Valves with oil film seal structure

A technology of oil film sealing and valves, which is applied in the direction of lifting valves, valve devices, sliding valves, etc. It can solve the problems of laborious opening or closing of the valve body, sealing of the sealing ring cannot meet the demand, and shorten the service life of the valve body. The operation and opening torque are reduced, and the effect of valve damage is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

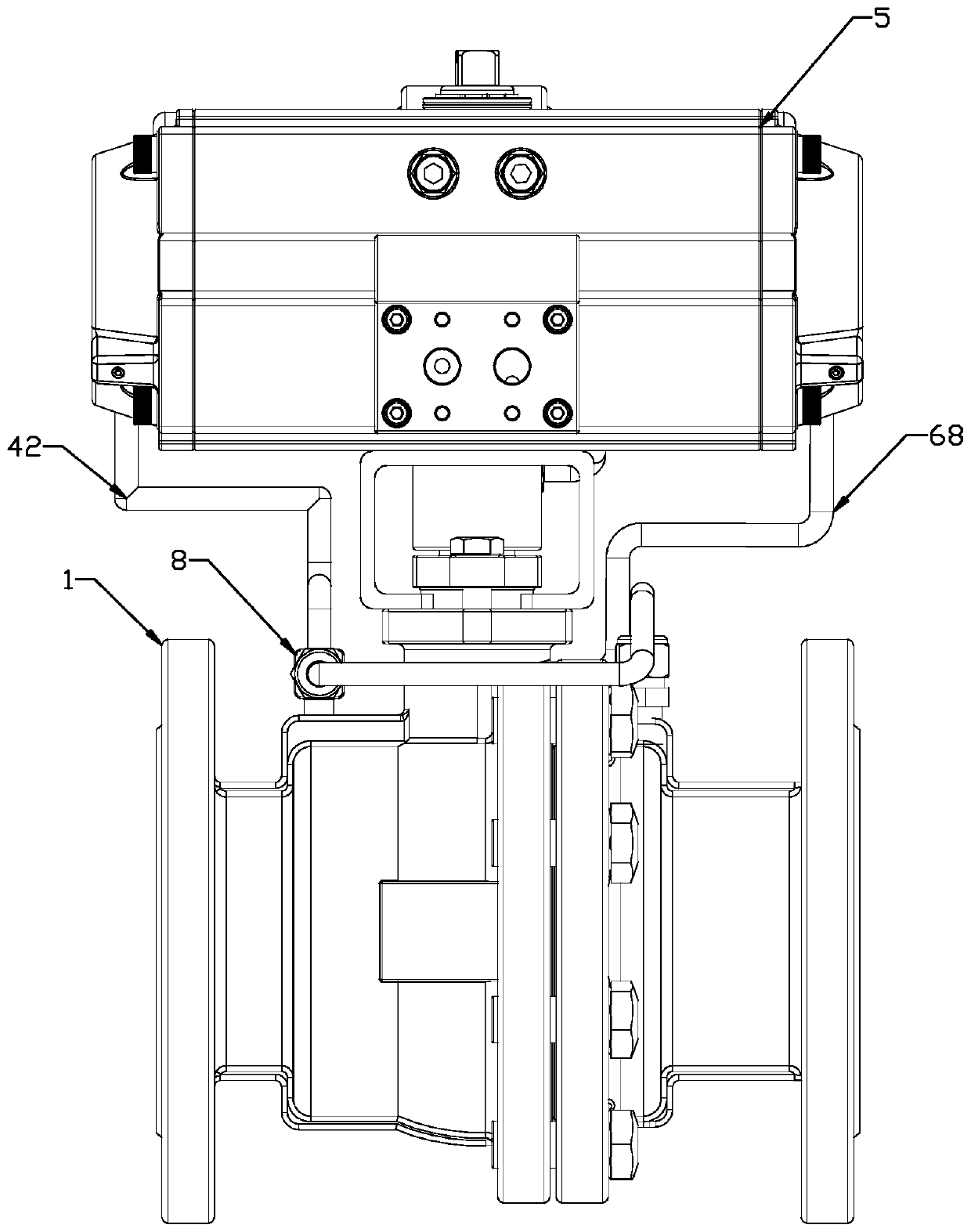

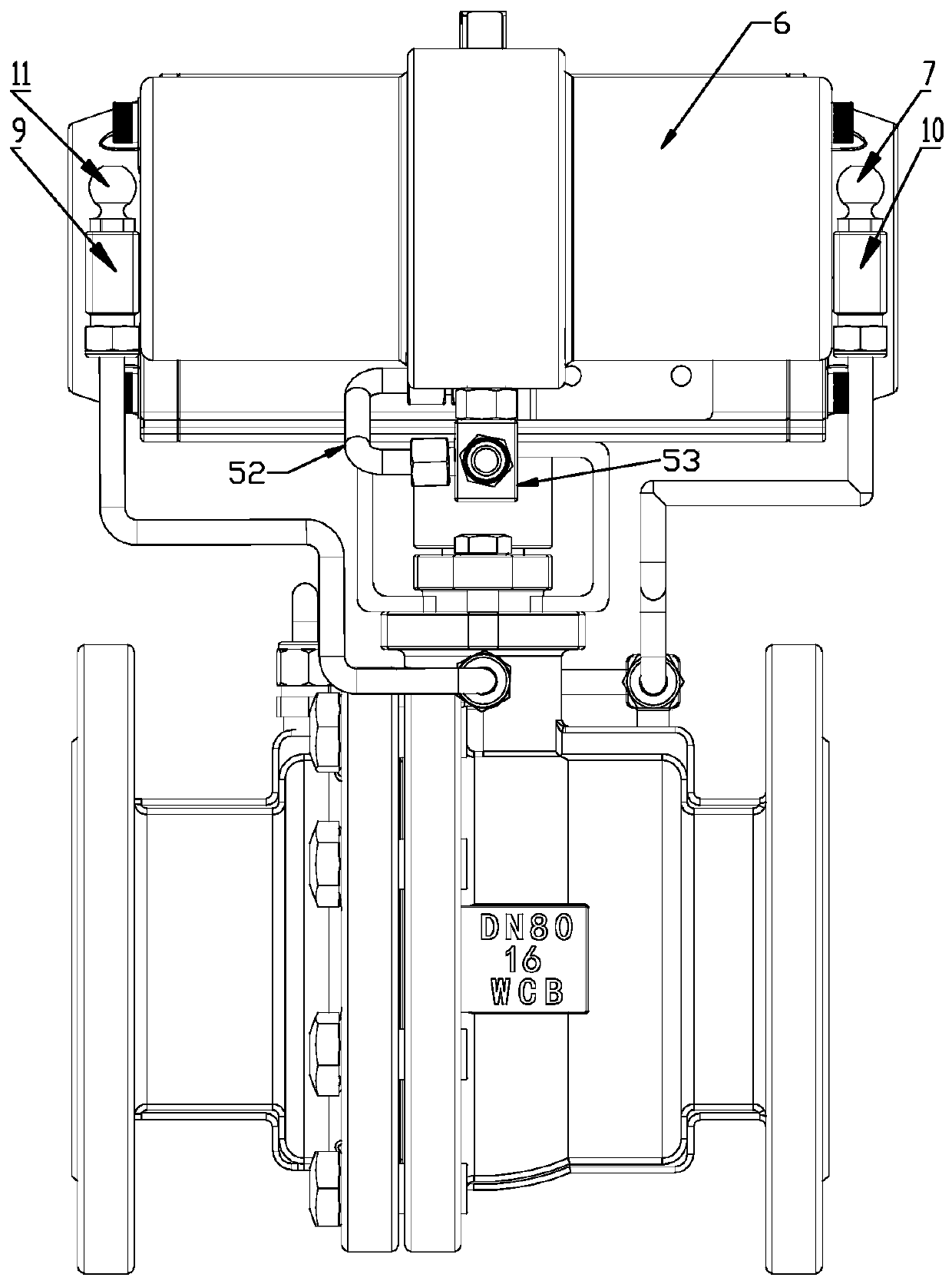

