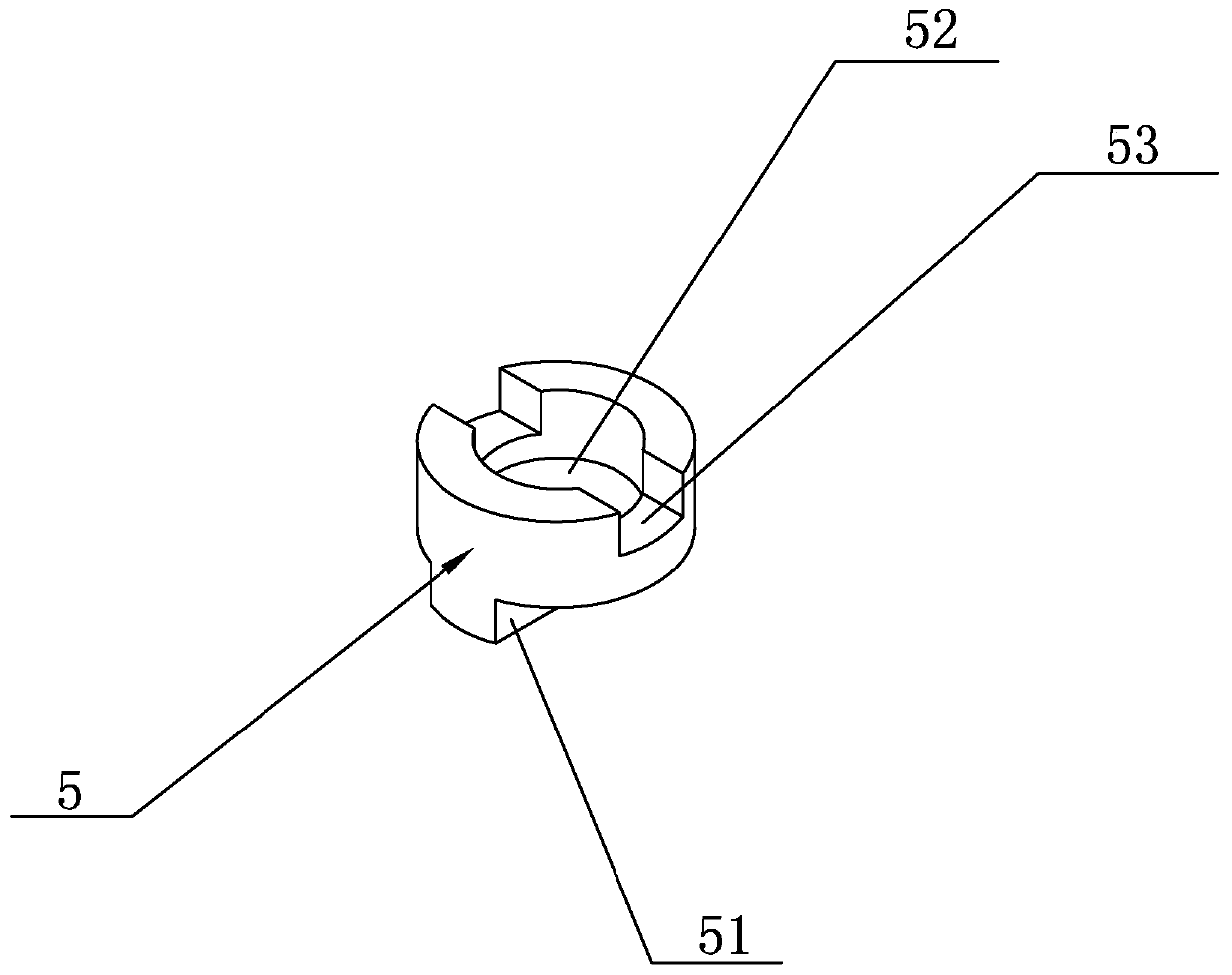

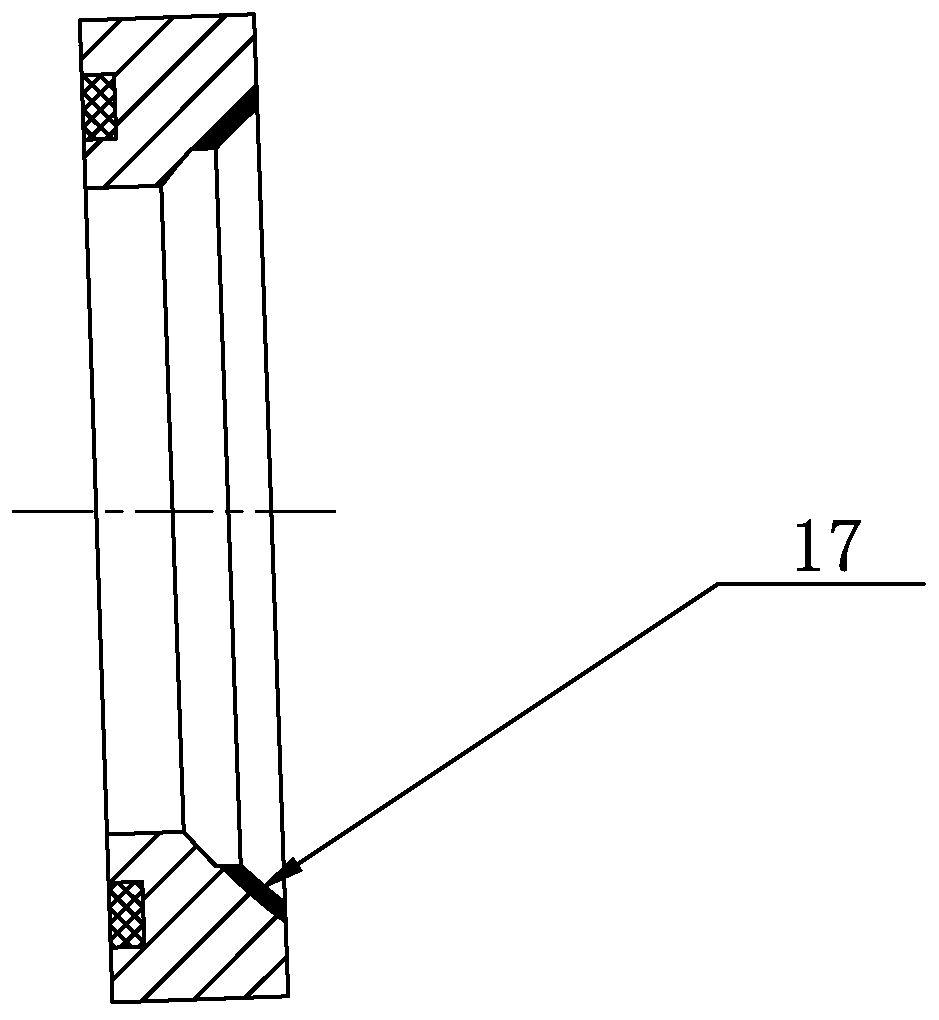

Pilot type parallel double-flat-plate high-temperature and high-pressure gate valve

PendingCN113202940AImprove the sealing effectSmall opening torqueSpindle sealingsPressure relieving devices on sealing facesPilot valveBypass valve

The invention is applicable to the technical field, and provides a pilot type parallel double-flat-plate high-temperature and high-pressure gate valve which comprises a valve body, a valve cap is arranged at the top end of the valve body, sealing seats are arranged on the two sides in the valve body respectively, a gate plate is arranged between the two sealing seats, and a first channel is formed in the middle of the gate plate. A pilot valve assembly is arranged on one side of the first channel, a gate plate seat is arranged at the top end of the gate plate, a valve rod is connected to the gate plate seat in a sliding mode, a fixing ring is arranged on the valve rod, a push-pull rod is arranged between the fixing ring and the pilot valve assembly, and the upper portion of the valve rod penetrates through the valve cap. The end, extending to the upper portion of the valve cap, of the valve rod is connected with an actuator. A first sealing ring and a second sealing ring are arranged, so that the sealing effect of the gate valve is greatly improved. A pilot valve is connected to a flashboard, the opening torque is greatly reduced through pressure relief of the pilot valve, configuration of the actuator can be greatly reduced, a bypass valve does not need to be welded, cost is saved, and safety and reliability are achieved.

