Patents

Literature

142results about How to "Reduce the chance of explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

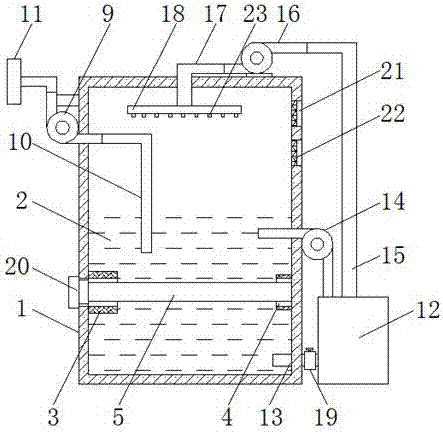

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

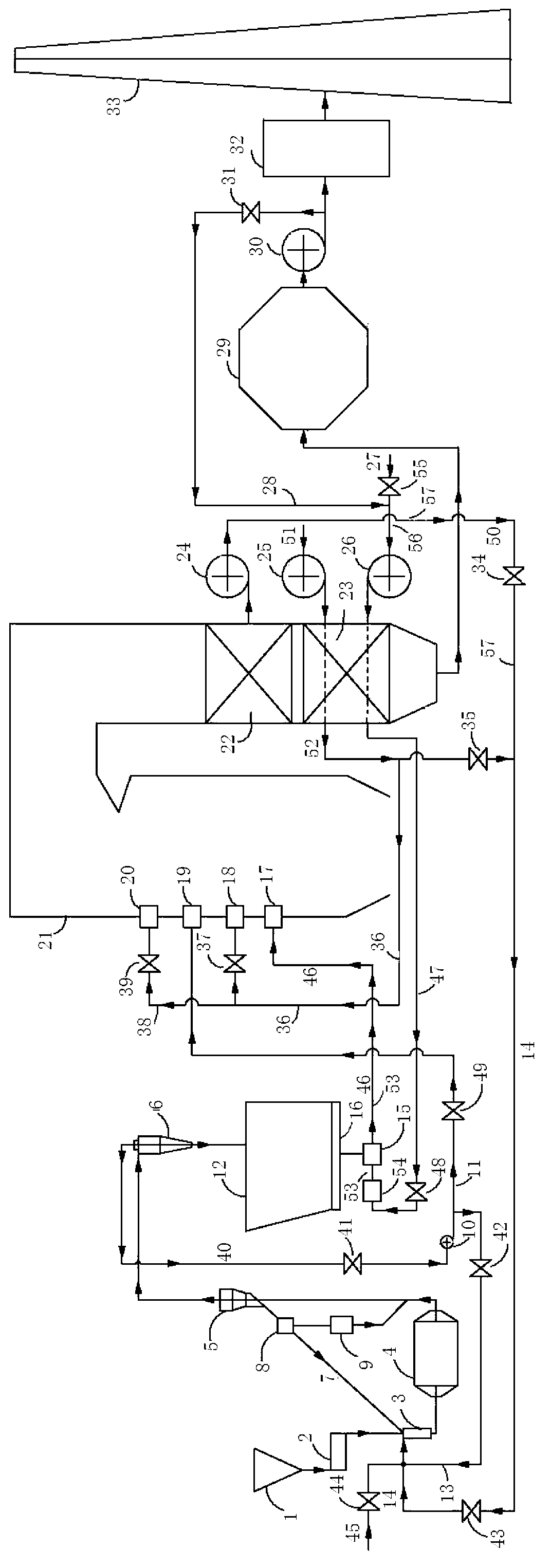

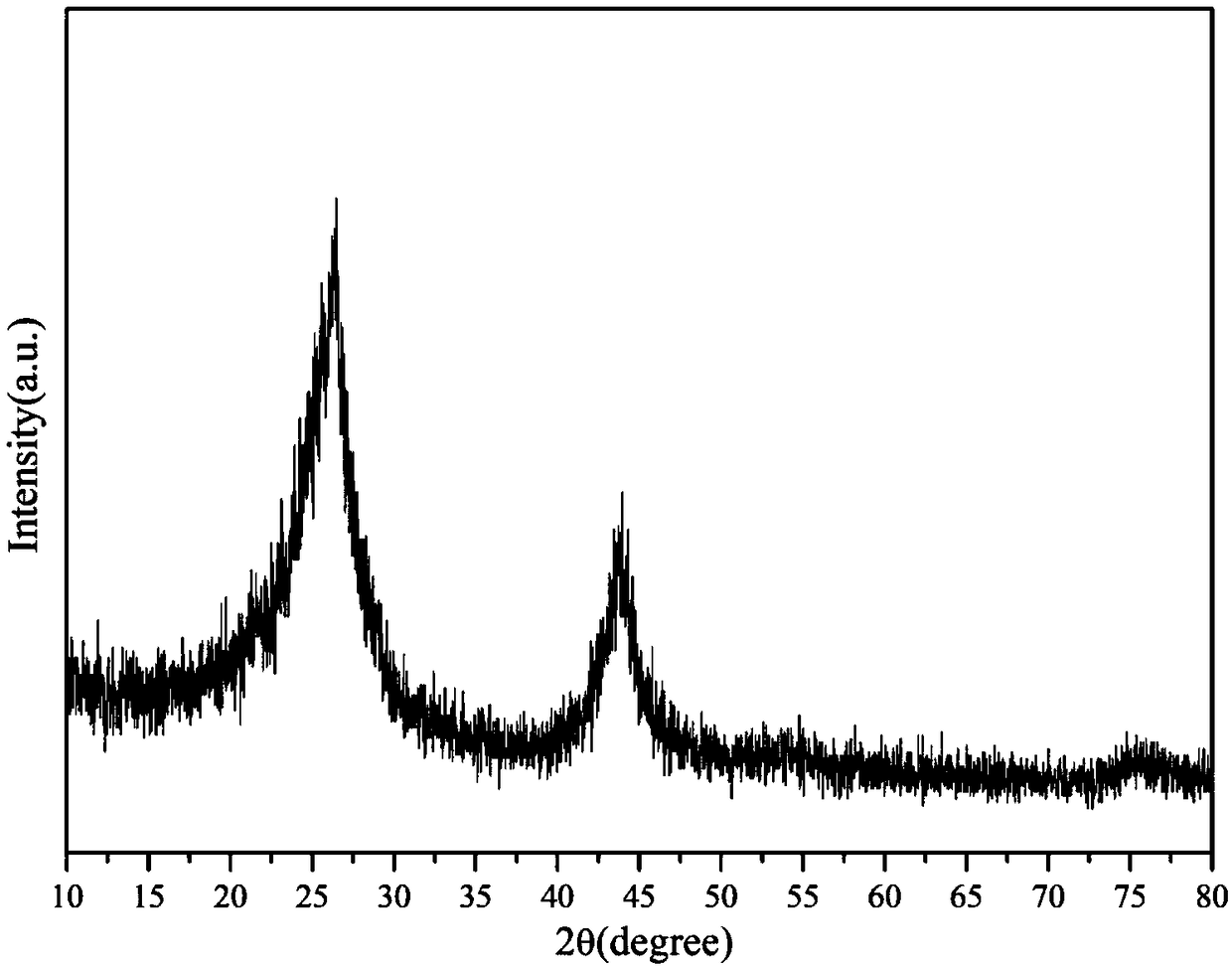

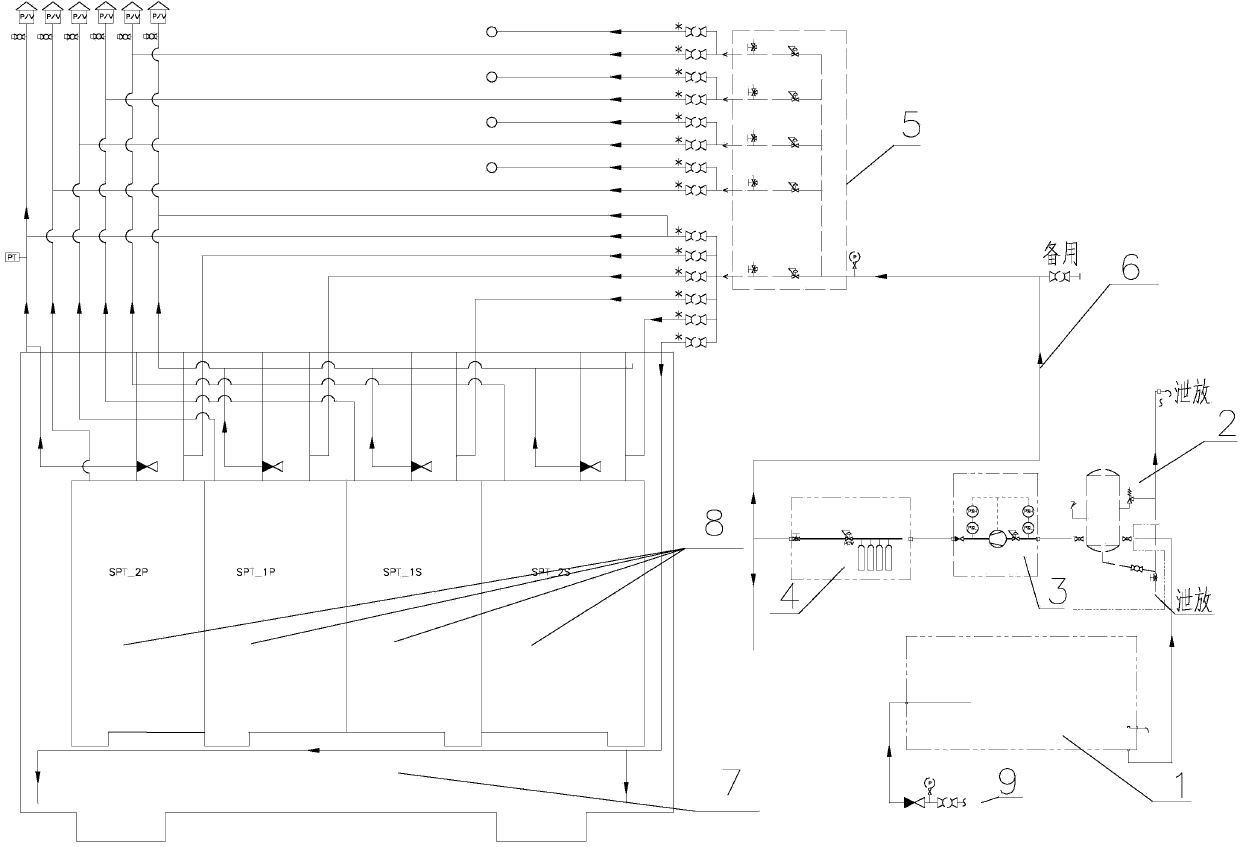

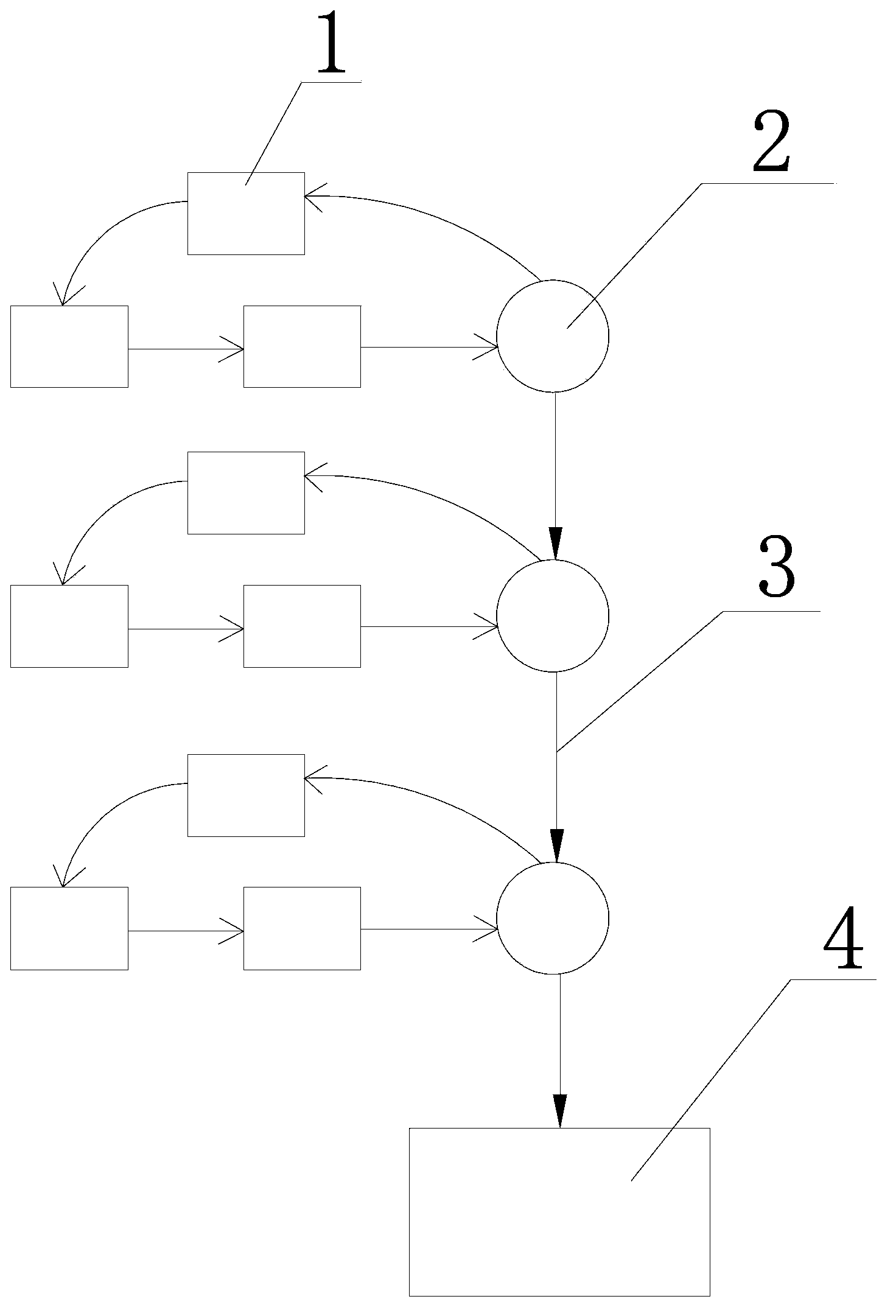

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

Coal mine gob area sealing method

ActiveCN104481588AFast fillWon't enterMining devicesGas removalSpontaneous combustionDifferential pressure

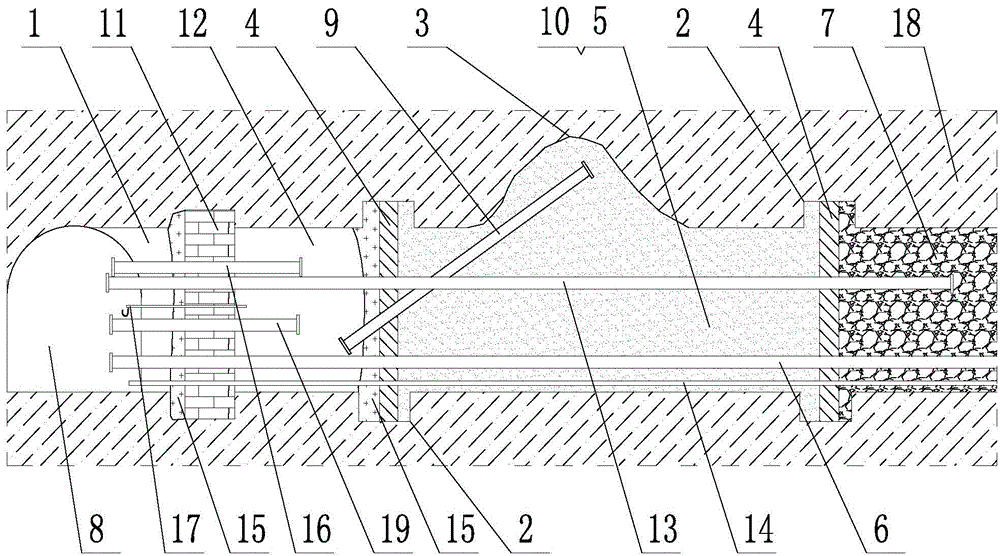

The invention discloses a coal mine gob area sealing method, and belongs to the technical field of coal mine gob area gas extraction. When retaining walls of a first sealing chamber or roadway surrounding rocks between the retaining walls are cracked, cracks can be rapidly filled by the aid of fine sand with flowability under the action of ground stress and mining dynamic stress, and tightness is ensured. By the aid of positive and negative differential pressure characteristics of a second sealing chamber, nitrogen pressure in the second sealing chamber is constantly higher than air pressure in a ventilating roadway, a gob area is separated from the ventilating roadway by the second sealing chamber, air in the ventilating roadway cannot enter the gob area, and gas in the gob area cannot permeate into the ventilating roadway. By double sealing of the first sealing chamber and the second sealing chamber, sealing reliability of the gob area is greatly improved, the probabilities of spontaneous combustion of float coal and gas explosion are minimized, and safety of nearby roadways or working faces is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

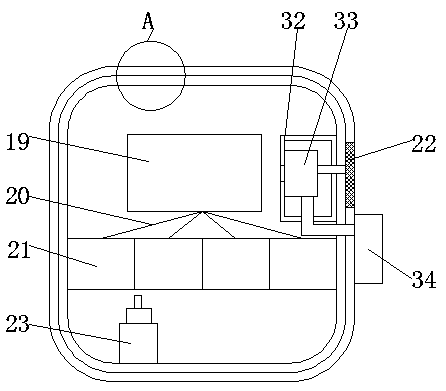

Explosion-proofing infrared UV flame detector

InactiveCN105931418AAvoid burnsSlow temperature conductionFire alarm radiation actuationEngineeringElectronic component

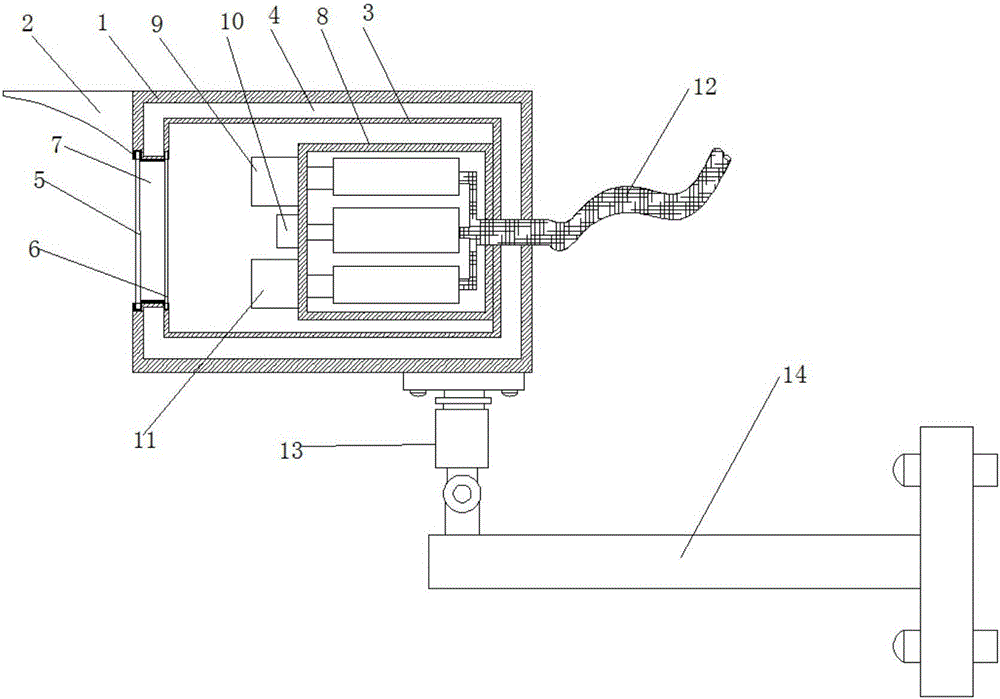

The invention discloses an explosion-proofing infrared UV flame detector including an explosion-proofing outer casing, one side of the explosion-proofing outer casing is provided with a shield plate, the inside of the explosion-proofing outer casing is provided with an explosion-proofing inner casing, a first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, one side, closing to the shield plate, of the explosion-proofing outer casing is provided with a piece of explosion-proofing outer glass, and one side, closing to the explosion-proofing outer glass, of the explosion-proofing inner casing is provided with a piece of explosion-proofing inner glass. The first vacuum layer is formed between the explosion-proofing outer casing and the explosion-proofing inner casing, a second vacuum layer is formed between the explosion-proofing outer glass and the explosion-proofing inner glass, the vacuum layers reduce the effect of heat transfer to make the temperature conduction of the inside and the outside of the sensor slow, thereby preventing internal electronic components from being melted, and reducing the internal blasting probability, and moreover, the detector main body is provided with an infrared flame detector, a UV flame detector, and a high-definition pick-up head, so that the scene of fire can be maximally detected.