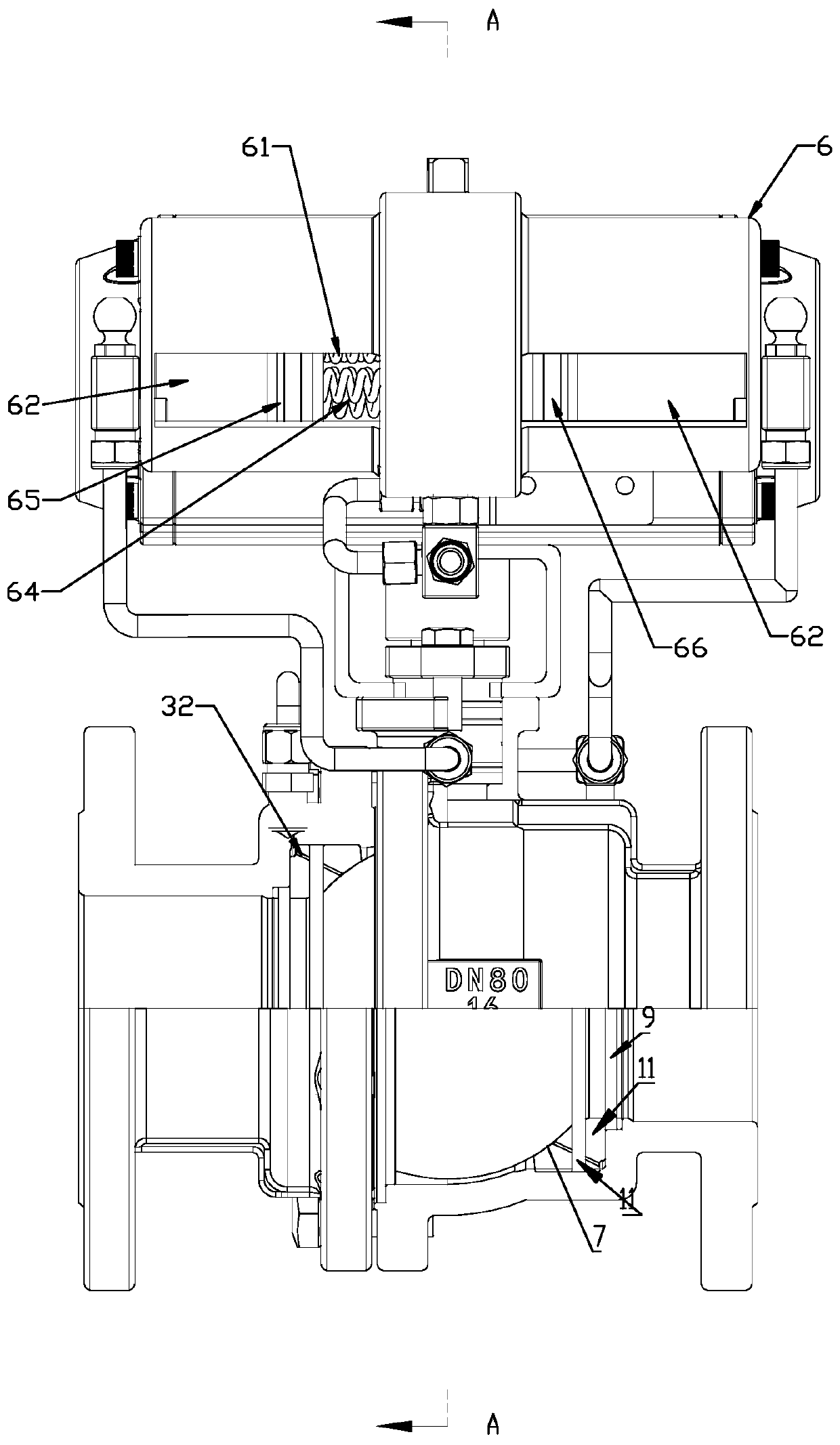

[0041] Specific embodiments of the present invention such as Figure 1-12 Shown is a valve with an oil film sealing structure, including a valve body 1. A fluid passage 11 is provided in the valve body 1. A valve core 2 that conducts or cuts off the fluid passage 11 is provided in the fluid passage 11. A valve core 2 is also provided in the valve body 1. There is a valve seat 3 that forms a sealed connection with the valve core 2, the valve core 2 is connected to the operating mechanism 5 through the valve shaft 4, the valve body 1 is provided with a valve channel 13 that is adapted to the valve shaft 4, the valve shaft 4 and the valve channel 13 There is a gap between the valve seat 3 and the surface of the valve core 2. The gap is filled with sealing paste. The sealing paste can be grease or ointment with a certain viscosity. The sealing paste is located between the valve seat 3 and the valve core. An oil film-like sealing surface is formed between the surfaces of the core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com