High-safety die forging ball valve

A safe, die-forging technology, applied in valve details, valve devices, shaft seals, etc., can solve problems such as adverse effects on service life and sealing performance, excessive valve opening and closing torque, and difficult maintenance and operation, achieving long service life, The valve opening and closing torque is small, and the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

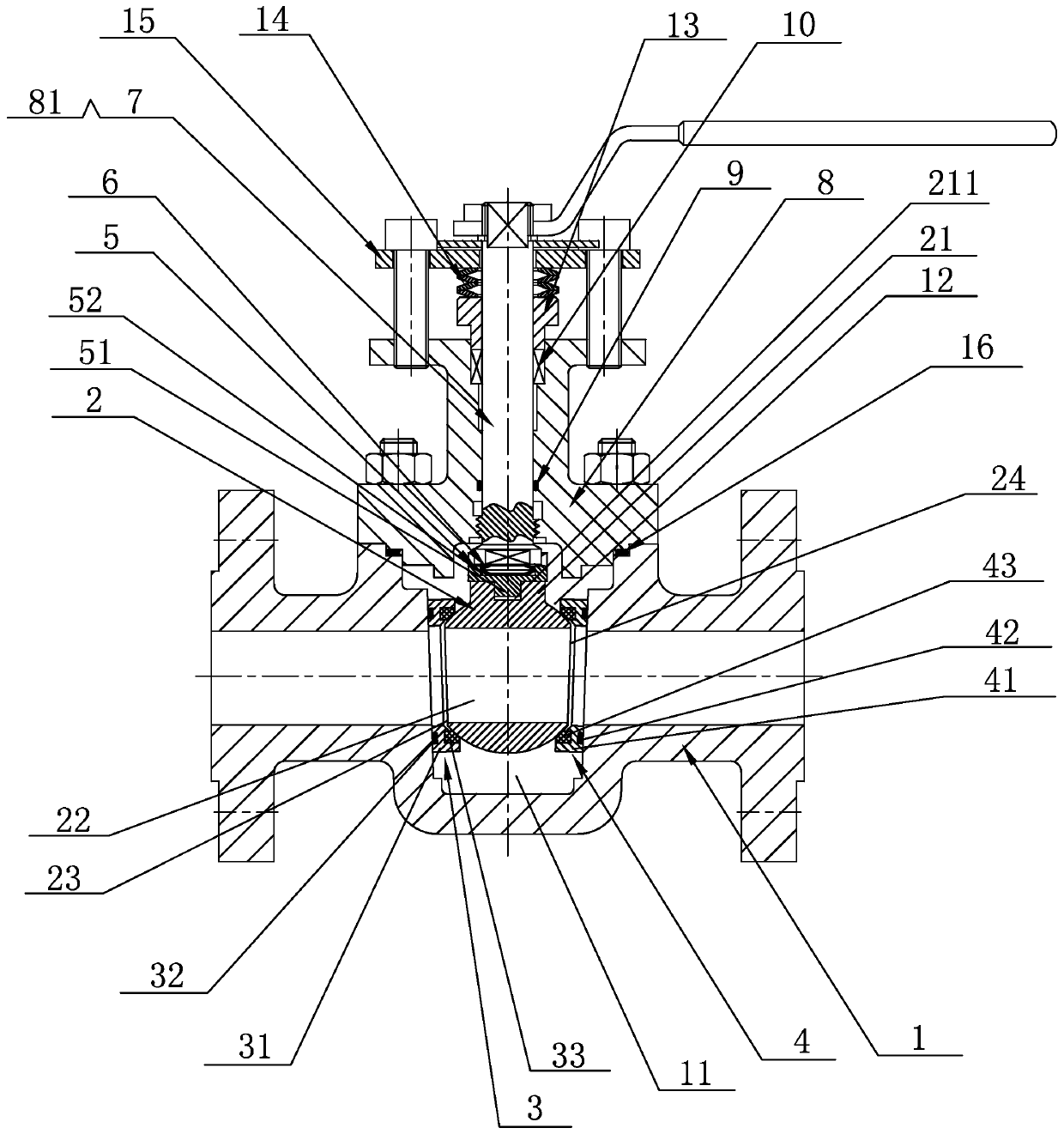

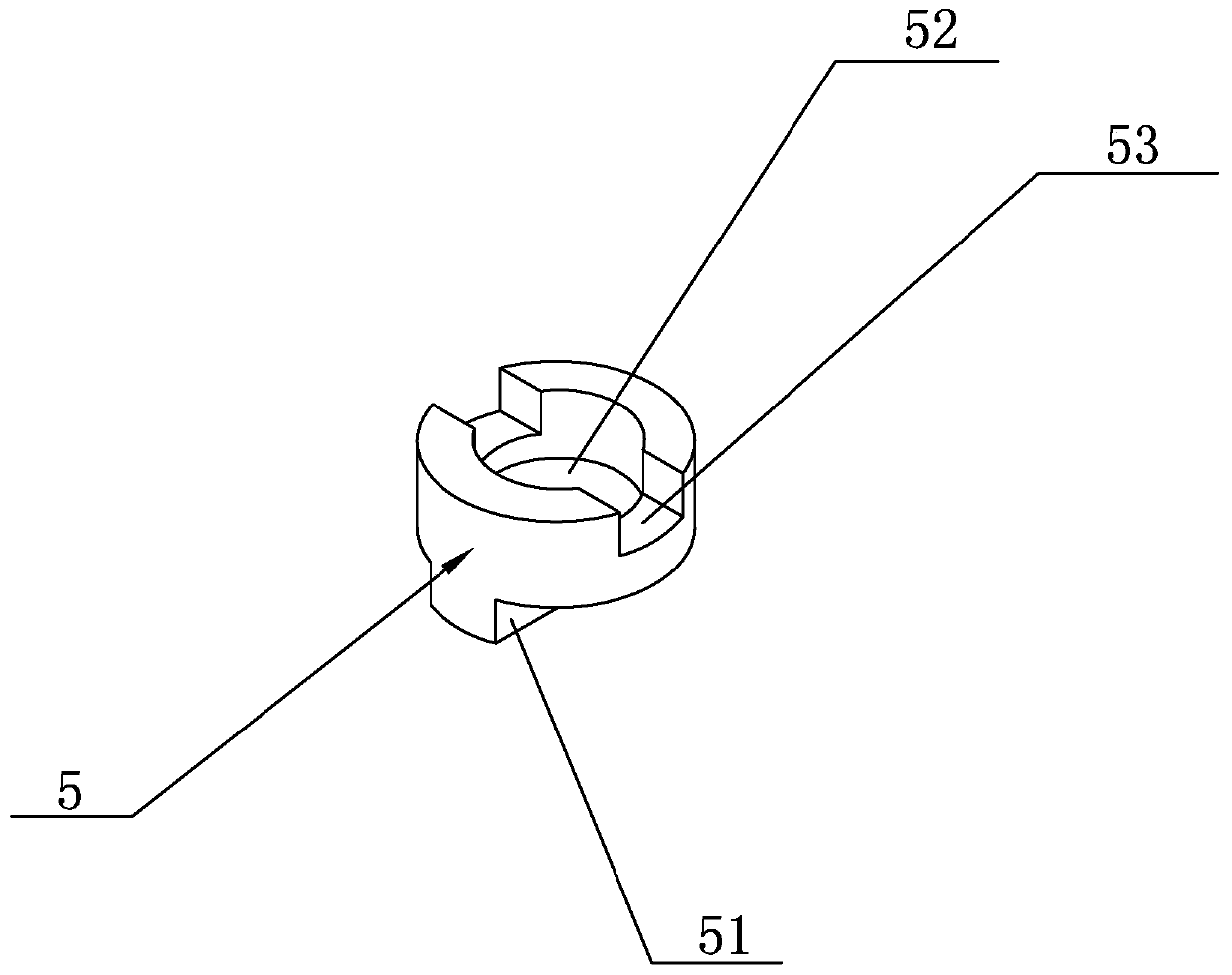

[0019] see figure 1 with figure 2 , a high-safety forged ball valve disclosed in the present invention, comprising a valve body 1, a valve chamber 11 is arranged inside the valve body 1, a valve ball loading port 12 is arranged at the upper end of the valve chamber 11, and a valve chamber 11 is provided inside the valve chamber 11. A valve ball 2 is provided, the left end of the valve ball 2 is provided with a first inclined-plane combined valve seat 3, the right end of the valve ball 2 is provided with a second inclined-plane combined valve seat 4, and the upper end of the valve ball 2 is provided with a positioning boss 21 A positioning groove 211 is vertically provided in the middle of the positioning boss 21, a slider 5 is arranged on the positioning boss 21, and a positioning protrusion 51 is integrally provided on the lower end surface of the slider 5, The positioning protrusion 51 is inserted into the positioning groove 211, and a spring groove 52 is vertically arrang...