Owner:ANHUI SHENGLONG ELECTRIC

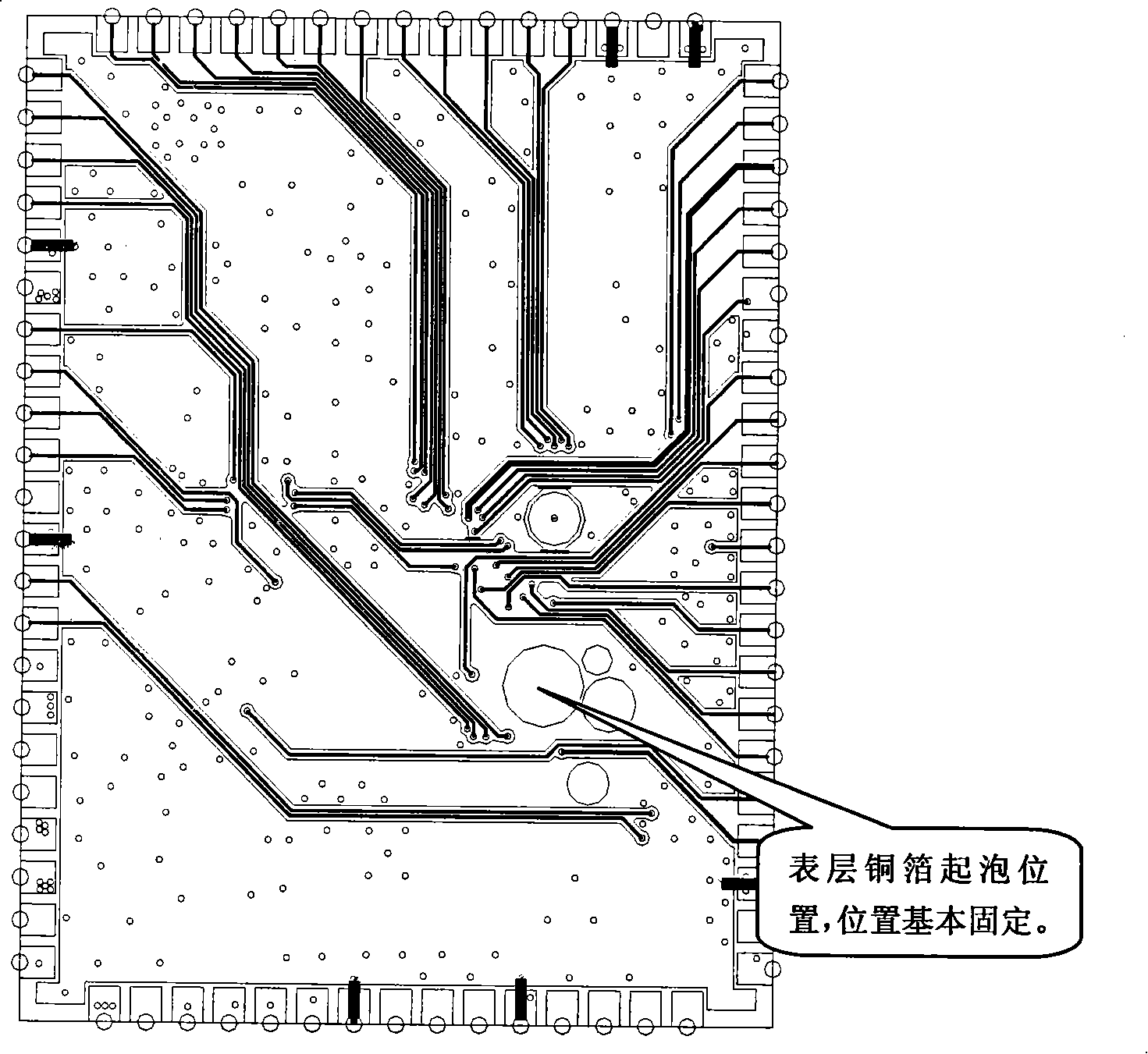

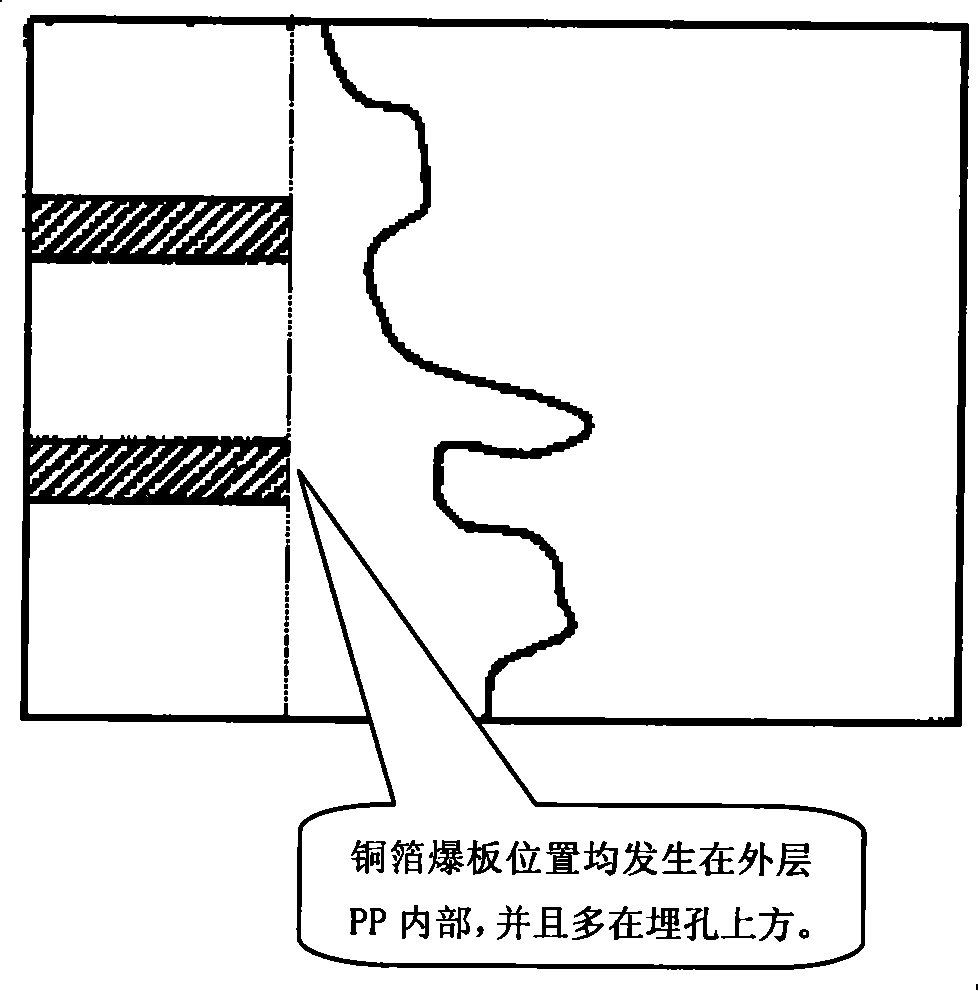

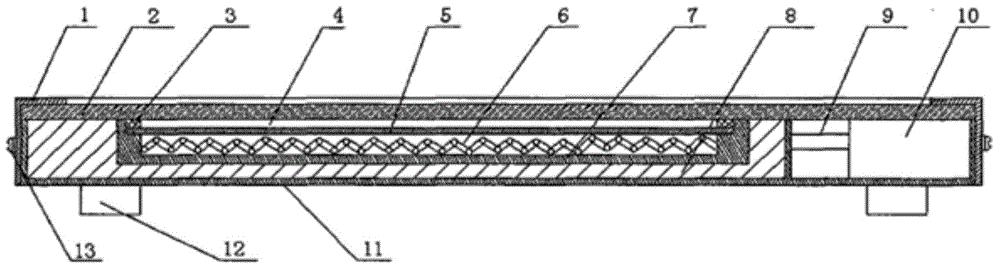

Design producing method of multi-layer printed circuit board

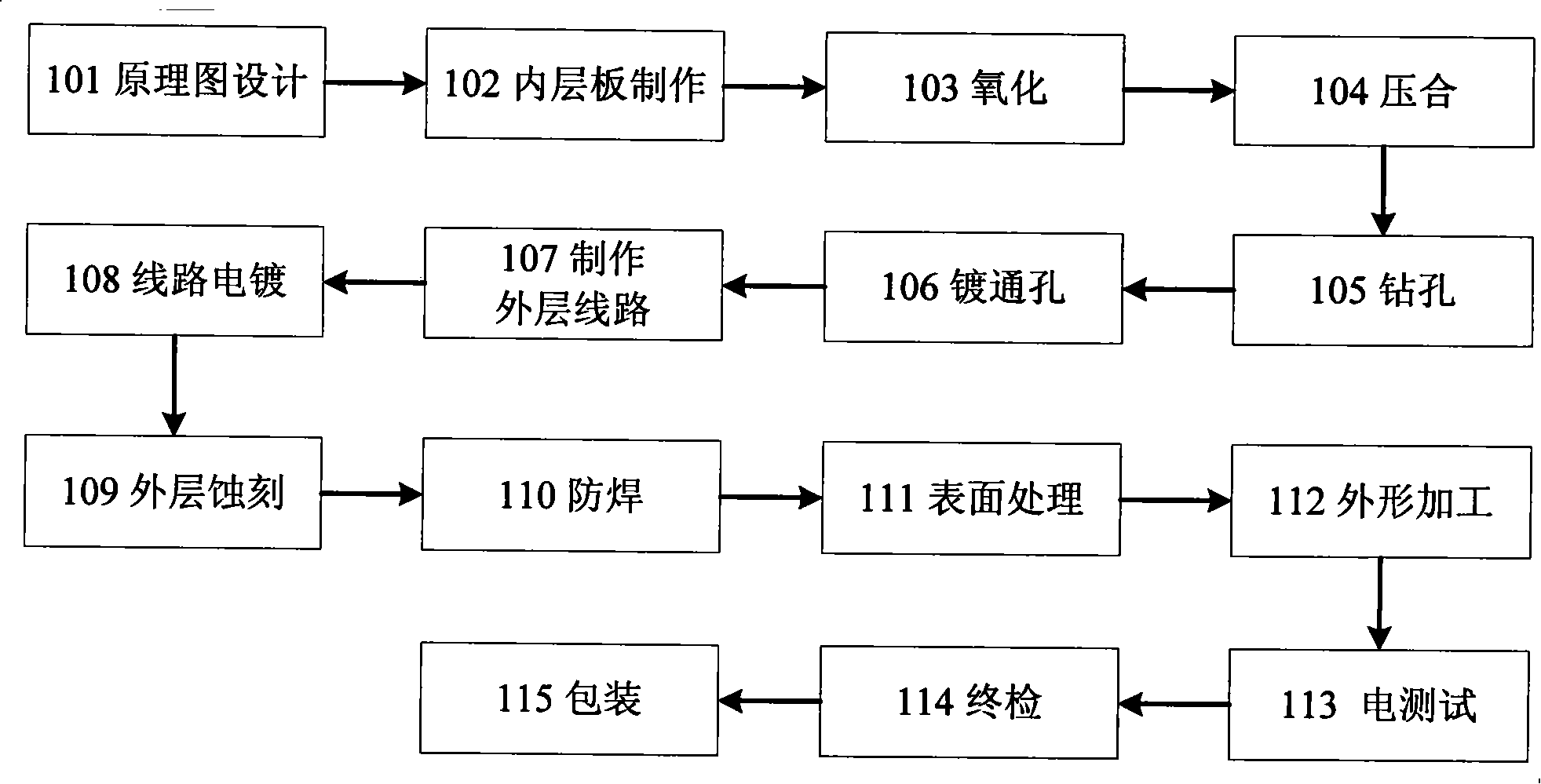

ActiveCN101252817AReduces the possibility of moisture absorptionReduce the chance of explosionMultilayer circuit manufactureCooking & bakingElectricity

The invention discloses a design production method of a multilayer printed circuit board. The method comprises the following steps: firstly, schematic diagram designing is performed to a printed circuit board; secondly, an inner layer circuit board is fabricated, and oxidation treatment is performed to the inner layer circuit board; thirdly, the inner layer circuit board is pressed into a multilayer printed circuit board with prepreg and copper foil after being baked through high temperature; fourthly, holes are drilled at the position of a multilayer circuit board which is required to perform interpenetrating and connection, and plated through hole operation is performed; fifthly, an electric circuit is etched on the outer layer substrate of the multilayer circuit board; sixthly, soldering resistant treatment is performed to the multilayer circuit board, and then high temperature baking is performed; seventhly, treatment is performed to the surface of the bonding pad of the multilayer circuit board, then appearance processing, electrical measurement and final-inspection are performed to the multilayer circuit board, and packaging is performed after the final-inspection is passed. The invention effectively reduces the probability for blistering of the copper foil on the PCB surface, has simple operation and is feasible, and is not require to increase the equipment invest.

Owner:ZTE CORP

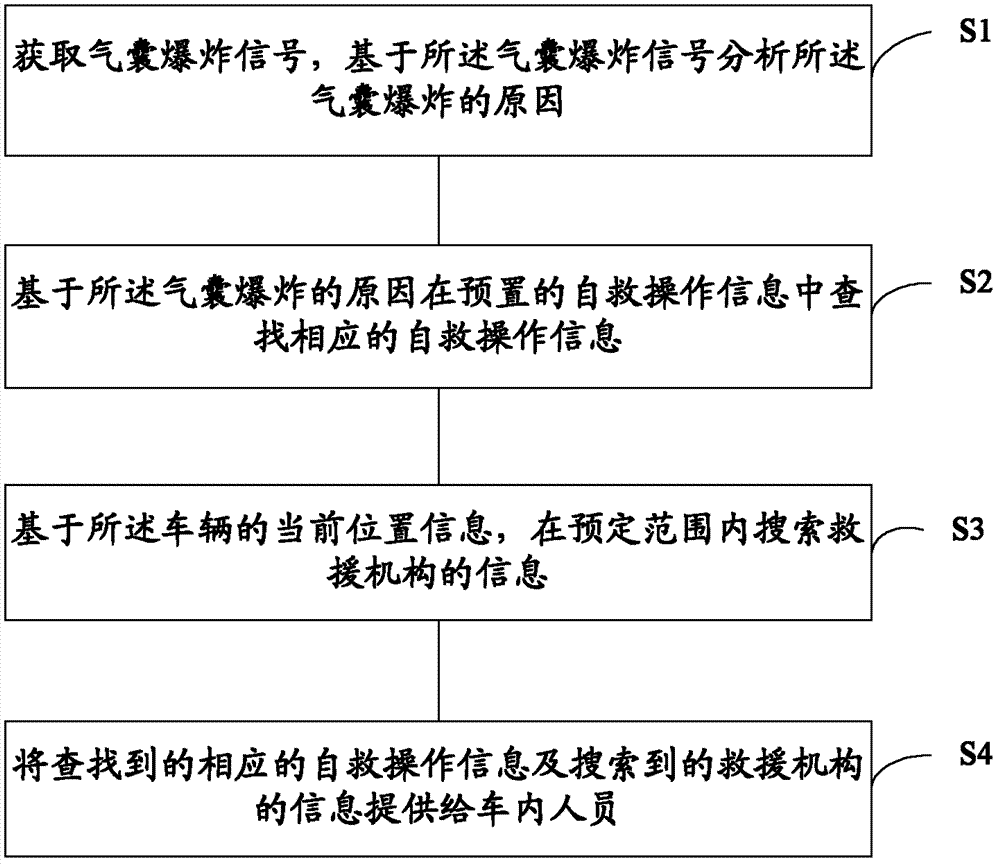

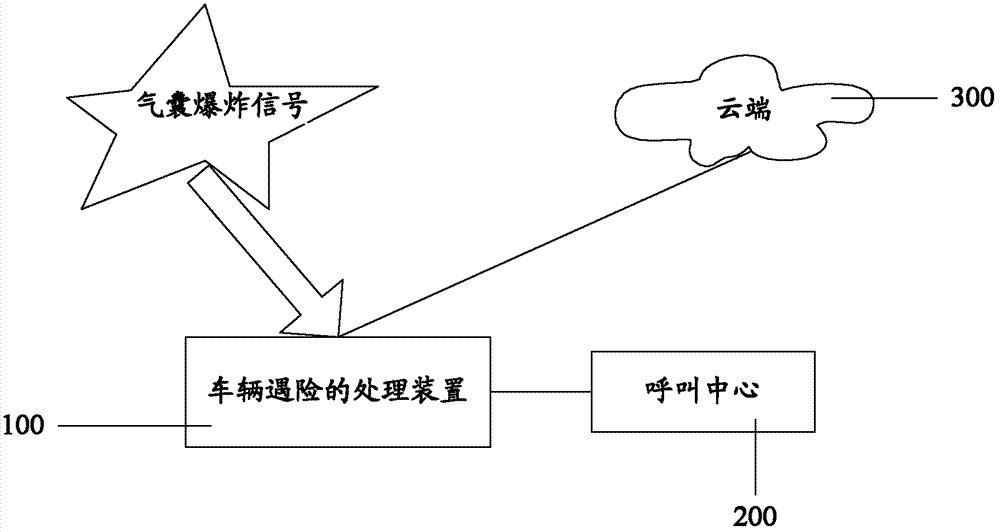

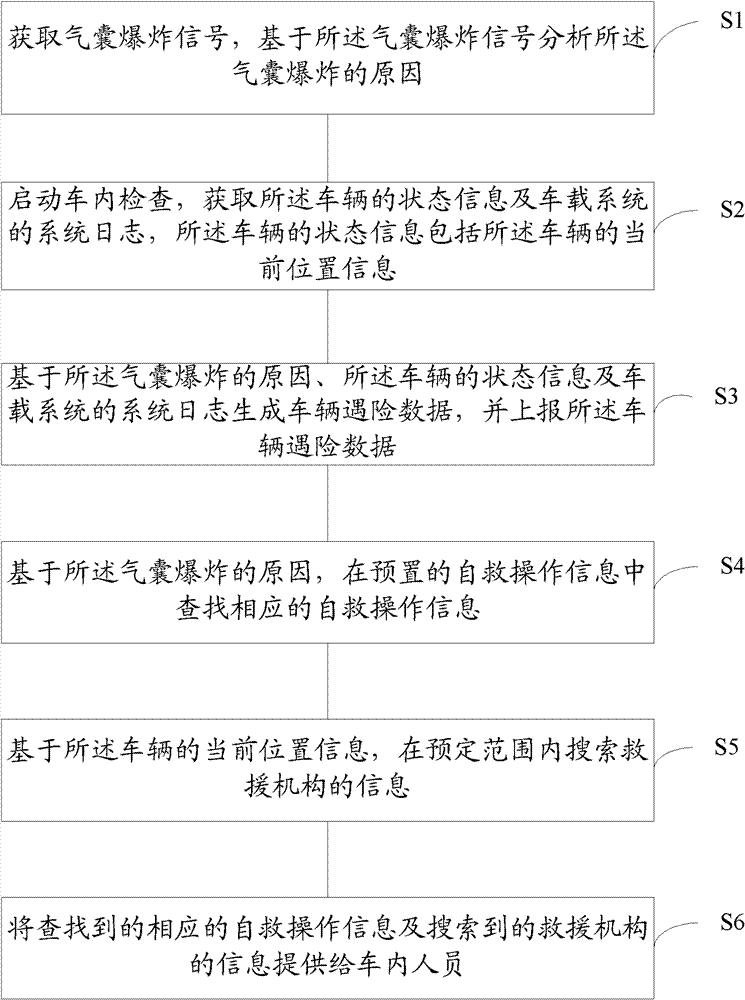

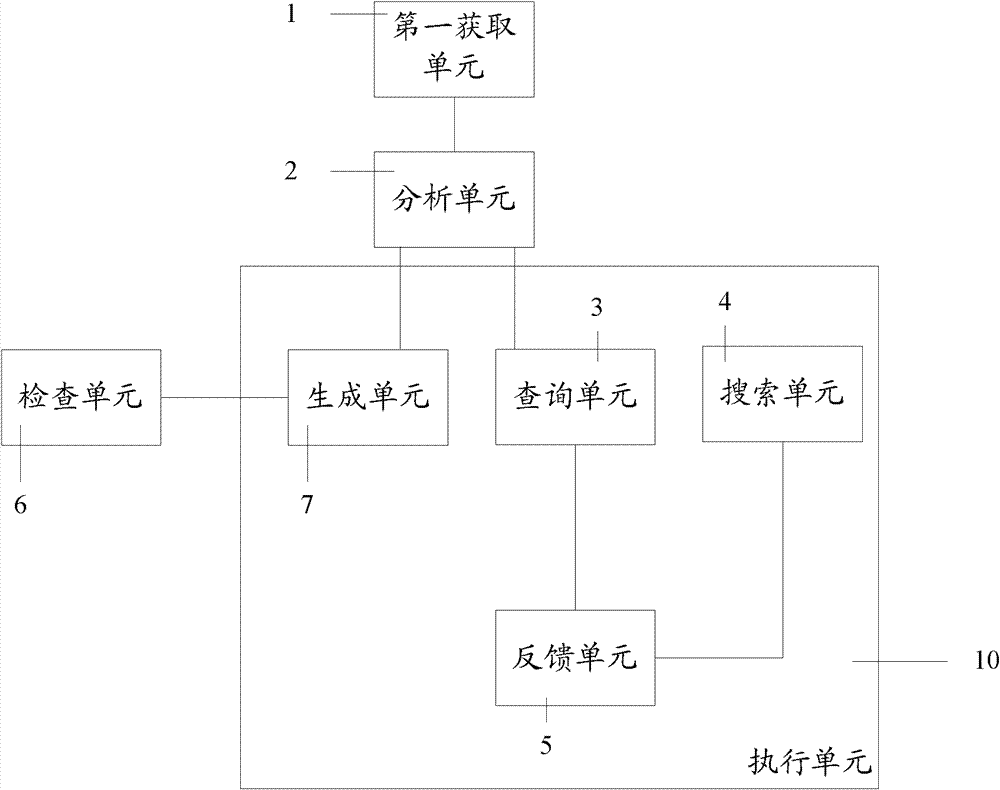

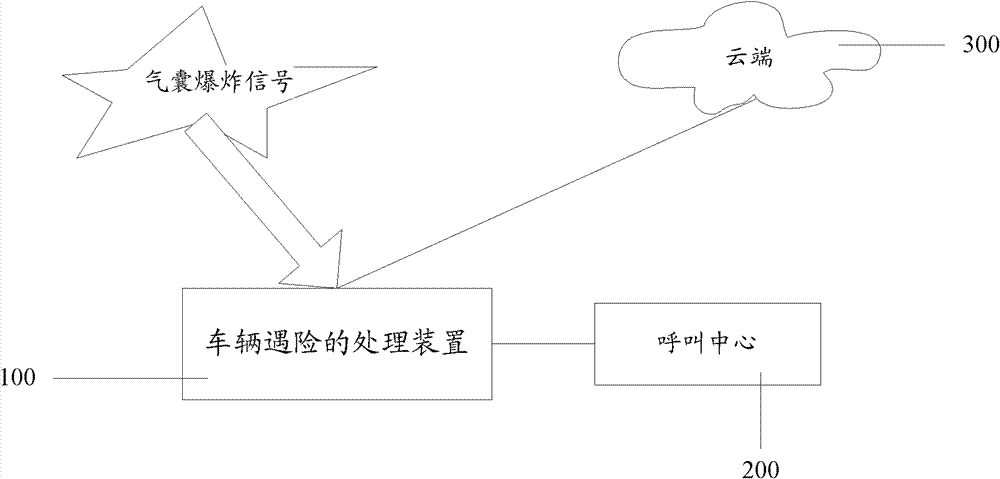

Handling method and device for vehicle distresses, and vehicle-mounted system

ActiveCN103085743ABuy time to rescueAvoid further harmPedestrian/occupant safety arrangementTelephonic communicationEngineeringAirbag

Disclosed are handling method and device for vehicle distresses, and a vehicle-mounted system. The handling method for vehicle distresses includes: acquiring an airbag explosion signal and analyzing the causes of airbag explosion according to the airbag explosion signal; searching corresponding self-rescue operation information from preset self-rescue operation formation according to the causes of airbag explosion; searching information of relief agencies in the preset range according to current location of a vehicle; and supplying the searched corresponding self-rescue operation information and the searched information of the relief agencies to personnel in the vehicle. By the handling method and device and the vehicle-mounted system, the condition of the vehicle in distress can be monitored and distress information can be sent out timely and effectively.

