Patents

Literature

60results about How to "Improve boiler efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

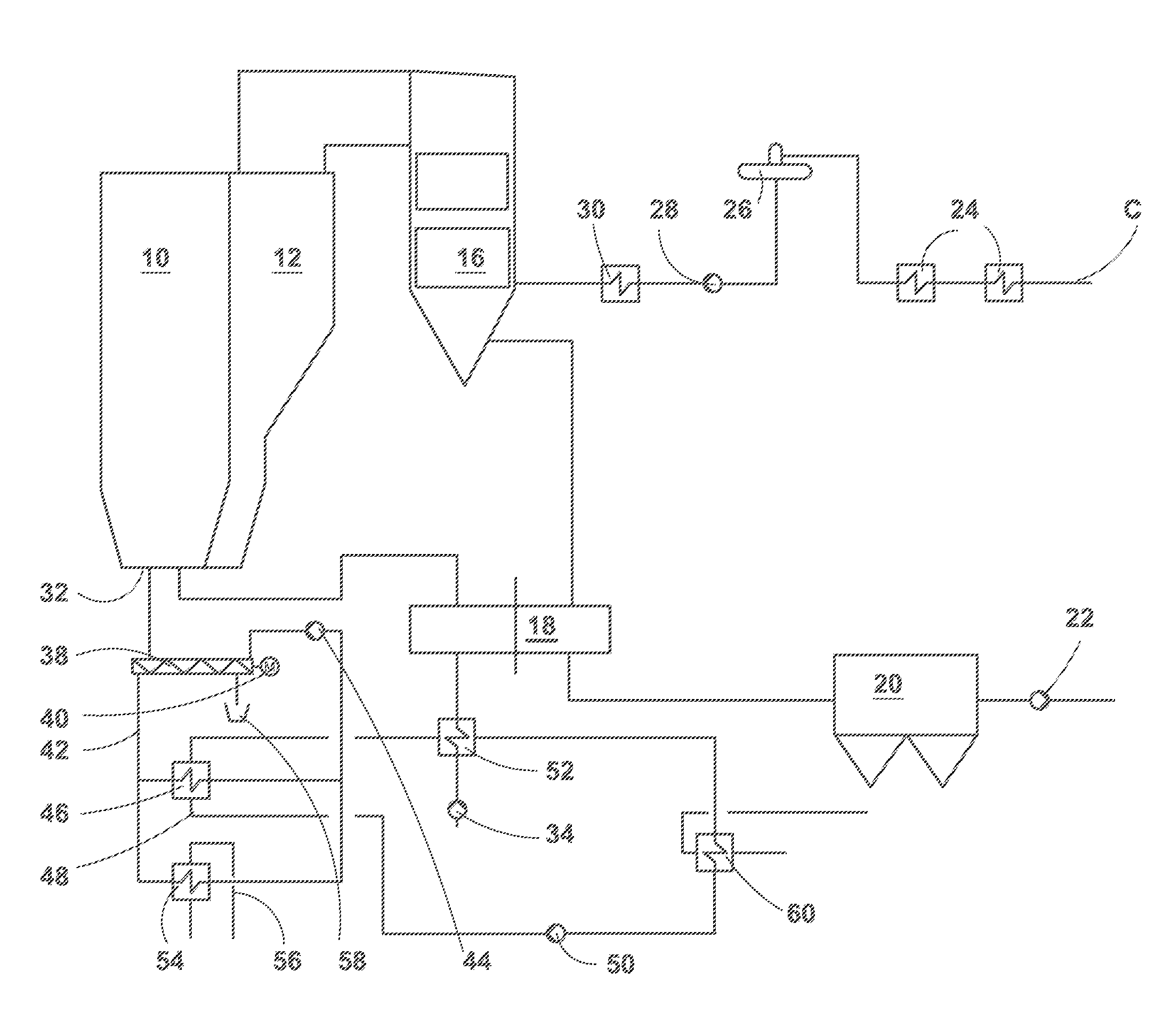

Apparatus for heat treatment of particulate materials

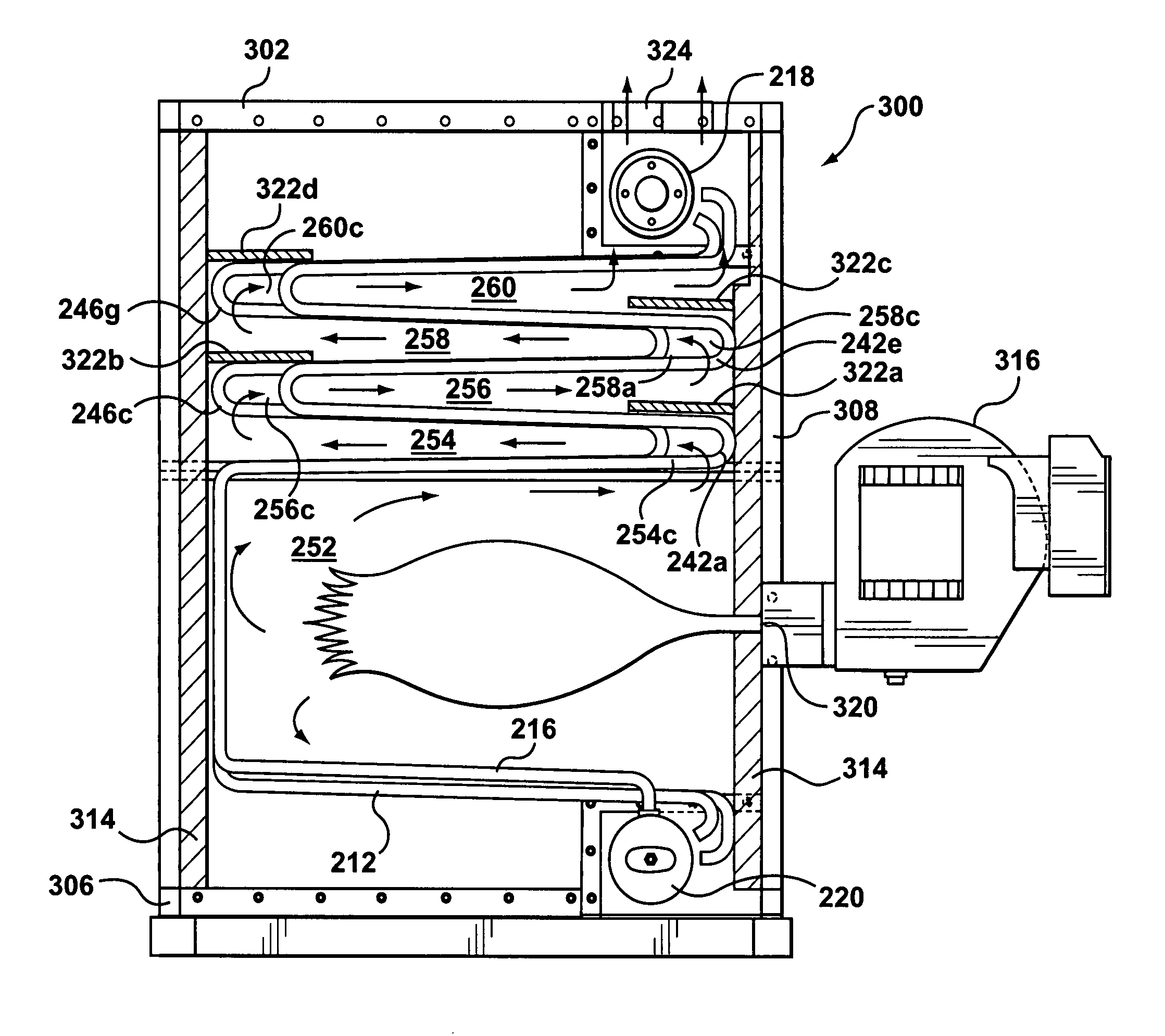

ActiveUS20060107587A1Reduce operating costsIncrease dryer efficiencyDrying solid materials with heatSolid fuelsParticulatesFluidized bed drying

The present invention constitutes a heat treatment apparatus like a fluidized-bed dryer for heat treating a particulate material in a low temperature, open-air process. Preferably, available waste heat sources within the surrounding industrial plan operation are used to provide heat to the dryer. Moreover, conveyor means contained within the dryer can remove larger, denser particles that could otherwise impede the continuous flow of the particulate material through the dryer or plug the fluidizing dryer. This invention is especially useful for drying coal for an electricity generation plant.