Owner:杭州巨久机械科技有限公司

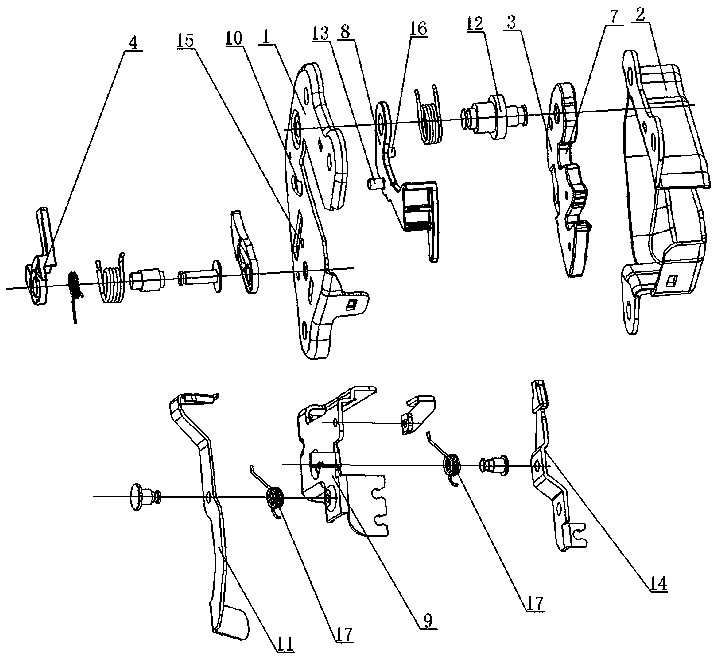

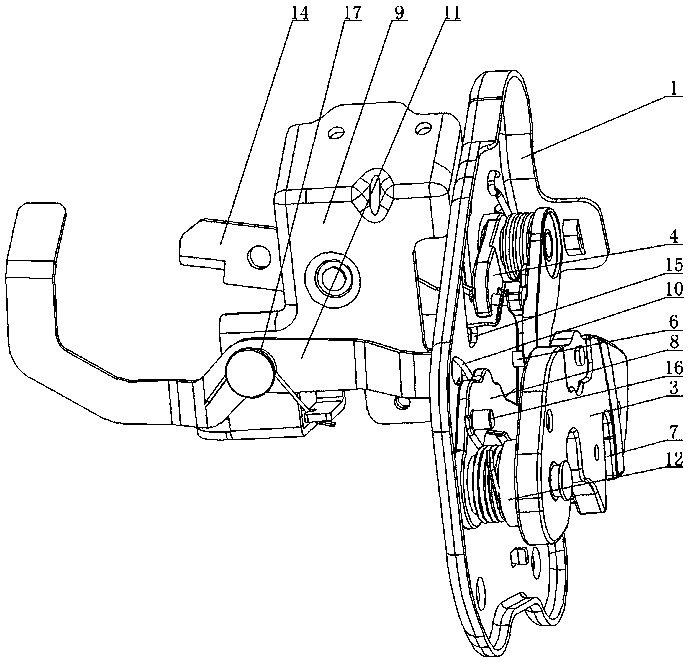

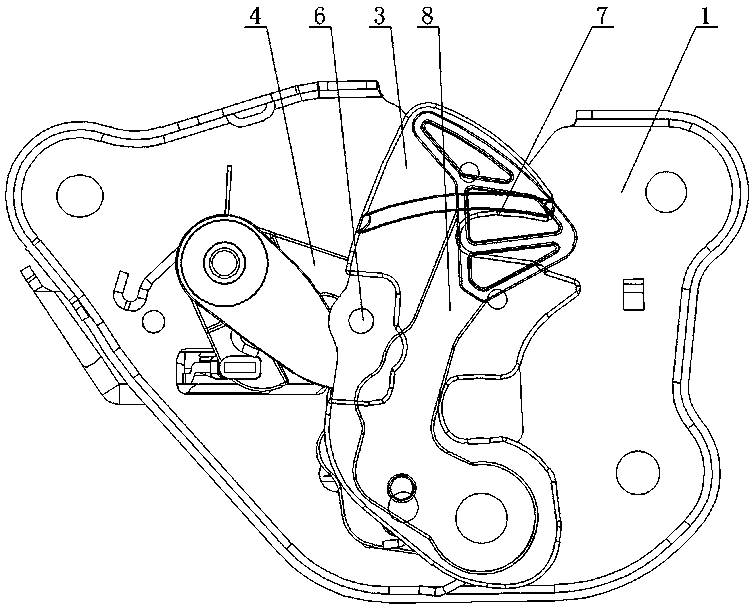

car seat back lock

The invention discloses an automobile seat back lock. The automobile seat back lock comprises a lock shell and a cover plate. A lock leaf and an unlocking rocker arm are arranged in the lock shell, one end of the lock leaf is rotationally connected to the lock shell, the lock leaf is provided with a torsional spring which promotes the lock leaf to swing towards the locking direction, the lock leaf is provided with a hinge pin and a lock groove, one end of the unlocking rocker arm is rotationally connected to the lock shell, and the other end of the unlocking rocker arm is movably connected with the hinge pin. An installation plate is arranged on the lock shell, the installation plate and the lock shell are arranged in an L shape, an unlocking lever is rotationally connected to the installation plate, a guide hole is formed in the lock shell, one end of the unlocking lever penetrates through the guide hole and is movably connected with the third end of the unlocking rocker arm, and the other end of the unlocking lever is connected with a pull rope. According to the automobile seat back lock, the unlocking structure is arranged on one face of the lock and can be installed in a seat, and therefore occupied space is saved; the lever principle is adopted for the unlocking lever, and therefore the unlocking force moment is greatly reduced; in addition, the lock has the early-warning function.