Embodiment 2

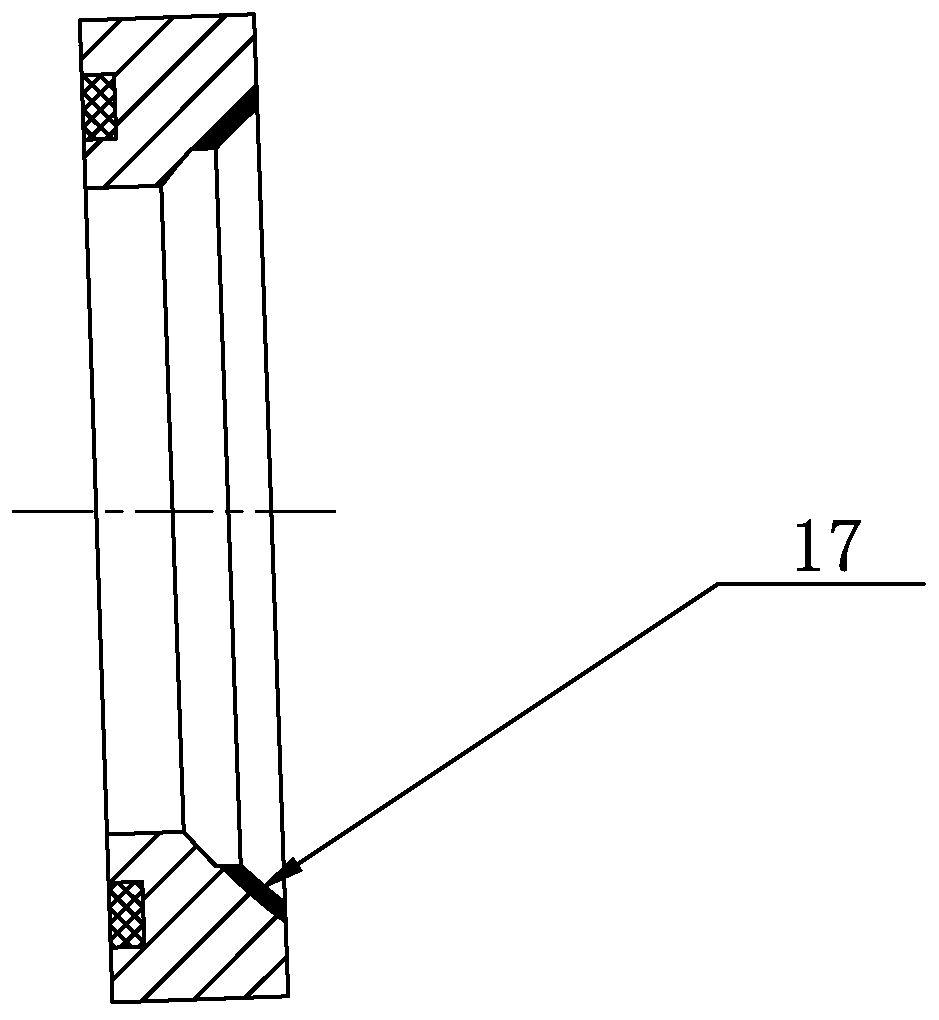

[0030] see image 3 , the second embodiment is to improve the valve seat on the basis of the first embodiment above: the valve ball sealing ring of the inclined-plane combined valve seat is replaced by a surfacing welding carbide layer 17 to make it a hard-sealed ball valve, that is, the above-mentioned A cemented carbide sealing layer 17 is welded on the right end surface of the first metal support ring 31 and the left end surface of the second metal support ring 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com