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

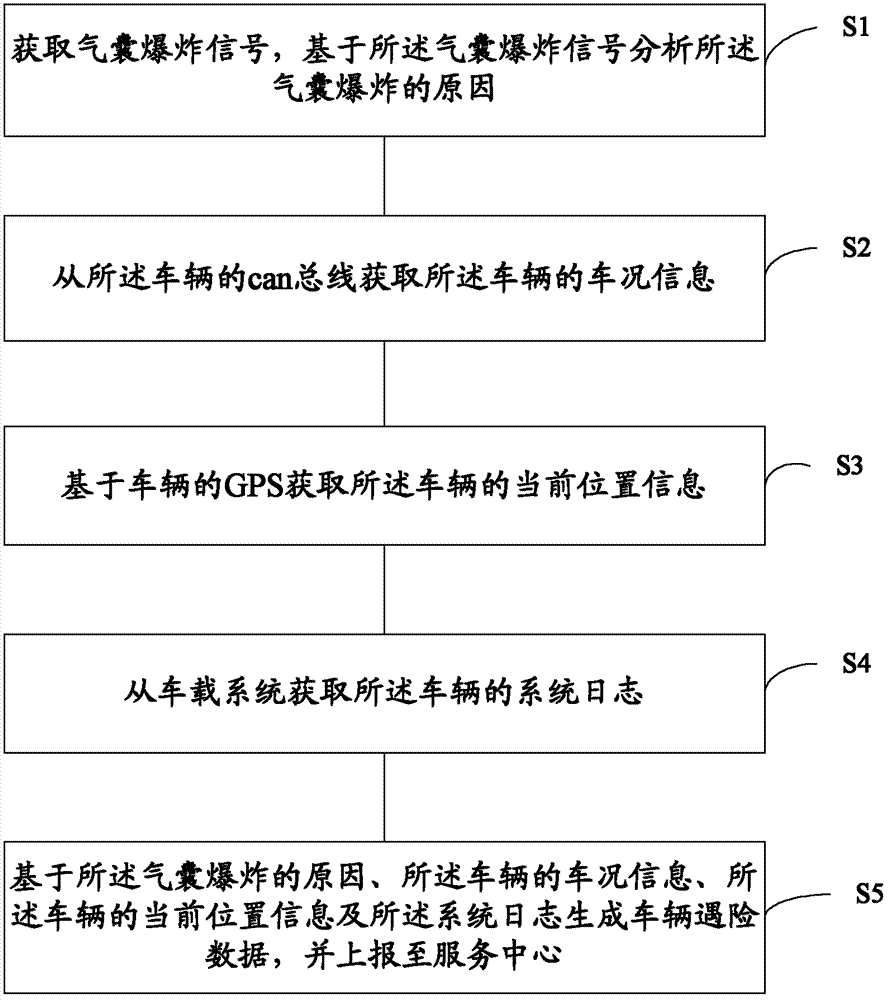

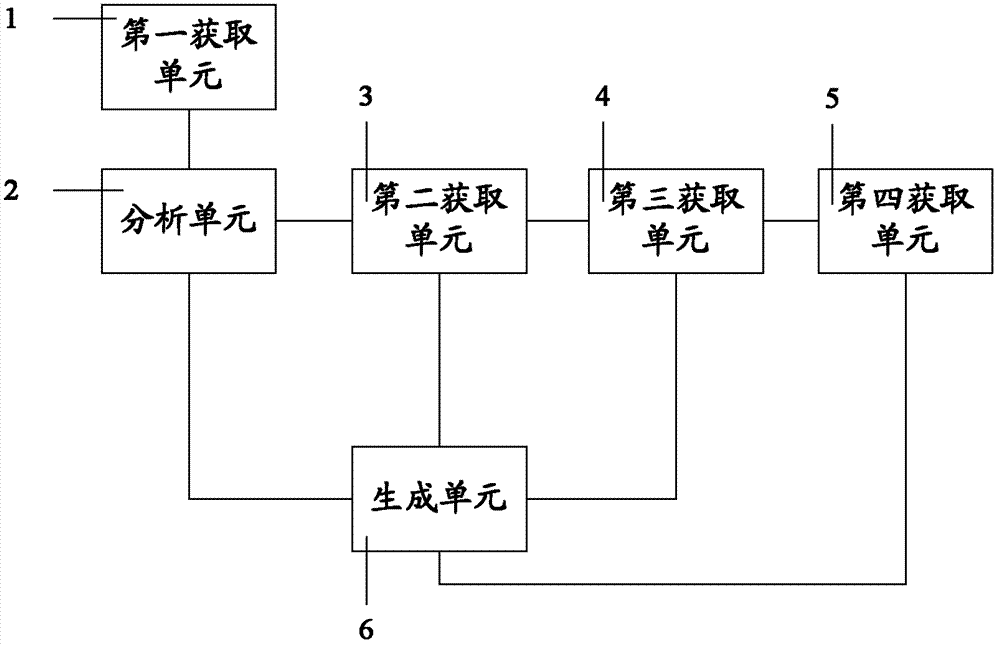

Handling method and device for vehicle distresses, and vehicle-mounted system

ActiveCN103085744ARescue time shortenedImprove rescue speedPedestrian/occupant safety arrangementAlarmsArea networkEngineering

Disclosed are handling method and device for vehicle distresses, and a vehicle-mounted system. The handling method for vehicle distresses includes: acquiring an airbag explosion signal, and analyzing causes of airbag explosion according to the airbag explosion signal; acquiring condition information of a vehicle according to a CAN (controlled area network) bus of the vehicle; acquiring current location of the vehicle by a GPS (global positioning system) of the vehicle; acquiring a system log of the vehicle from the vehicle-mounted system; generating vehicle distress data according to the airbag explosion causes, the vehicle condition information, the current location of the vehicle and the system log, and reporting the vehicle distress data to a service center. By the method and device and the vehicle-mounted system, the condition of the vehicle in distress can be monitored and distress information can be sent out timely and effectively.

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

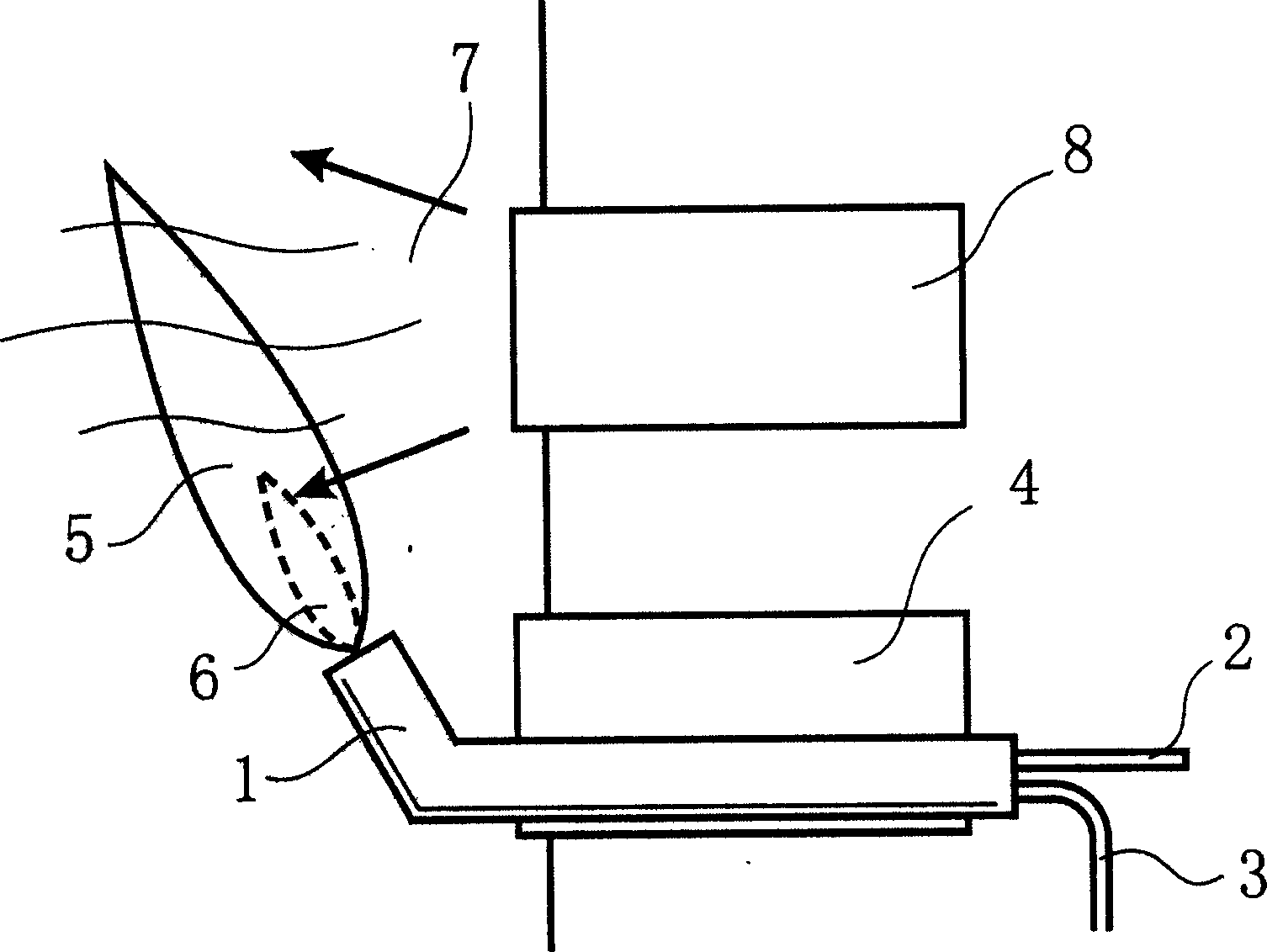

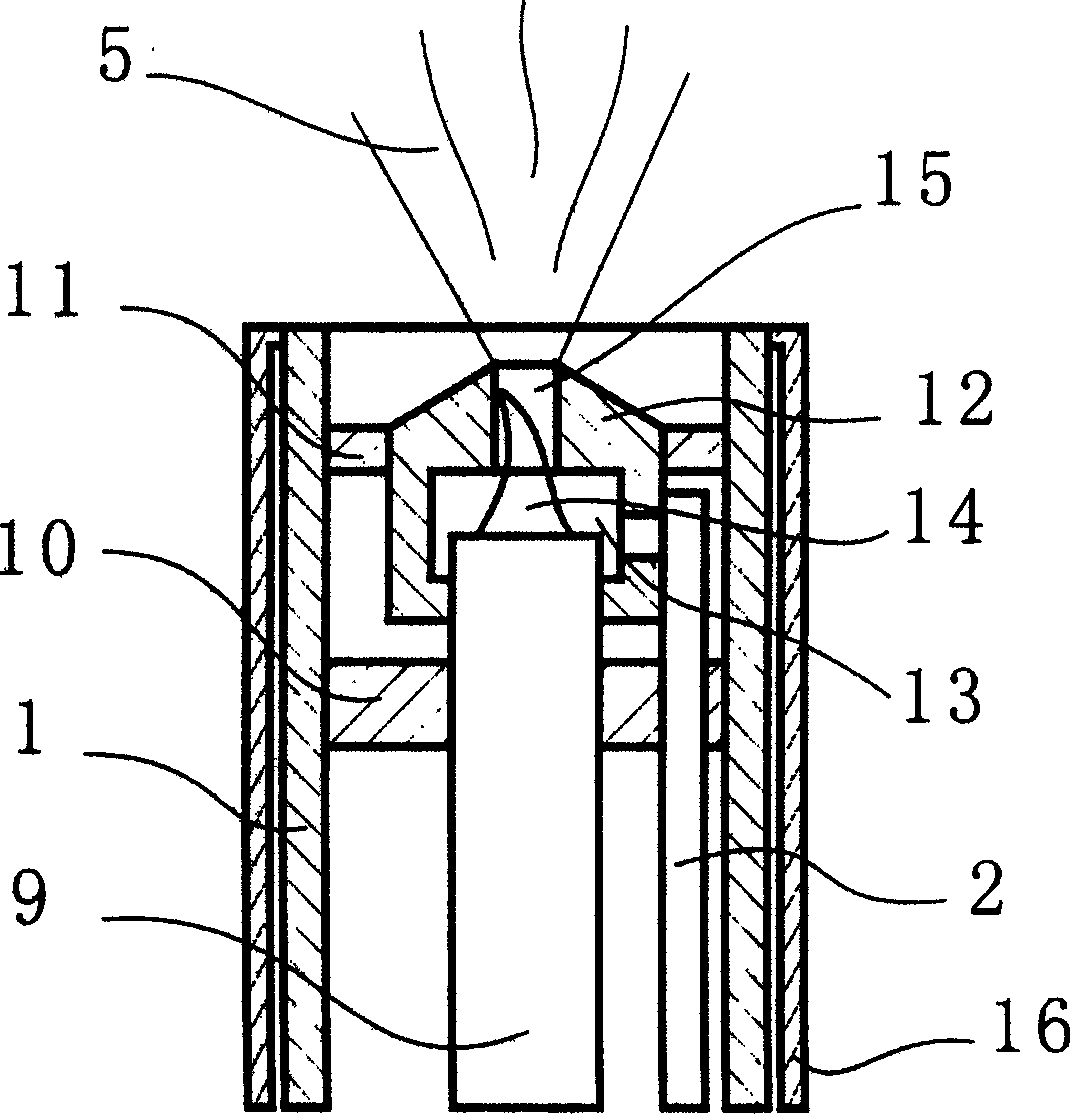

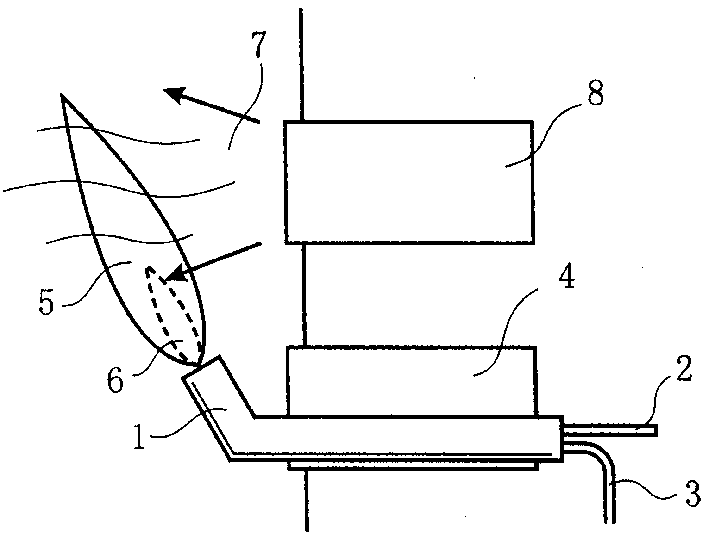

Method and device for igniting boiler powder coal by using water high temperature electrolysis technology

A method for igniting the powdered coal in boiler features that the plasma arc generated by plasma generator and the water steam are simultaneously delivered in an energy converting chamber for plasma ionizing to generate H2-O2 plasmas, and the high-energy H2-O2 plasmas are sprayed from igniter into powdered coal stream to generate flame and water, so igniting powdered coal and forming a stable burning kernel. Its apparatus is composed of igniter and the primary air and powdered coal channel.