Owner:ZHEJIANG HUAYUAN LOCK IND CO LTD

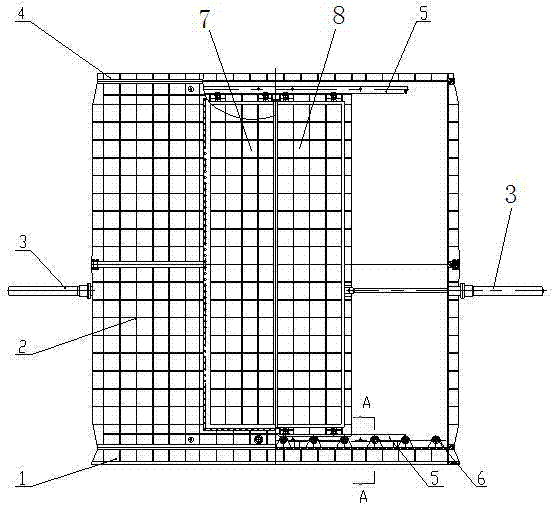

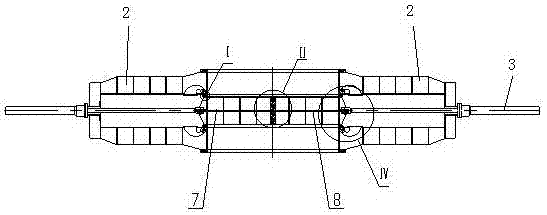

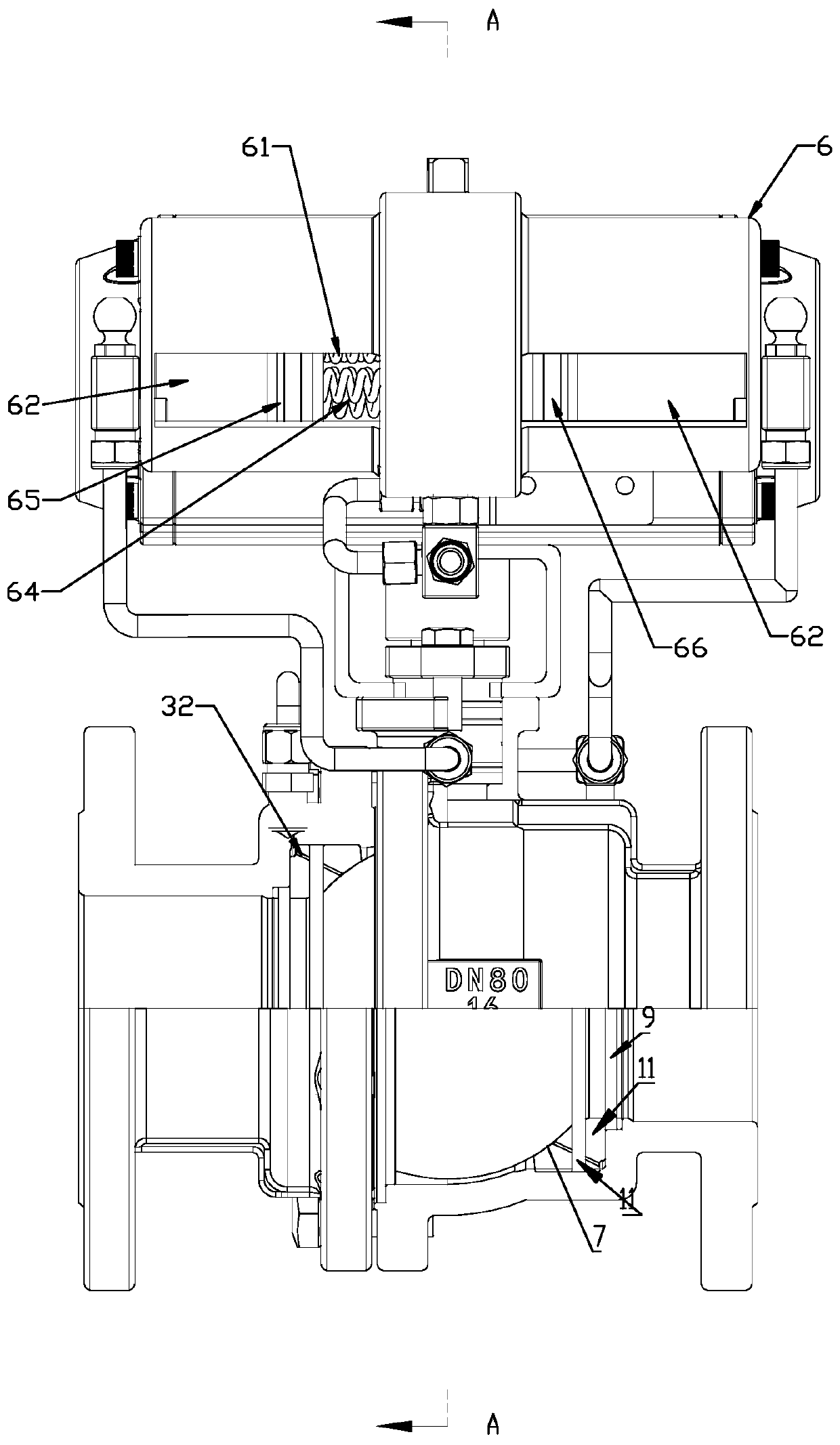

Middle cavity inner swinging type fast-starting and fast-closing gate valve

ActiveCN110056665AFlexible adjustment performanceFlexible operationSpindle sealingsOperating means/releasing devices for valvesGraphiteGate valve

The invention discloses a middle cavity inner swinging type fast-starting and fast-closing gate valve. The gate valve comprises a gate valve body, a gate valve cover, a driving valve rod and a gate valve middle cavity, wherein a gate valve seat is arranged above the gate valve body, a limiting movable groove is formed in the inner side of the gate valve seat, the driving valve rod is located at the upper portion of the inner side of the gate valve cover, a movable connecting sleeve is arranged in the middle of the inner side of a rotating wheel, limiting clamping blocks are uniformly distributed at the lower end of the movable connecting sleeve, a connecting tooth groove is formed below the gate valve cover, a second movable gate is arranged on the right side of a first movable gate, and aflexible graphite sealing gasket is arranged on the side face of the second movable gate. According to the middle cavity inner swinging type fast-starting and fast-closing gate valve, the first movable gate and the second movable gate which perform synchronous parallel swing opening and closing are arranged, the device can be quickly opened and closed under the synchronous transmission of the connecting tooth groove, and meanwhile, the limiting clamping blocks of the movable connecting sleeve can be used for conveniently and flexibly limiting the device, so that the practicability of the device is improved.

Owner:TANGSHAN WEIDE MARINE EQUIP CO LTD

Electric regulating valve capable of completely cutting off seal

ActiveCN101354081BAutomatically cut off the medium flow directionIncrease pressureLift valveBall bearingRestoration device

The invention relates to an electric control valve which can be completely sealed off and shut off, consisting of two parts, namely an executing mechanism and a valve body being connected; a drive motor, a transmission nut, a transmission screw, a coupling and a valve shaft are connected in sequence for transmission; a position signal feedback device, an analog quantity controller and a power failure restoration device are also installed in the executing mechanism; a pilot valve plate and a spool spring are installed in the middle of a valve plate and a connecting flange; seal rings of polypropylene substrate material are installed on the valve plate and the pilot valve plate; two ends of the transmission nut are additionally installed with a plane thrusting ball bearing; a butterfly spring is installed in the coupling. The valve has no leakage and can automatically restore when the power fails, thus saving energy and reducing consumption; the valve has easy and labor-saving opening and closing, advanced technology and excellent performance.

Owner:张跃

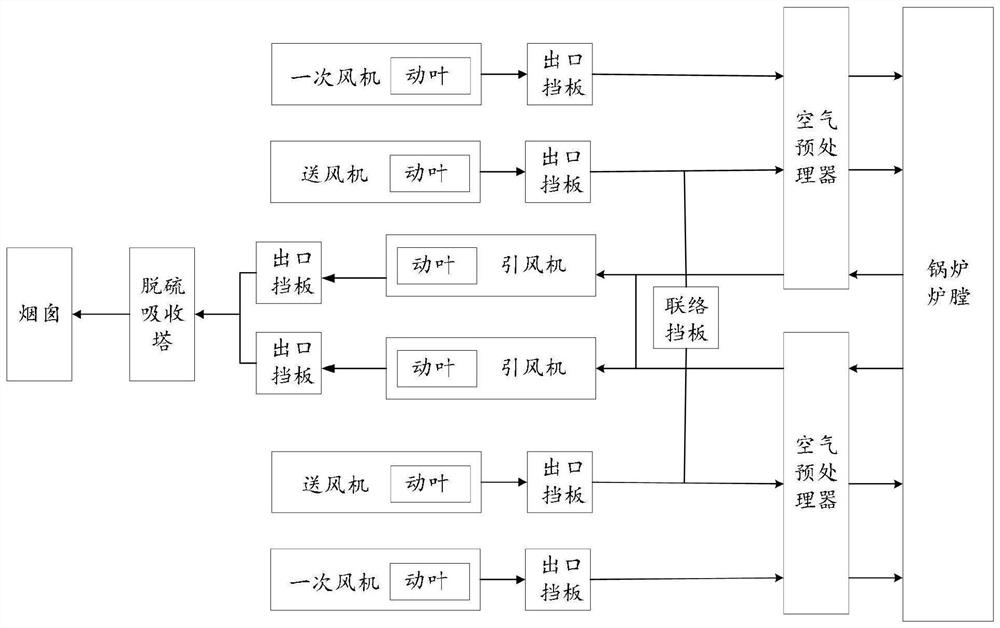

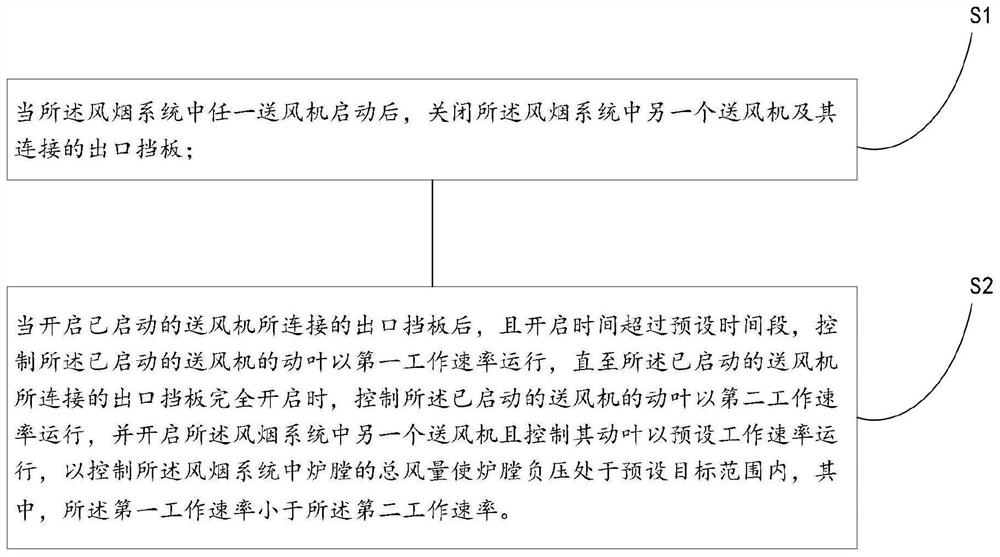

Hearth negative pressure control method and system and electronic equipment

ActiveCN113819485APrevent backwindReduce the chance of explosionAir supply regulationEfficient regulation technologiesAir volumeProcess engineering