Owner:RAINBOW ENERGY CENT LLC

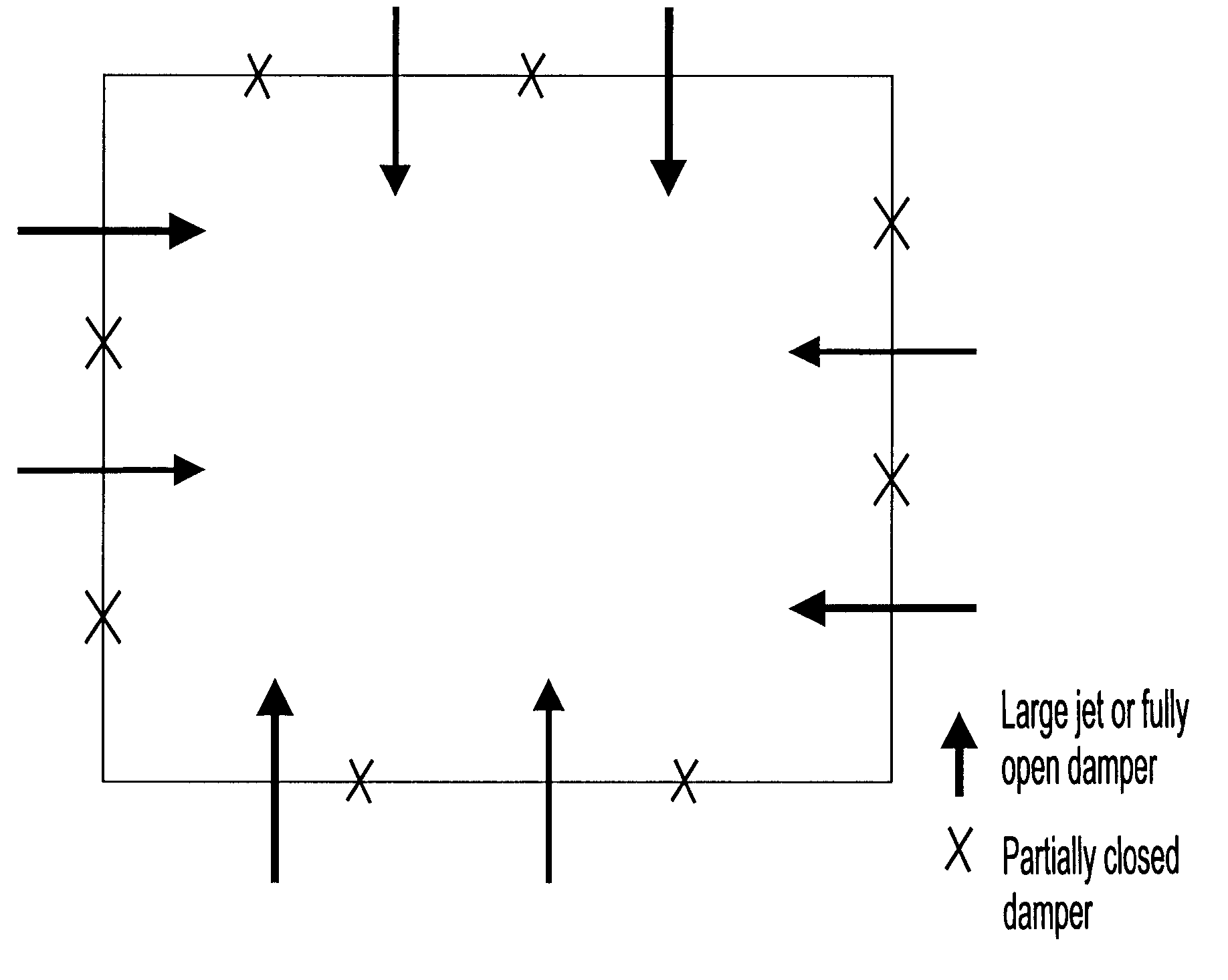

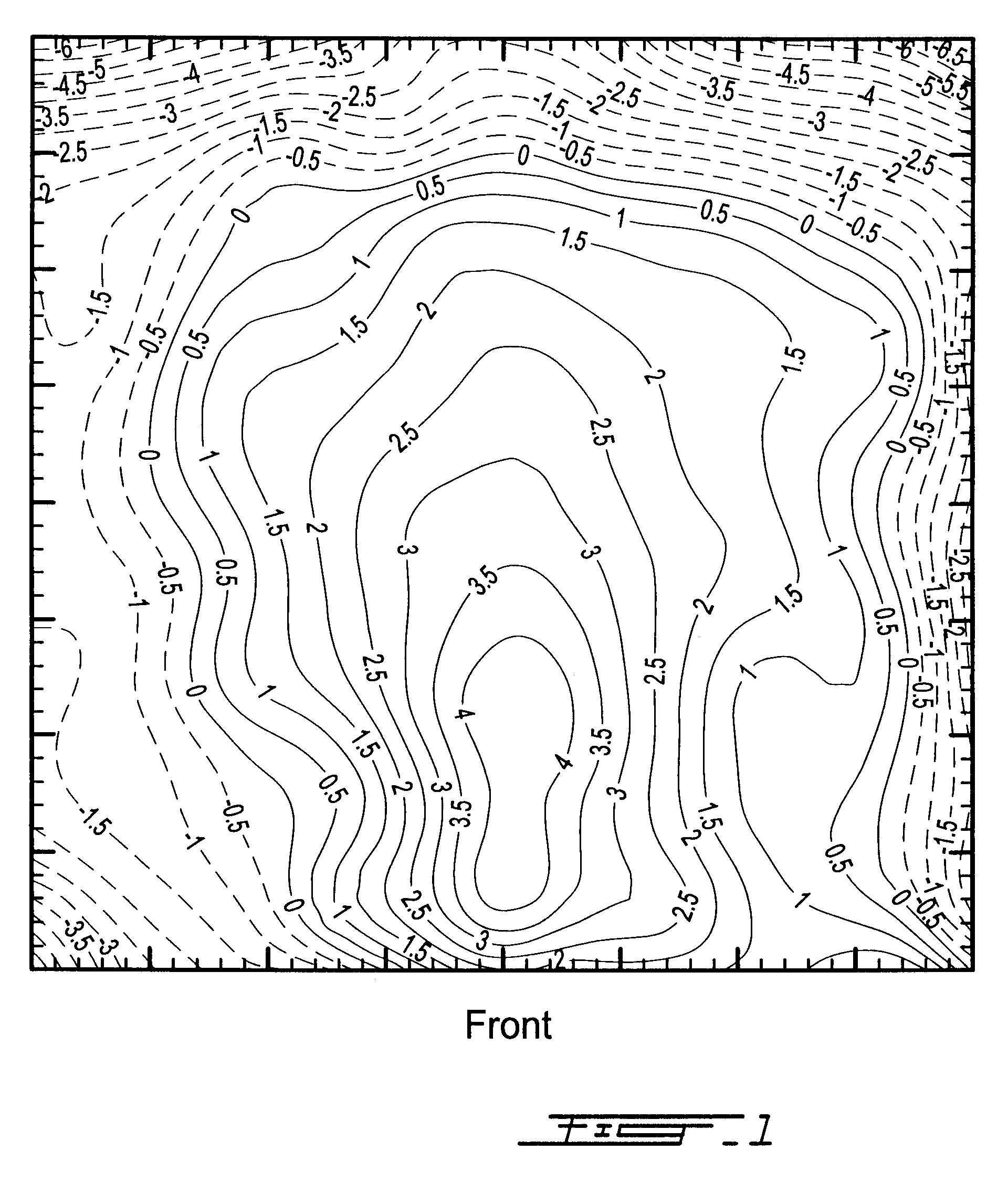

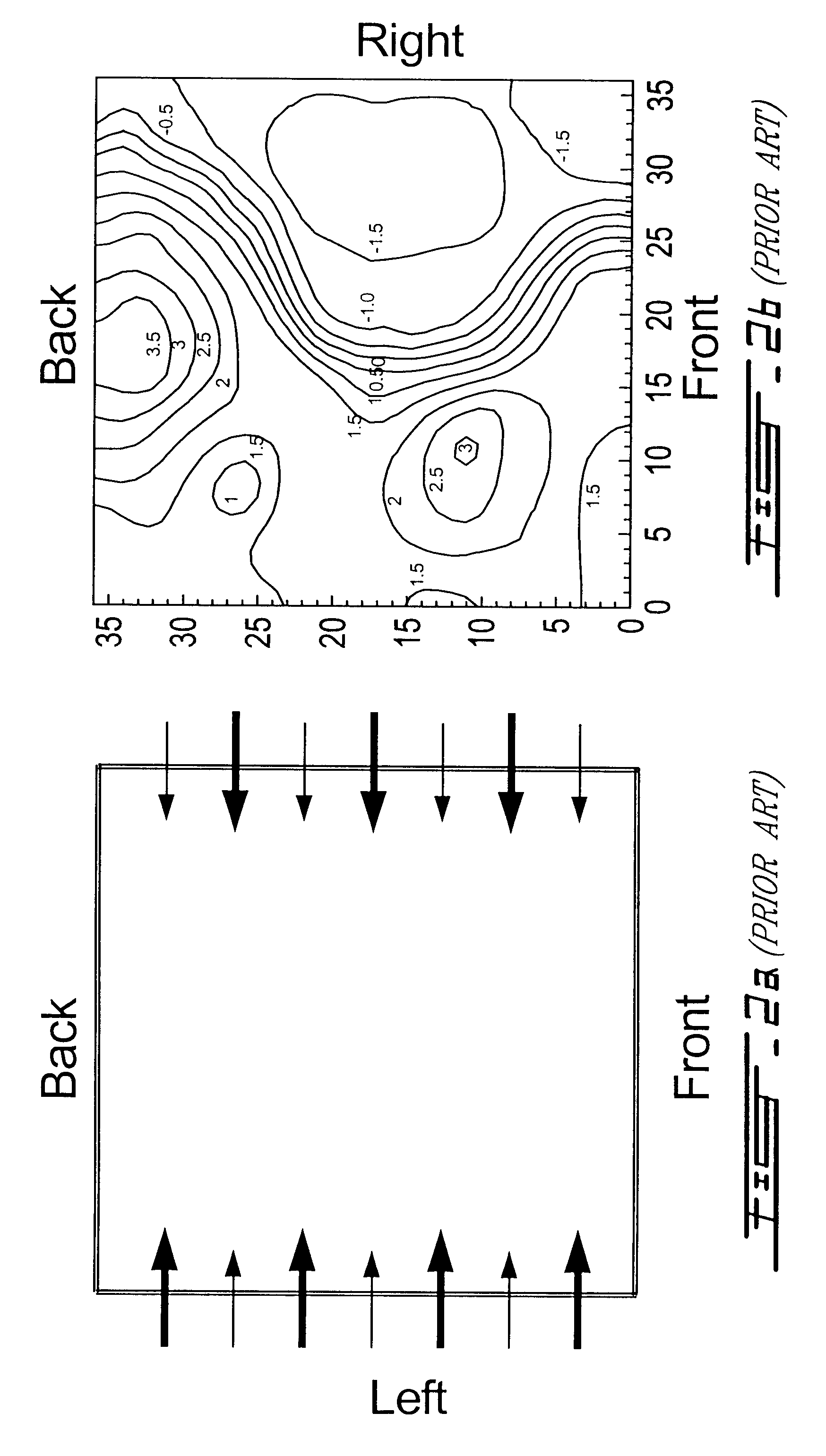

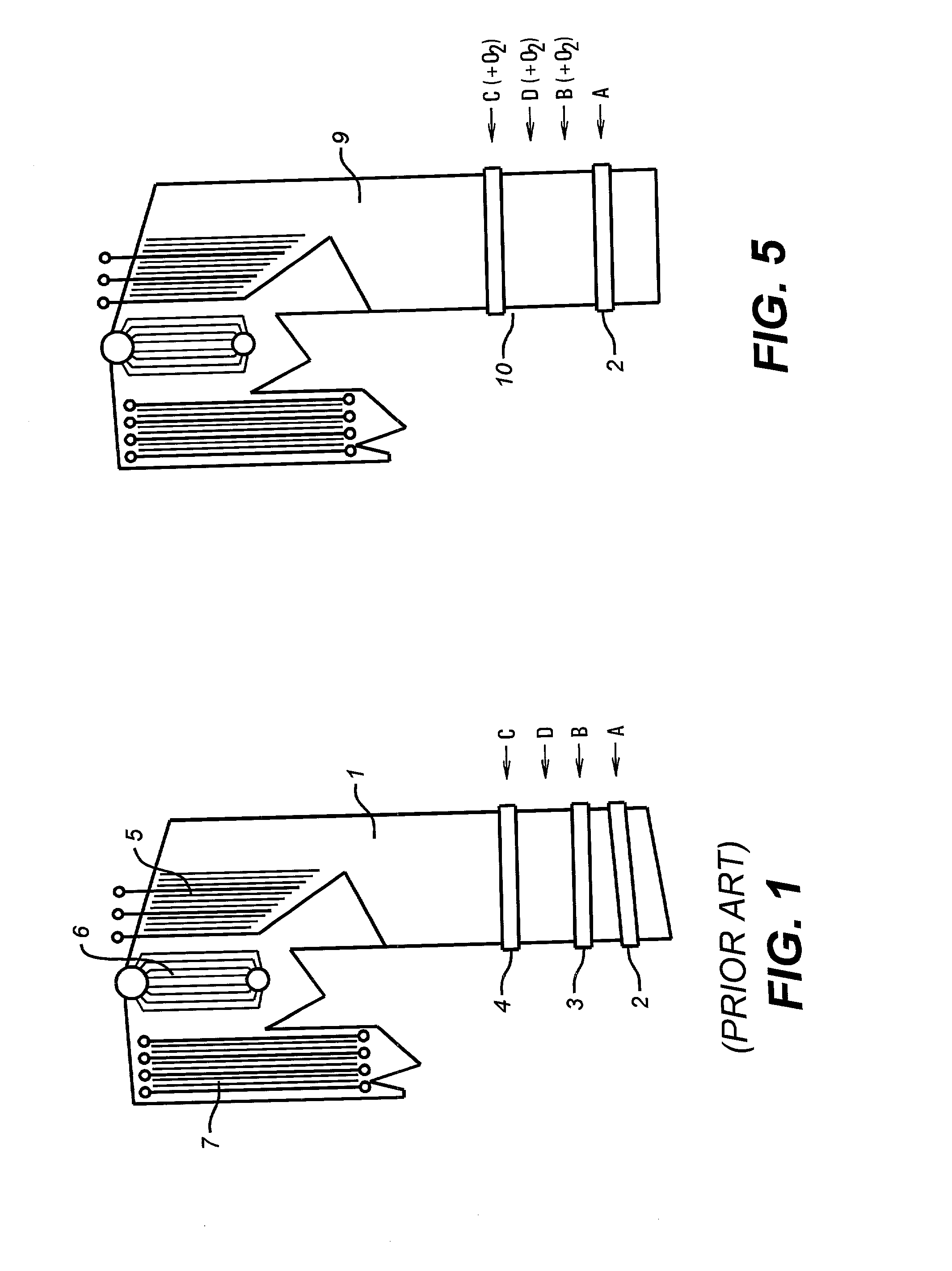

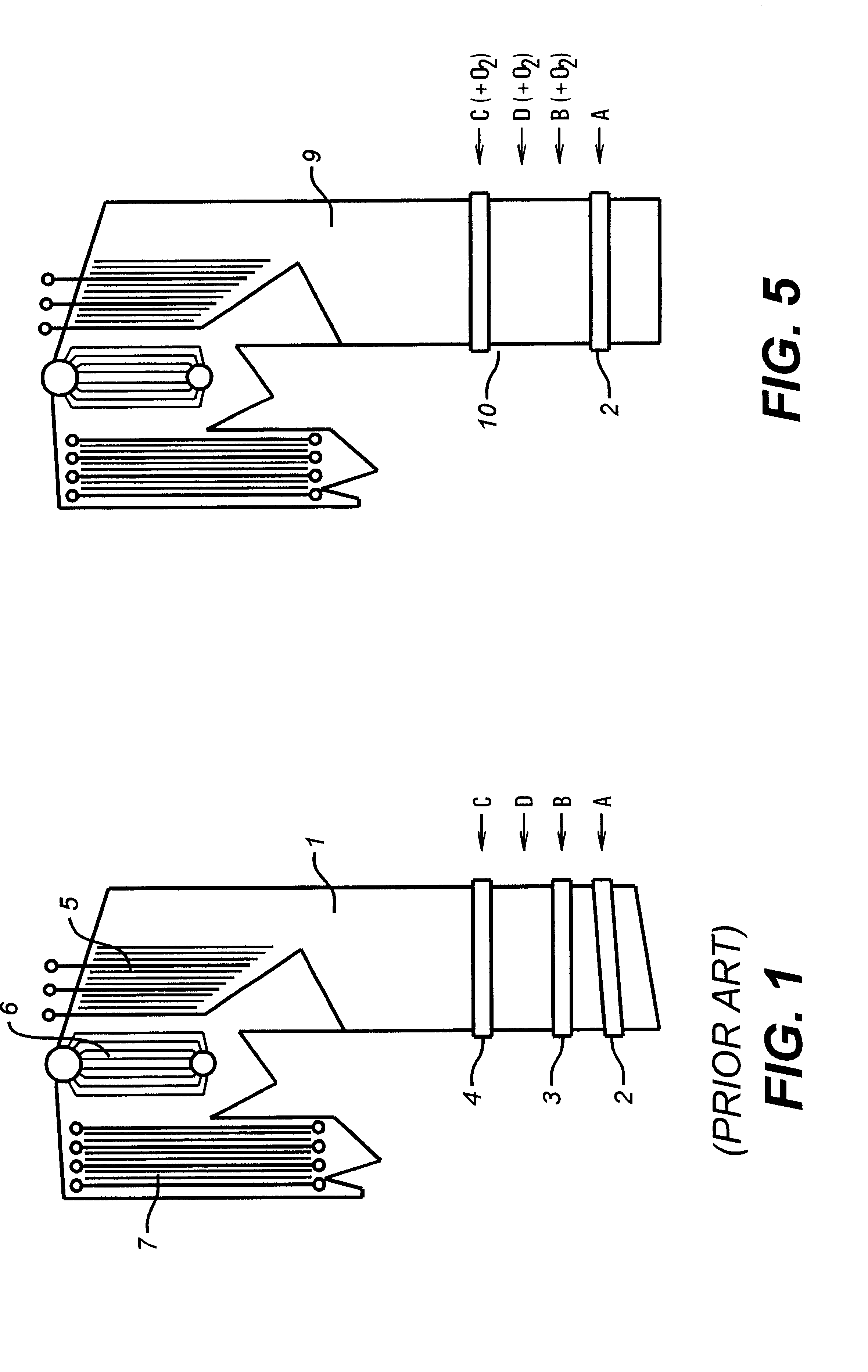

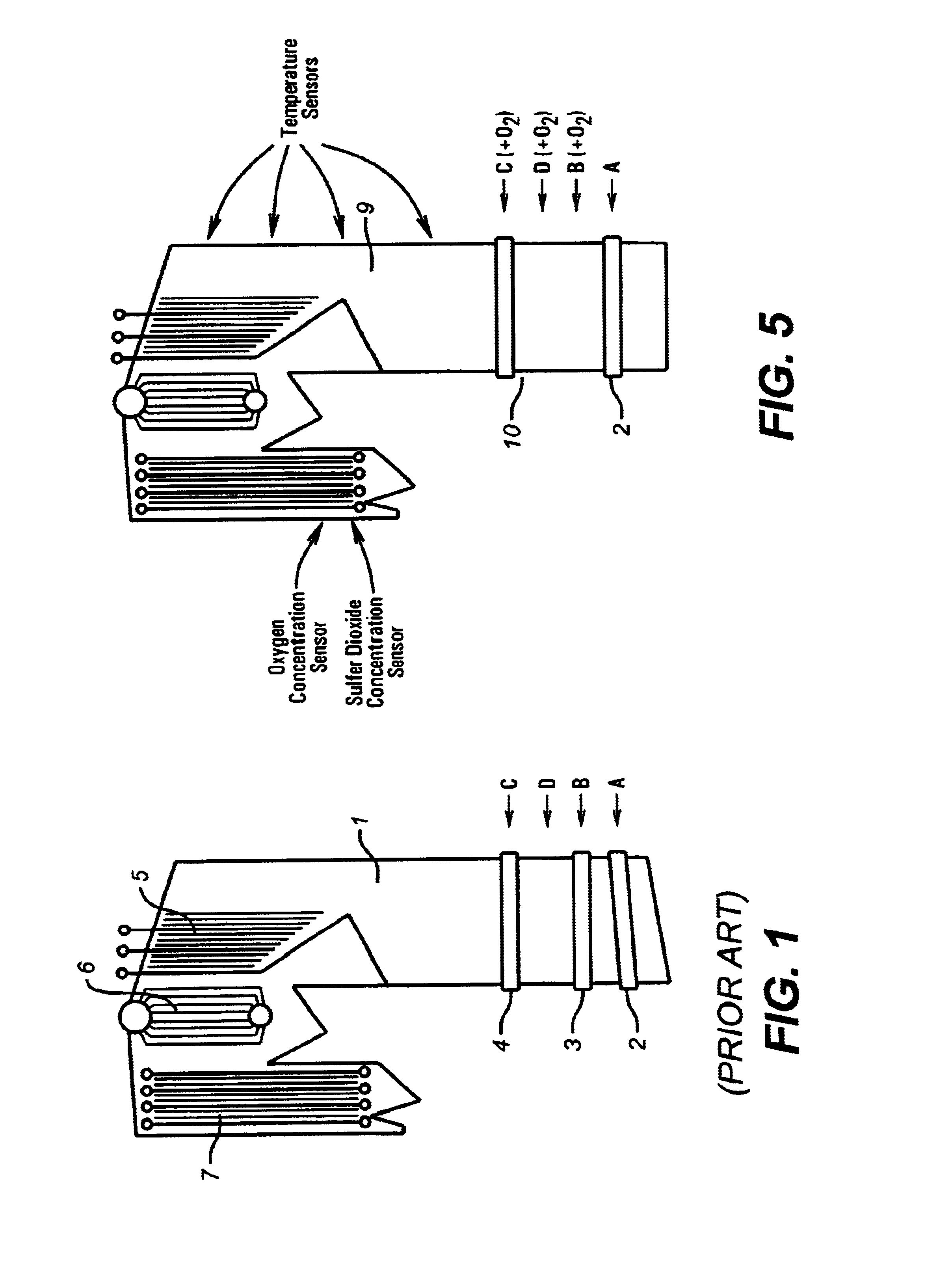

Method and apparatus for optimizing the combustion air system in a recovery boiler

InactiveUS6279495B1Improve boiler efficiencyAvoid costly modificationPulp liquors combustionSolid fuel combustionParticulatesChemical recovery

A method and an apparatus for optimizing the combustion air system in a power boiler or chemical recovery boiler by improving fluid flow and gas mixing are disclosed, whereby one can increase boiler capacity and combustion uniformity and reduce particulate and gaseous emissions. The method involves interlacing of the secondary and, where applicable, the tertiary air supply through opposing air ports on all four walls of the boiler, and is implemented by alternately opening wide or partially closing a port damper on one side, while partially closing or opening wide a port damper on the opposite side, such that a 70-100% open damper on one side opposes a partially closed (10-40% open) damper on the other and vice versa in an alternating fashion, along opposing walls. In a preferred embodiment, the optimization is further enhanced by balancing primary air flow, achieved by adjusting port dampers and windbox pressures so that the primary air flow is evenly distributed between opposite walls, between all four walls of the boiler and between individual airports on each wall. Windbox pressure and other key measurements of boiler operation ensure proper balancing and an adequate interlacing of air flows at the primary, secondary and tertiary elevations, respectively.

