Coal mine gob area sealing method

A technology for gobs and coal mines, applied in mining equipment, mining equipment, earth cube drilling, etc., can solve problems such as gas explosion accidents, increase the spontaneous combustion probability of floating coal, etc., achieve low spontaneous combustion probability, low gas explosion probability, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

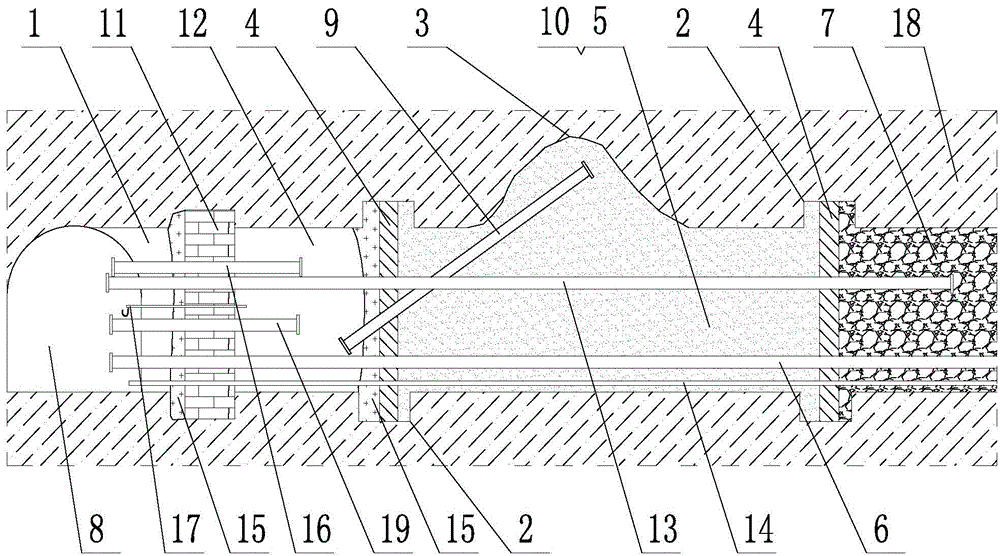

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The sealing method of the described coal mine goaf comprises the following steps:

[0027] Step 1: Excavate two grooves 2 on the surrounding rock 18 of the roadway near the stop line in the air inlet and return airway 1 of the working face, and the two grooves 2 are distributed at intervals, and the interval distance is 10m;

[0028] Step 2: Excavate a conical cave 3 on the roadway roof between the two grooves 2, the cave height is 2m;

[0029] Step 3: Embedding baffle walls 4 in the two grooves 2 respectively, and the first sealed chamber 5 is composed of the two baffle walls 4 and the roadway surrounding rock between the baffle walls;

[0030] Step 4: install the sand injection pipe 9, the sand injection pipe 9 passes through the baffle wall 4, one end is located in the conical cave 3 of the first sealed chamber 5, the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com