The invention relates to a hearth negative pressure control method and system and electronic equipment. The method comprises the steps that after any one air feeder in an air and smoke system is started, the other air feeder in the air and smoke system and an outlet baffle connected with the other air feeder are closed; when an outlet baffle connected with the started air feeder is opened and the opening time exceeds a preset time period, a movable blade of the started air feeder is controlled to operate at a first working speed until the outlet baffle connected with the started air feeder is completely opened; and the movable blade of the started air feeder is controlled to operate at a second working speed, the other air feeder in the air and smoke system starts, a movable blade of the other air feeder is controlled to operate at a preset working speed so as to control the total air volume of a hearth in the air and smoke system to enable the negative pressure of the hearth to be within a preset target range, and the first working rate is smaller than the second working rate. Compared with an existing regulation and control method, disturbance to the negative pressure of the hearth is small and is within the preset target range, and the probability of hearth explosion is reduced.

Owner:北京京能电力股份有限公司 +1

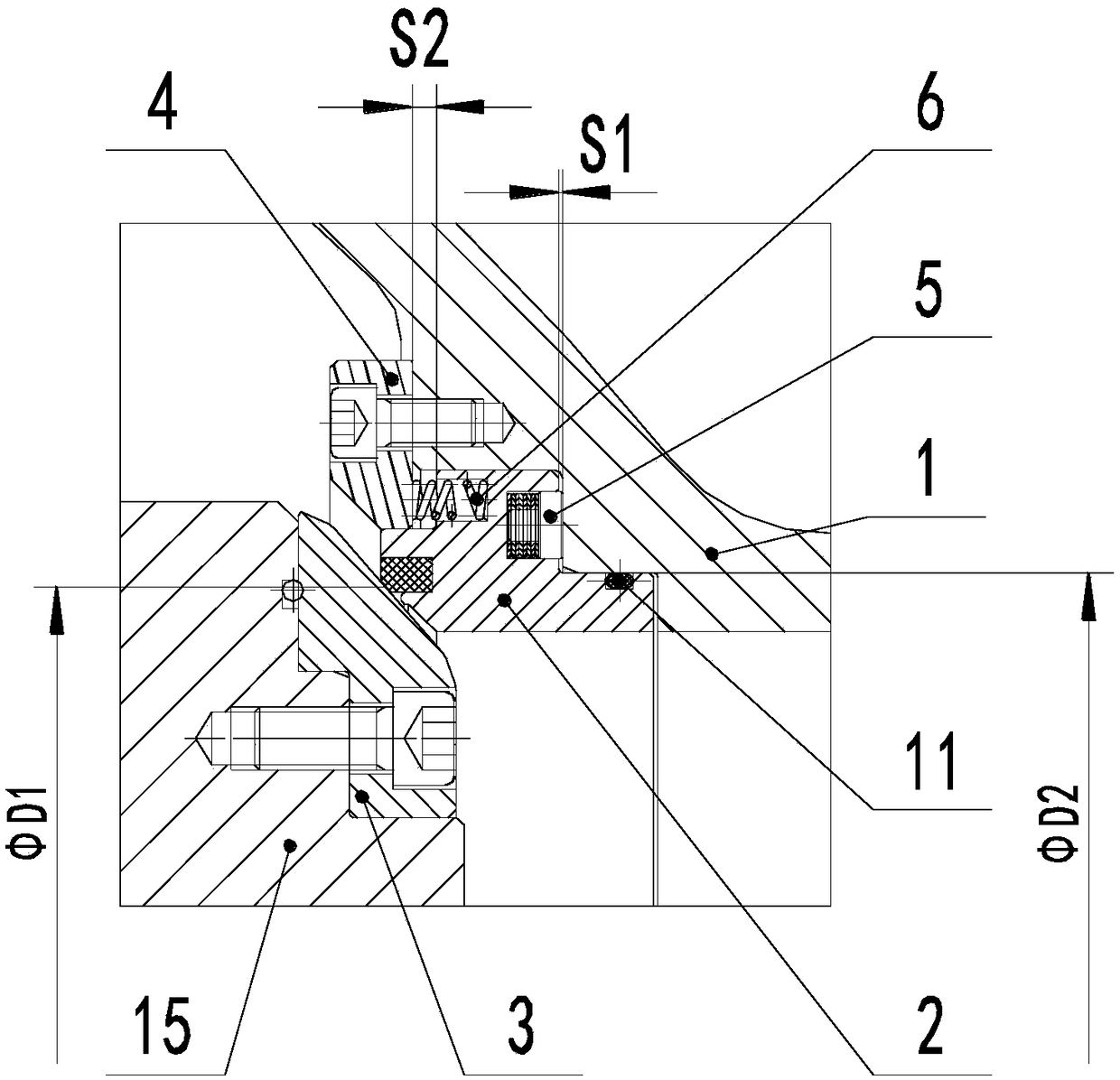

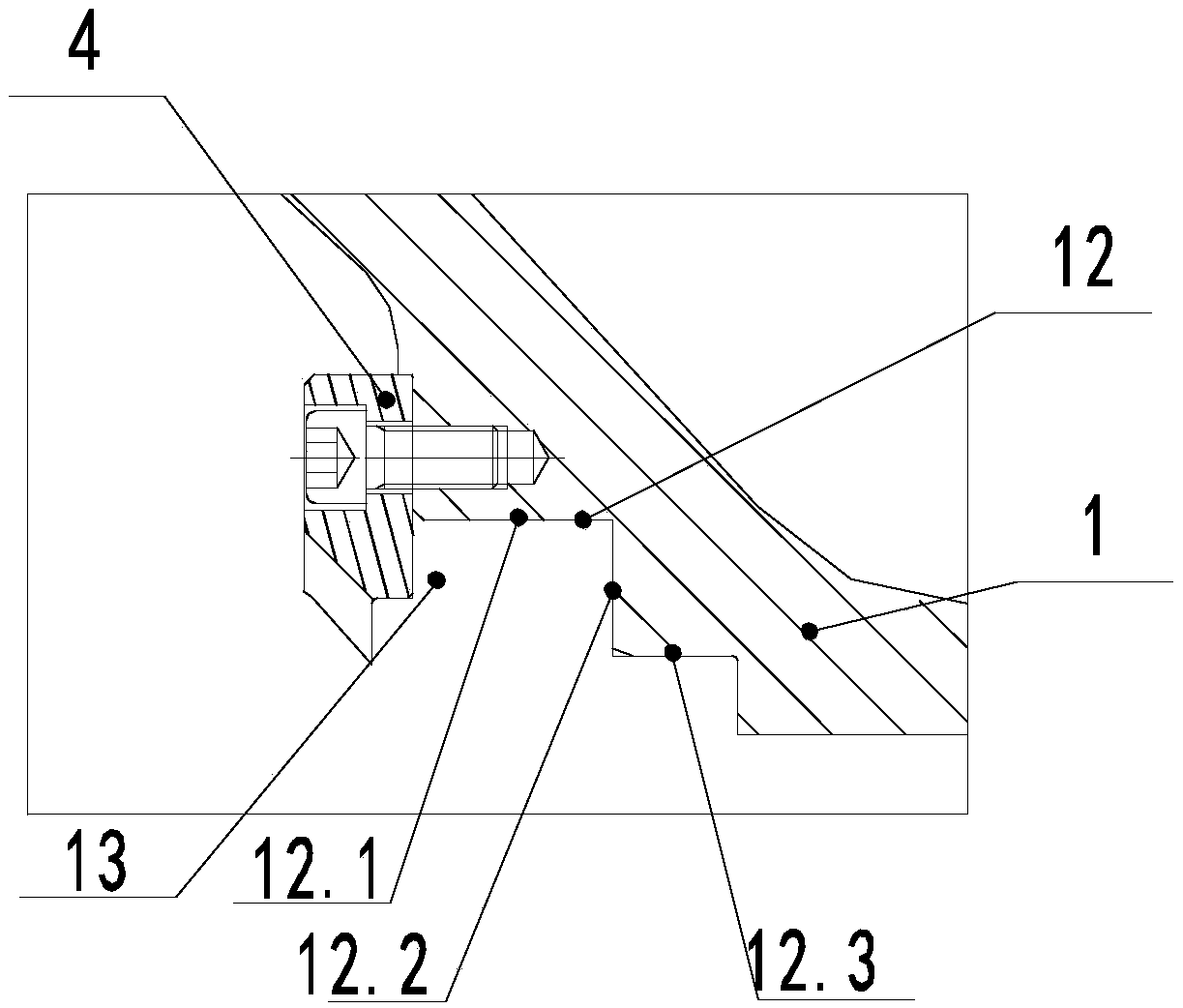

An Adaptive Bidirectional Floating Seat Structure

ActiveCN106151576BGood bi-directional sealing performanceImprove sealingPlug valvesWorking pressureEngineering

The invention discloses a self-adaptive bidirectional floating valve seat structure. The structure comprises a valve body; a valve seat and a spherical crown which are matched with each other are arranged in the valve body; the structure is characterized by further comprising a circular pressing plate connected on one side, close to the spherical crown, of the valve body; the valve seat is located between the pressing plate and the valve body, an axial gap exists between one side of the valve seat and the pressing plate, and an axial gap exists between the other side of the valve seat and the valve body; an axially compressed first spring is arranged between the valve seat and the valve body; an axially compressed second spring is arranged between the valve seat and the pressing plate; the valve seat floats between the valve body and the pressing plate axially; and the first spring and the second spring jointly enable the valve seat and the spherical crown to be fit in a sealed manner at the sealing surface. According to the structure, sealing pressure is applied to a sealing pair under the resultant action of the two springs, the valve seat and the springs can be adjusted in a self-adaptive manner under different working pressure, the reasonable sealing force is applied to the sealing surface, and the self-adaptive bidirectional floating effect is realized.

Owner:WUHAN DAYU VALVE

Emergency cut-off valve at bottom of built-in tank in low-temperature liquid storage tank

ActiveCN102927293BSmall opening torqueGuaranteed zero leakage sealing performanceOperating means/releasing devices for valvesLift valveLiquid storage tankEngineering

Disclosed is an emergency cut-off valve of at the bottom of a built-in tank in a low-temperature liquid storage tank. The emergency cut-off valve mainly comprises a main valve portion and a driving portion, the main valve portion is welded to the bottom of the low-temperature liquid storage tank through a bottom plate; the driving portion is placed at the top of the low-temperature liquid storage tank, and the main valve portion and the driving portion are connected through two stainless steel ropes, wherein one rope is a work rope, and the other rope is an emergency rope; a valve seat is fixed on the bottom plate of the main valve portion and connected with a guide frame, and a large valve clack which is capable of vertically moving and is matched with the valve seat to form a large sealing pair is built in the guide frame; and a small valve clack which is capable of vertically moving and is matched with a centre valve hole of the large valve clack to form a small sealing pair is arranged above the large valve clack through a valve rod. Compared with ordinary emergency cut-off valves, the emergency cut-off valve is small in executing mechanism, reasonable and compact in structure and good in using effects.