Owner:FPINNOVATIONS INC

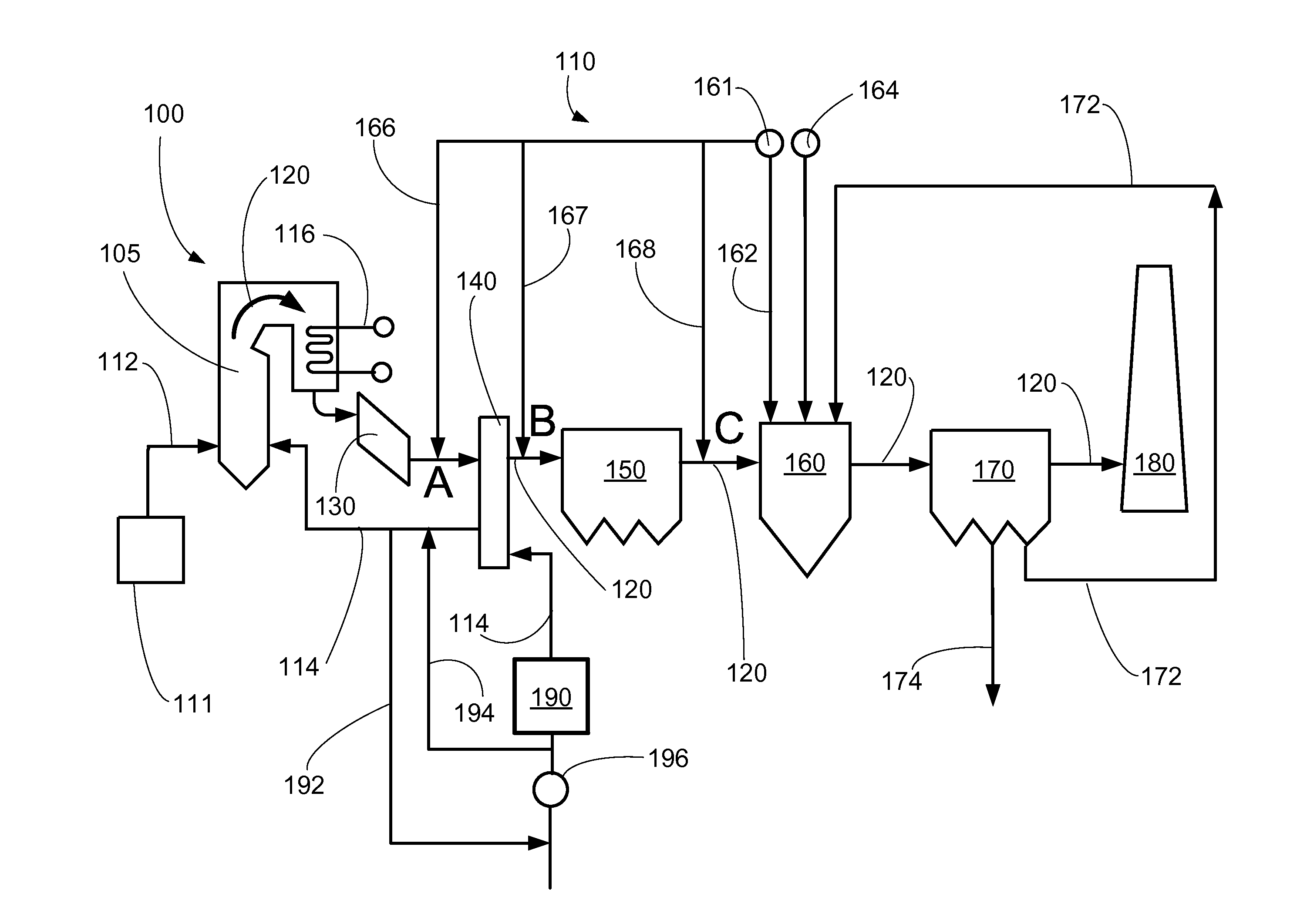

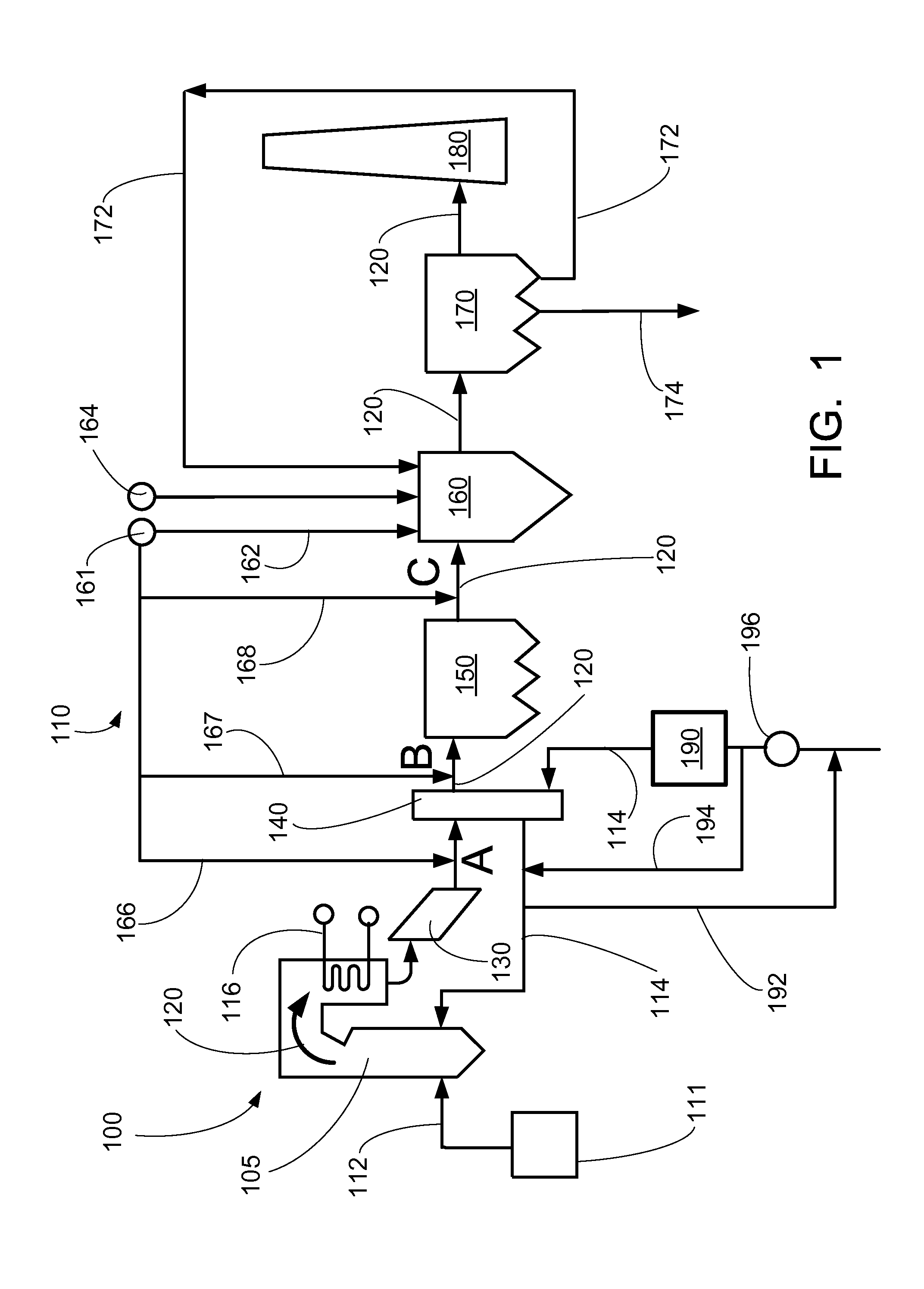

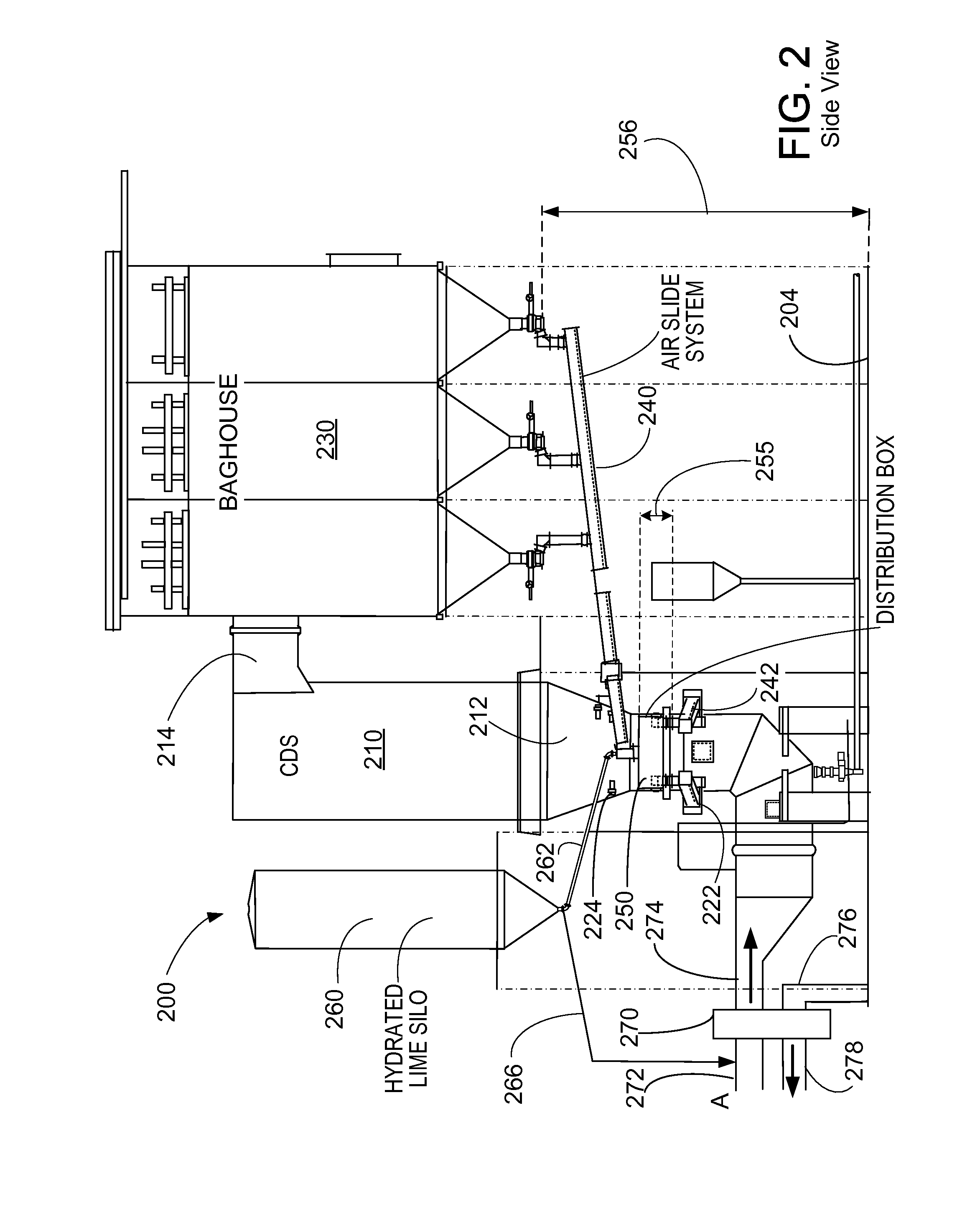

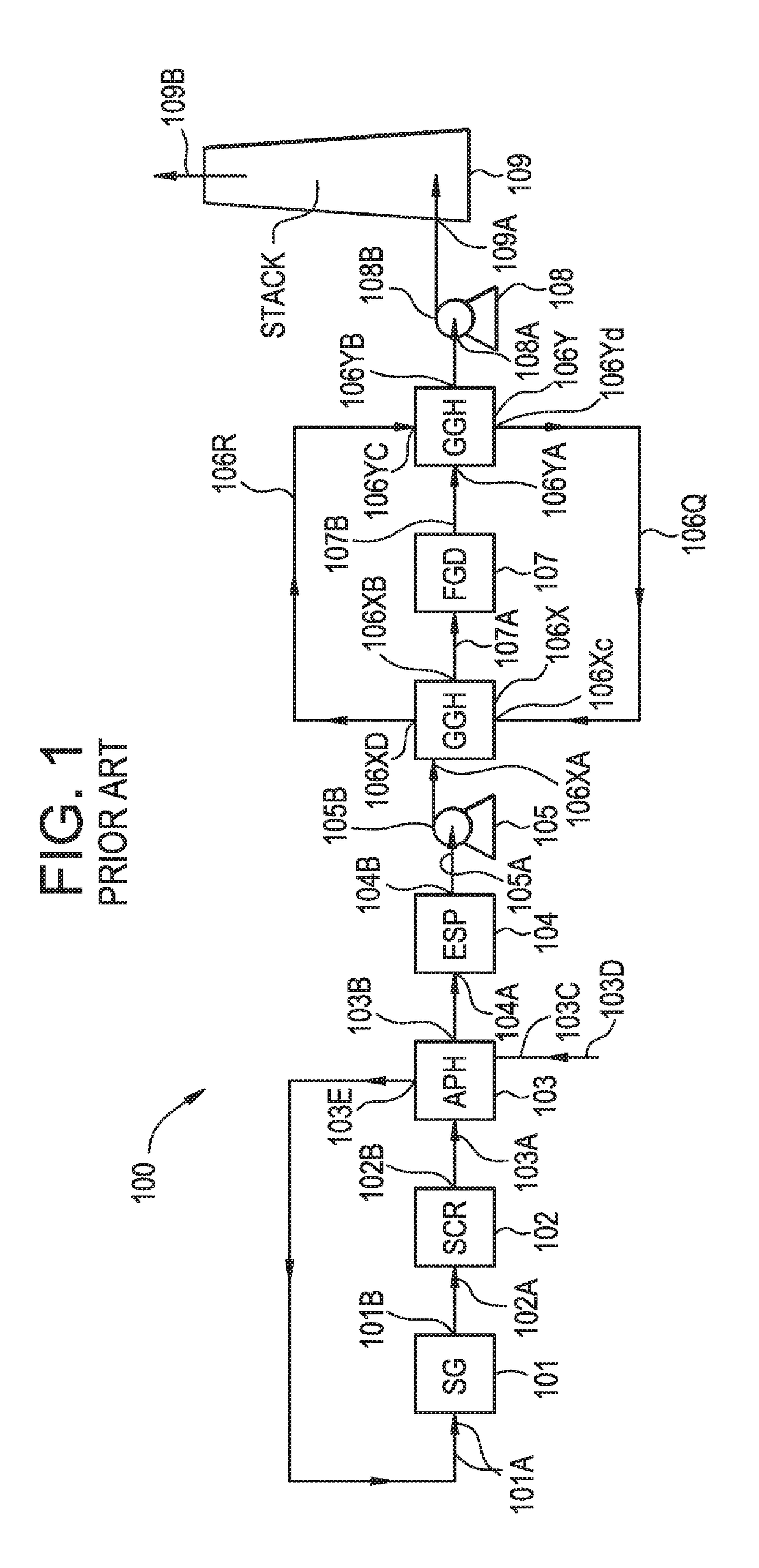

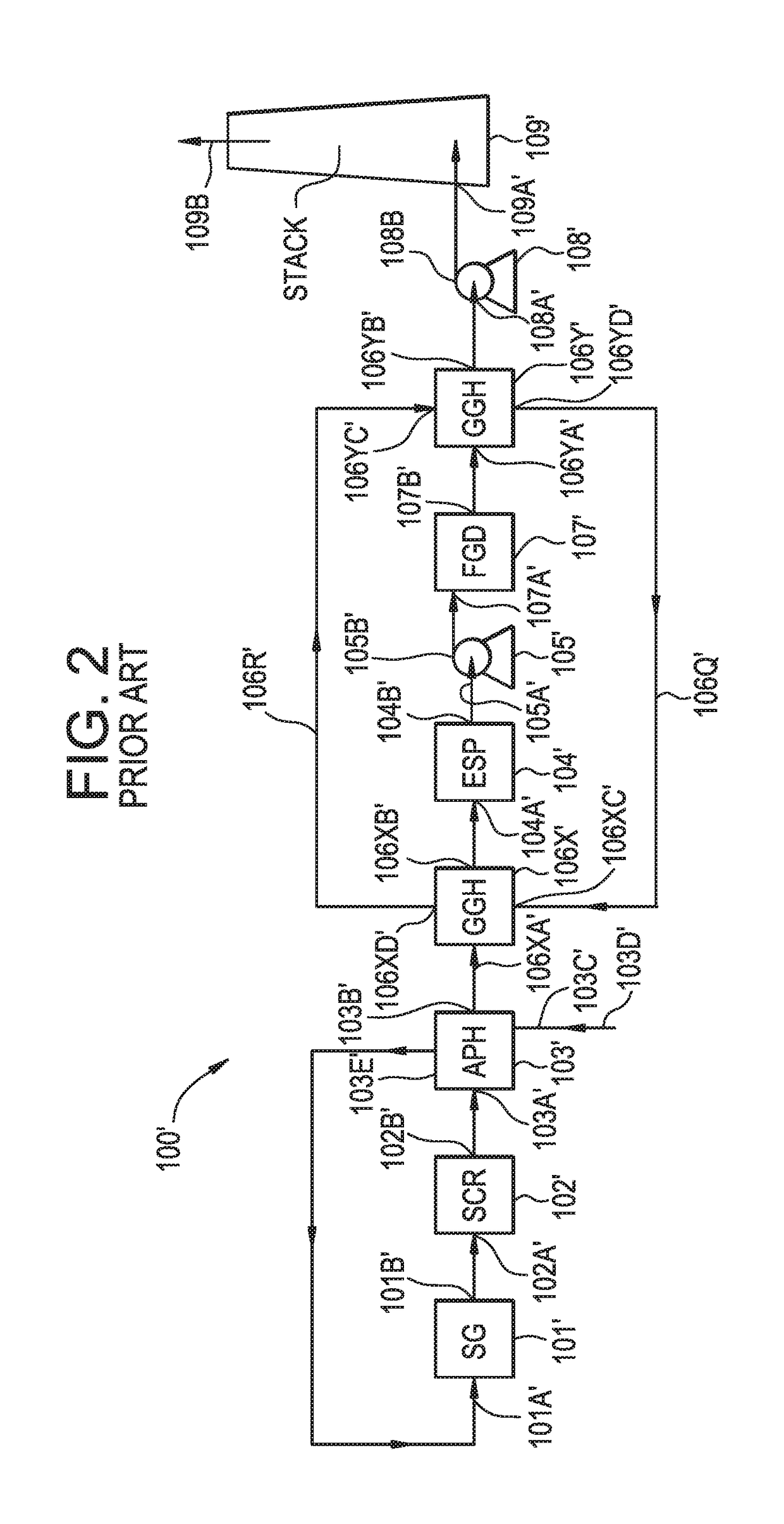

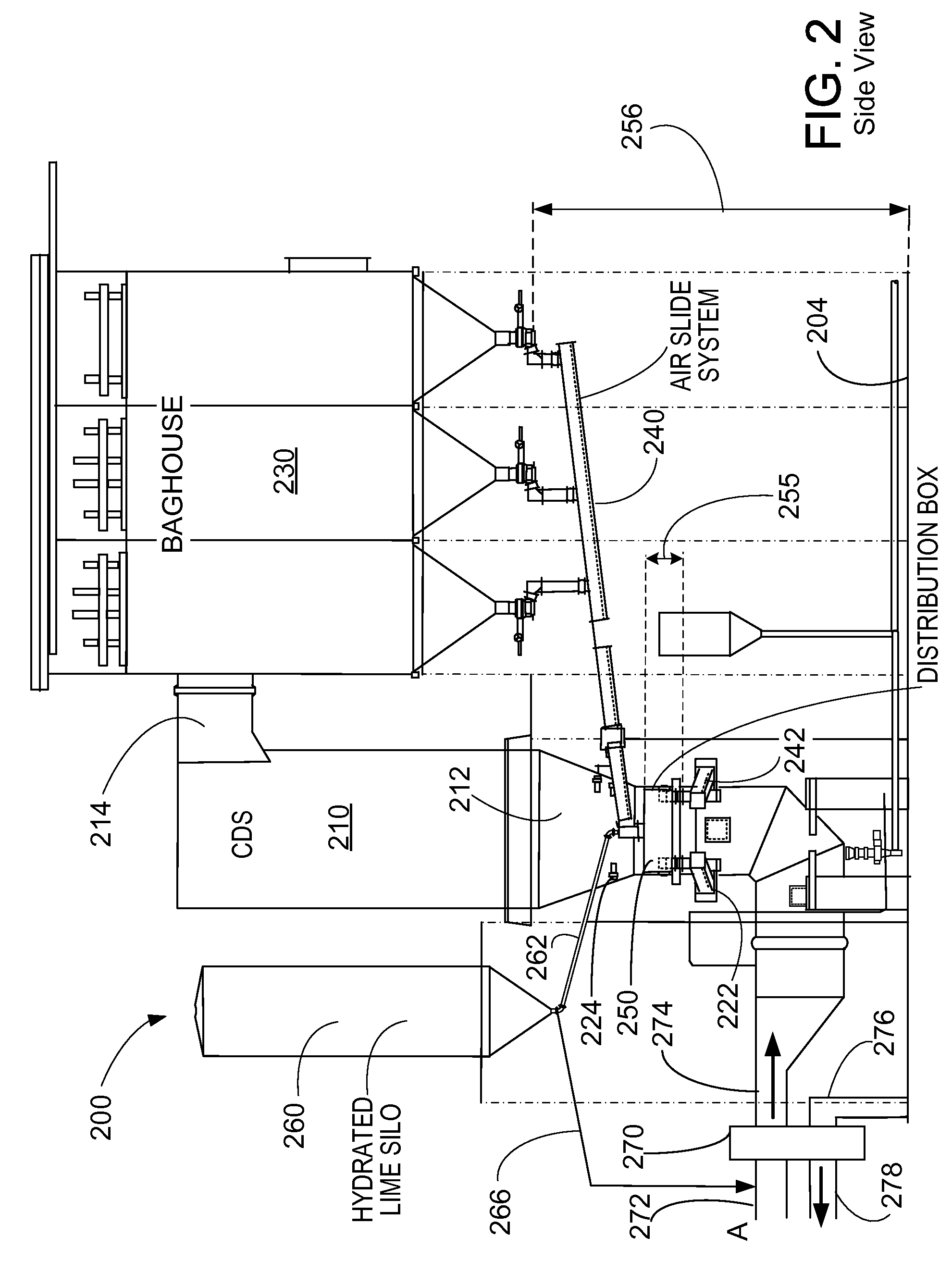

Integrated sorbent injection and flue gas desulfurization system

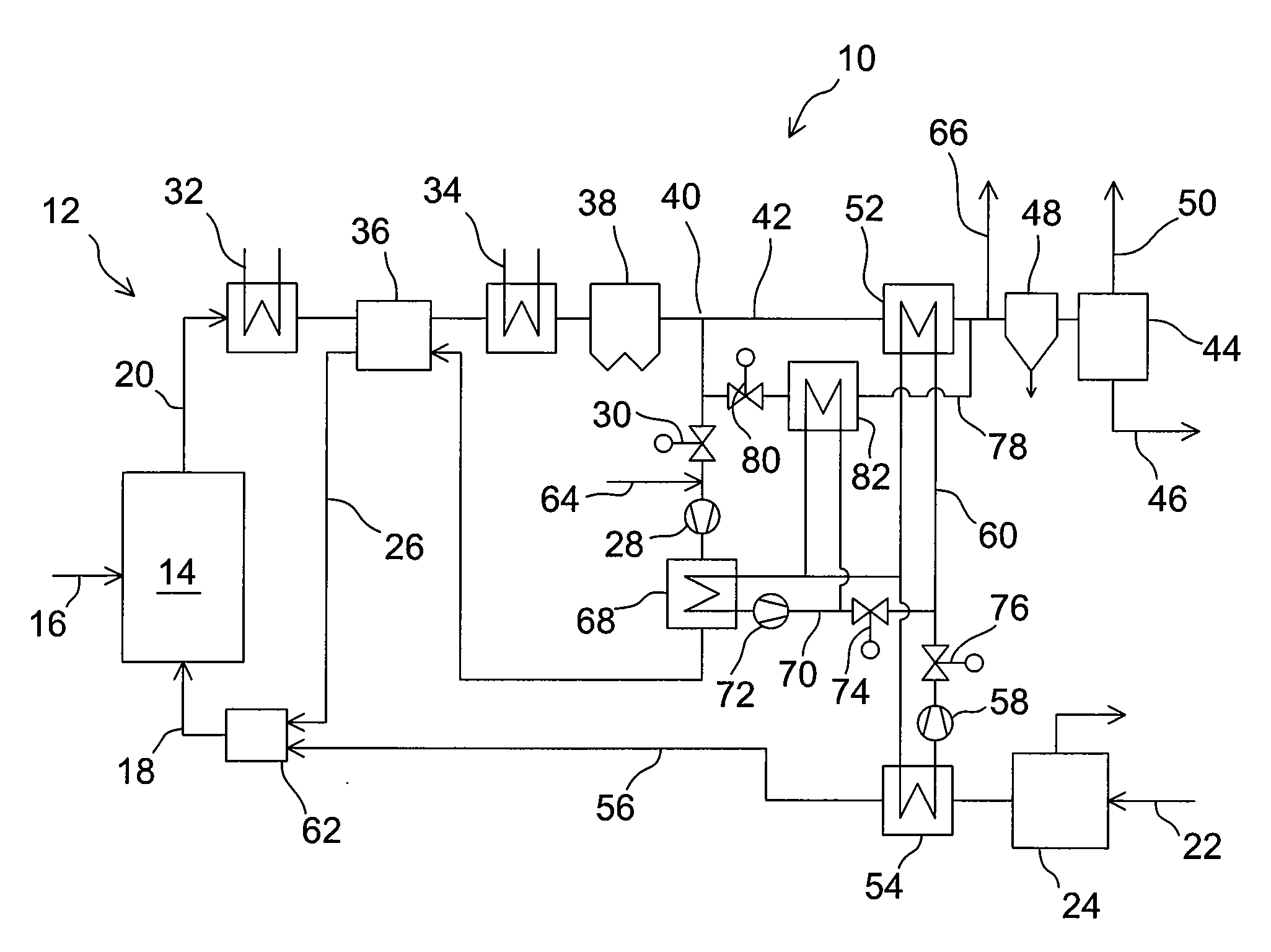

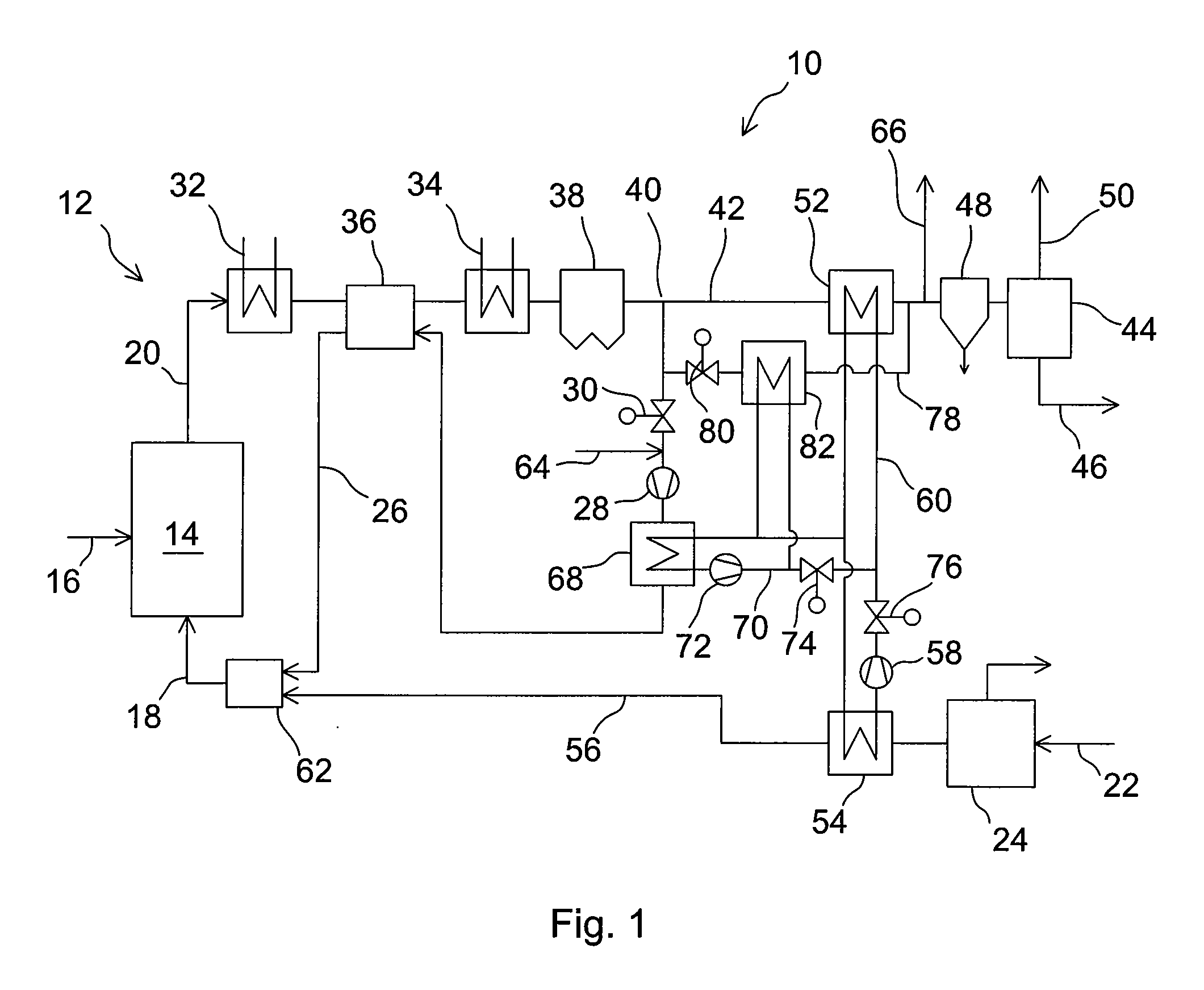

ActiveUS20150139882A1Operational securityLowering of average gas temperatureCombination devicesGas treatmentThermal energySorbent

An integrated sorbent injection, heat recovery, and flue gas desulfurization system is disclosed. A dry sorbent is injected into the flue gas upstream of the air heater. This reduces the acid dew point temperature, permitting additional heat energy to be captured when the flue gas passes through the air heater. The flue gas then passes through a desulfurization unit and through a baghouse, where solids are captured. The capture of additional heat energy permits the overall boiler efficiency to be increased while safely operating at a lower flue gas temperature. The integrated system consumes no greater quantity of sorbent than conventional methods but provides the benefit of improved plant heat rate.