Owner:王满家 +2

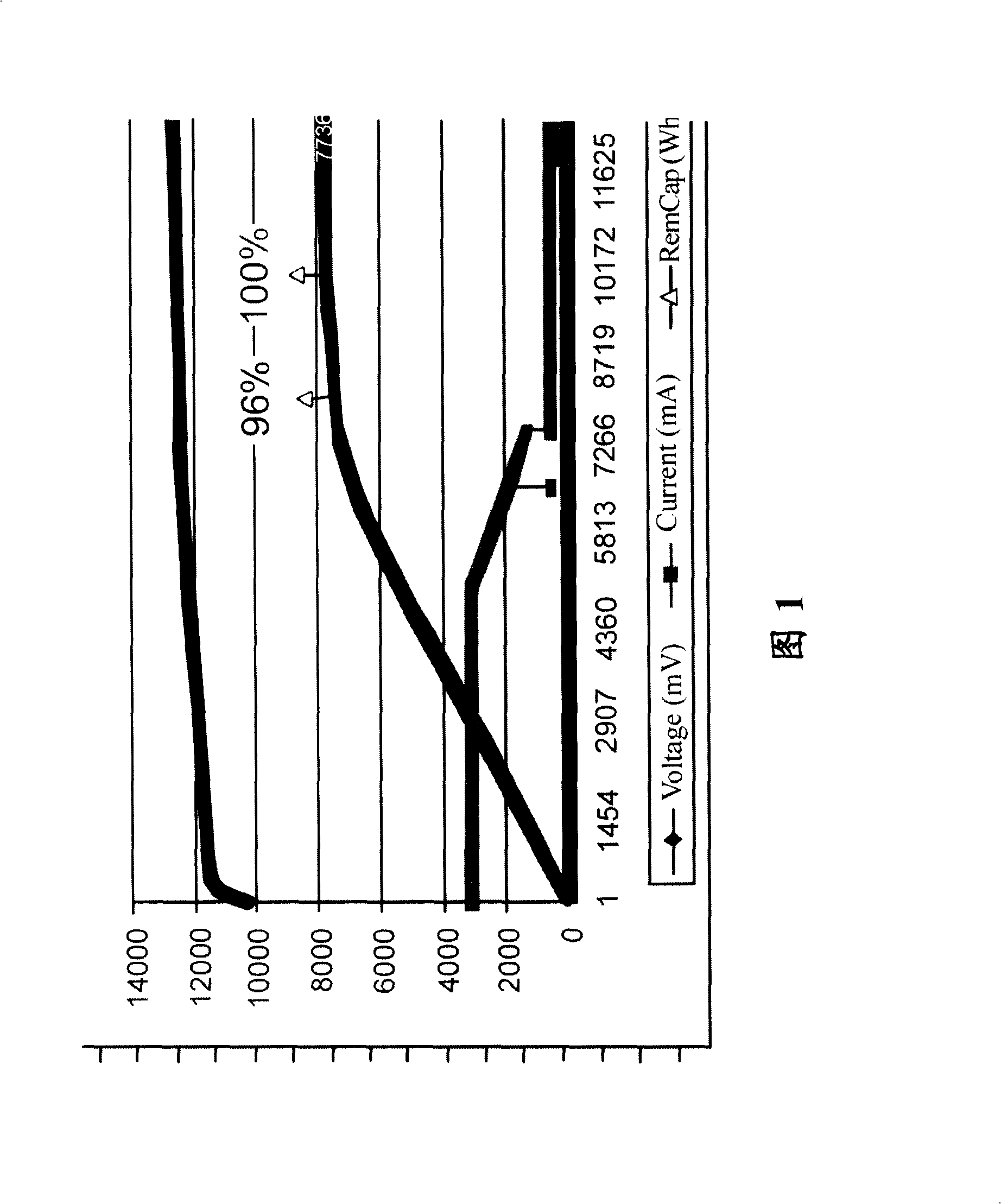

Charging management method and apparatus for mobile phone battery

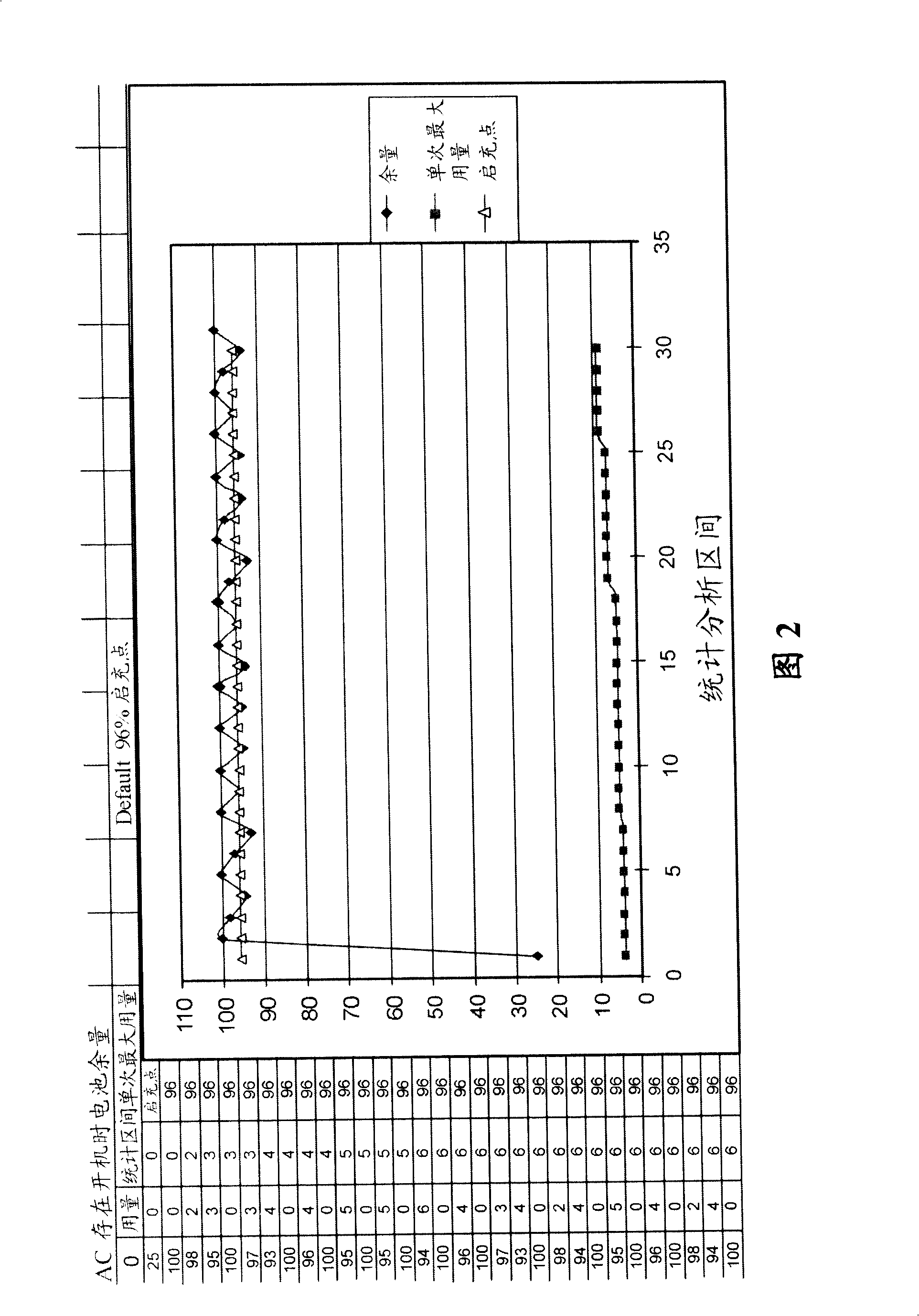

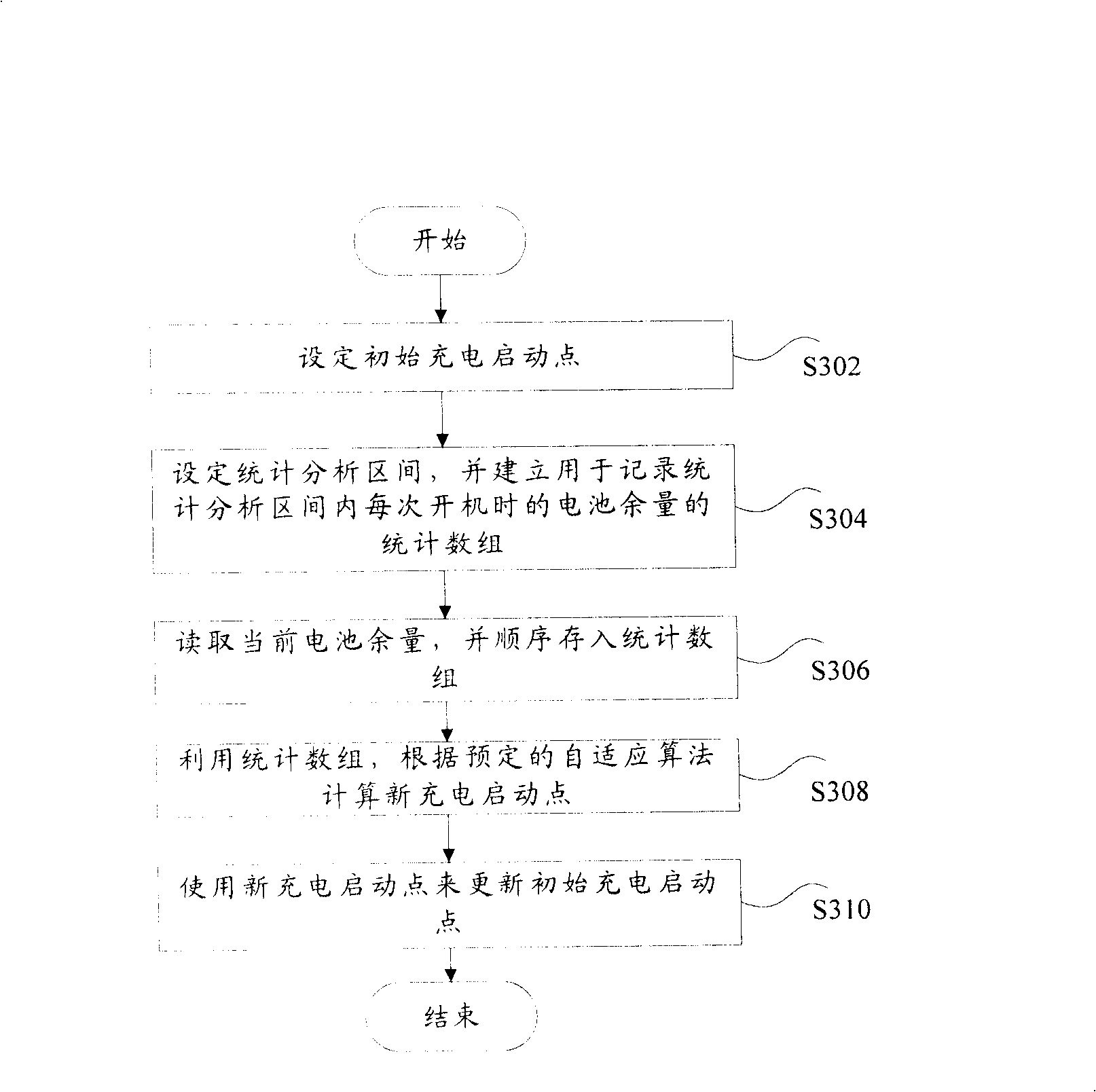

ActiveCN101335369AReduce the number of chargingExtended service lifeCircuit monitoring/indicationSecondary cells charging/dischargingArray data structureStatistical analysis

The invention provides a charging management method of a mobile terminal battery, which includes steps as follows: step S302. an initial charging starting point is set; step S304. a statistical analysis section for counting surplus of a battery at the beginning time is set and a statistical array for recording the surplus of the battery in the statistical analysis section at every start-up time is established; step S306. current surplus of the battery is read and is stored into the statistical array in sequence; step S308. a new charging starting point is calculated according to preset self-adapting algorithm; and step S310. the initial charging starting point is updated by the new charging starting point. In addition, the invention also provides a charging management device for the mobile terminal battery. Through the application of the method of the invention, an optimized charging starting point can be calculated by measurement, thus lengthening service life of the battery; particularly as to those users rarely using the battery for power supply, the method of the invention can lengthen the service life of the battery and reduce the probability of explosion to a large extent in an intelligent mode.

Owner:LENOVO (BEIJING) LTD

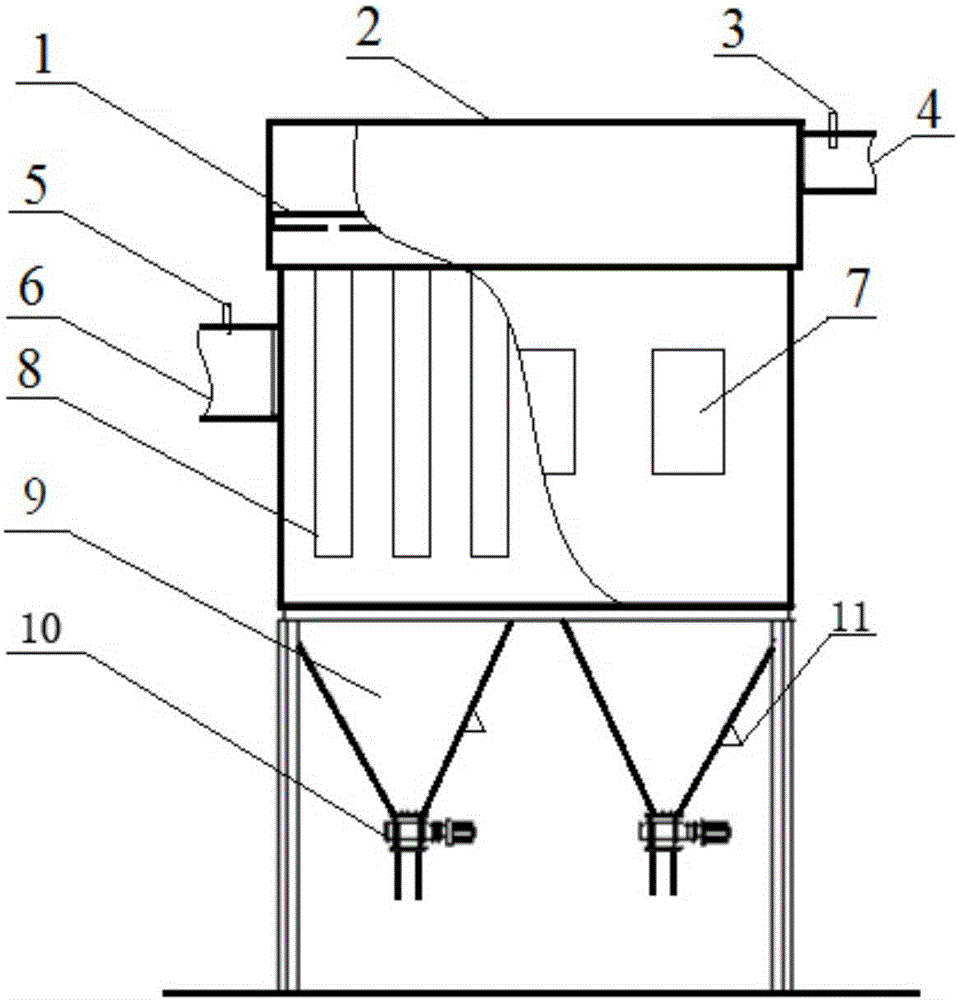

Textile workshop dust removal equipment

InactiveCN107149844ADischarge in timeEfficient dischargeCombination devicesGas treatmentDust explosionWorking environment

The invention discloses textile workshop dust removal equipment, which comprises a dust removal box, wherein dust removal liquid is filled inside the dust removal box; two position limiting plates are fixedly connected with the bottom of the left side of an inner cavity of the dust removal box; a U-shaped block is fixedly connected with the right side of the inner cavity of the dust removal box; the inner cavity of the dust removal box is movably connected with a separation plate; the right side of the separation plate extends to an inner cavity of the U-shaped block; the left side of the separation plate passes through a position between the two position limiting plates and extends to the left side of the dust removal box; a filtering groove is formed in the top of the separation plate; a filtering net is arranged in an inner cavity of the filtering groove. The textile workshop dust removal equipment has the advantages that floccules and dust of a textile workshop can be timely and effectively discharged out; the floccules and the dust can be absorbed to the inside of the dust removal liquid through the dust removal liquid inside the dust removal box; the work environment of the textile workshop is greatly improved; the work environment quality of workers is effectively improved; the dust explosion probability is reduced; the personnel safety of the workers is guaranteed.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

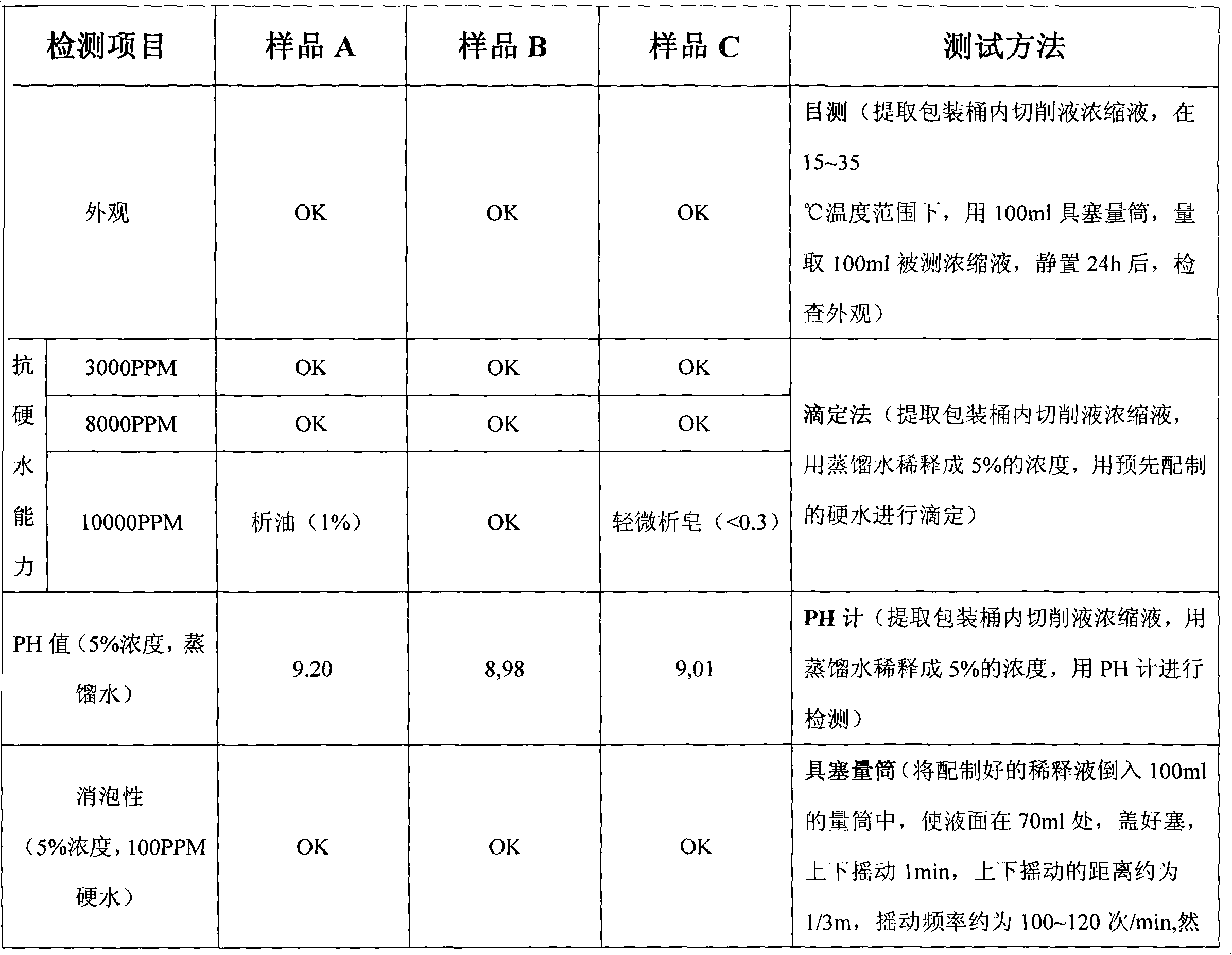

Magnesium alloy cutting fluid and preparation method thereof

InactiveCN101886021AExtended service lifePrevent precipitationLubricant compositionPhosphateDisinfectant

The invention discloses magnesium alloy cutting fluid, which comprises the following raw materials in percentage by mass: 20 to 30 percent of water, 3.0 to 5.0 percent of EDTA4 sodium, 3.0 to 7.0 percent of isopropanolamine, 30 to 50 percent of naphthenic base oil, 5.0 to 7.0 percent of T702, 4.0 to 8.0 percent of phosphate ester, 3.0 to 6.0 percent of AEO-9, 2.0 to 5.0 percent of disinfectant and 4.0 to 8.0 percent of span 80. Specific bacterial inhibitors and mold inhibitors are added into the magnesium alloy cutting fluid respectively, so that the magnesium alloy cutting fluid avoids corrosion of magnesium alloy materials, can control bacterial reproduction effectively, and extend the service life of the cutting fluid greatly by synergizing with an extraordinary hard water resistance capability.

Owner:范成立

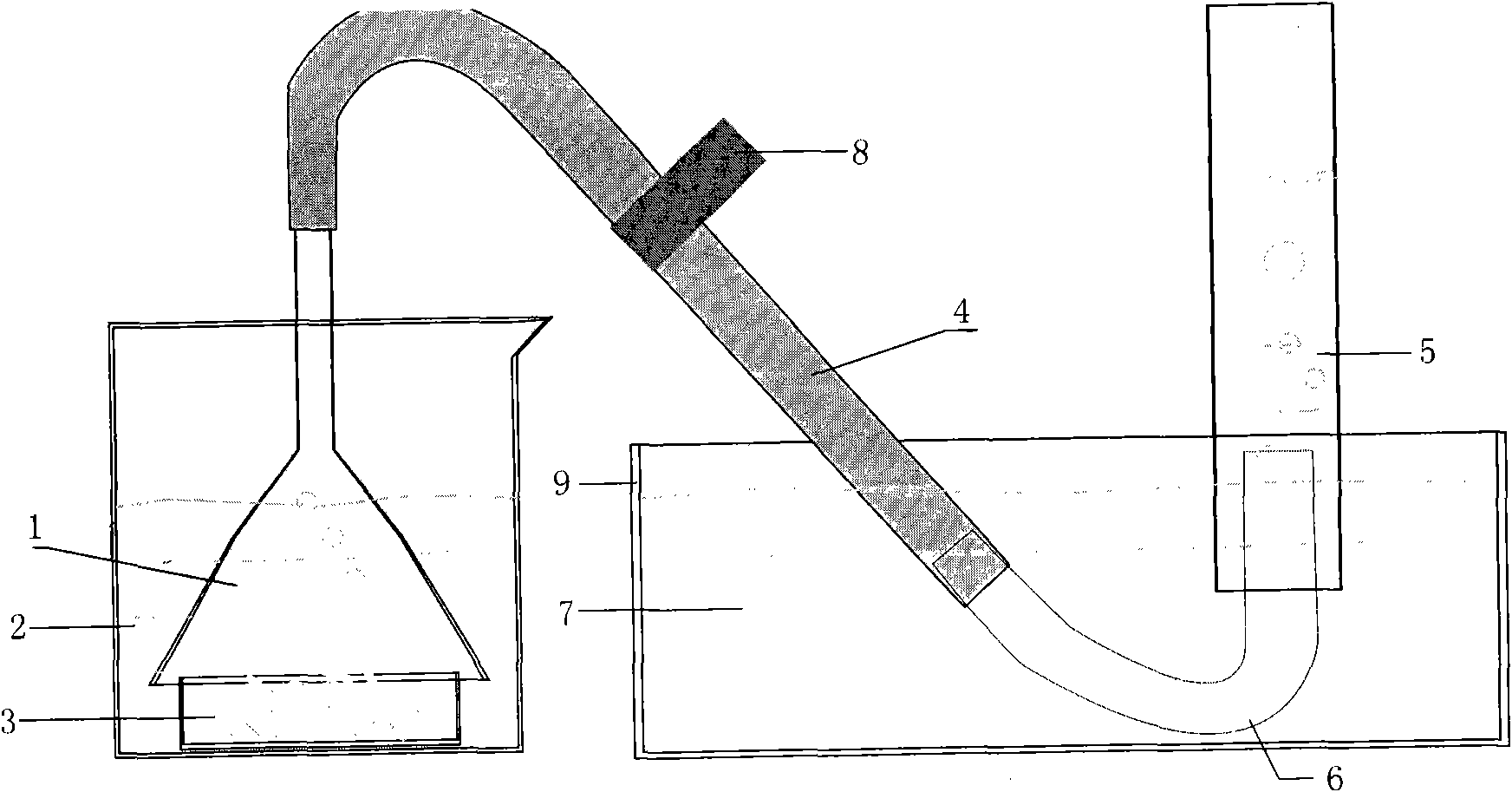

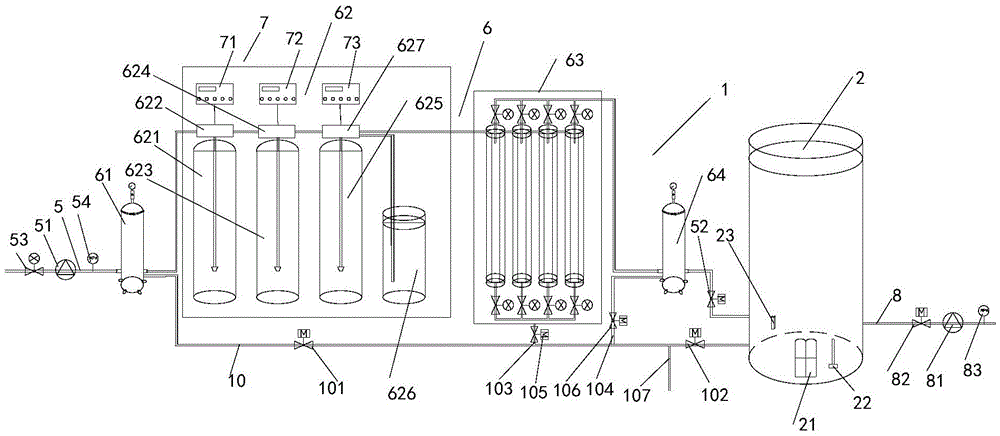

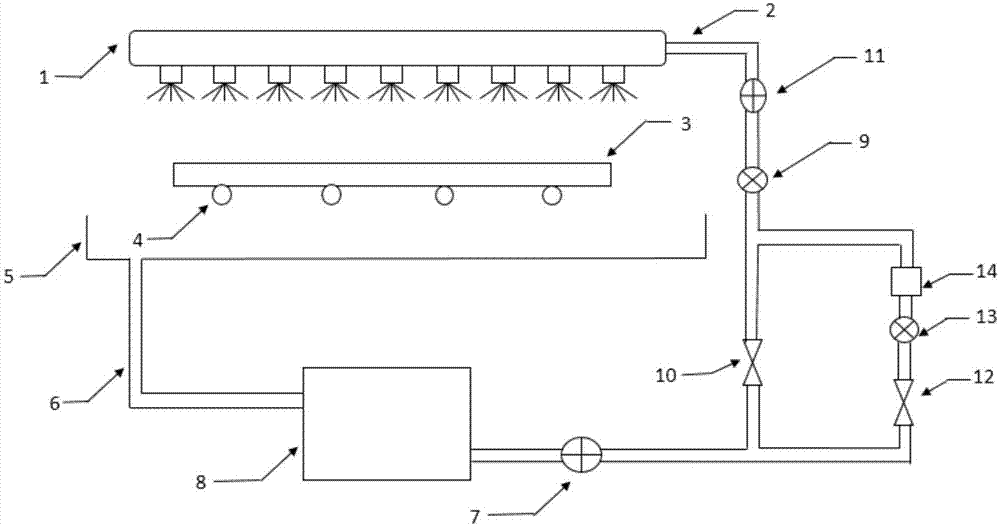

Air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method

InactiveCN105617798APrecision FiltrationEasily brokenGas treatmentUsing liquid separation agentWater storage tankWater source

The invention relates to an air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method. The system comprises a water quality filtering and softening device, a water storage tank, a dry fog dust suppression device and a local controller. An adjustable atomization plate in the dry fog dust suppression device scatters and atomizes a constant-temperature water source which is filtered and softened through the water quality filtering and softening device in the water storage tank, a large amount of micron-grade dry fog and negative ions are produced, a frequency conversion high pressure centrifugal fan in the dry fog dust suppression device blows the large amount of micron-grade dry fog and negative ions out of the dry fog dust suppression device, then the dust is adsorbed, condensed and precipitated, and therefore the purpose of dust removal is achieved. Millimeter-grade visible dust particles can be effectively treated, micrometer-grade inhalable dust particles can also be effectively treated, pollution of dust on the atmosphere is lowered, the work environment of on-site workers is improved, and occupational disease occurrence rate is lowered; the system is small in occupied area, safe and convenient to operate and high in practicability and is controlled in a full-automatic mode.

