Emergency cut-off valve at bottom of built-in tank in low-temperature liquid storage tank

A low-temperature liquid, shut-off valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as safety hazards, liquid leakage, safety accidents, etc., achieve reasonable structure, reduce valve opening torque, and zero leakage sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

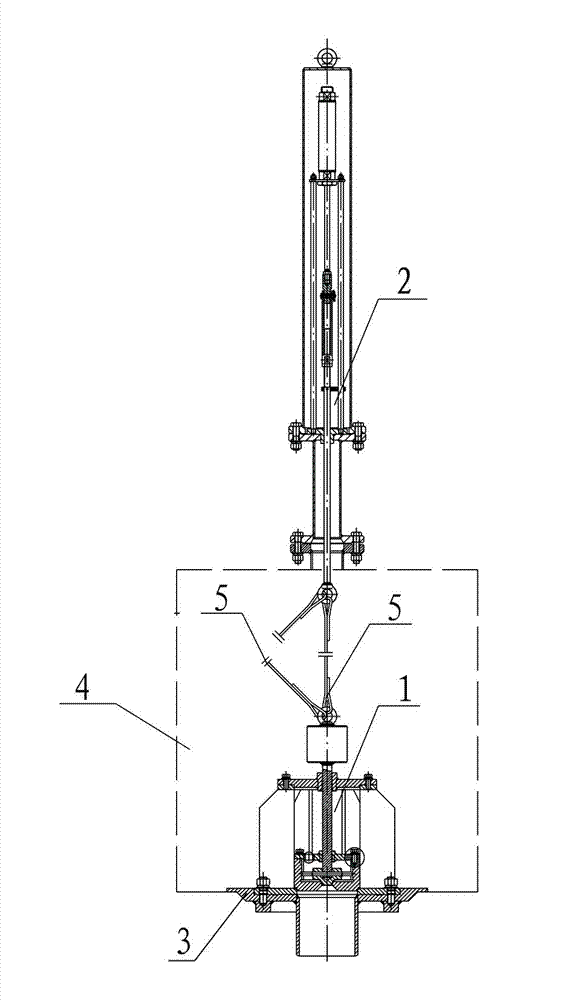

[0018] Embodiment: The built-in tank bottom emergency shut-off valve of the present invention is a special valve for large cryogenic liquid storage tanks. The valve is divided into two parts: main valve and drive.