Owner:THE BABCOCK & WILCOX CO

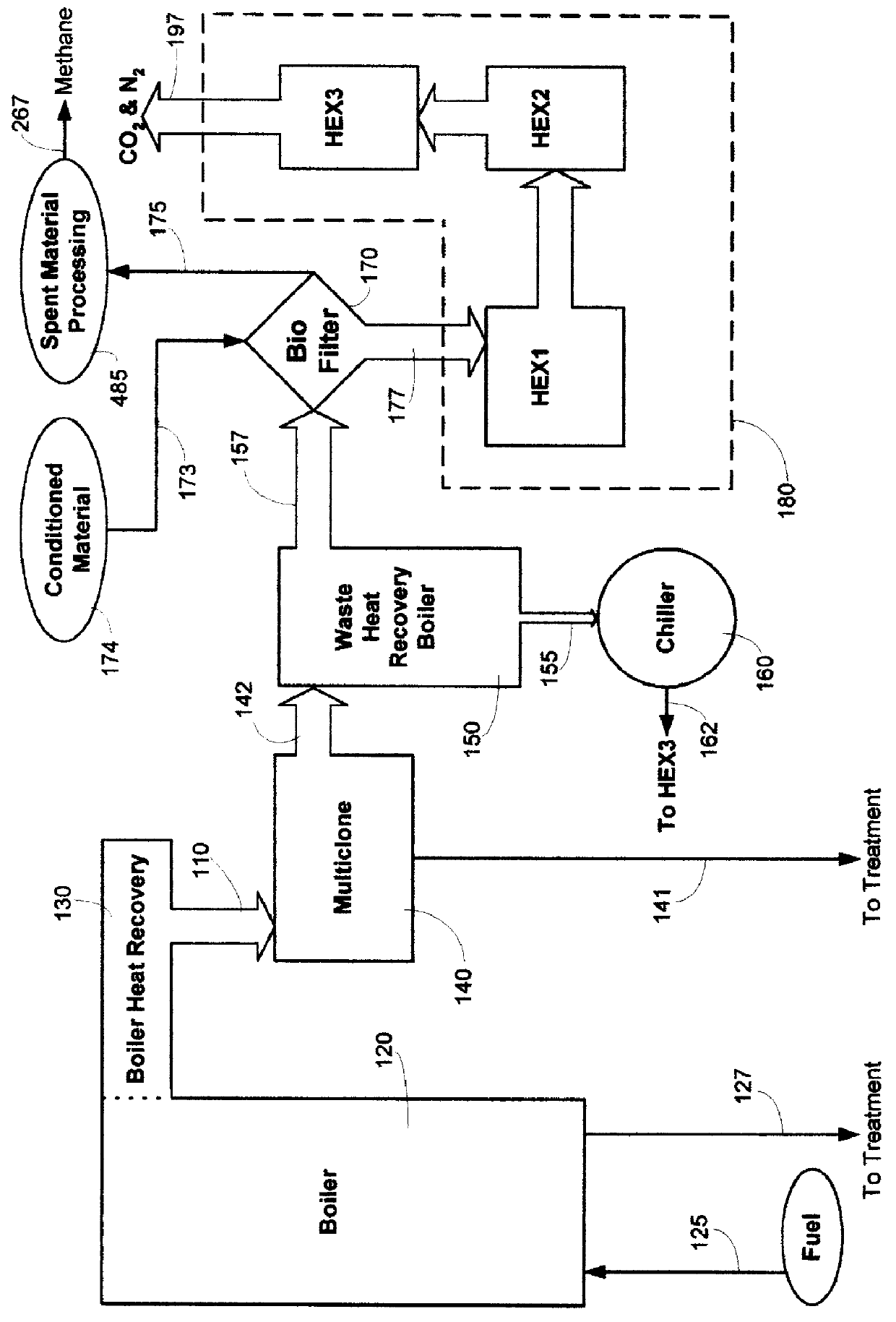

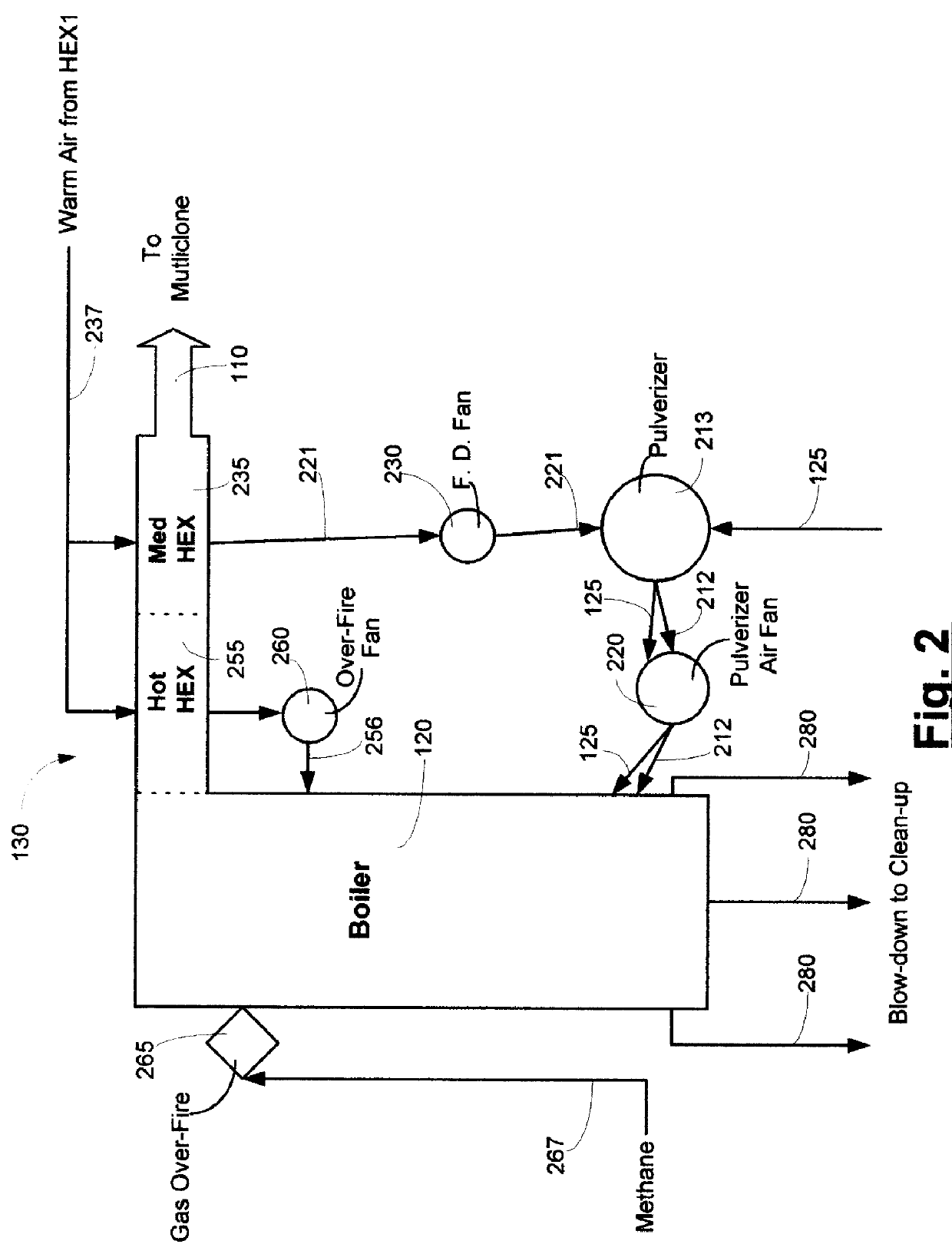

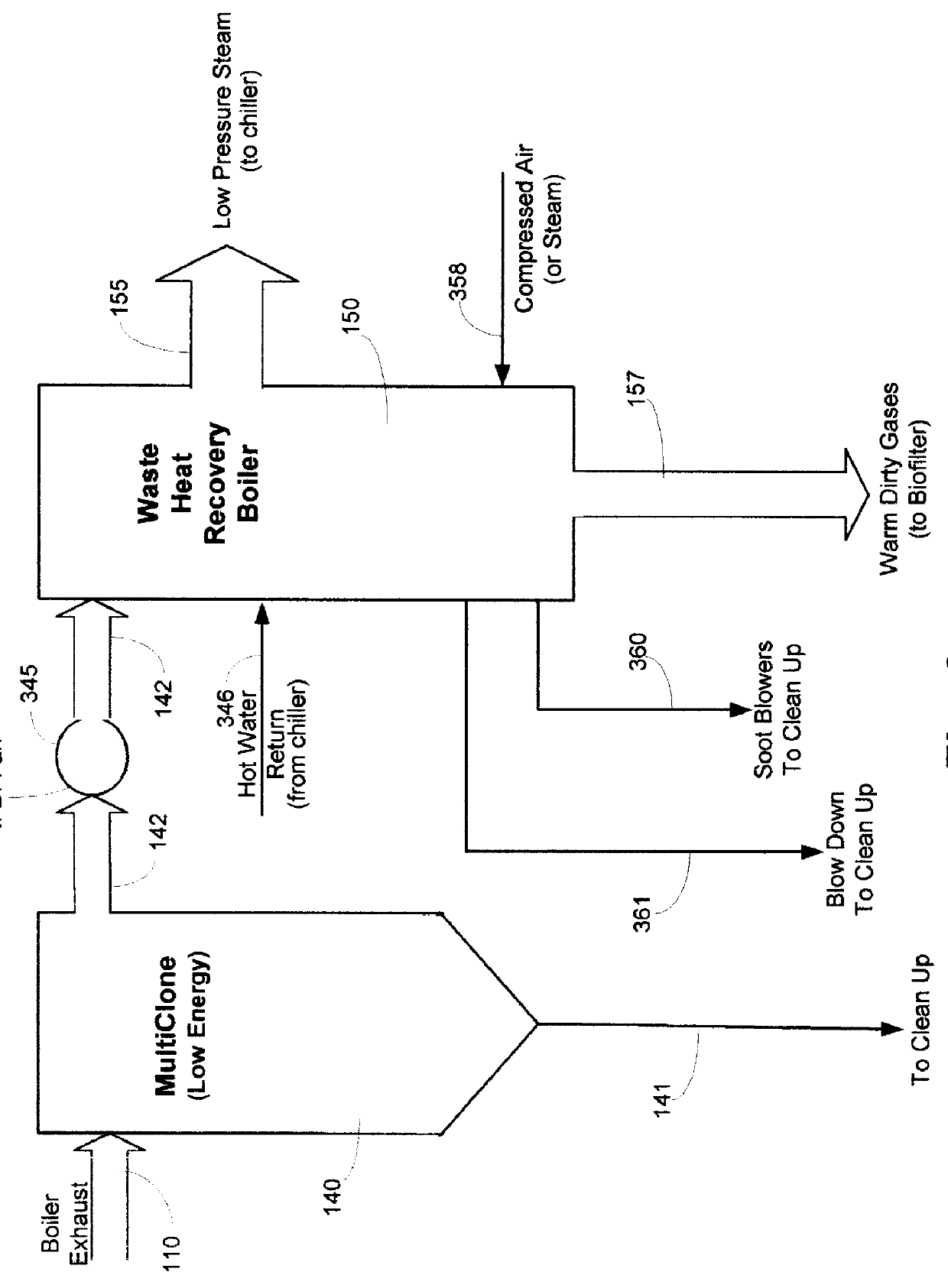

Moving bed biofilter and condenser for flue gas pollutant removal and collection

InactiveUS6117672ALow costReduce water consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid wasteCombustion chamber

A system for removing particulate, sulfur dioxide, nitrogenous oxides and other condensables from the flue gas of a coal, lignite, or other solid fuel combustor. The system can combine biomass filtration, anaerobic digestion, steam absorption refrigeration, and heat exchangers to minimize parasitic energy consumption, solid and liquid waste disposal and interference with combustion efficiency, while achieving near total reduction of contaminants without regard to sulfur or ash content of fuel. Gases at the exit of a multiclone of a fuel-combustor enter a waste heat boiler, generating low pressure steam that drives a steam absorption chiller. The flue gas which still contains small particulate material pass through a moving belt system conveying a mat of chopped biomass that can be impregnated with bacteria that feed on nitrogenous oxides. The mat is sufficiently thick and moist to entrap the remaining solids and smoke in the exhaust stream. The particulate-free flue gas passes through a staged heat exchanger which can utilize ambient air, pond water, and the refrigerated water from the steam absorption chiller to condense the water vapor in the exhaust stream. Sulfur oxides exits the flue gas stream with the condensed water vapor which can be processed in an anaerobic digester. Methanogenic bacteria within the digester can convert the mat and the acidic condensate into a biogas, a combination of methane and carbon dioxide, and plant growth media.

Owner:TECHN INFORMATION

Method of and system for generating power by oxyfuel combustion

InactiveUS20090293782A1Increase heating capacityIncrease feed rateEmission preventionGas turbine plantsExhaust fumesProcess engineering

A method of generating power by oxyfuel combustion. Carbonaceous fuel and oxidant gas are fed into a furnace. In a first operating mode, the oxidant gas includes a stream of substantially pure oxygen conveyed from an oxygen supply for combusting the fuel with the oxygen to produce exhaust gas including mainly carbon dioxide and water. The exhaust gas is discharged from the furnace and is divided into a recycling portion and an end portion. The recycling portion is recycled to the furnace. Heat is transferred from the end portion to the stream of substantially pure oxygen by circulating a liquid heat transfer medium in a passage between an exhaust gas cooler and an oxygen heater.

