Hearth negative pressure control method and system and electronic equipment

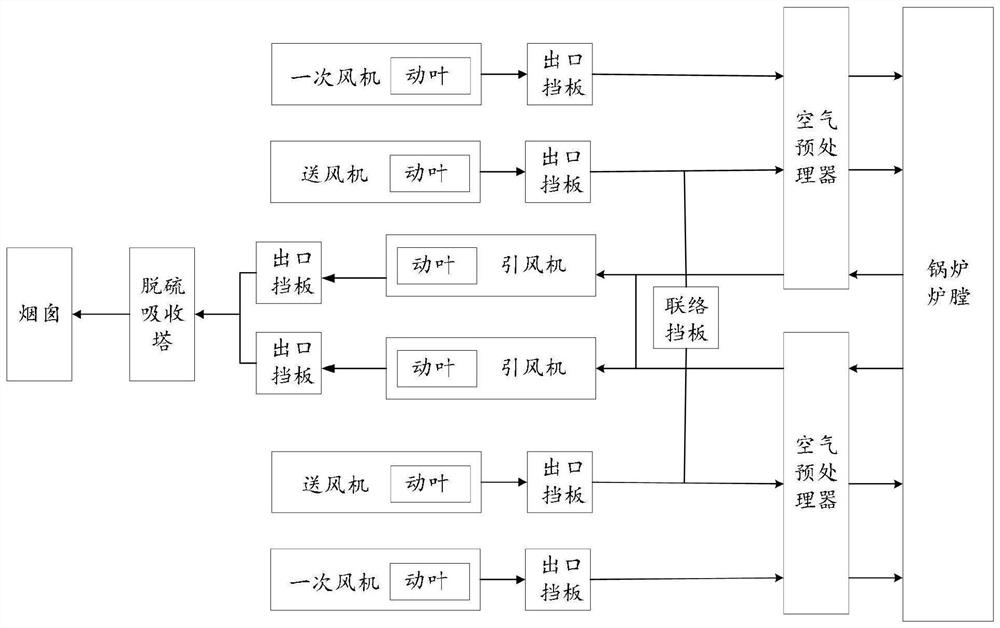

A furnace negative pressure and control method technology, which is applied in the field of furnace negative pressure control methods, systems and electronic equipment, can solve the problems of large furnace damage, ineffective adjustment of furnace negative pressure, large disturbance, etc., to avoid jamming, The effect of reducing the opening torque and reducing the probability of furnace explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

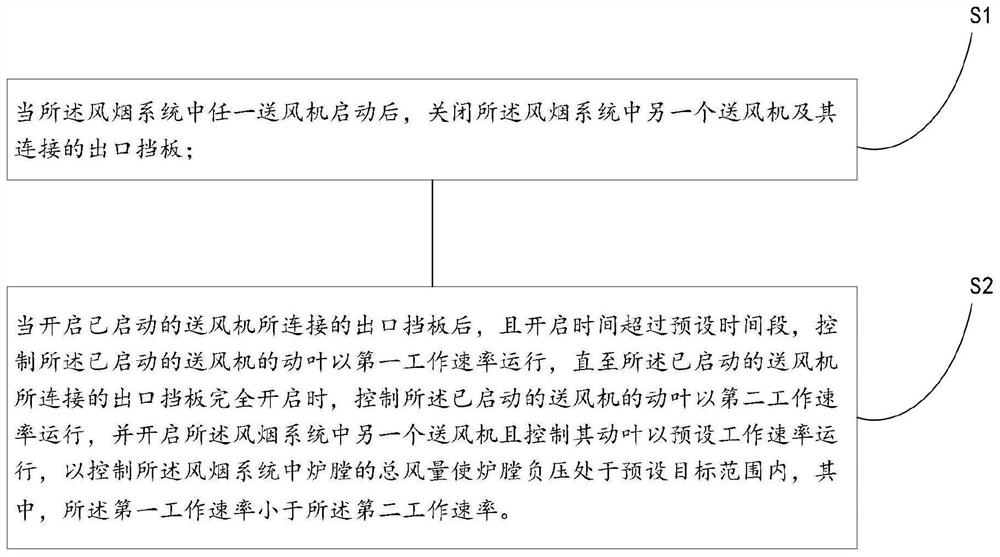

[0038] Such as figure 2 As shown, a kind of furnace negative pressure control method of the embodiment of the present invention comprises the following steps:

[0039] S1. When any blower in the air-smoke system is activated, close the other blower in the air-smoke system and its connected outlet baffle;

[0040] S2. When the outlet baffle connected to the activated air blower is opened, and the opening time exceeds the preset time period, control the rotor blades of the activated air blower to run at the first working speed until the activated air blower reaches the When the connected outlet baffle is fully opened, control the moving blade of the started blower to run at the second working speed, and turn on another blower in the air-smoke system and control its moving blade to run at the preset working speed to The total air volume of the furnace in the air and smoke system is controlled so that the negative pressure of the furnace is within a preset target range, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com