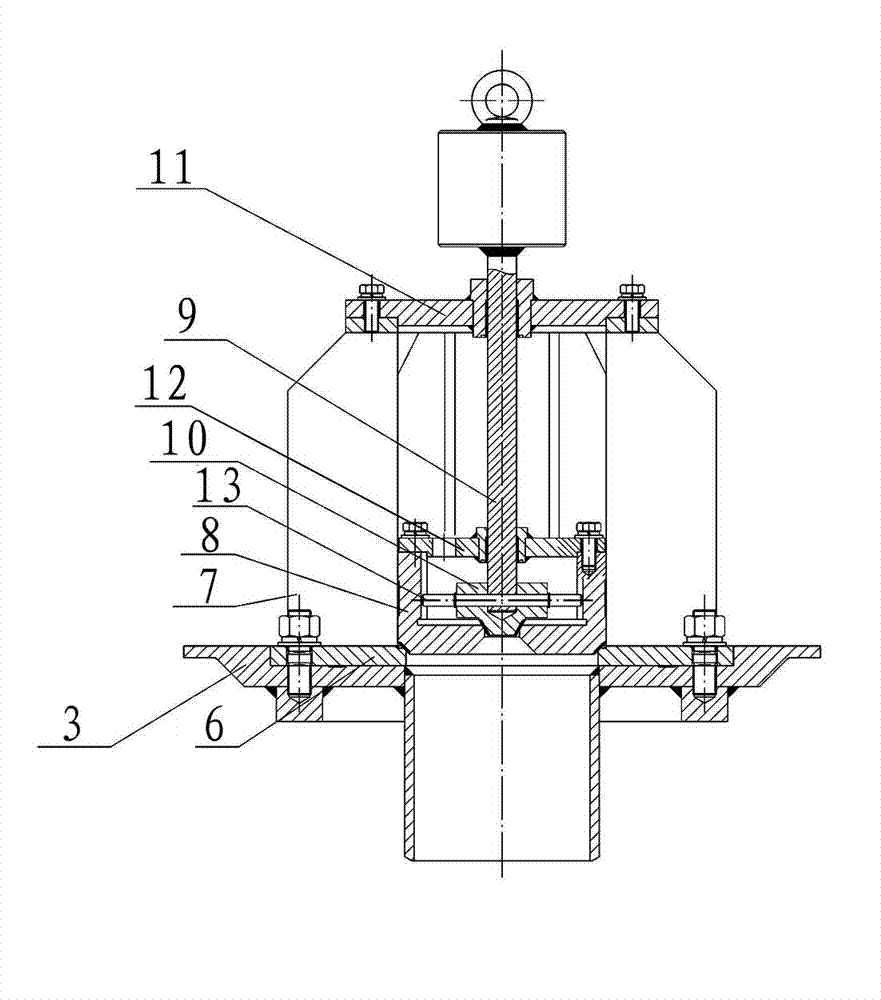

[0019] The main valve part 1 is mainly composed of bottom plate, valve seat, guide frame, large and small valve discs, valve disc cover, guide frame cover, guide rod, etc. (see figure 2 ). The small disc and the large disc form a sealing pair, and the large disc and the valve seat form a sealing pair. The small disc can move up and down in the large disc and is guided by a guide rod; the large disc can move up and down in the guide frame. sports.

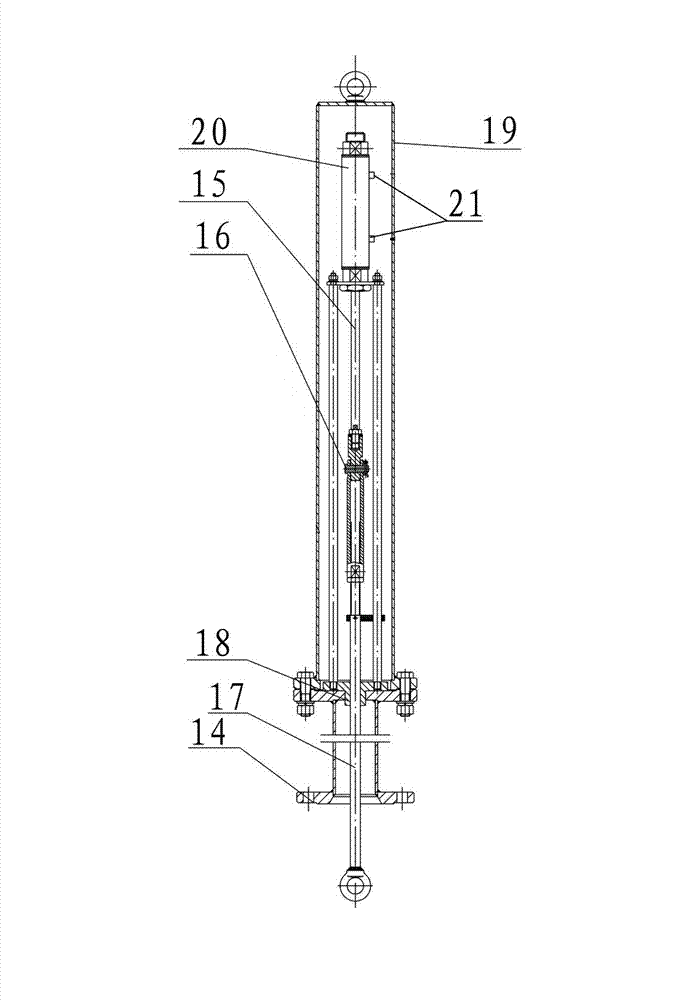

[0020] The driving part 2 is mainly composed of an actuator (with a spring inside), a piston rod, a transmission pin, an upper valve stem, a guide block, a connecting pipe, a protective cover, and an air inlet and outlet, etc. (see image 3 ). The bottom plate in the main valve part is welded to the bottom of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com