Owner:HANGZHOU HANGYANG KOSO PUMP & VALVE

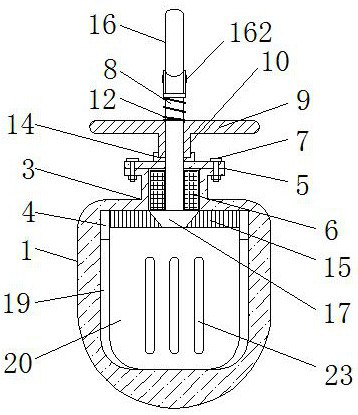

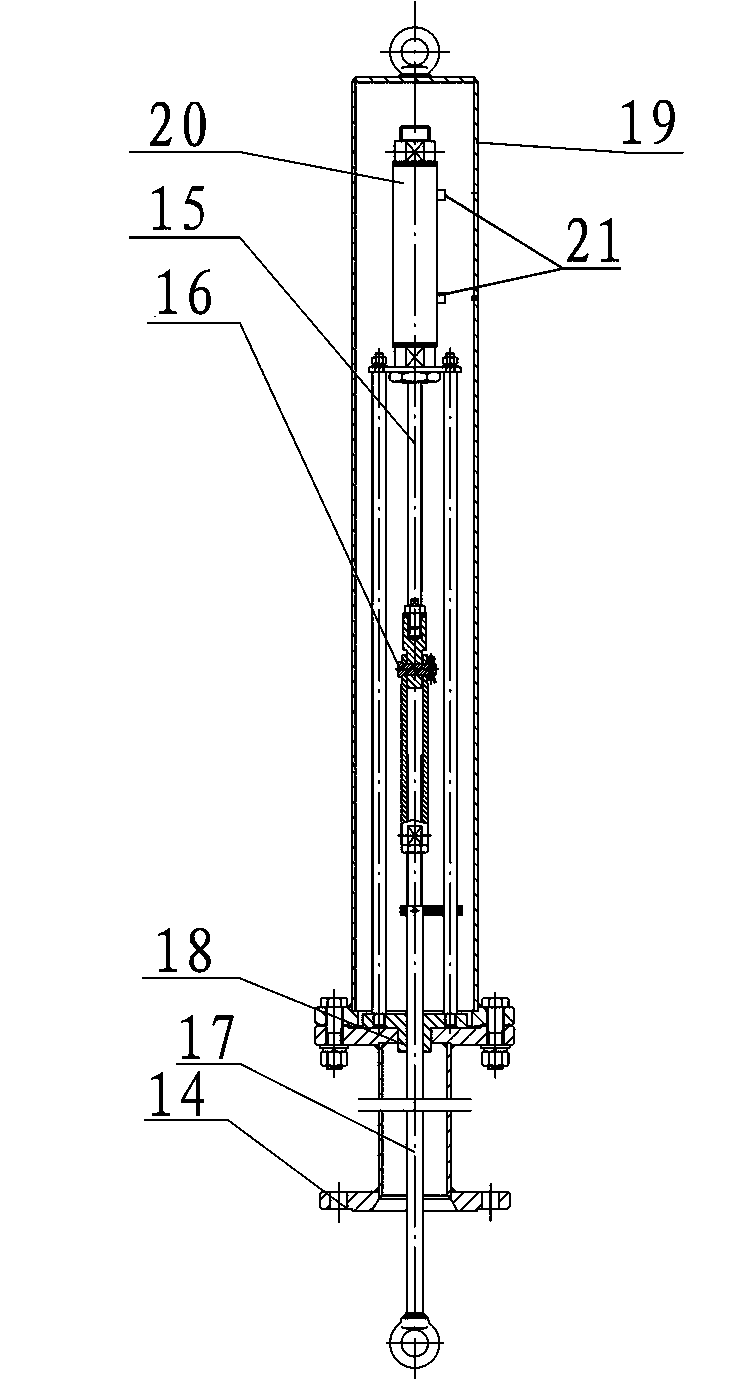

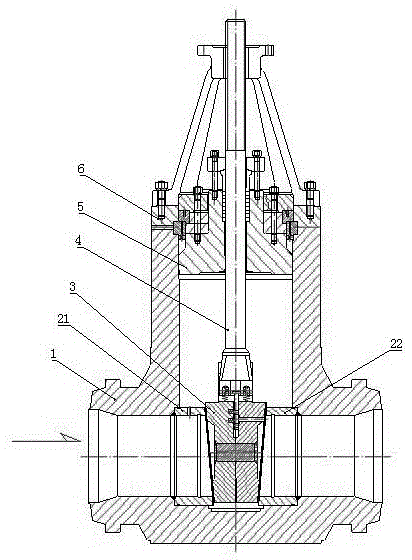

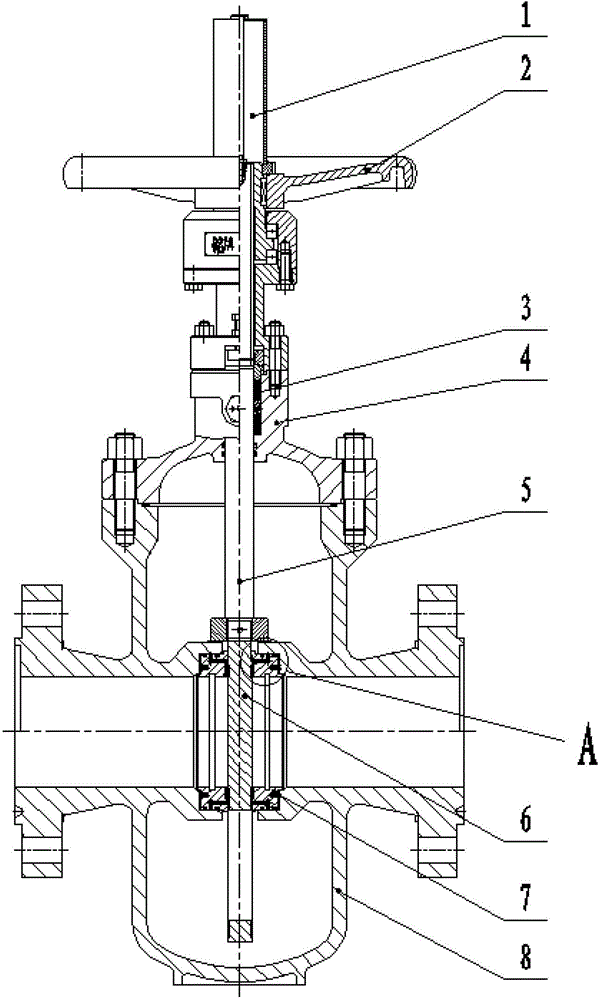

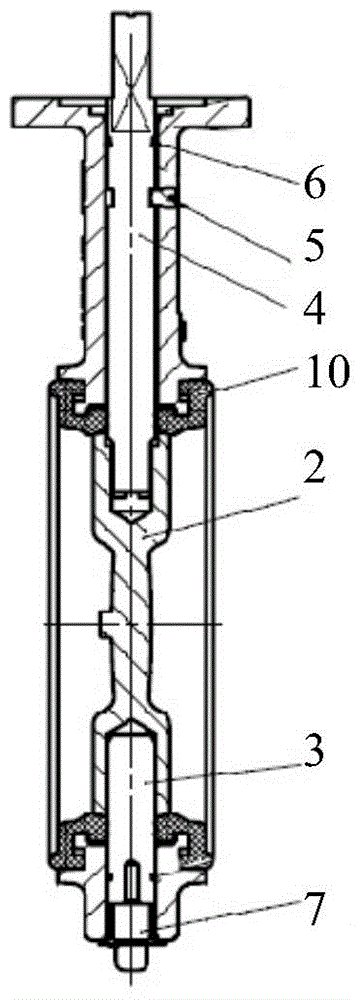

Firstly-opened adjustment valve

PendingCN110345265ASmall opening torqueReduce torquePressure relieving devices on sealing facesLift valveOpen adjustmentMedicine

The invention discloses a firstly-opened adjustment valve. The firstly-opened adjustment valve comprises an execution mechanism, a valve rod, a stroke pointer, stroke scales, a medium outlet in a firstly-opened valve element, a valve body main body and a guide ring, wherein the valve rod is installed at the middle below the execution mechanism, and the stroke pointer is fixed to the left side of the valve rod; the stroke scales are formed at the left side of the stroke pointer; the execution mechanism is fixed to the left side of the stroke scales, and a support is arranged at the bottom end of the execution mechanism; the bottom end of the valve rod penetrates through the support and a gland, and is connected with a small valve element main body, and a valve body main body is fixed to thebottom end of the support; and a valve plug main body is installed in the valve body main body. The firstly-opened adjustment valve is provided with a cross-shaped small valve element, and the smallvalve element adopts a firstly-opened structure, and is low in opening torque compared with a traditional sleeve structure; and when the valve is opened, a pressure charge-in valve in the central cavity of the small valve element main body is opened at first, and then the upper pressure and the lower pressure of the valve plug main body are balanced, and at this moment, the valve plug main body isopened, and the torque is reduced.

Owner:HUIZHENG AUTOMATIC CONTROL VALVE GRP CO LTD

A pilot-operated power station gate valve

Owner:NANTONG POWER STATION VALVE

Flat gate valve with compound seal valve seat structure

The invention relates to a flat gate valve with a compound seal valve seat structure. The flat gate valve comprises a valve body, a gate segment, a valve cover, a valve seat seal assembly and a valverod; the valve cover is fixedly connected with the valve body; the gate segment is arranged in the valve body and is in seal fit with the valve seat seal assembly; the valve seat seal assembly comprises a valve seat body, a seal pressing ring, a primary seal ring and a secondary seal ring; the seal pressing ring, the primary seal ring and the secondary seal ring are installed on the valve seat body; the seal pressing ring, the primary seal ring and the secondary seal ring are sequentially arranged from a medium channel to the outside; the primary seal ring is compacted in an annular hole of the valve seat body by the seal pressing ring; the bulged end of the seal pressing ring is flush with that of the secondary seal ring; the bulged end of the primary seal is higher than that of the sealpressing ring; and the primary seal ring is made of rubber. Seal is mainly completed by the primary seal ring, and the secondary seal ring and the seal pressing ring immediately seal when the primaryseal ring is damaged, so that the valve continues to work, and the seal property is more reliable; and a rubber ring serves as primary seal, the seal specific pressure is small, and a rubber materialis more wear-resistant, so that the service life of the valve is prolonged.

Owner:CHENGDU CHENGFENG VALVE +2

Valves with oil film seal structure