Owner:刘坤

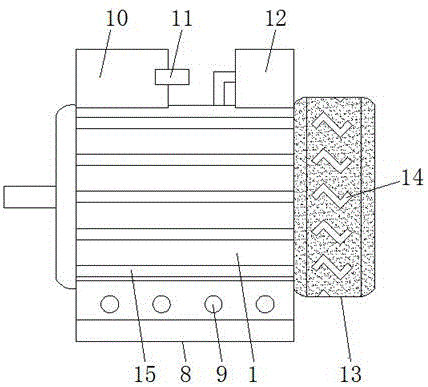

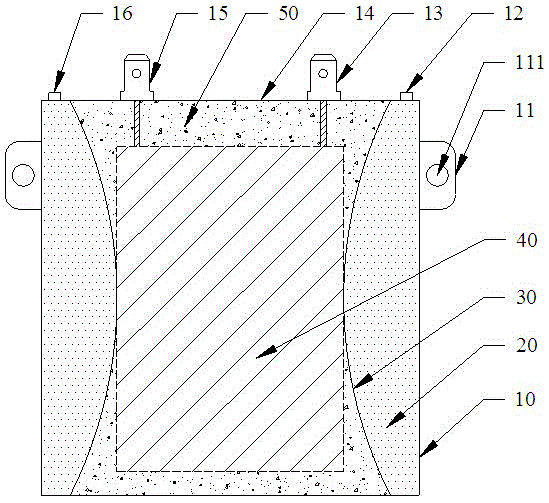

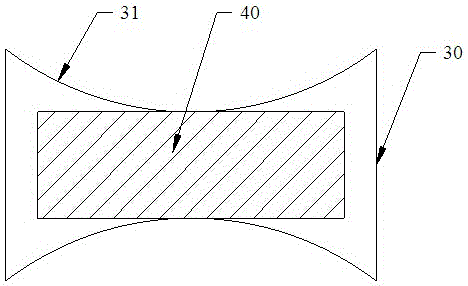

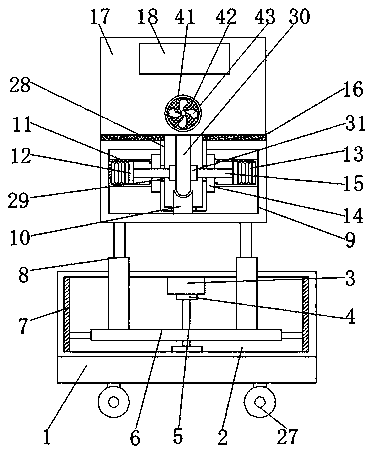

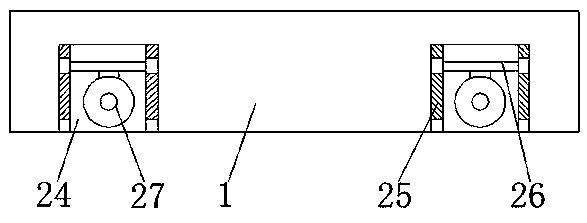

Electric motor with anti-explosion function

InactiveCN106253550AWith explosion-proof functionReduce the chance of explosionCooling/ventillation arrangementSupports/enclosures/casingsNitrogen generatorInternal pressure

The invention discloses an electric motor with an anti-explosion function. The electric motor comprises an anti-explosion shell, wherein the anti-explosion shell comprises a shell wall; the shell wall comprises an inner layer and an outer layer; a hollow cavity is formed between the inner layer and the outer layer; a solid body anti-explosion layer is arranged on one side, far from the outer layer, of the inner layer; a ceramic insulating layer is arranged on one side, far from the inner layer, of the solid body anti-explosion layer; uniformly-arranged heat dissipation sheets are arranged on the outer side face of the anti-explosion shell; a pressure relief cavity and a nitrogen generator are arranged on the top of the anti-explosion shell; an air delivery pipe is arranged on one side, close to the pressure relief cavity, of the nitrogen generator; and a safety relief valve is arranged on one side, close to the nitrogen generator, of the pressure relief cavity. By adoption of the electric motor with the anti-explosion function, the internal pressure of the anti-explosion shell is effectively reduced, so that the explosion probability of the electric motor is lowered, the safety coefficient of the electric motor in use is improved, and the internal temperature of the electric motor is effectively lowered; and even if the electric motor runs for a long time, the internal temperature of the electric motor is not too high, thereby providing effective guarantee to personnel security and property security.

Owner:陈节庆

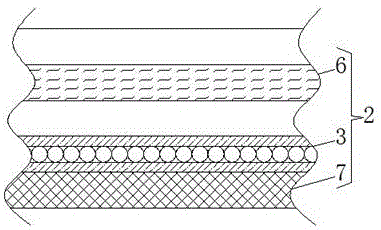

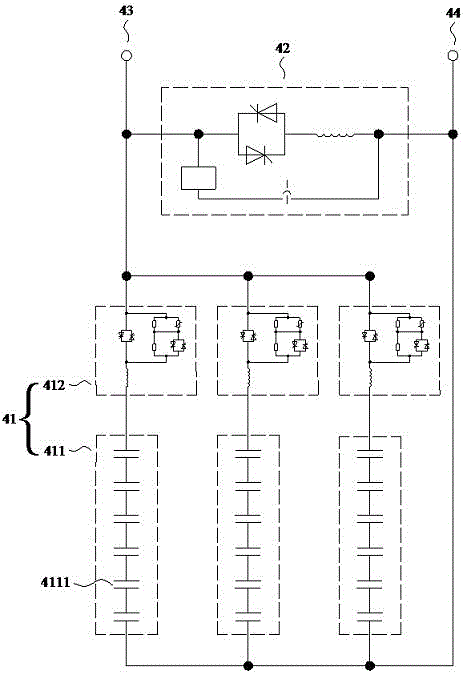

Novel explosion-prevention thin film capacitor

ActiveCN105097285ACompact structureSave installation spaceThin/thick film capacitorStacked capacitorsFilm capacitorCurrent limiting

The invention relates to a novel explosion-prevention thin film capacitor, belonging to the field of a capacitor. A "serial-parallel" connection mode is adopted between winding cores, and thus, the influence of winding core breakdown to the capacitor is reduced; energy storage is low by connecting a bypass component in series, and adjacent winding cores are difficult to be damaged during winding core breakdown or a shell is insulated; the heat exchange effect is improved by using heat conduction epoxy resin, heat conduction oil and an arc concave surface, and fault expansion or shell explosion is favorably prevented; with the arrangement of an overvoltage current-limiting device, breakdown caused by too high current in a bypass component circuit is effectively avoided to burn the circuit or explode, and the current and the voltage in the bypass component are ensured to be continuously stable; and with the arrangement of an overvoltage protection device, an electrical component is prevented from impact of overvoltage and high voltage. The capacitor has the advantages of compact structure, low overall loss and low cost, the installation space is saved, the running fault rate is reduced, the quality defect is favorably reduced, and the electrical component is high in capacitor, few in winding core number, high in production efficiency and good in explosion performance.

Owner:安徽令群电力电容器制造有限公司

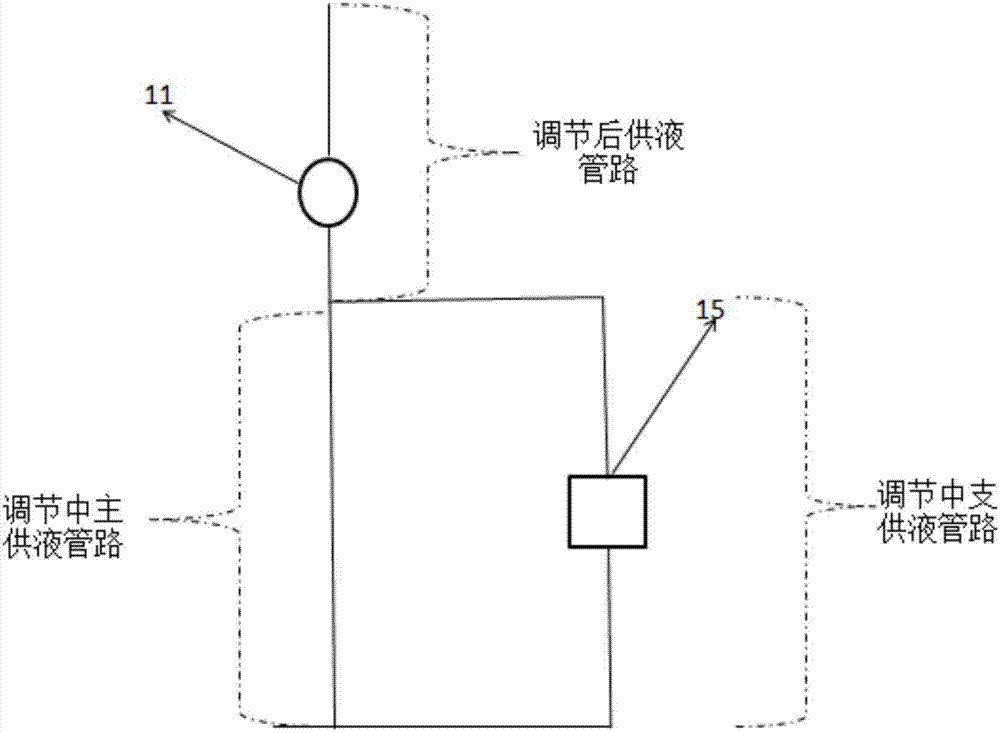

Metal ion concentration regulation device and method, and etching equipment

The invention discloses a metal ion concentration regulation device and method, and etching equipment. The metal ion concentration regulation device comprises a liquid supply pipeline, a metal ion regulation system, a metal ion detection system and a control circuit. The metal ion regulation system and the metal ion detection system are sequentially in the liquid supply pipeline in the direction of etching liquid flowing through the liquid supply pipeline and both communicate with the liquid supply pipeline. The control circuit is electrically connected with the metal ion regulation system and the metal ion detection system and is used for controlling the metal ion regulation system to regulate the concentration of metal ions in the etching liquid according to the current metal ion concentration, transmitted by the metal ion detection system, of the etching liquid and preset metal ion concentration upper and lower threshold values. Through cooperative operation of all the components, the metal ion concentration regulation device conducts regulation on the concentration of metal ions in the etching process, so that the etching rate tends to be stable, the etching effect is improved, and the probability of short circuiting, disconnection and the like of metal conducting wires is reduced.

Owner:BOE TECH GRP CO LTD

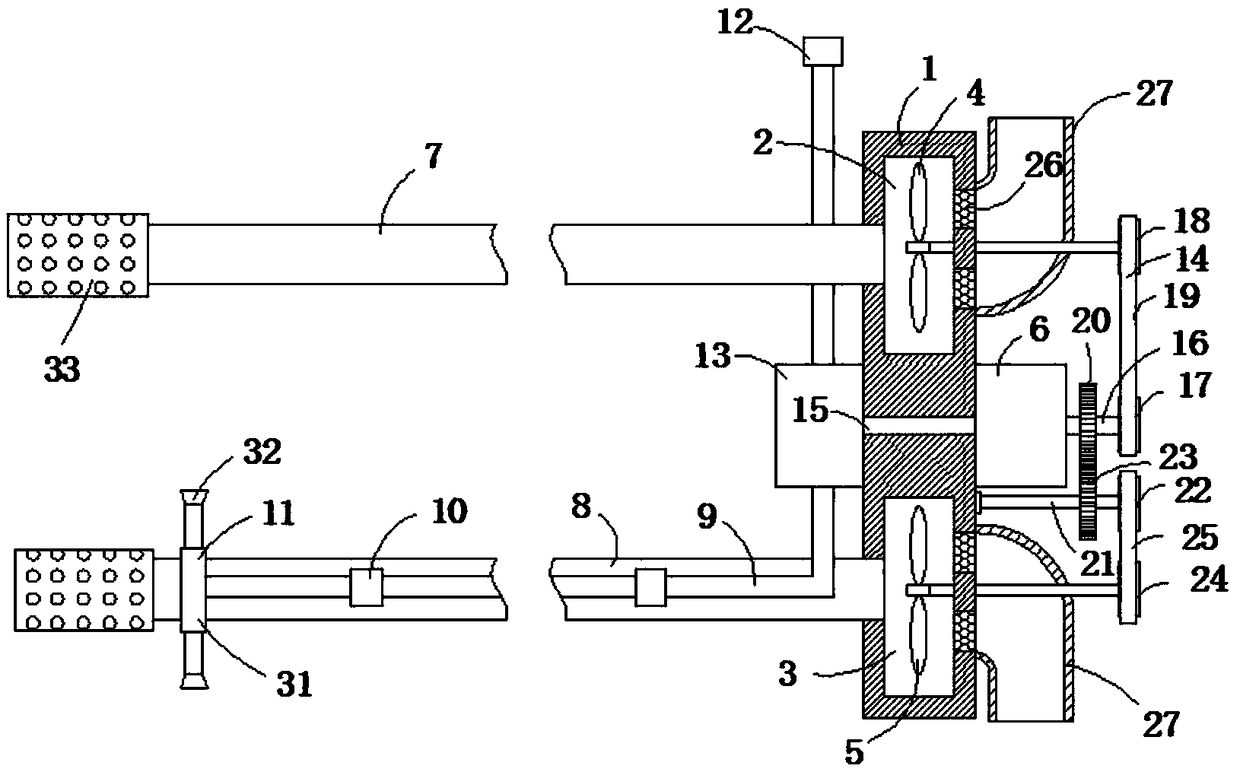

Top corner gas extraction device for coal mine coal-mining working face

ActiveCN109113783ADilution concentrationIncrease humidityDust removalFire preventionDrive shaftFresh air

The invention belongs to the technical field of coal mines, and particularly relates to a top corner gas extraction device for a coal mine coal-mining working face. The top corner gas extraction device comprises a shell internally provided with a first cavity and a second cavity. An exhaust fan is arranged in the first cavity. The other output end of a double-axis motor is coaxially and fixedly connected with a transmission shaft. Two annular ventilating openings are formed in the side walls, away from a first opening and a second opening, of the shell. One end of a water pipe is fixedly connected with a spraying mechanism, and the other end of the water pipe is fixedly connected with a water pipe joint. A water pump is fixedly connected to the water pipe and fixedly connected with the shell. The input end of the water pump and the transmission shaft are coaxially and fixedly connected. The top corner gas extraction device has the advantages that top corner gas of the working face canbe extracted, meanwhile, fresh air can be delivered into a mine, water mist can be sprayed to increase humidity, and thus the danger of gas explosion is lowered; and one motor is adopted to drive multiple functions, and the energy saving effect is achieved.

Owner:湖南省煤业集团嘉禾矿业有限公司

Treatment method of cooling water leakage in vacuum circulating degassing furnace vacuum chamber

The invention provides a treatment method of cooling water leakage in a vacuum circulating degassing furnace vacuum chamber. Under the circumstance of a small water leakage, the method includes: stopping oxygen blowing, raising a top lance to a standby position, and reducing the insert tube blowing strength to 0.16-0.28Nm<3> / ht; and closing a vacuum valve, introducing a gas to conduct system vacuum breaking, and when the pressure in a vacuum chamber reaches over 90kPa, transferring the top lance and a camera lens out of the vacuum chamber, and closing a water inlet valve. Under the circumstances of a large water leakage, the method includes: stopping oxygen blowing, raising the top lance to the standby position, shutting an insert tube lifting gas and the top lance or a camera lens water inlet valve, reducing the vacuum pressure to less than 1kPa, making use of a vacuum pump to eliminate water vapor, and when a normal vacuum pressure is achieved in the vacuum chamber, normal pipeline air or nitrogen is utilized to conduct system vacuum breaking, and when the pressure in the vacuum chamber reaches over 90kPa, moving the top lance and the camera lens out of the vacuum chamber. The invention can effectively reduce the harm of water leakage, and lower the risk of explosion, thus avoiding personal injury, equipment damage and other serious accidents.

Owner:ANGANG STEEL CO LTD

Molecular resonance furnace

InactiveCN105805792AImprove safety and reliabilityReduce the chance of explosionDomestic stoves or rangesLighting and heating apparatusLiquid mediumLiquid state

The invention discloses a molecular resonance furnace. The molecular resonance furnace comprises a furnace shell of which the top is provided with a heat transfer hole, a furnace plate arranged in the furnace shell, a unidirectional heat-conducting plate which is connected to the top of the furnace plate, forms an enclosed chamber and is located at the bottom end of the heat transfer hole, and an electrothermal conversion wave production device which is arranged in the enclosed chamber and divides the enclosed chamber into a heating chamber and a liquid molecule resonance chamber, wherein the liquid molecule resonance chamber is located at the top of the heating chamber, the heating chamber is provided with an electrothermal body, a liquid medium is arranged in the liquid molecule resonance chamber and one side of the unidirectional heat-conducting plate close to the liquid molecule resonance chamber transfers heat to one side away from the liquid molecule resonance chamber. The molecular resonance furnace utilizes liquid molecular resonance to heat an objected to be heated. Compared with the existing furnace utilizing gaseous molecular resonance to heat, the molecular resonance furnace effectively reduces explosion probability in resonance because of use of stable liquid molecules and improves safety and reliability.

Owner:GREE ELECTRIC APPLIANCES INC

An electrolyte solution for improving the safety of lithium-manganese batteries

InactiveCN102263291AReduced responseReduce the chance of explosionSecondary cellsOrganic solventCarbonate ester

The invention relates to a lithium battery electrolyte solution, which is an electrolyte solution for improving the safety of lithium-manganese batteries. The electrolyte solution is composed of two types of components: (1) a composite lithium salt composed of component A and component B; (2) carbonate class and / or ether organic solvents; the molar concentration range of the composite lithium salt in this electrolytic solution is 0.01-2 mol / liter, and the balance is carbonates and / or ether organic solvents; the composite lithium salt component A is At least one of the following substances: LiAsF6, LiPF6, LiBF4, LiClO4LiCF3SO3, LiN(CF3SO2)2, LiC4F9SO3, LiN(CxF2x+1SO2) (CyF2y+1SO2), where x and y are natural numbers; composite lithium salt component B It is at least one of the following substances: LiB(C2O4)2 or LiBF2C2O4; the molar concentration percentage of component A in the composite lithium salt is 0.01-99.99%, and the molar concentration percentage of component B in the composite lithium salt is 0.01-99.99% . The invention can greatly reduce the potential safety hazard of the lithium-manganese battery, prevent explosion accidents, and highlight and improve the safety problem of the battery.

