Method for purifying nano-diamond

A nano-diamond and purification method technology, which is applied in the field of nano-diamond purification, can solve the problems of complicated nano-diamond removal routes and low removal efficiency, and achieve the effects of avoiding metal ion precipitation, improving removal efficiency, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

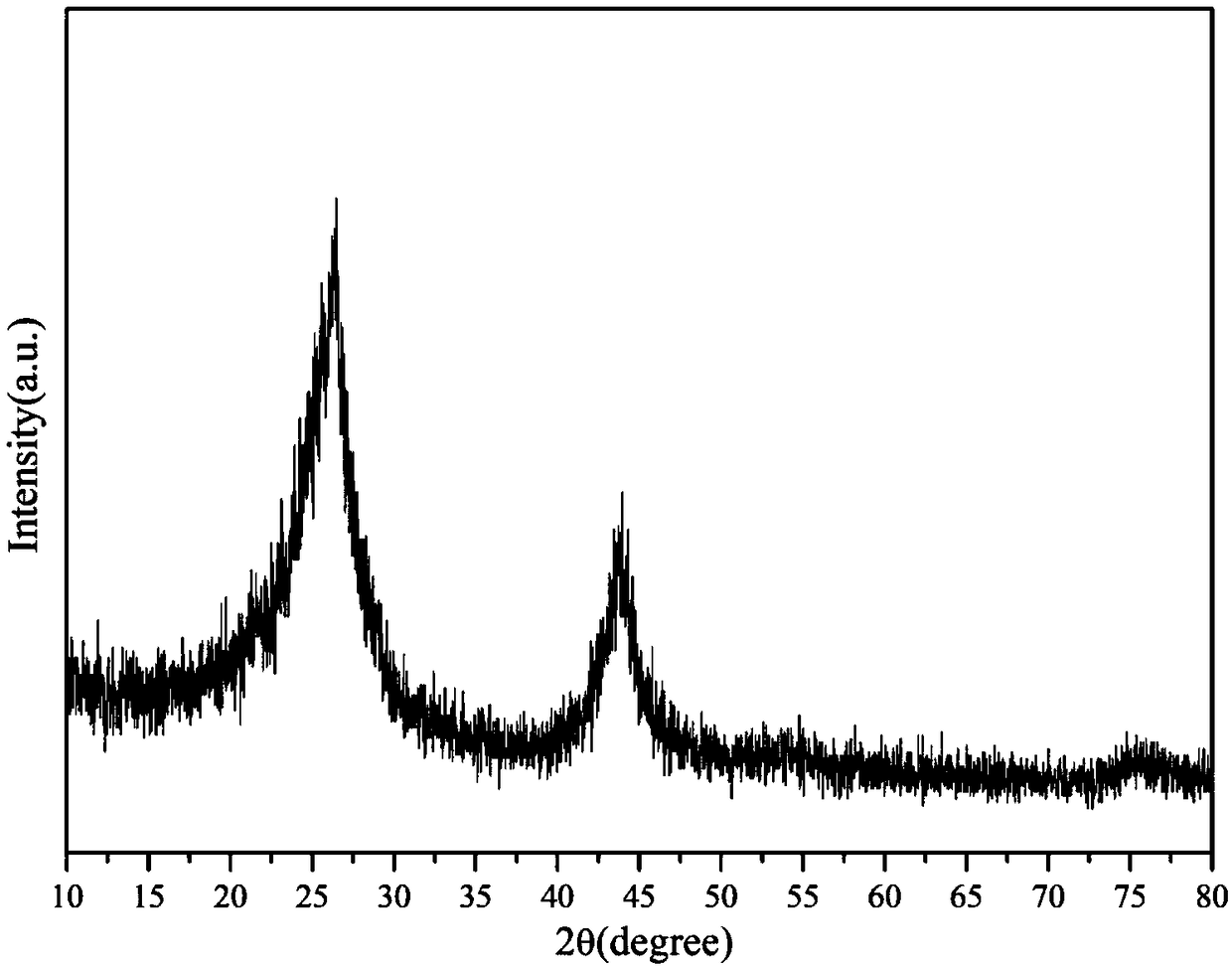

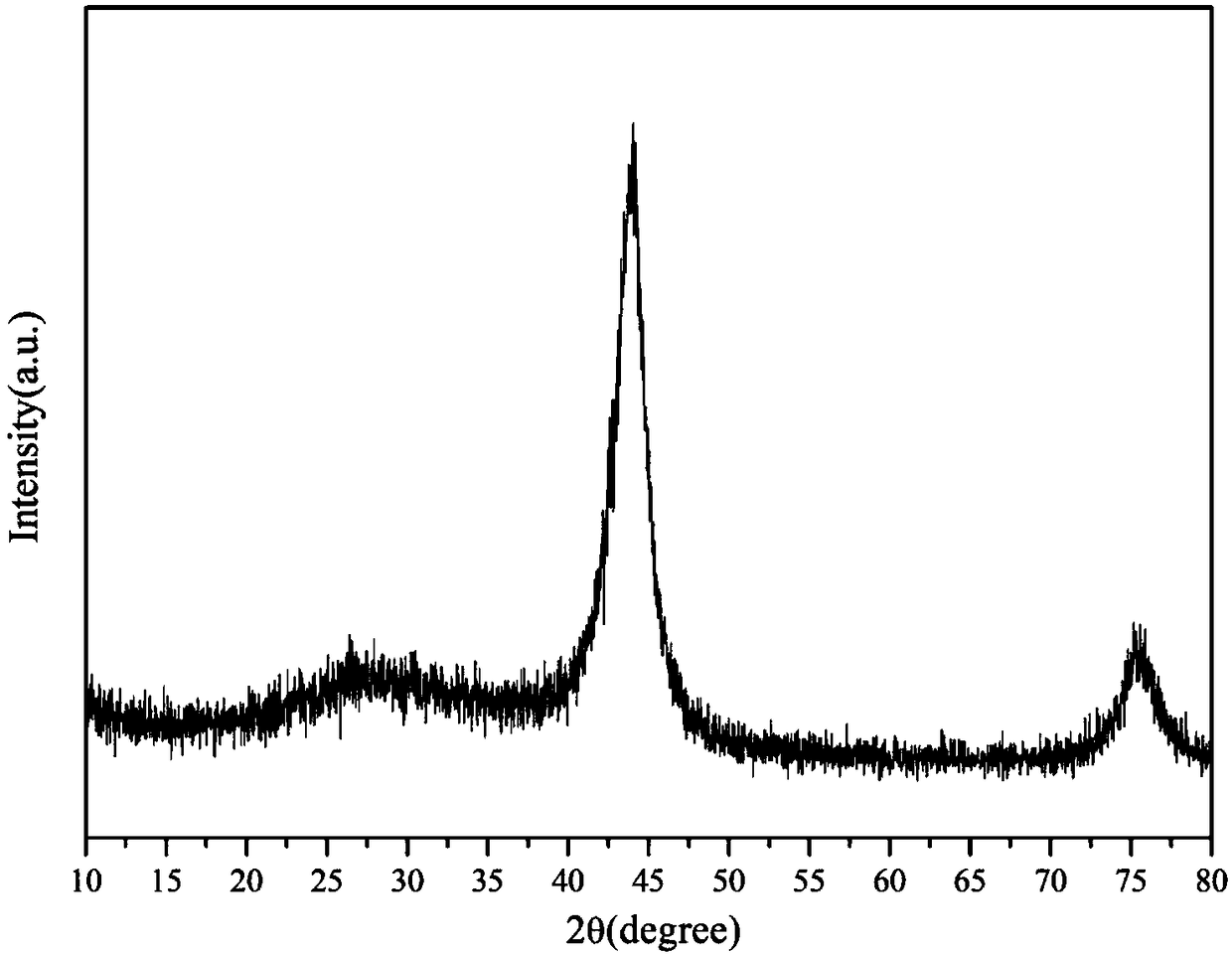

Image

Examples

Embodiment 1

[0035] A method for purifying nano-diamonds, comprising the following steps:

[0036] (1) Adding the nano-diamond black powder to a mass concentration of 96% H 2 SO 4 solution and a mass concentration of 90% H 3 PO 4 solution mixture, heated and stirred for 30min, then added KMnO 4, the temperature of the control system is 75°C, and the reaction is 3h, wherein, nano-diamond black powder, mixed solution, KMnO 4 The mass ratio is 1:4:0.6, H 2 SO 4 solution and H 3 PO 4 The volume ratio of the solution is 1:1;

[0037] (2) the solution after step (1) reaction is cooled to room temperature, then adopts ceramic membrane filter to filter, wash with water, obtain the nano-diamond after rough extraction;

[0038] (3) Adding the nano-diamond after rough extraction in step (2) into a NaOH solution with a concentration of 0.6mol / L and stirring for 3h;

[0039] (4) The solution after the reaction in step (3) is filtered by a ceramic membrane filter, washed with water, and dried ...

Embodiment 2

[0043] A method for purifying nano-diamonds, comprising the following steps:

[0044] (1) Adding the nano-diamond black powder to a mass concentration of 90% H 2 SO 4 solution and a mass concentration of 85% H 3 PO 4 solution mixture, heated and stirred for 45min, then added KMnO 4 , the temperature of the control system is 85°C, and the reaction is 2.5h, wherein, nano-diamond black powder, mixed solution, KMnO 4 The mass ratio is 1:6:0.8, H 2 SO 4 solution and H 3 PO 4 The volume ratio of the solution is 2:1;

[0045] (2) the solution after step (1) reaction is cooled to room temperature, then adopts ceramic membrane filter to filter, wash with water, obtain the nano-diamond after rough extraction;

[0046] (3) Adding the nano-diamond after rough extraction in step (2) into a KOH solution with a concentration of 1mol / L and stirring for 2.5h;

[0047] (4) The solution after the reaction in step (3) is filtered by a ceramic membrane filter, washed with water, and drie...

Embodiment 3

[0051] A method for purifying nano-diamonds, comprising the following steps:

[0052] (1) Adding the nano-diamond black powder to a mass concentration of 82% H 2 SO 4 solution and a mass concentration of 81% H 3 PO 4 solution mixture, heated and stirred for 60min, then added KMnO 4 , the temperature of the control system is 100°C, and the reaction is 2h, wherein, nano-diamond black powder, mixed solution, KMnO 4 The mass ratio is 1:9:1, H 2 SO 4 solution and H 3 PO 4 The volume ratio of the solution is 3:1;

[0053] (2) the solution after step (1) reaction is cooled to room temperature, then adopts ceramic membrane filter to filter, wash with water, obtain the nano-diamond after rough extraction;

[0054] (3) Adding the nano-diamond after rough extraction in step (2) into a NaOH solution with a concentration of 2mol / L and stirring for 1h;

[0055] (4) The solution after the reaction in step (3) is filtered by a ceramic membrane filter, washed with water, and dried at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com