The invention discloses a valve oil film sealing structure. The valve oil film sealing structure comprises a valve seat arranged on a valve body and a valve element surface arranged in the valve body and corresponding to the valve seat. A gap is reserved between the valve seat and the valve element surface and is filled with sealing paste. The sealing paste is located between the valve seat and the valve element surface to form an oil-film-shaped sealing face. The end face, facing the valve element surface, of the valve seat is provided with a storage groove filled with the sealing paste. The valve seat is provided with a feeding channel, the inlet end of the feeding channel extends to the position of a sealing paste feeding port of the valve body, and the outlet end of the feeding channel communicates with the storage groove. The valve oil film sealing structure has the beneficial effects of being good in closing performance, resistant to abrasion, stable in performance and long in service life.

Owner:开立基业(北京)阀门制造有限公司

Pressure balance type plug valve and driving device thereof

PendingCN113294583AAvoid self-lockingIncreased closing torquePlug valvesOperating means/releasing devices for valvesPhysicsPlug valve

The invention discloses a pressure balance type plug valve and a driving device thereof. According to the valve and the driving device, when the valve is opened, under the action of driving force, a valve rod of the whole valve can conduct vertically-downward linear motion at first and then rotate by 90 degrees anticlockwise to achieve a full-open state; and when the valve is closed, under the action of driving force, the whole valve can realize that the valve rod firstly performs vertical upward linear motion and then clockwise rotates by 90 degrees to realize a fully-closed state, most friction torque generated between a plug cock and a valve body due to medium force is eliminated in the opening process, the opening and closing torque is effectively reduced, and meanwhile, the current situation that a cock wedge is tighter and cannot be opened due to deformation of the valve body caused by the medium force in the opening and closing process is avoided.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

Low friction plate gate valve

The invention relates to a low friction flat gate valve which comprises a valve body, a valve cap, valve seats, a flashboard, a valve rod and a hand wheel, wherein a pair of the valve seats is fixedly mounted inside the valve body in a coaxial and hermetic manner; the flashboard is mounted between the valve seats in the vertical direction in a sliding and guiding manner; the valve rod is fixedly mounted at the upper end of the flashboard in the vertical direction in a coaxial manner; the upper part of the valve rod extends out of the valve cap; the hand wheel is mounted at the upper part, positioned at the upper part of the valve cap, of the valve rod in a coaxial manner; combined filling material is mounted on the valve cap inner side between the valve rod and the valve cap; a spring hole is formed in one of the valve seat at the axial contact position with the valve body; a spring is mounted inside the spring hole in a propping manner; a wedge boss is arranged on the surface, in contact with the flashboard, of the valve seat; a guide bevel step is manufactured on the flashboard at the position corresponding to the wedge boss. According to the flat gate valve, the abrasion of the hermetic surfaces of the valve seats and the removal torque of the valve are effectively reduced, and the service life of the valve is greatly prolonged.