Owner:BASF BATTERY MATERIALS SUZHOU

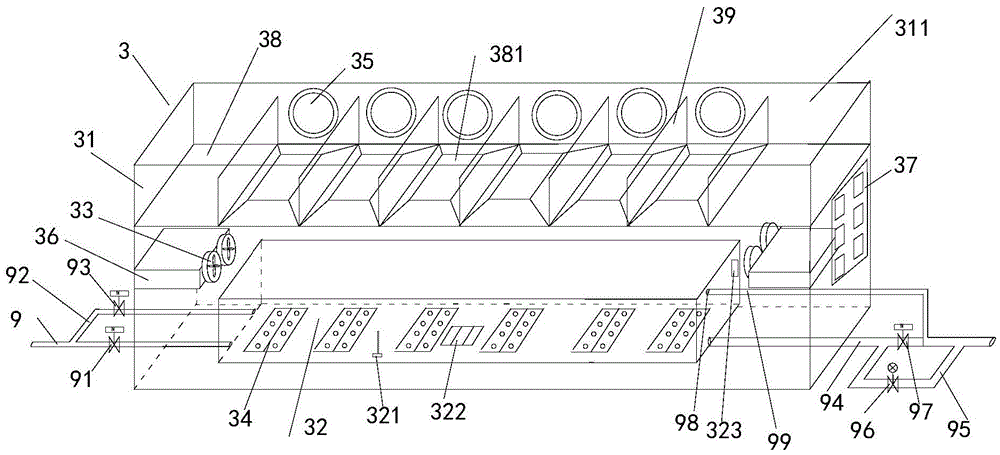

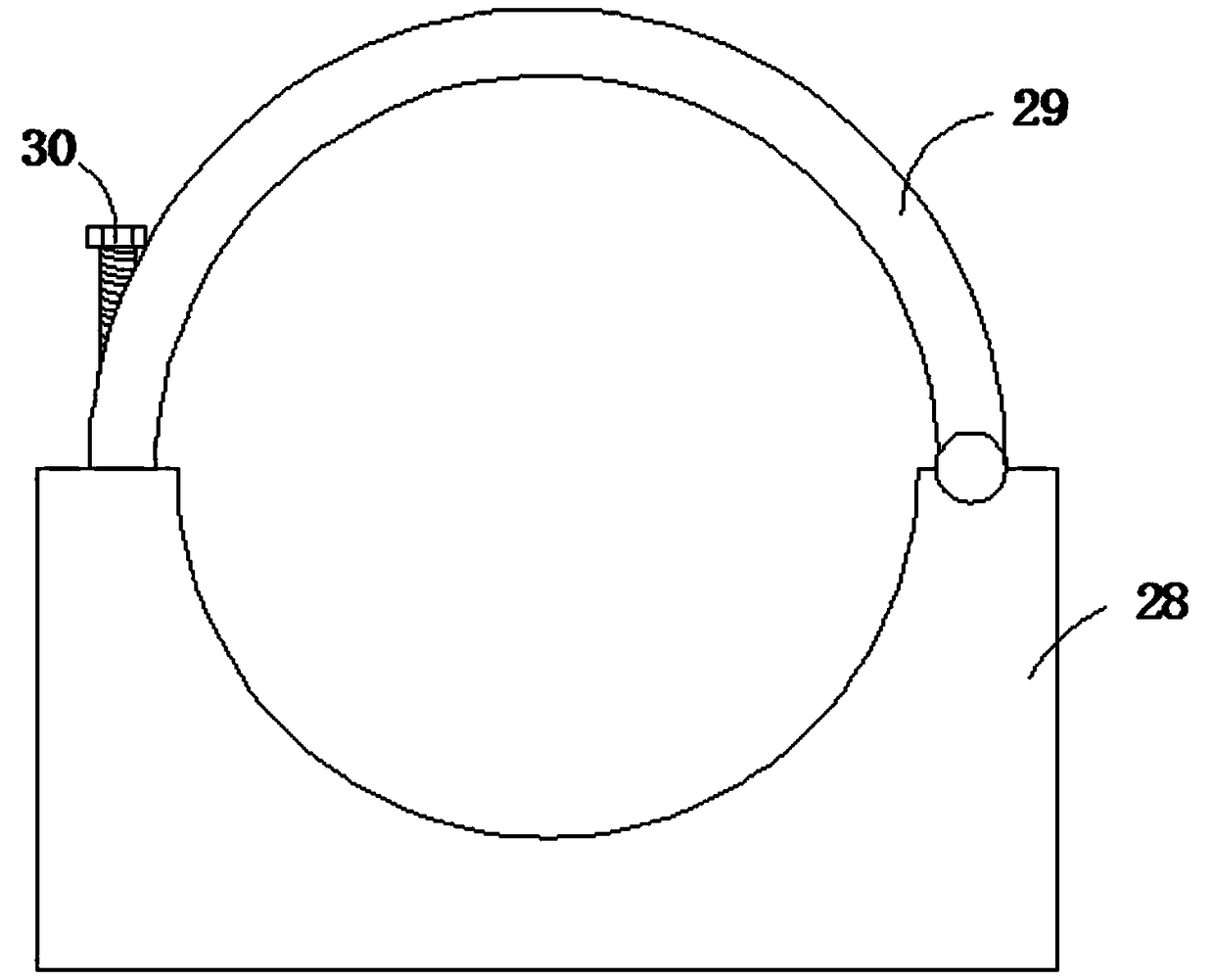

Explosion prevention type dust collector and control method thereof

InactiveCN106422568ASimple structureImprove explosion-proof performanceCombination devicesDispersed particle filtrationEngineeringPrevention types

The invention relates to an explosion prevention type dust collector, which comprises a box body, wherein the box body is provided with a dust gas inlet; the upper end and the lower end of the box body are respectively provided with a collector cover plate and a discharging hopper; the collector cover plate is provided with a dust gas outlet; a spray blowing pipe is arranged in the collector cover plate; the inlet end of the spray blowing pipe is provided with a pulse valve; a plurality of anti-static filter bags communicating with the spray blowing pipe are also arranged inside the box body; explosion prevention films are arranged on the outer side surface of the box body and the upper end surface of the collector cover plate; meanwhile, the invention also provides a control method of the explosion prevention type dust collector. The explosion prevention type dust collector has the advantages that the structure is simple; the explosion prevention effect is good; charges can be discharged out; the explosion rate can be reduced; the dust accumulation is reduced; the smooth discharging of the dust is ensured; the inside dust humidity can be well controlled; the spraying and blowing conditions are strictly controlled; the regular flowing of the inside dust is ensured; the generation of dust charges is reduced; the safety is higher.

Owner:SOUTHWEAT UNIV OF SCI & TECH

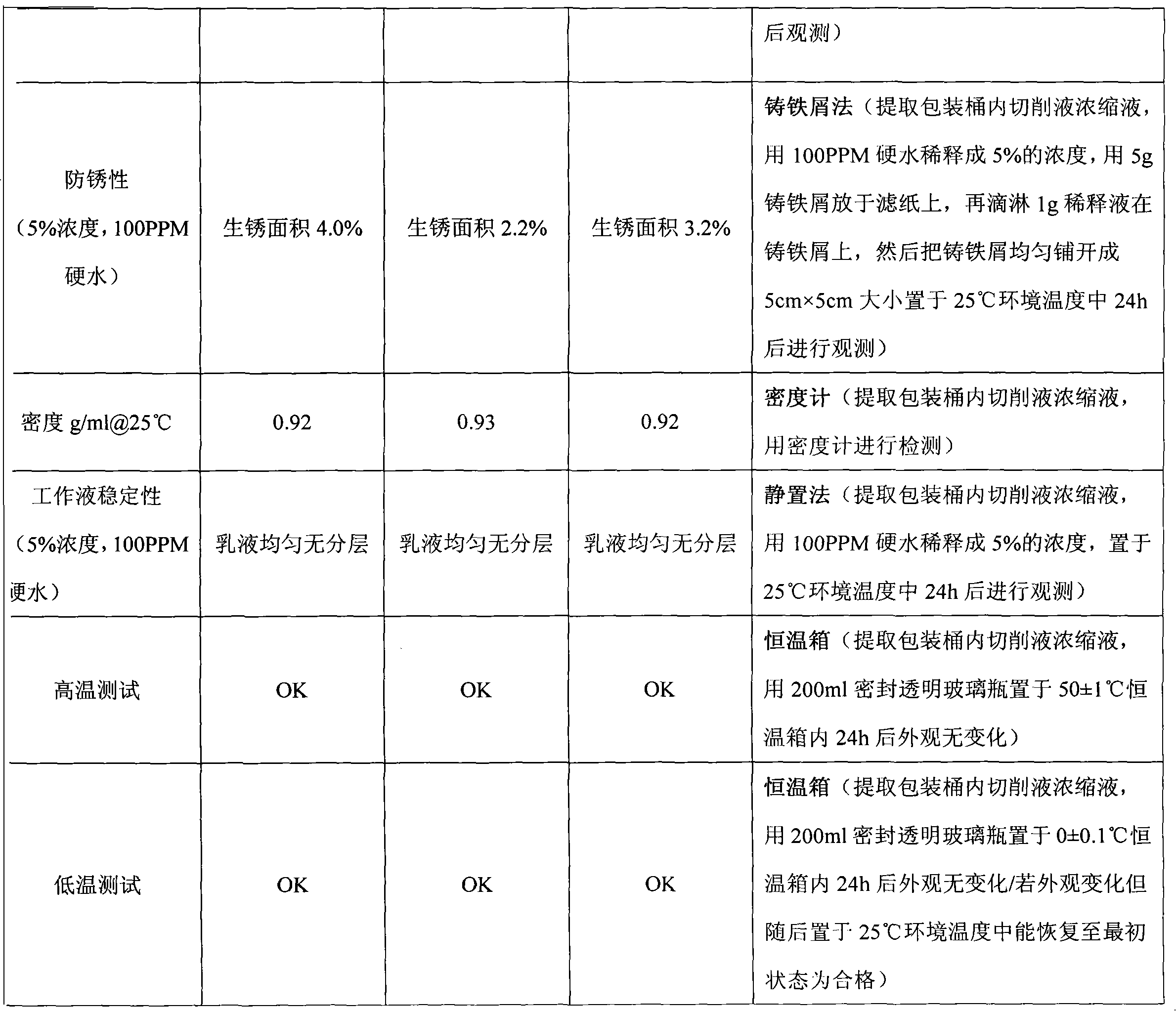

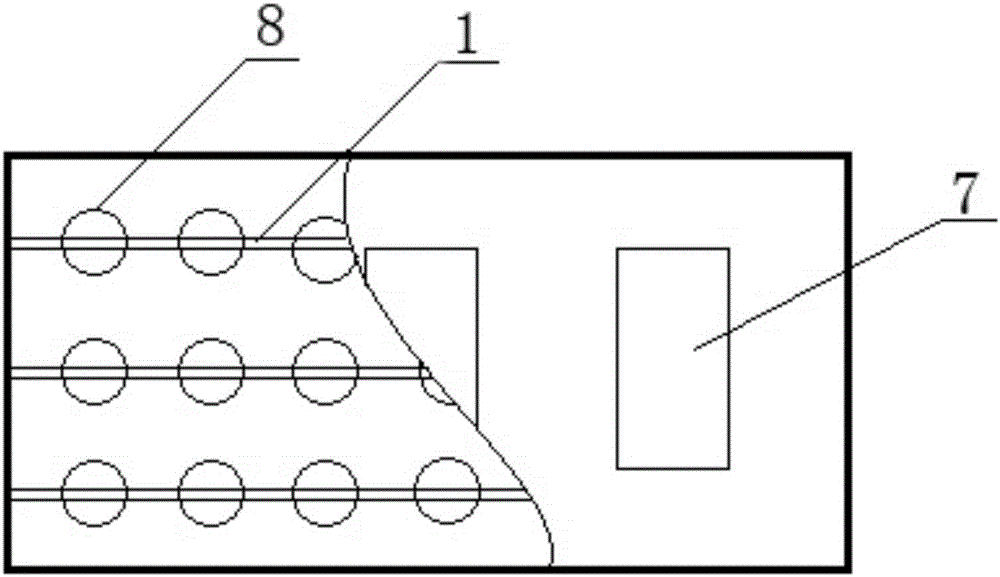

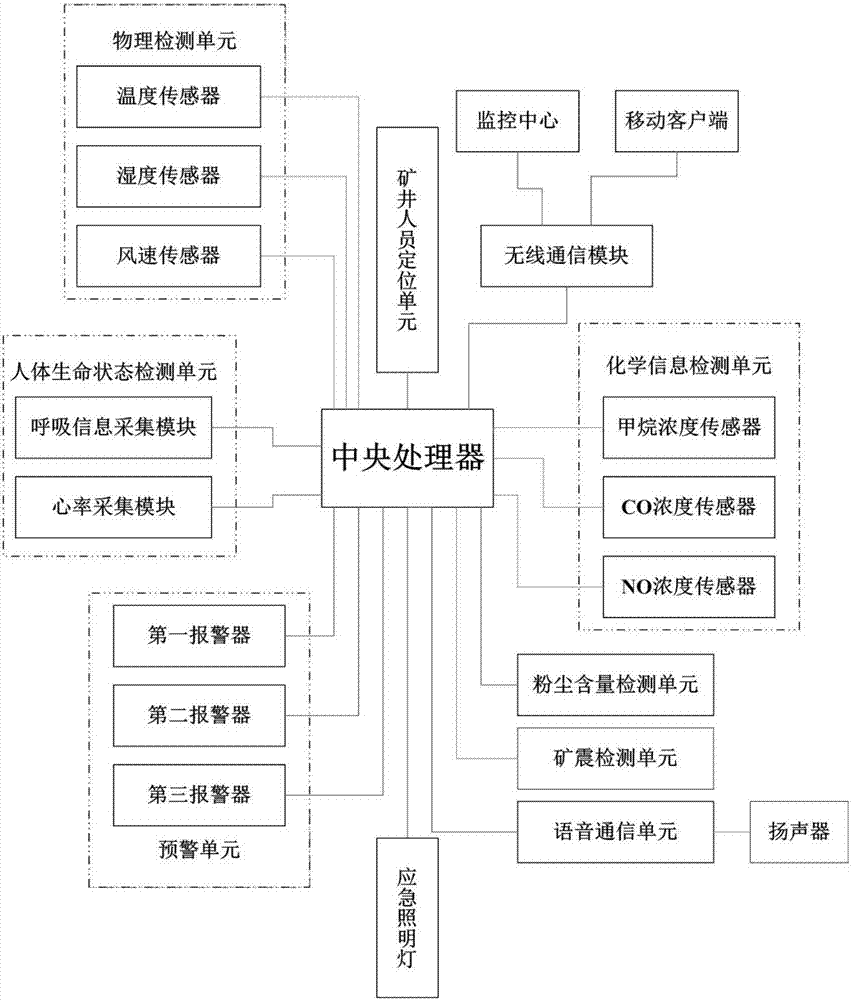

Coal mine security detection system

InactiveCN107091115ARealize real-time detectionReduce the chance of explosionMining devicesFactor of safetyHuman life

The invention discloses a coal mine security detection system. The system comprises a physical detection unit, a chemical information detection unit, a human life condition detection unit, a central processing unit, an early-warning unit and a wireless communication module; the physical detection unit is used for detecting the temperature, humidity and wind speed in a mine in real time; the chemical information detection unit is used for detecting the concentration of methane, CO and NO in the mine in real time; the human life condition detection unit is used for detecting breath information and heart rate information of workers in the mine in real time. According to the coal mine security detection system, the detection for all risk factors in mine construction is ensured, the safety factor in construction is increased, the real-time detection for all parameters under the mine is achieved, the system cost is reduced, the mounting period is shortened, the stability of the system is improved, and therefore a modern monitoring system which is easy to maintain and has ultrahigh cost performance is obtained.

Owner:HENAN POLYTECHNIC UNIV +1

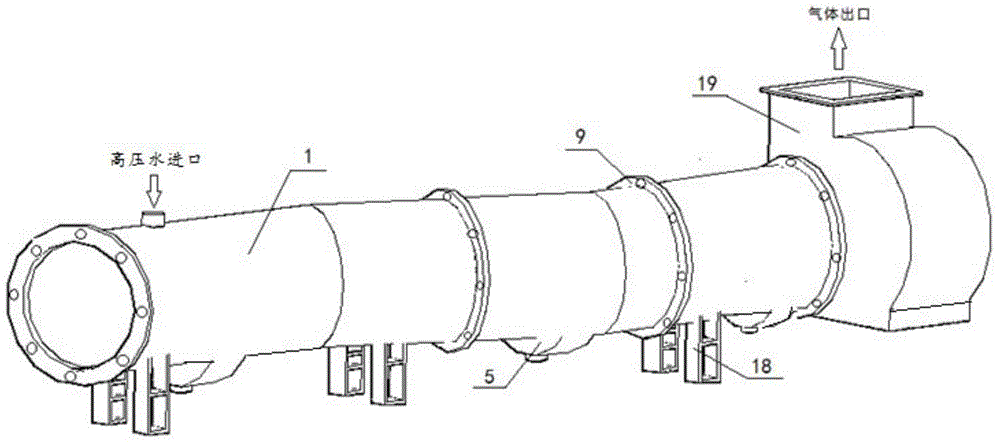

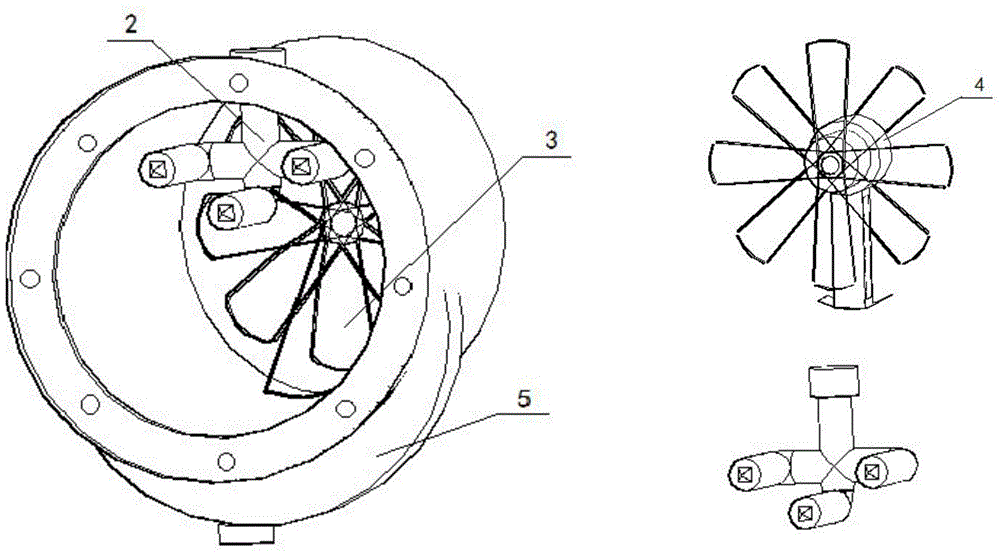

Combined wet-type pipeline dedusting device

InactiveCN104785059ALow input costEasy to use and maintainCombination devicesSpray nozzleHigh pressure

The invention relates to a combined wet-type pipeline dedusting device. A first-stage dedusting system comprises a dedusting air duct I, a high-pressure spray nozzle, fan blades and a dirt removal channel, wherein the fan blades are connected on a motor, the motor is fixed to the inner wall of the dedusting air duct I, and the dirt removal channel is arranged at the bottom of the dedusting air duct I. A second-stage dedusting system comprises a dedusting air duct II, wherein an annular inclined pipeline is arranged in the dedusting air duct II, and spiral rotary pieces are arranged in the pipeline and connected on a fixing rod in the pipeline. A third-stage dedusting system comprises a dedusting air duct III, wherein a filter barrel is arranged in the dedusting air duct III, three wet-type filters are arranged in the filter barrel, and the filter barrel is connected on two shafts through a pair of connection tripods. The three dedusting air ducts are fixedly connected through bolt flange structures, and the whole dedusting system is fixed on the ground through fixing supports. The combined wet-type pipeline dedusting device has the advantages and the benifits that a multi-stage dedusting technique is adopted on the basis of existing inside spraying and outside spraying, an efficient dedusting purpose is achieved and the combined wet-type pipeline dedusting device is suitable for wide popularization and application in a mine.

Owner:ANHUI UNIV OF SCI & TECH

Industrial workshop gas detection device

InactiveCN108918767AAvoid excessive heatPrevent electric leakage and fireGas analyser construction detailsEnvironmental resistanceNitrogen gas

The invention provides an industrial workshop gas detection device. The industrial workshop gas detection device comprises a pedestal; a receiving chamber is arranged in the pedestal; the top of the receiving chamber is fixedly provided with a motor; the bottom of the motor and the bottom of the receiving chamber are fixedly provided with a bearing pedestal; the internal side of the bearing pedestal is fixedly connected with a screw rod; the surface of the screw rod is fixedly connected with a connecting plate; the left side and the right side of the receiving chamber are fixedly provided withslide rails; the slide rails are connected with the connecting plate through slide rods on the surface of the slide rails in slide connection. The industrial workshop gas detection device is providedwith a nitrogen spray box, nitrogen is sprayed to the internal part of a detection housing, so that rapid cooling is realized, overhigh temperature is avoided, effective cooling of the internal partof the detection housing is realized, damage on internal detection devices caused by overhigh temperature is avoided, explosion-proof performance is improved; a gas-water separation device is controlled to pump gas in the detection housing to the outside, water gas separation is realized, environment is protected, the efficiency is high, and electric leakage fire disasters of internal detection devices caused by moisture are avoided.