Owner:FOSTER WHEELER ENERGIA OY

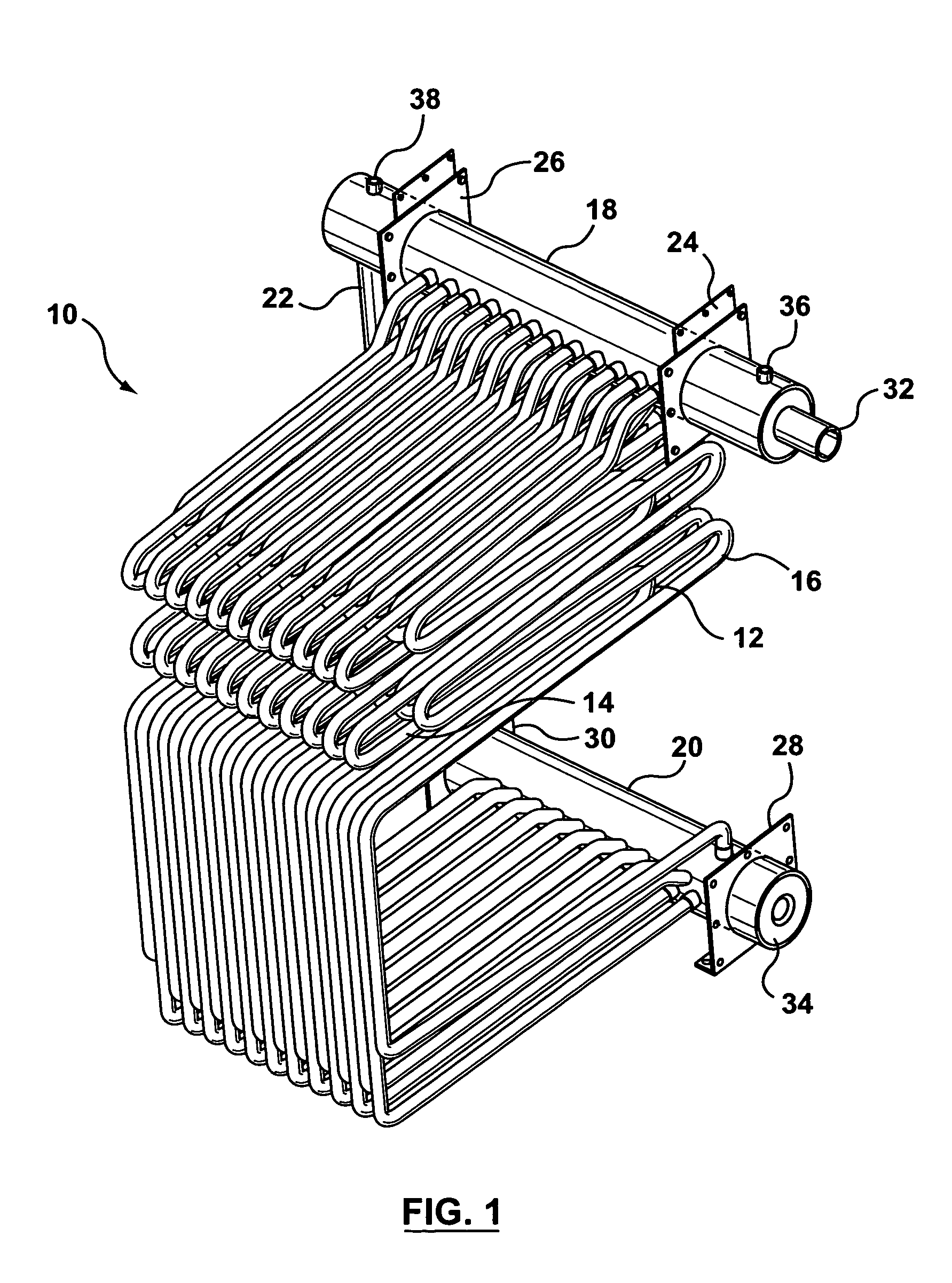

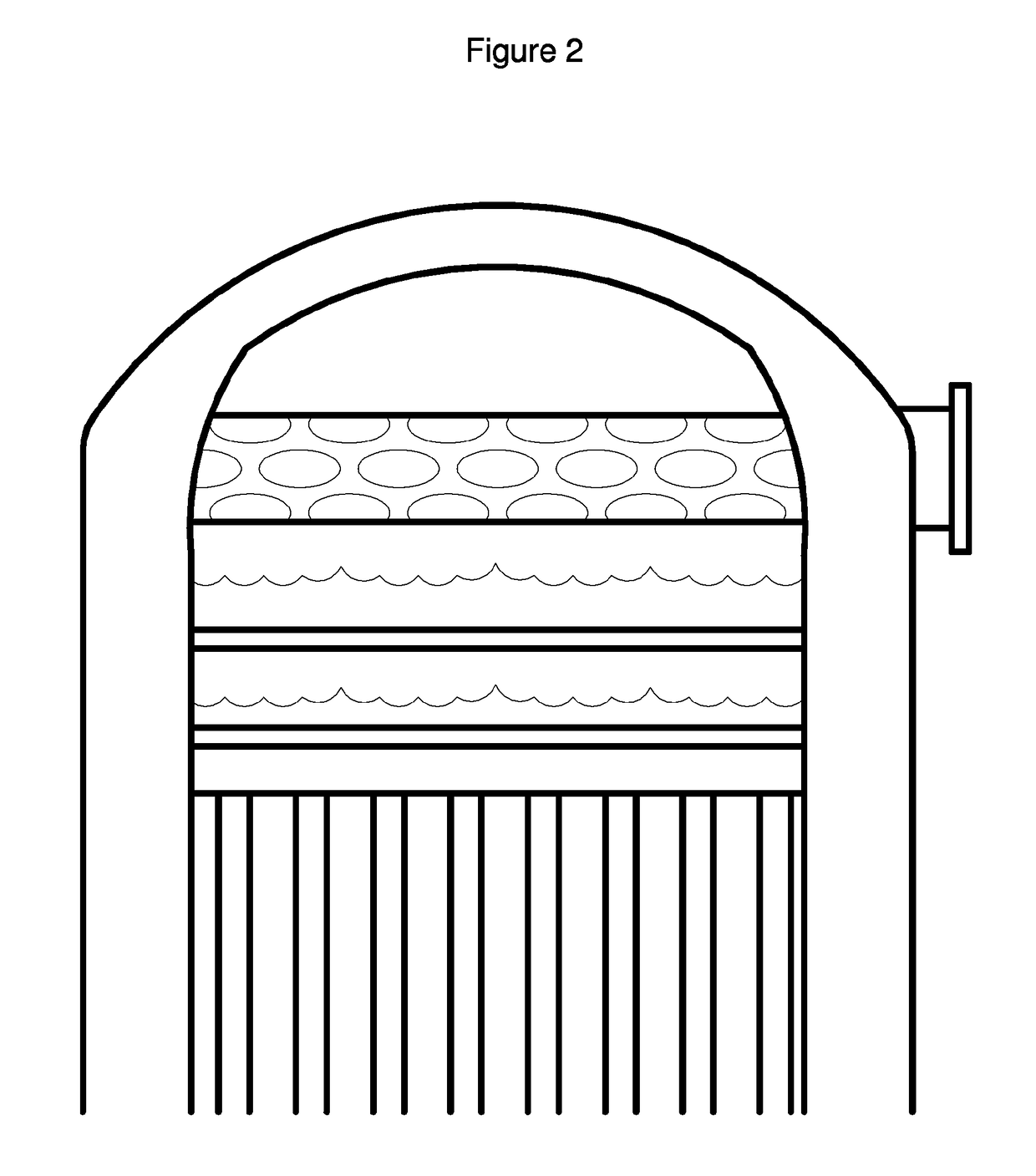

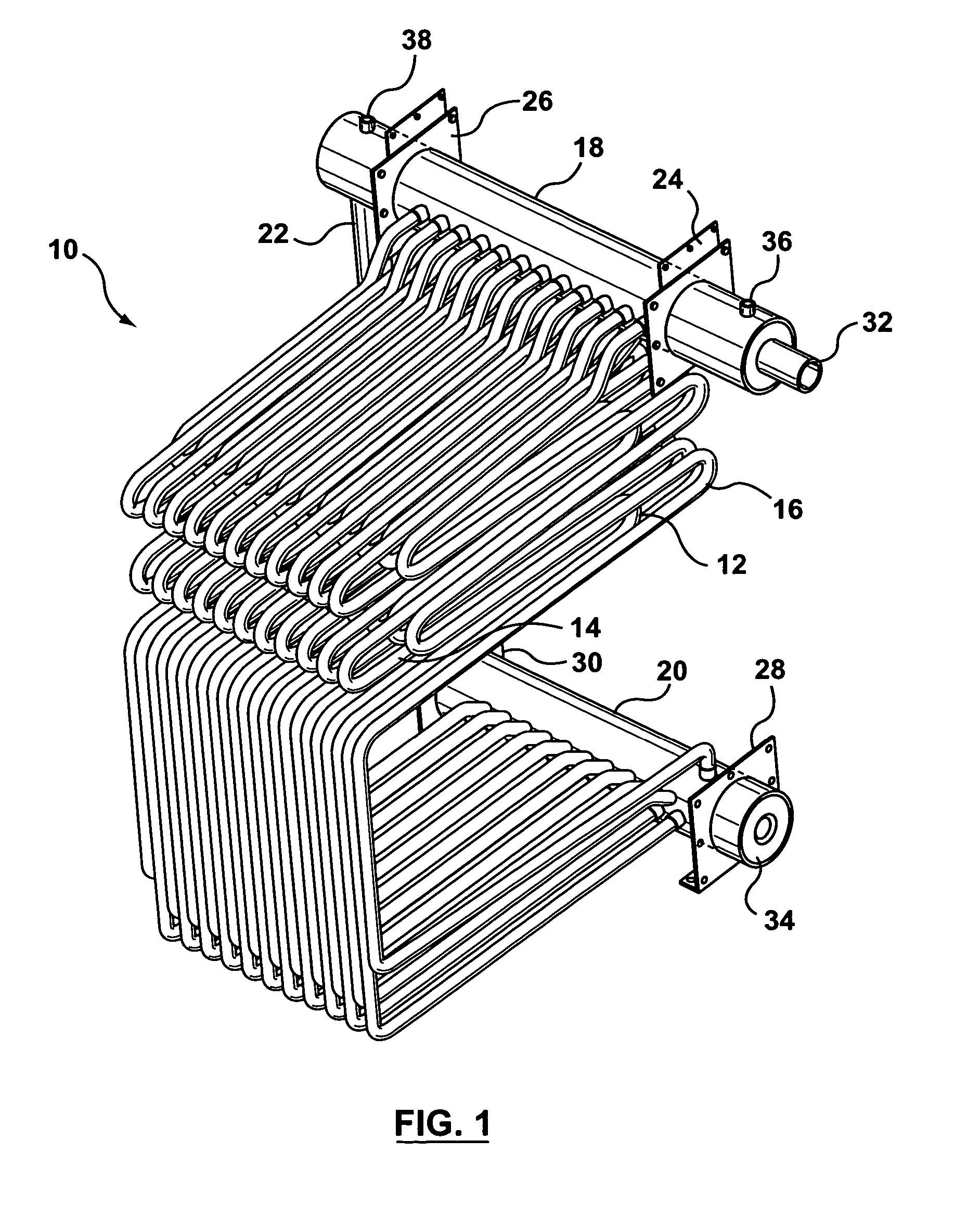

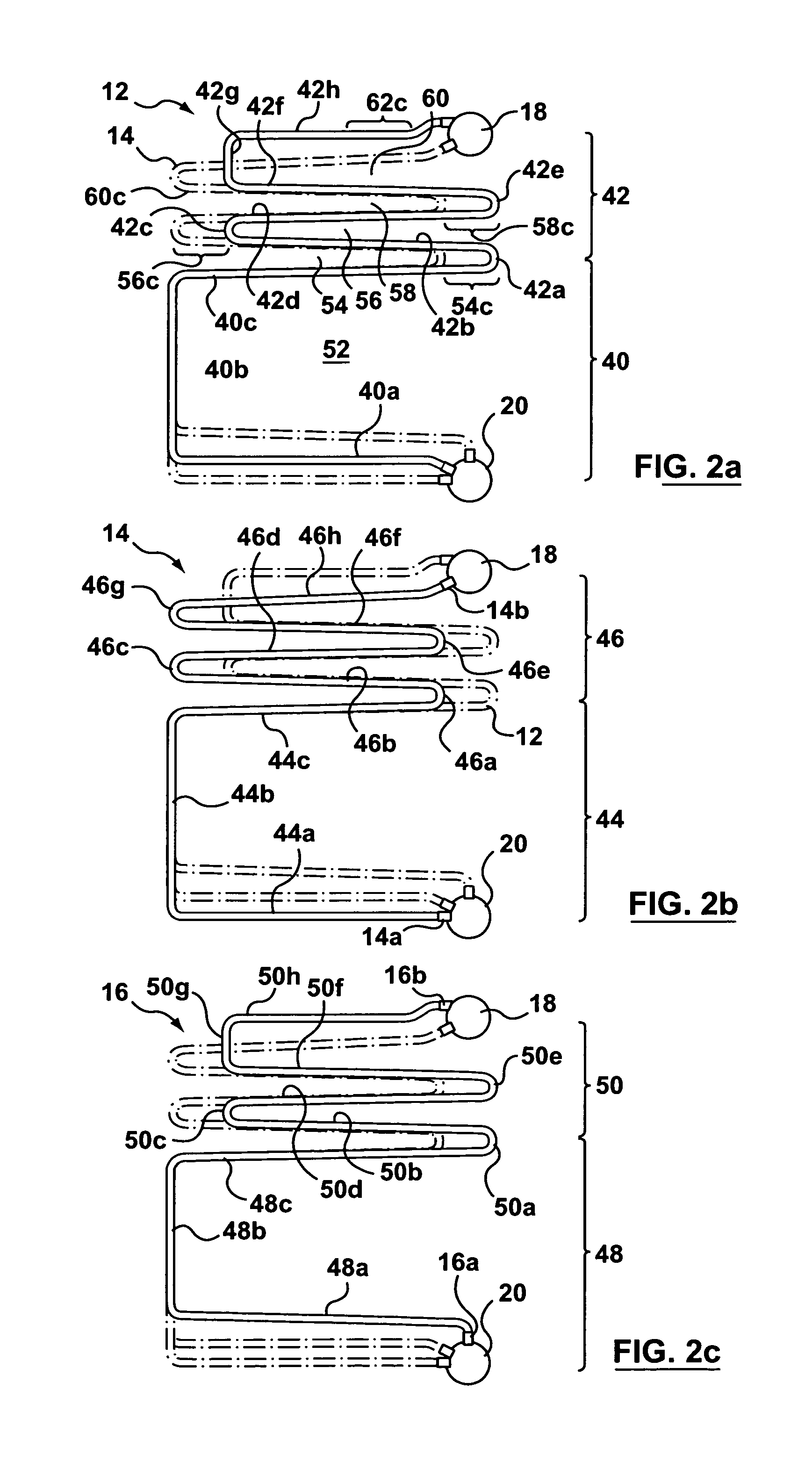

Tube assembly for a boiler

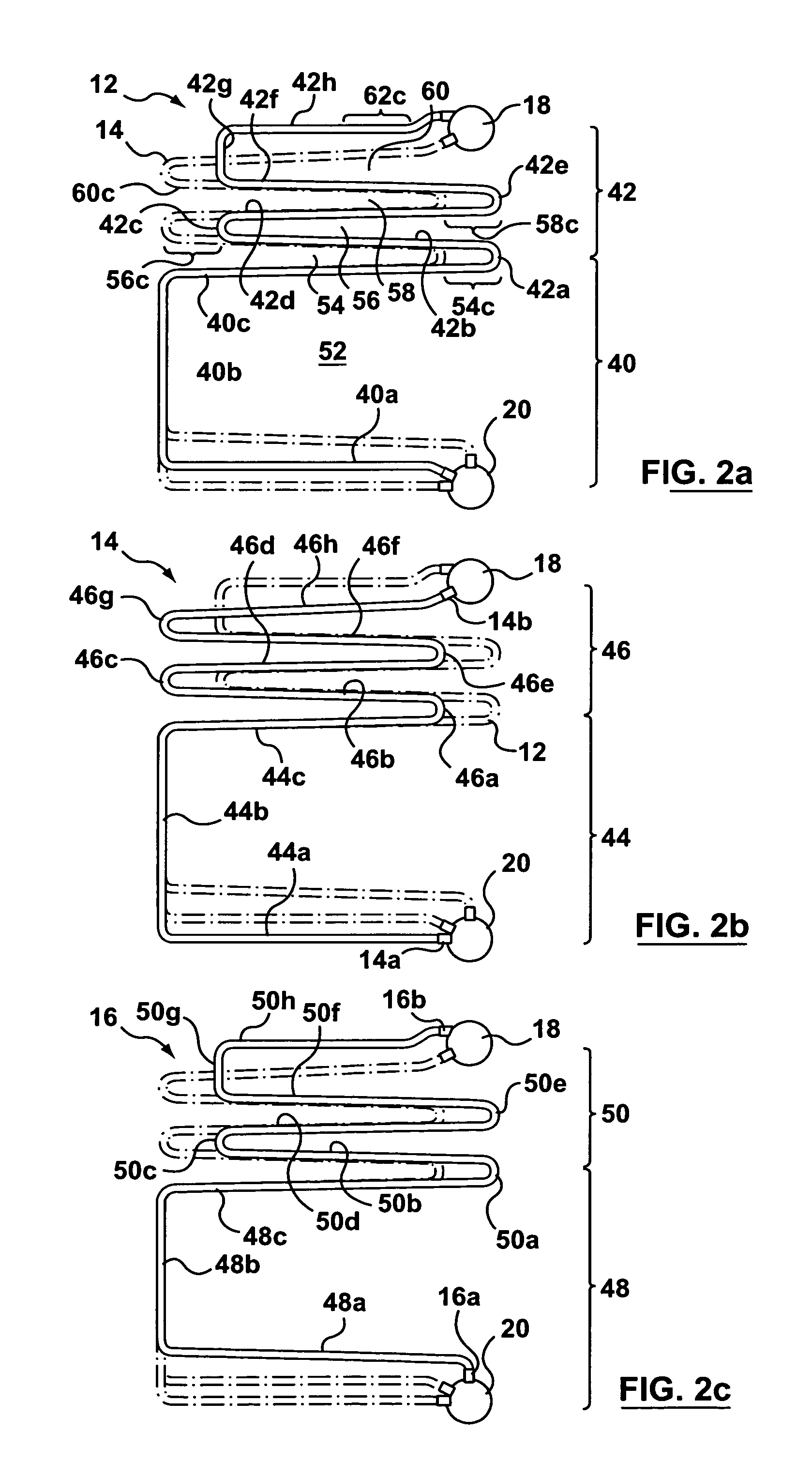

InactiveUS7137360B1Improve boiler efficiencyGood coefficientBoiler water tubesEnergy industryFlue gasEngineering

A boiler is described comprising a housing with a flue gas inlet for receiving a hot gas flame and an outlet for venting a hot gas produced by the hot gas flame, and a tube assembly mounted within the housing. The tube assembly comprises a lower manifold for receiving a liquid, an upper manifold for receiving a heated version of the liquid; and, a plurality of tubes disposed between the lower and upper manifolds. Each tube is shaped to provide a hot gas pathway that travels in a parallel fashion along at least a lower portion of the longitudinal extent of each tube in the tube assembly to the outlet, whereby the liquid introduced into the lower manifold travels in the plurality of tubes and receives heat from the hot gas along the extent of the hot gas pathway.