Owner:TIANJIN BAILIZHANFA GRP

Energy-saving type low-torque butterfly valve

InactiveCN104482227AExtended service lifeGuaranteed tightnessOperating means/releasing devices for valvesLift valveButterfly valveEngineering

The invention discloses an energy-saving type low-torque butterfly valve which comprises a valve body, a valve base, a valve plate and a valve shaft, wherein the inner wall of the valve base is in a cylindrical shape; an outer side wall of the valve plate is a convex spherical surface; indent spherical slots matched with the spherical surface are respectively formed in the parts, corresponding to the upper end and the lower end of the valve plate, of the valve base. A unique spherical sealing type structure is adopted by the energy-saving type low-torque butterfly valve, the inner wall of the valve base is of a cylindrical structure, and the position, in contact with the valve plate, of the inner wall of the valve base is of the cylindrical structure; the peripheral surface of the valve plate is the spherical surface; the indent spherical slots are only respectively formed in the parts, corresponding to the upper end and the lower end of the valve plate, of the valve base; the sealing of the spherical surface is utilized to ensure the sealing property; the spherical surface is easily separated from the cylindrical structure, so that the starting torque is effectively reduced; the requirement of the customer on a small torque is met; the service life of the valve is effectively prolonged.

Owner:TIANJIN FSK FLOW CONTROL EQUIP

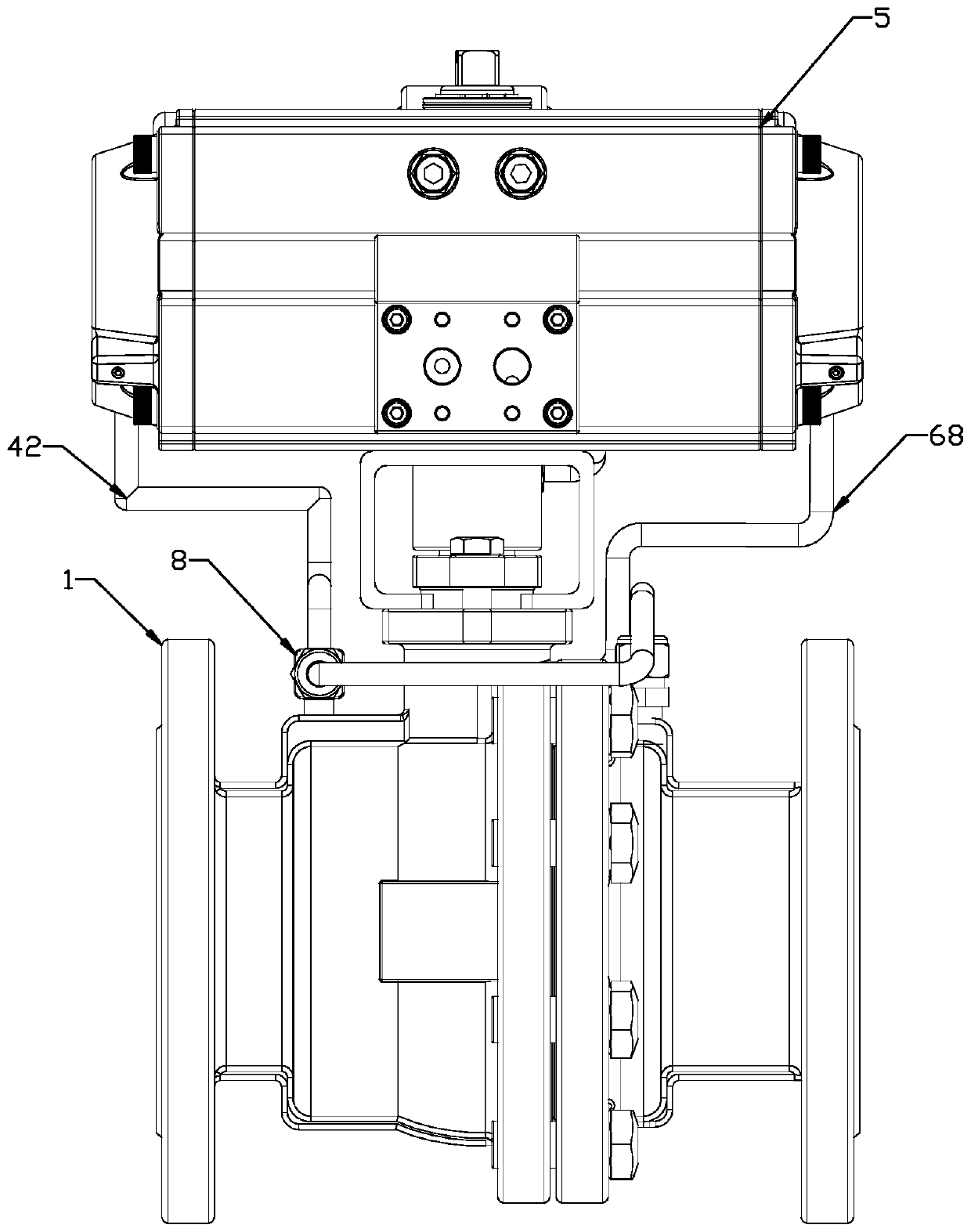

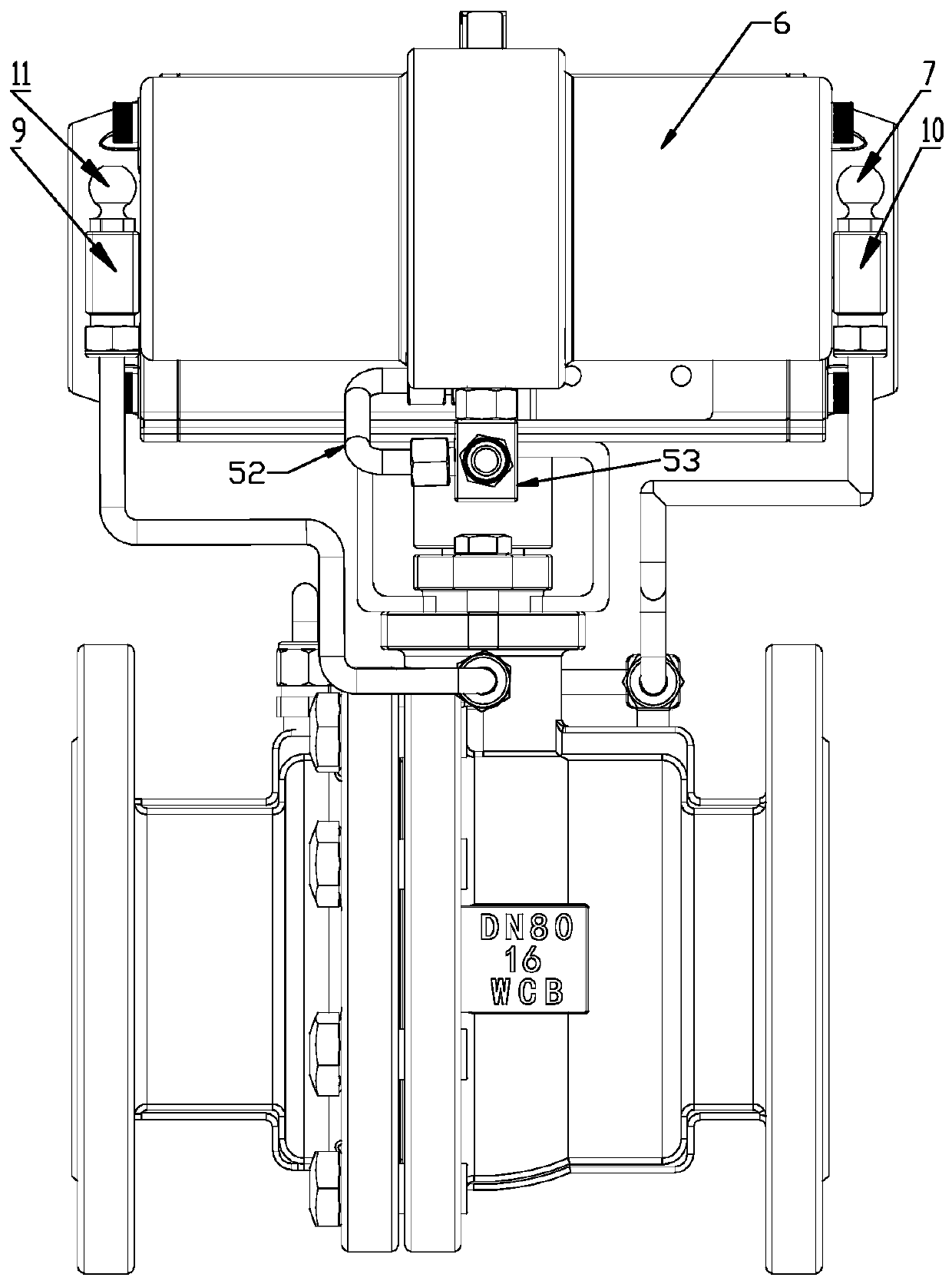

High-safety die forging ball valve

PendingCN110285230AReasonable structureReasonable structural designSpindle sealingsPlug valvesEngineeringValve opening

The invention discloses a high-safety die forging ball valve. The high-safety die forging ball valve comprises a valve body, wherein a valve ball loading port is formed in the upper end of a valve cavity of the valve body, a valve ball is arranged inside the valve cavity, a first inclined plane combined type valve base is arranged at the left end of the valve ball, and a second inclined plane combined valve base is arranged at the right end of the valve ball; a positioning boss is arranged at the upper end of the valve ball, a positioning groove is vertically formed in the middle of the positioning boss, a sliding block is arranged on the positioning boss, a positioning lug is integrally arranged on the lower end surface of the sliding block, and the positioning lug is inserted into the positioning groove; a spring groove is vertically formed in the middle of the upper end surface of the sliding block, a spring assembly is arranged inside the spring groove in a embedded mode, a valve rod is arranged right above the spring assembly, and a valve cover is arranged on the valve rod in a sleeved mode. According to the technical scheme, the structure design is reasonable, the structure is simple, the high-safety die forging ball valve is not easy to leakage, the sealing performance is good, the valve rod is not easy to bend or deform, the valve opening and closing torque is small, the maintenance is convenient, the service life is long, the work is stable, and the practicability is good.

Owner:OVIKO GRP CO LTD

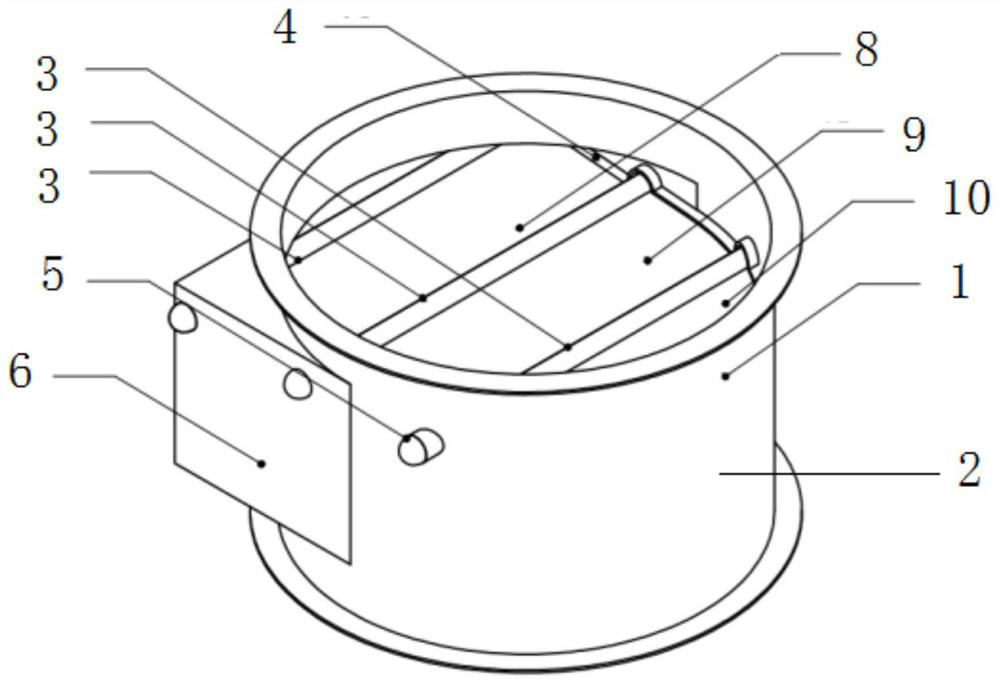

Composite material special-shaped air pipe check valve for circular gas pipeline