Owner:芜湖渤江智能科技有限公司

Ethylene-propylene-diene monomer rubber for thermal protection of lithium ion battery and preparation method of ethylene-propylene-diene monomer rubber

ActiveCN108929494AImprove thermal protection performanceReduce surrounding surface temperatureFiberCombustion

Provided are a thermal protection material for a lithium ion battery and a preparation method of the thermal protection material. Raw materials of the thermal protection material comprises ethylene-propylene-diene-monomer rubber, resin, fiber and assistants, wherein the assistants comprise a flame retardant and one or more selected from a plasticizer, an activator, a coupling agent, a reinforcingagent, a promoter, a vulcanizing agent and other matter. Through the thermal protection material, the thermal protection performance of the lithium ion battery can be improved significantly in the case of sudden combustion, and the surface temperature of the periphery adjacent to and near the lithium ion battery can be reduced by controlling the temperature field, so that the probability of combustion and explosion of the lithium ion battery is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

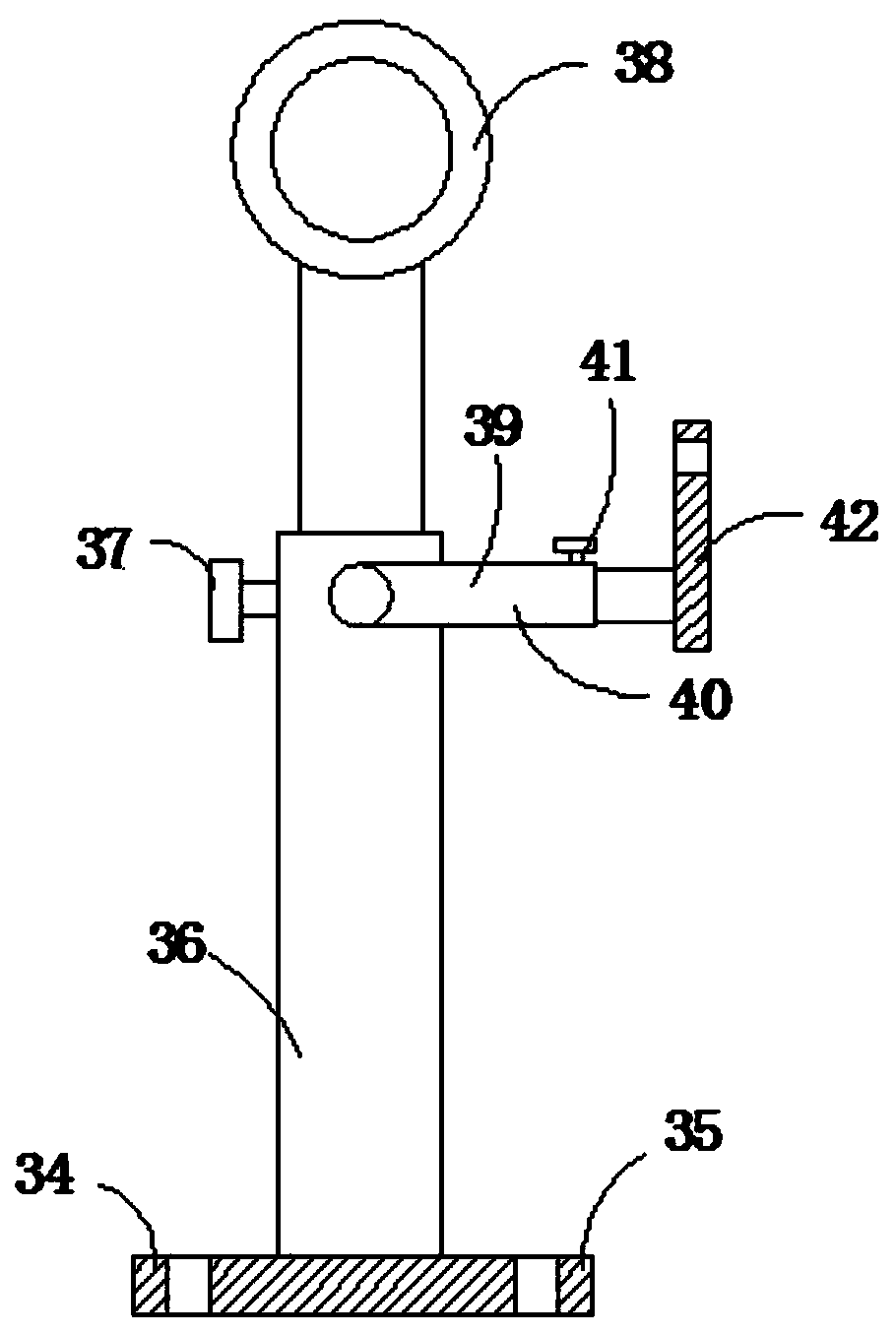

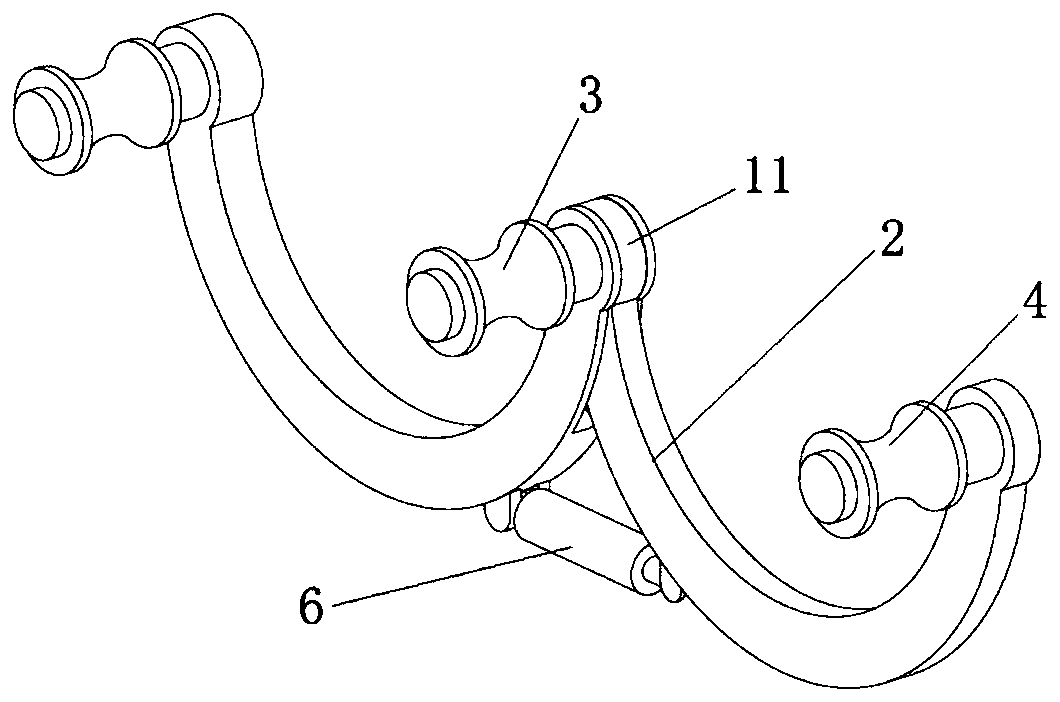

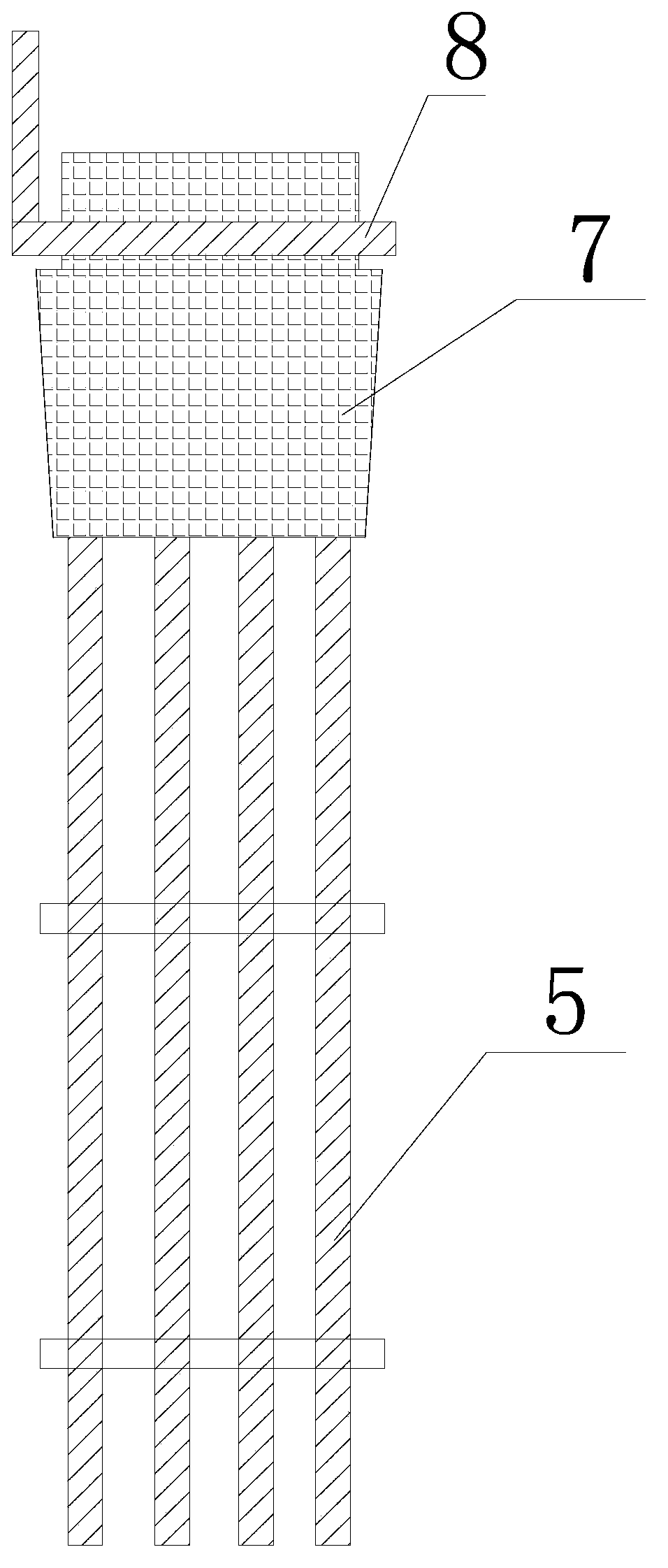

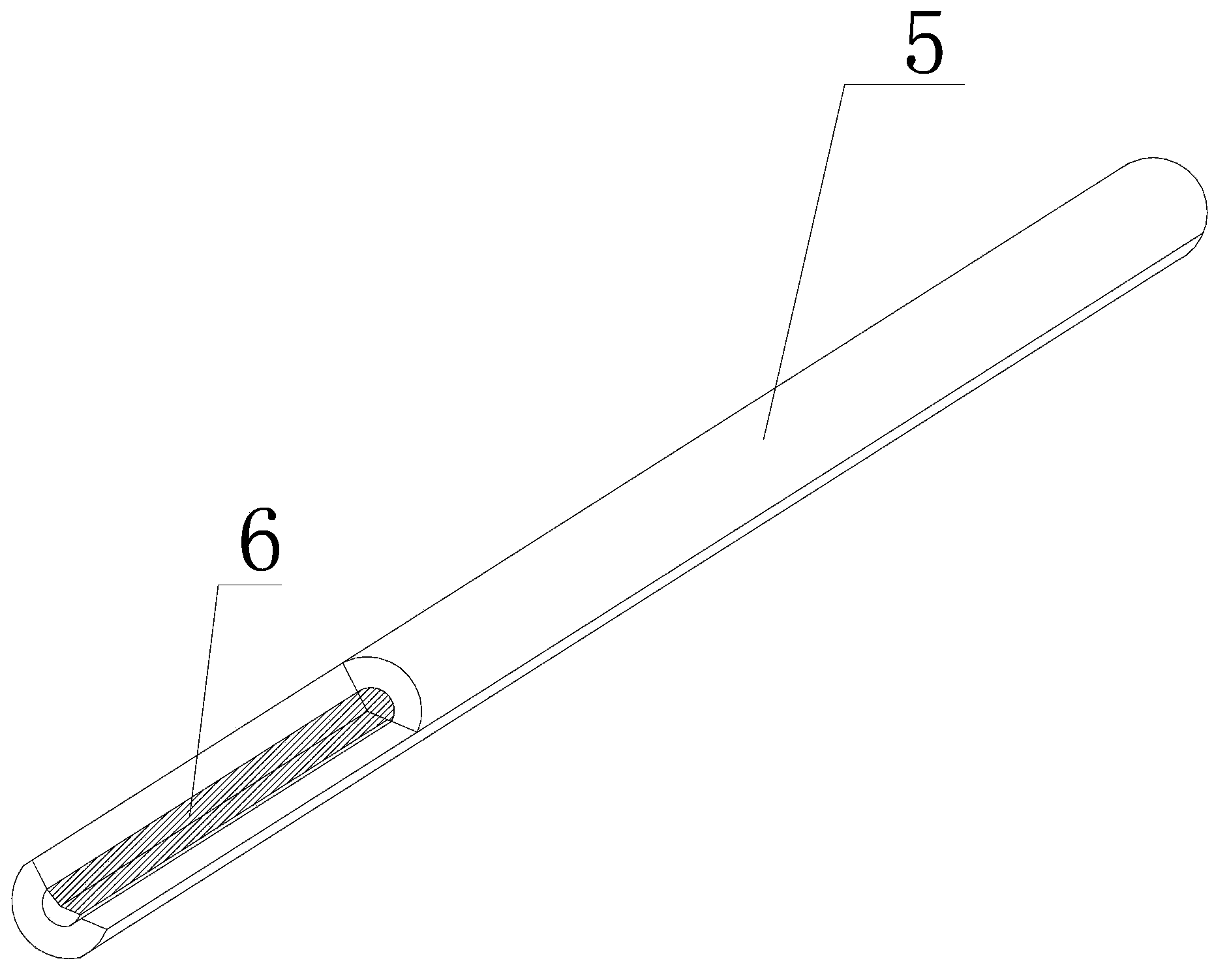

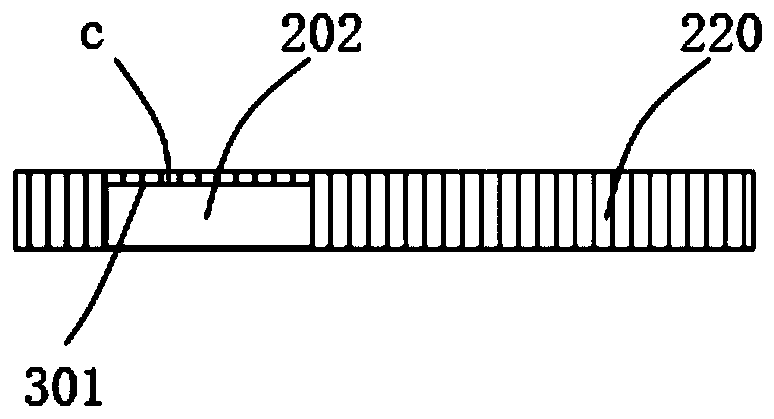

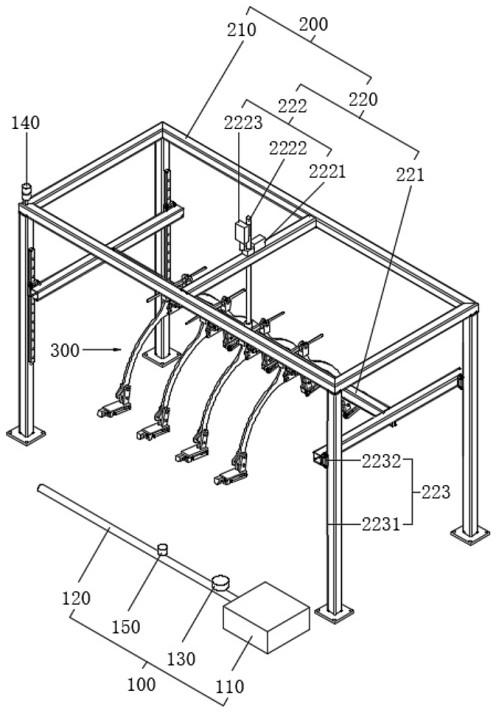

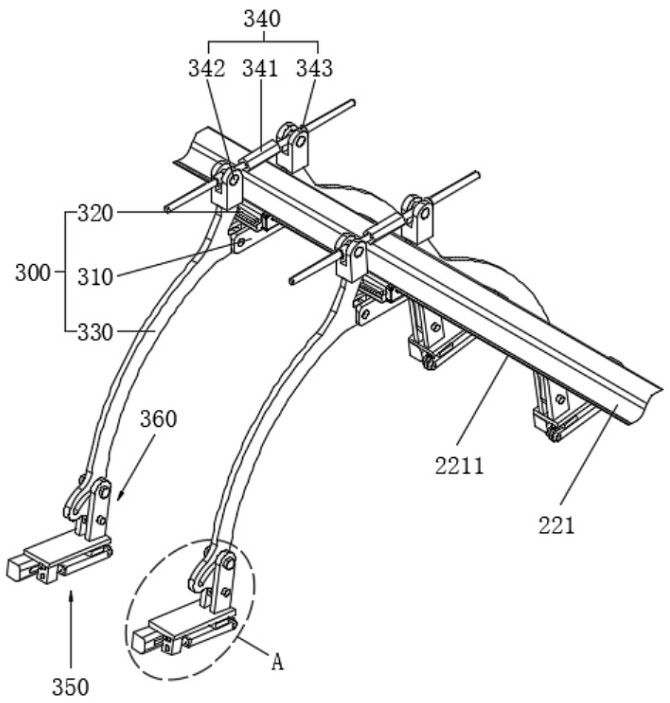

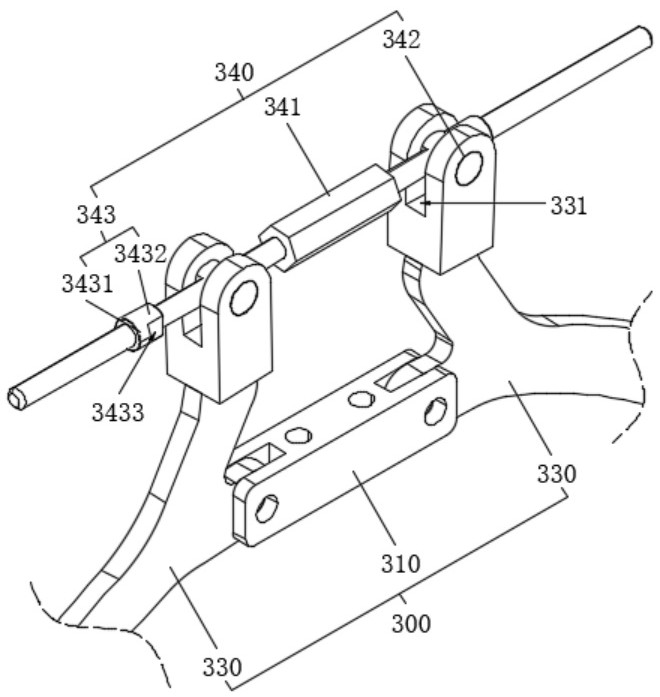

Multifunctional cable laying device and application

PendingCN111276905AReduce power usageStable non-linear layingFilament handlingApparatus for laying cablesCentre of rotationElectric cables

The invention discloses a multifunctional cable laying device and application, and relates to the technical field of cable laying equipment, the multifunctional cable laying device comprises a support, a rotating shaft installed on the support, two rotating arms installed with the rotating shaft as the rotating center, a driving roller with a built-in first servo motor installed at the position ofthe rotating shaft, wherein the axis of the driving roller is parallel to the axis of the rotating shaft; guide pulleys of which the axes are parallel to the driving roller are mounted at the tail ends of the two rotating arms; and a plurality of mounting holes are formed in the rotating arm.

Owner:昆明瑞建送变电工程有限公司

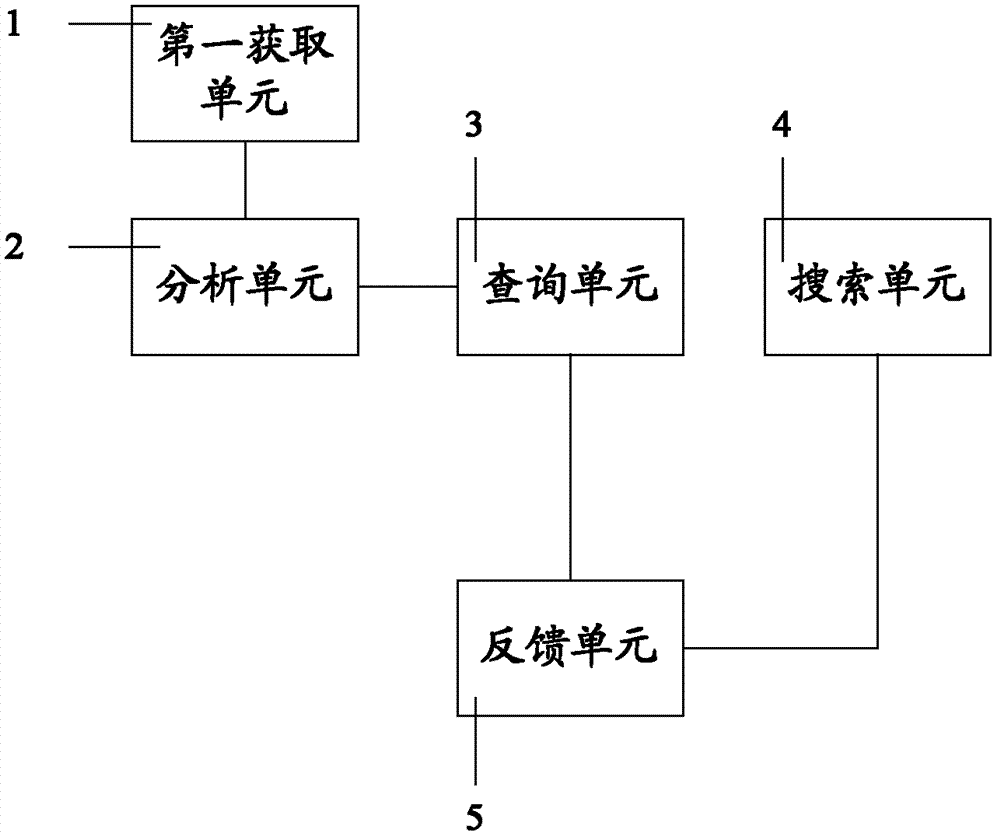

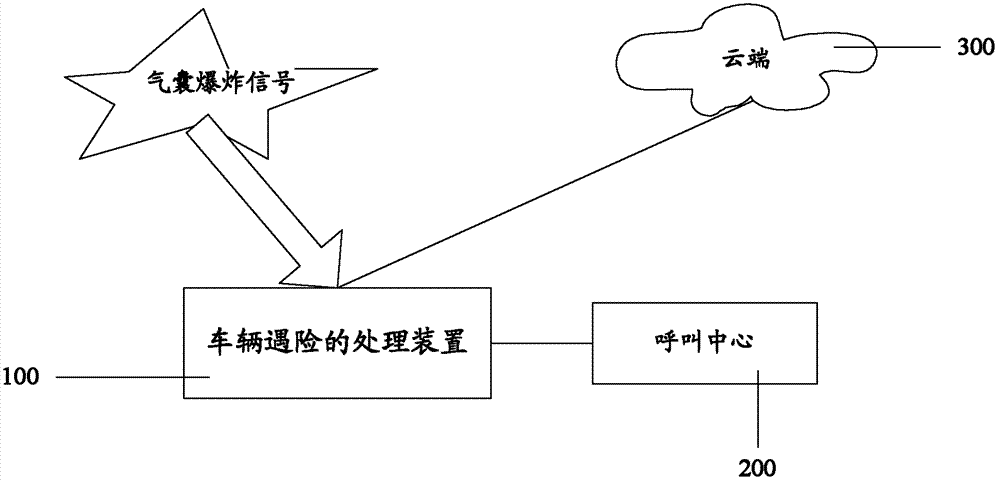

Handling method and device for vehicle distresses, and vehicle-mounted system

ActiveCN103085749AIncrease chances of rescueIncrease chance of rescuePedestrian/occupant safety arrangementEngineeringInformation searching

Disclosed are a handling method and a device for vehicle distresses, and a vehicle-mounted system. The handling method for vehicle distresses includes: acquiring an airbag explosion signal, and analyzing causes of airbag explosion according to the airbag explosion signal; starting interior check to acquire condition information of a vehicle and a system log of the vehicle-mounted system; and executing rescue operations. The condition information of the vehicle includes current location of the vehicle. The rescue operations include at least two operations of distress data reporting, self-rescue information searching and relief agency searching. By the handling method and device and the vehicle-mounted system, the condition of the vehicle in distress can be monitored and calling-for-help information can be sent out timely and effectively.

