Deformation detection mechanism, pressure vessel detection device and detection system

A detection mechanism and detection device technology, which are applied to measurement devices, use stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of prone to wrinkles, inaccurate signal values of compensation sheets, and large errors in pressure vessel deformation. and other problems to achieve the effect of improving safety and reducing the probability of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Attached to the following Figure 1-4 The present invention will be described in further detail.

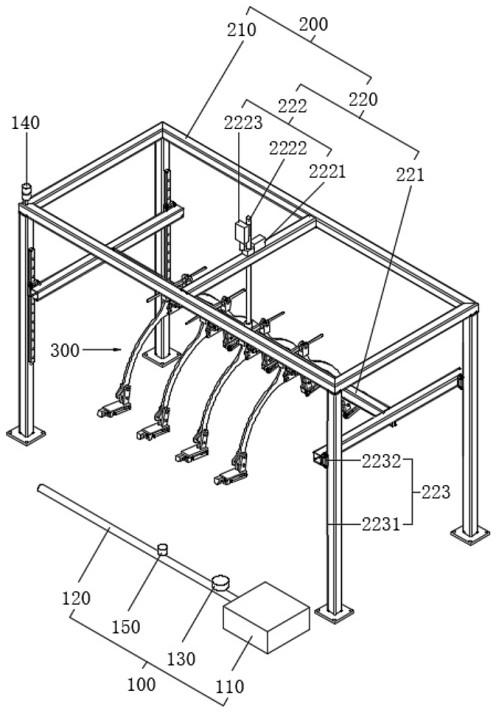

[0046] The embodiment of the present application discloses a detection system, refer to figure 1 , the inspection system includes an inflation device 100 for inflating the pressure vessel and a pressure vessel inspection device 200 for inspecting the pressure vessel. When the pressure vessel is detected, the inflation device 100 is connected to the pressure vessel, and then the pressure vessel is filled with air. At the same time, the pressure vessel detection device 200 detects the deformation of the pressure vessel, so as to reduce the risk of explosion of the pressure vessel during the detection process. probability.

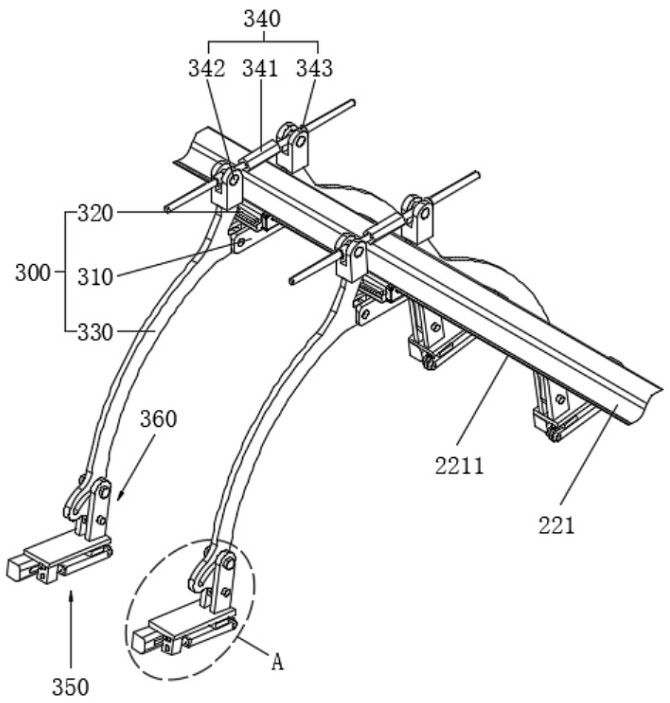

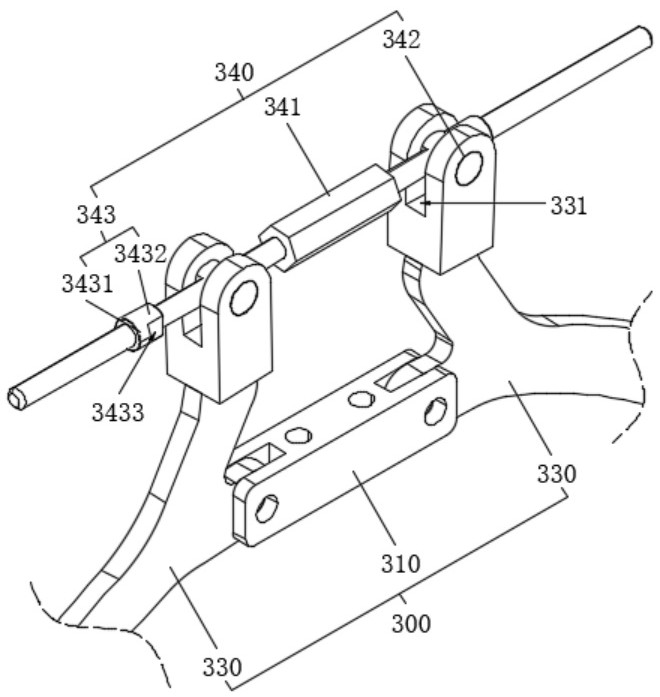

[0047] refer to figure 1 , the pressure vessel detection device 200 includes a frame 210, a deformation detection mechanism 300 for detecting the deformation of the pressure vessel, and an adjustment mechanism 220 for adjusting the position of the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com