ActiveCN113483127AReduce volumeReduce material costsCheck valvesDomestic articlesRotational axisEngineering

The invention discloses a composite material special-shaped air pipe check valve for a circular gas pipeline in the technical field of check valves. The composite material special-shaped air pipe check valve comprises a check valve body, the check valve body comprises a circular valve body part and a square valve body part, an upper blade, a middle blade and a lower blade are arranged on the inner side of the check valve body, the upper blade, the middle blade and the lower blade are all connected with rotating shafts, the rotating shafts are rotationally arranged in the check valve body, sealing sleeve caps are arranged at the outer ends of the rotating shafts, three limiting baffles are arranged on the inner side of the check valve body, and a sealing baffle is arranged on the inner side of the check valve body. The size of the whole check valve body can be reduced, manufacturing materials and manufacturing cost are reduced, transportation, installation and maintenance are easy, machining is conducted through a mold and a winding method, manufacturing is convenient and fast, the appearance is attractive and elegant, the opening torque of valve blades is reduced by reducing the weight, the influence of part of structural dead angles on gas conveying is eliminated, and the pressure loss of the check valve body is reduced.

Owner:江苏瑞雨斯环保科技有限公司

High Pressure Differential Switchable Kelly Plug Valve

ActiveCN103742106BImprove reliabilityImprove securityWell/borehole valve arrangementsSealing/packingVertical tubeEngineering

Owner:黑龙江北方双佳钻采机具有限责任公司

Small electric valve for shock-absorbing protecting torsion force

InactiveCN101354094BAutomatically cut off the medium flow directionIncrease pressureOperating means/releasing devices for valvesBall bearingCoupling

Owner:张跃

Elastic wedge-caulking type flat gate valve

The invention relates to an elastic wedge-caulking type flat gate valve. The elastic wedge-caulking type flat gate valve comprises a valve body, a valve seat, a valve cover, a valve rod and gate plates, the gate plates are composed of a main gate plate and an auxiliary gate plate, the main gate plate and the auxiliary gate plate are in contact with each other through inclined surfaces in a cooperating mode, a limiting plate fixedly connected with the auxiliary gate plate is arranged above the main gate plate, a positioning pile is arranged at the bottom of an inner cavity of the valve body, anelastic separation device is arranged between the main gate plate and the auxiliary gate plate mainly, the elastic separation device adopts a hook-shaped spring to be arranged between the main gate plate and the auxiliary gate plate, one end of the hook-shaped spring is pressed into a hook groove formed in one side of the inclined surface of the main gate plate, the other end of the hook-shaped spring penetrates through the auxiliary gate plate, and is fixedly arranged on a mounting inclined plane manufactured on one side of a sealing surface of the auxiliary gate plate through a nut. Friction-free opening and closing between the sealing surfaces of the two sides of the gate plates and the sealing surface of the valve seat are achieved, and the advantages that opening and closing are light, the sealing performance is reliable, the service life is long and the like are achieved.

Owner:ZHEJIANG JINPU IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com