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

Method for purifying nano-diamond

The invention discloses a method for purifying nano-diamond. The method comprises the following steps: (1) adding nano-diamond black powder into a mixed liquor of a H2SO4 solution and a H3PO4 solution, heating and stirring, adding KMnO4, controlling the system temperature at 70-100 DEG C, and reacting for 2-3h; (2) cooling the solution after the reaction to room temperature, filtering, and washingwith water to obtain coarsely extracted nano-diamond; (3) adding the crudely extracted nano-diamond to an alkaline solution for stirring and reacting; (4) filtering the reacted solution, washing withwater, and drying to obtain pure nano-diamond. According to the invention, metal ions formed after removal of metal impurities are combined with phosphate anions to form a coordination compound, themetal ions precipitation can be avoided, so that the removal of the metal impurities and graphite can be simultaneously performed, the route is simplified, and the impurity removal efficiency is improved, and concentrated hot phosphoric acid can corrode silicon dioxide to achieve the purpose of preliminary removal of Si and improve the subsequent Si removal efficiency.

Owner:成都天成鑫钻纳米科技股份有限公司

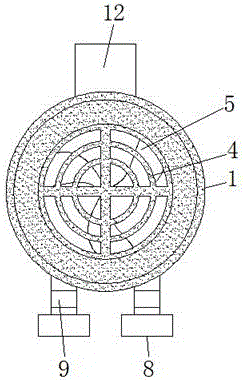

Inert gas protection device for low-flash-point system of marine ship

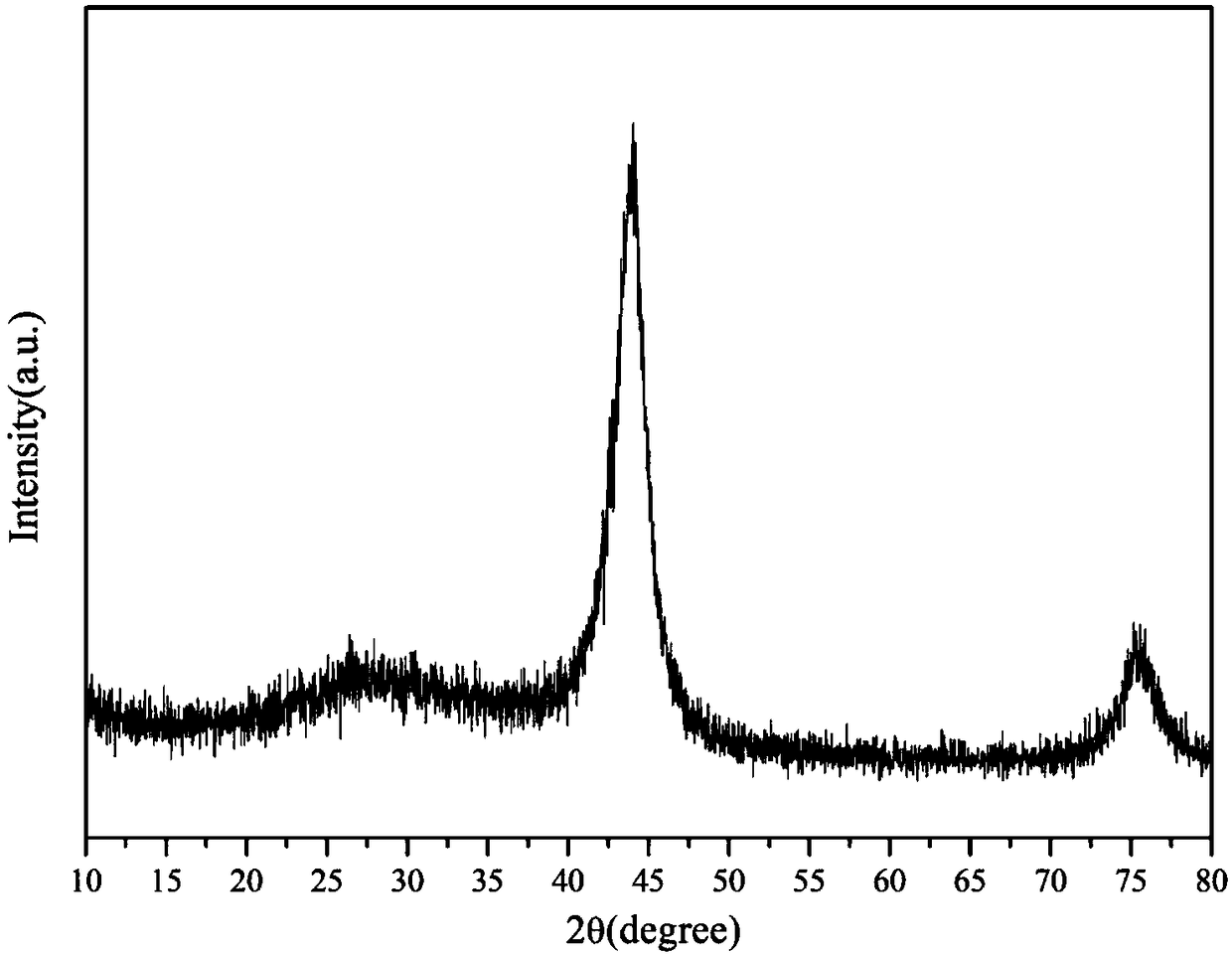

InactiveCN103691079AImprove securityReduce the chance of explosionFire rescueNitrogen generatorIsolation valve

The invention relates to an inert gas protection device for a low-flash-point system of a marine ship. The inert gas protection device comprises a nitrogen generator and a nitrogen collector, wherein the nitrogen generator is connected with the nitrogen collector through a delivery pipeline; the nitrogen collector is connected with a booster air compressor through a delivery pipeline; a plurality of nitrogen storage cylinders are respectively connected with the booster air compressor through delivery pipelines, and are all connected with pressure reducing valve group control stations through delivery pipelines. Both pressure control valves and isolating valves are arranged on all the nitrogen storage cylinders. The inert gas protection device has the benefits that the safety of the marine ship for transporting low-flash-point substances is effectively improved; the explosion rate of the transported low-flash-point substances in marine accidents is effectively reduced; the inert gas protection device can also be used as a standby gas choice for the marine ship.

Owner:ZHEJIANG SHIPBUILDING CO LTD

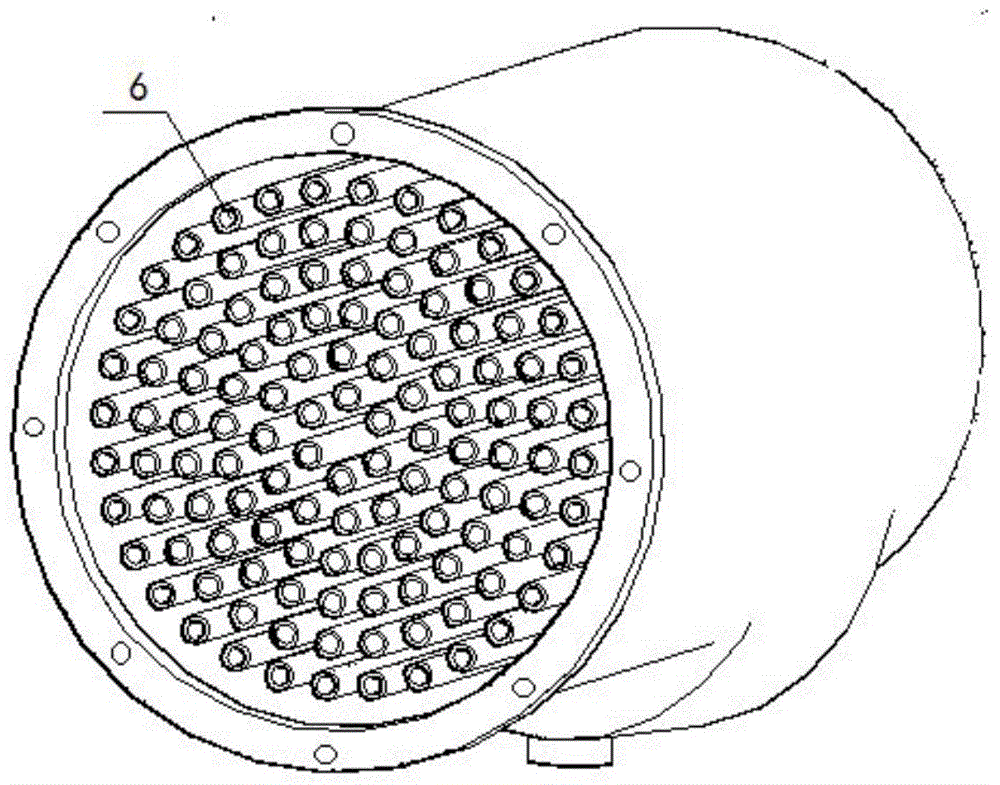

Perchlorate electrolyzer and electrolytic process

ActiveCN103409770AImprove conversion rateImprove current efficiencyCellsLiquid storage tankEngineering

The invention discloses a perchlorate electrolyzer which comprises a plurality of electrolysis baths, wherein the electrolysis baths are divided into at least three groups, the electrolysis baths in each group are connected in series, each group of the electrolysis baths is further connected with a circulation barrel, the circulation barrels are in stepped distribution and connected through overflow pipes, and the overflow pipe of the circulation barrel at a lowest position is connected with an electrolyzed liquid storage tank. An electrolytic process of perchlorate is as follows: chlorate electrolyte solution is used for electrolyzing in an electrolysis bath so as to obtain electrolyzed liquid, and the electrolyzed liquid is used for producing perchlorate products; the electrolytic process comprises that the perchlorate electrolyzer is used for circulated electrolyzing to electrolyte solution, and the electrolyzing temperature is controlled to be 60 to 70 DEG C. The perchlorate electrolyzer and the electrolytic process, provided by the invention, has the advantages that the current efficiency is improved and the chlorate conversion rate is increased.

Owner:ZHUZHOU QIANGSHENG ELECTRODE

Battery end cover with fire extinguishing function

PendingCN110400894AImprove securityStop burningFire rescueCell lids/coversChemical reactionEngineering

The invention relates to a battery end cover with the fire extinguishing function. The battery end cover comprises a cover body and a fuse group. A fire extinguishing agent cavity is formed in cover body. A first fuse and a second fuse are oppositely arranged in the fire extinguishing agent cavity at intervals. When the pressure in the battery cavity rises, the surface, close to the battery cavity, of the battery end cover is extruded to push the first fuse to gradually get close to the second fuse. The first fuse is electrically connected with a negative current collector, and the first fuseis positively charged. The second fuse is electrically connected with a positive electrode current collector, and the second fuse is negatively charged. When the first fuse and the second fuse are incontact, the first fuse and the second fuse are short-circuited to release heat. A fire extinguishing agent is heated to generate chemical reaction to generate a flame-retardant gas. The flame-retardant gas can prevent gas in the battery from burning. The flame-retardant gas breaks through the cover body, so that the gas in the battery cavity is discharged. The explosion probability is reduced.

Owner:TSINGHUA UNIV

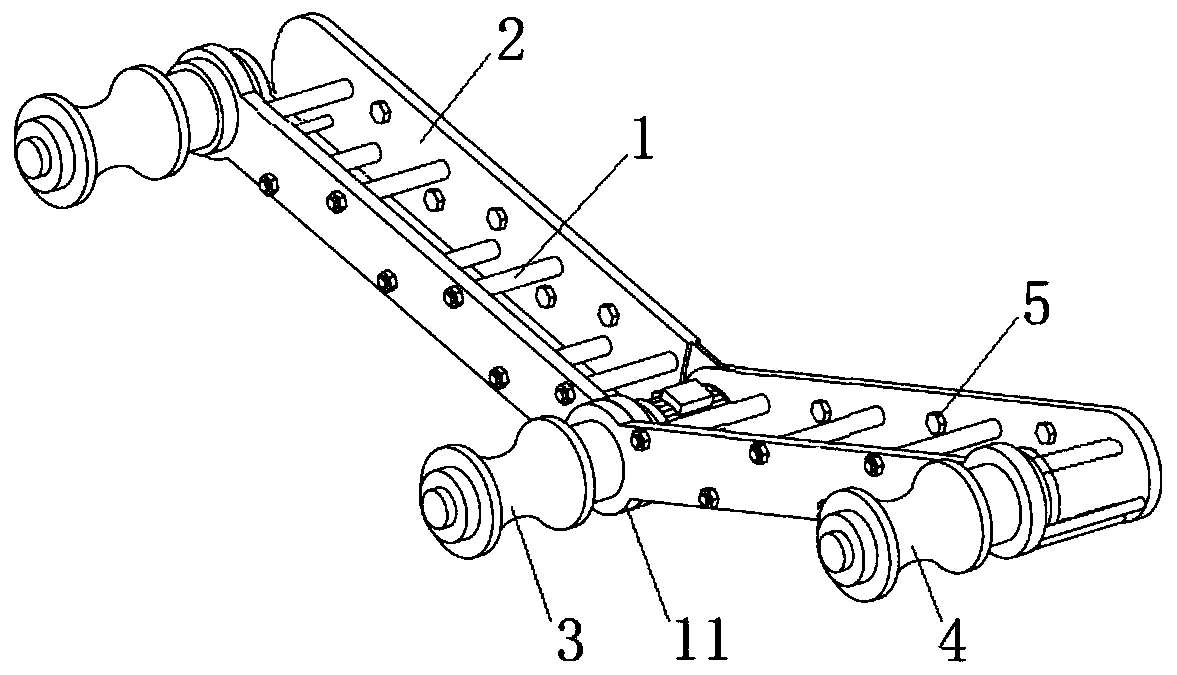

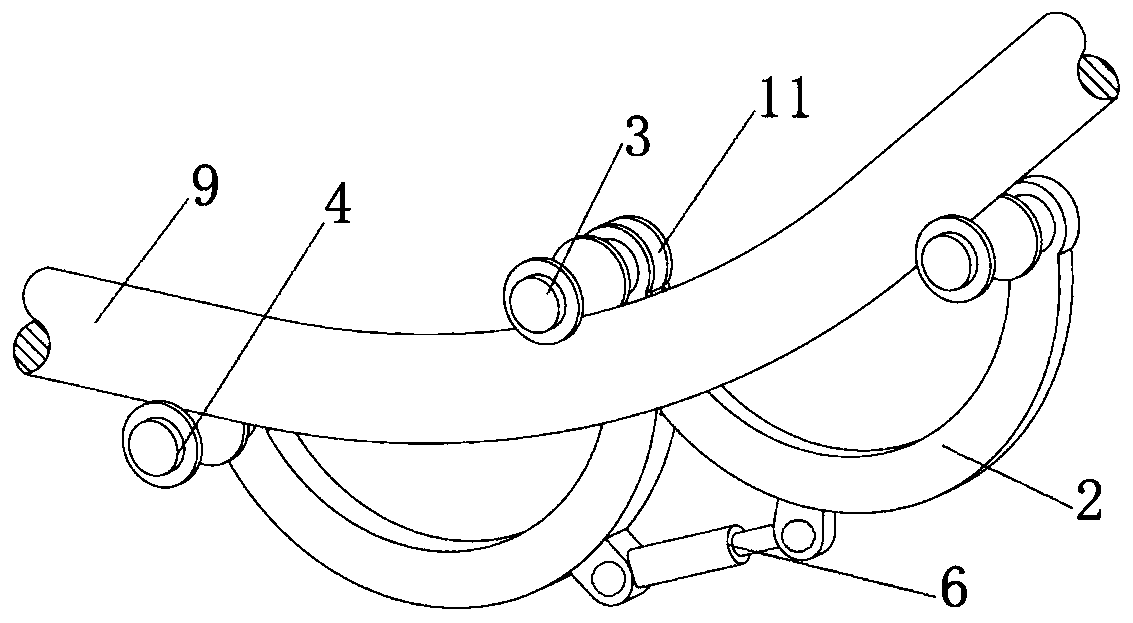

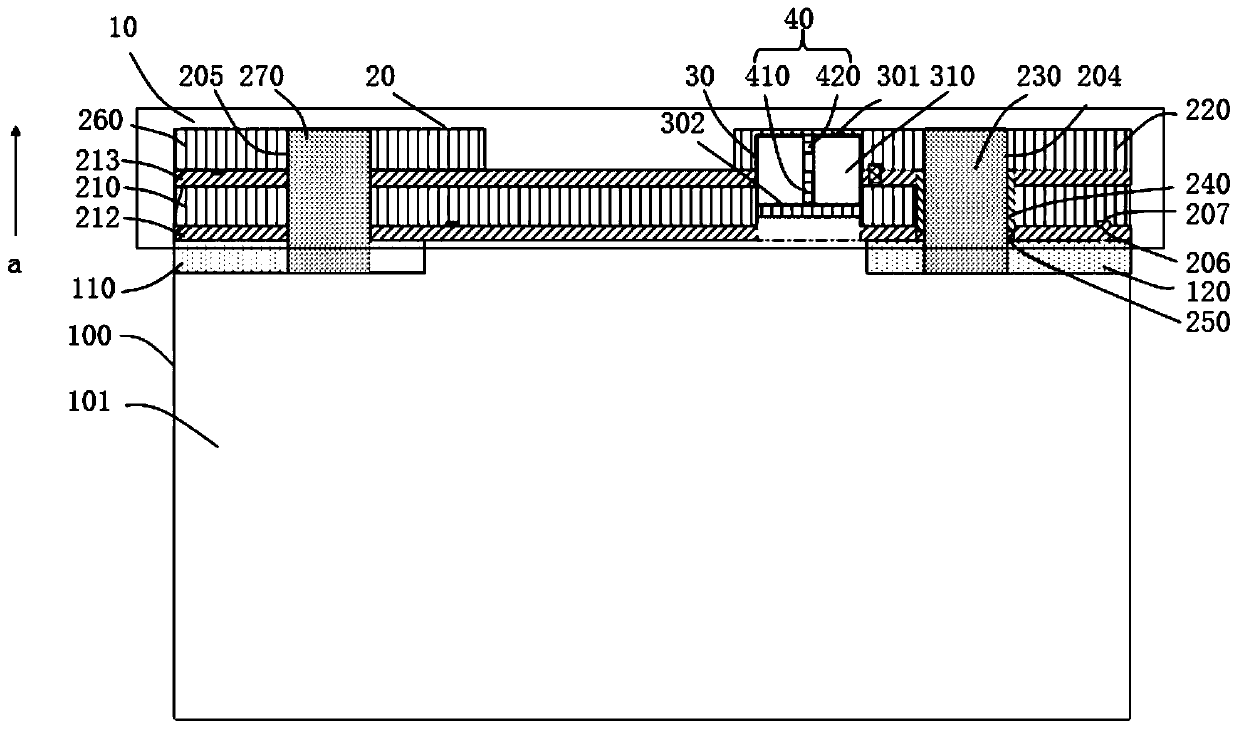

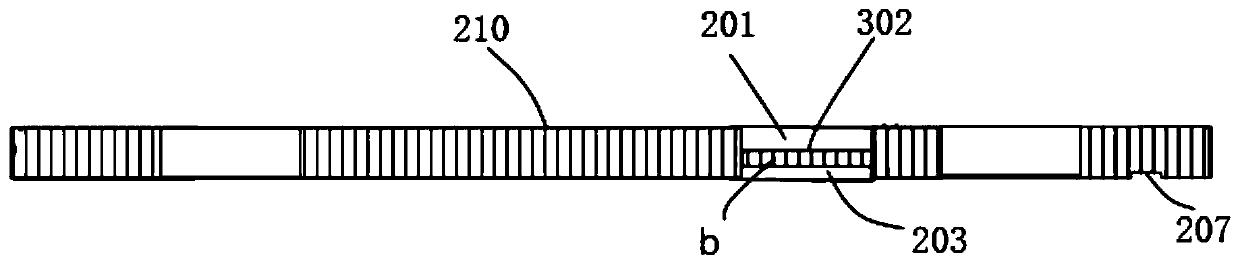

Deformation detection mechanism, pressure vessel detection device and detection system

ActiveCN114878320AReduce the chance of explosionLow trial safetyNuclear energy generationMaterial strength using tensile/compressive forcesStructural engineeringMechanics

The invention relates to a deformation detection mechanism, a pressure vessel detection device and a detection system, and relates to the technical field of pressure vessel detection, the detection system comprises an inflation device and a pressure vessel detection device, the pressure vessel detection device comprises a rack, an adjusting mechanism and a plurality of deformation detection mechanisms, the deformation mechanism comprises a connecting frame, a first driving assembly, two fishbone plates and two displacement detection assemblies, the two fishbone plates are arranged on the two sides of the connecting frame respectively, the fishbone plates are rotationally connected to the connecting frame, the first driving assembly is arranged on the fishbone plates, one displacement detection assembly corresponds to one fishbone plate, and the other displacement detection assembly corresponds to the other fishbone plate. The displacement detection assembly comprises a displacement sensor, and the displacement sensor is arranged on the fishbone plate. According to the invention, the explosion probability of the pressure vessel during the pressure test can be reduced, the safety is improved, and the technical prejudice that the test safety is low when air is used as a medium is changed.

Owner:济南德洋低温科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com