Owner:PRIME BOILERS

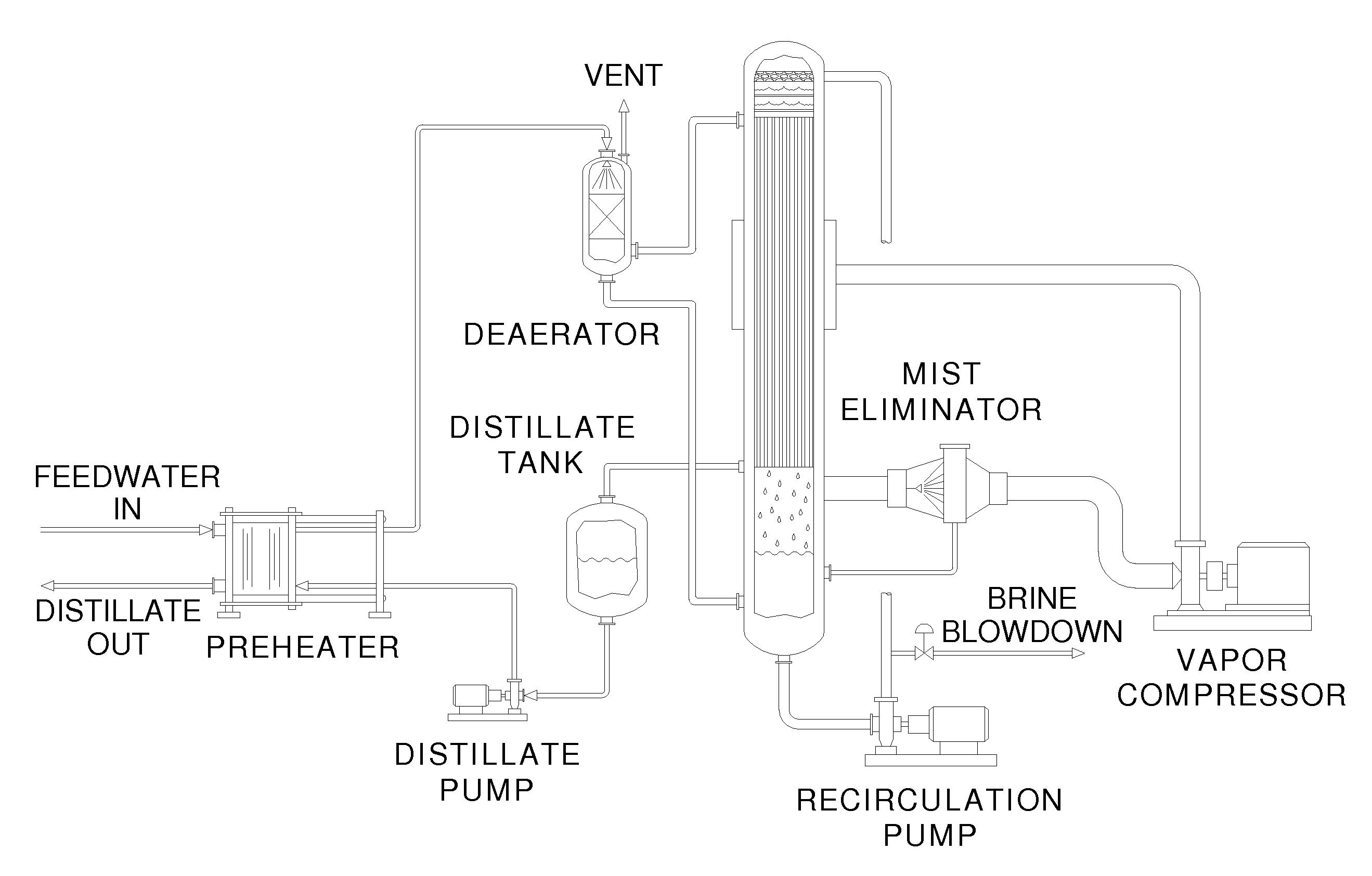

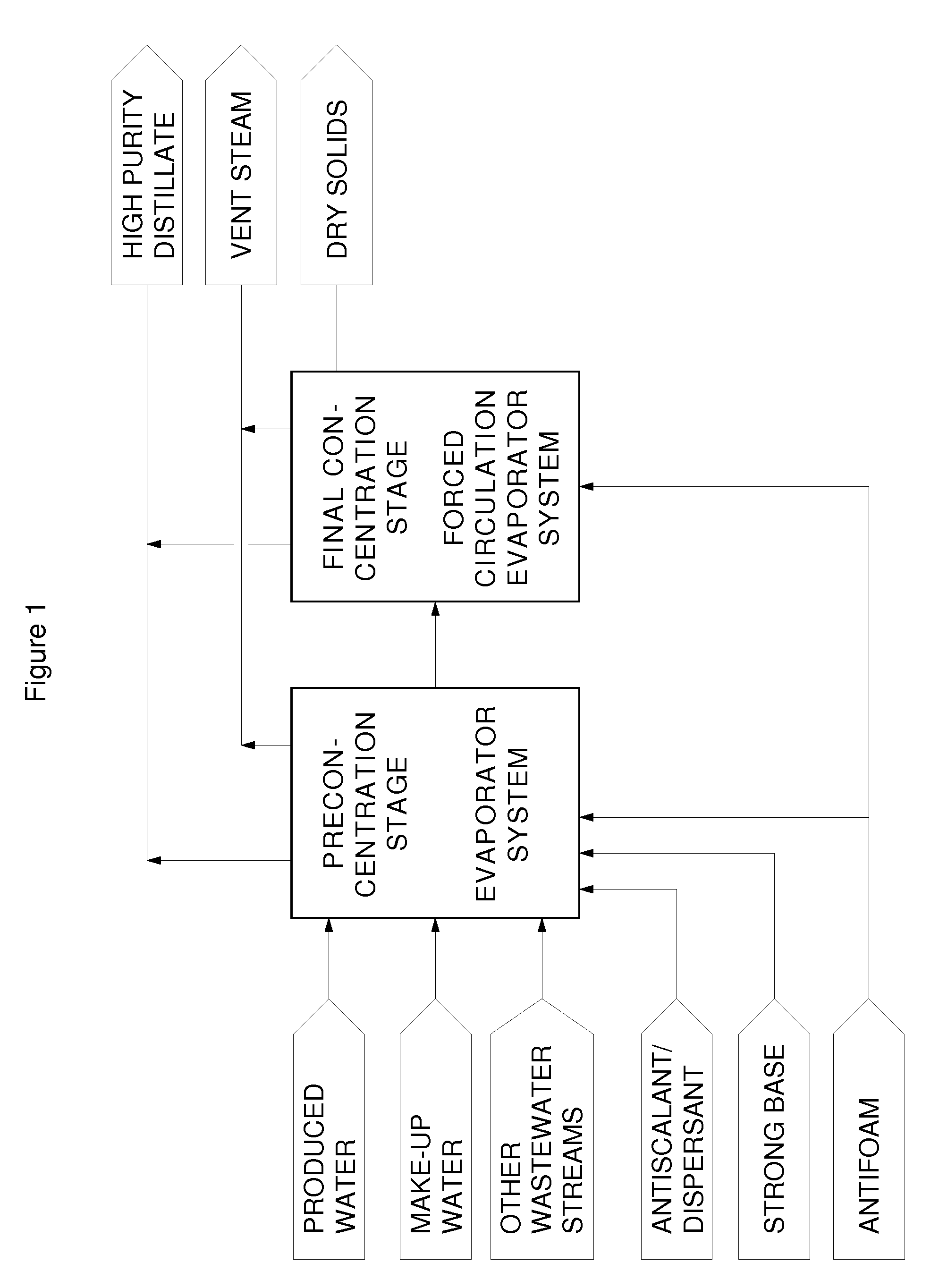

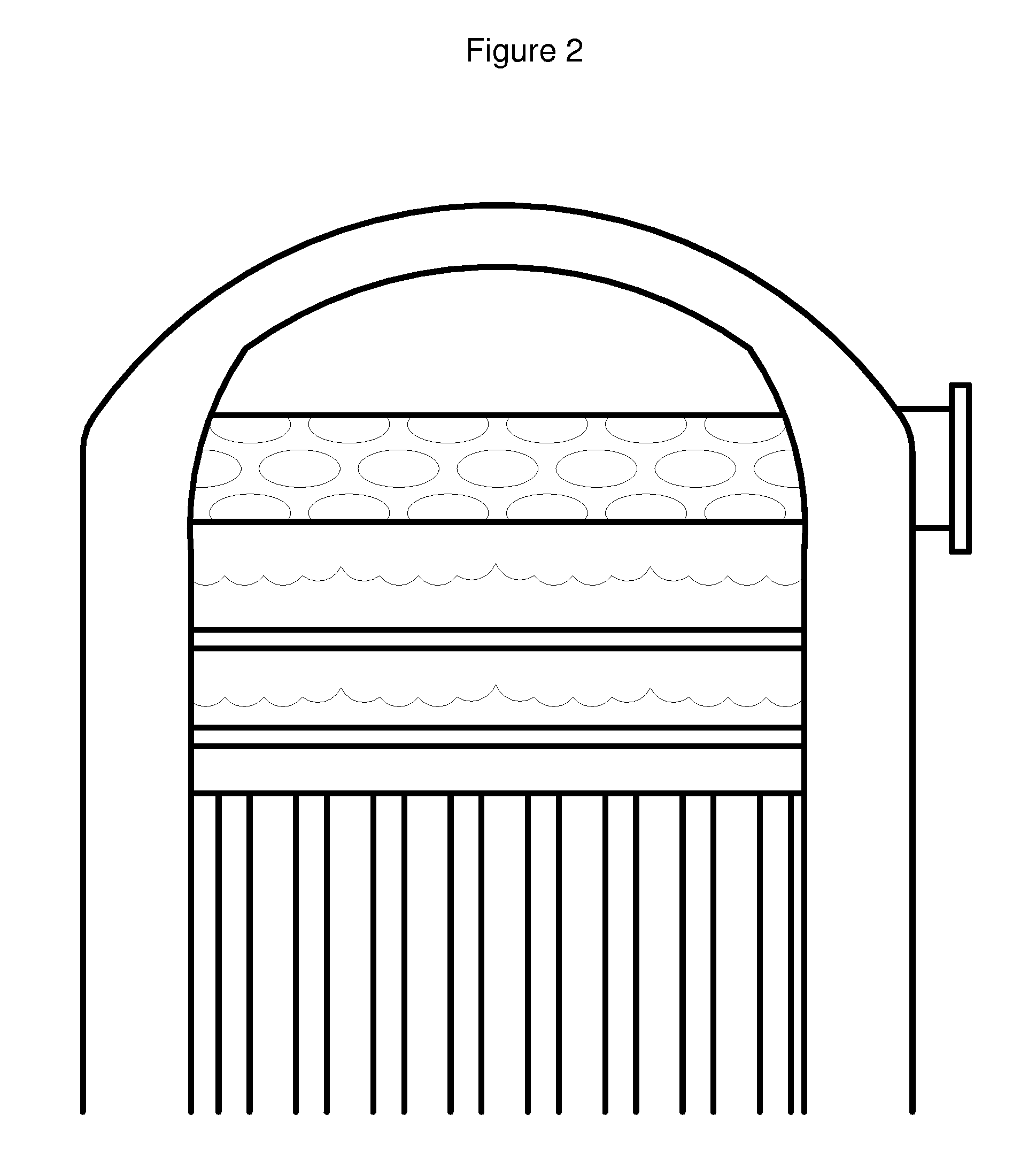

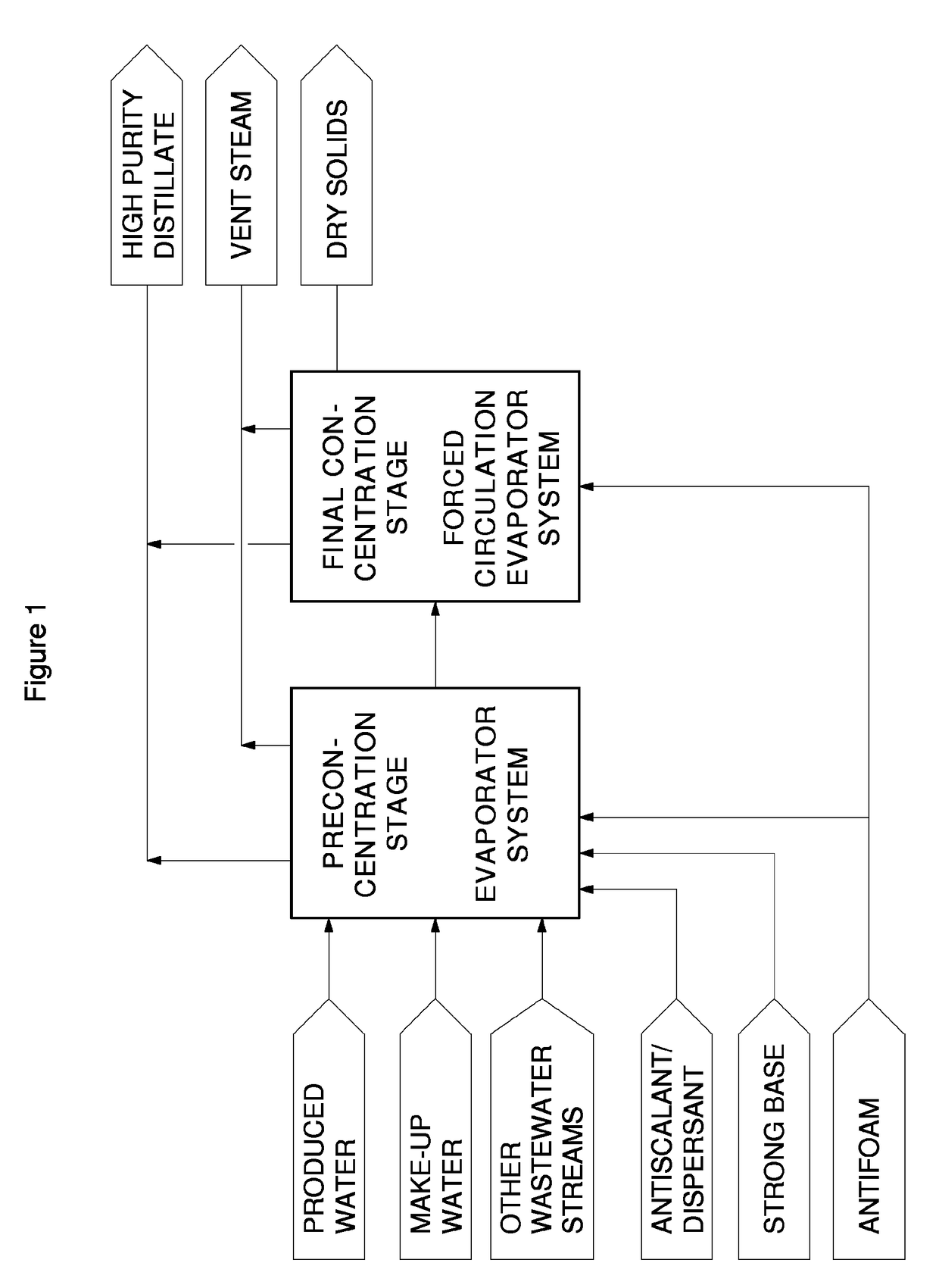

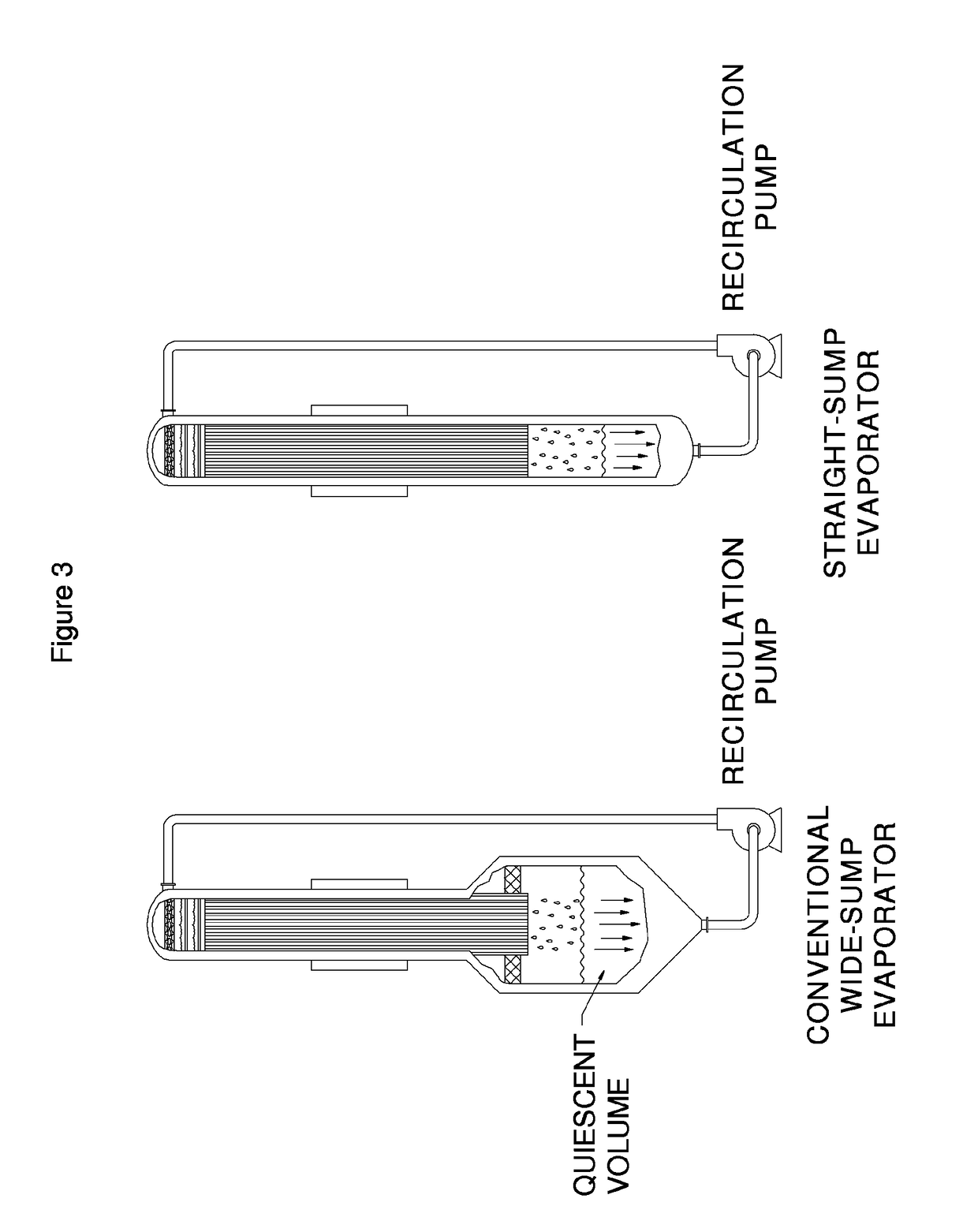

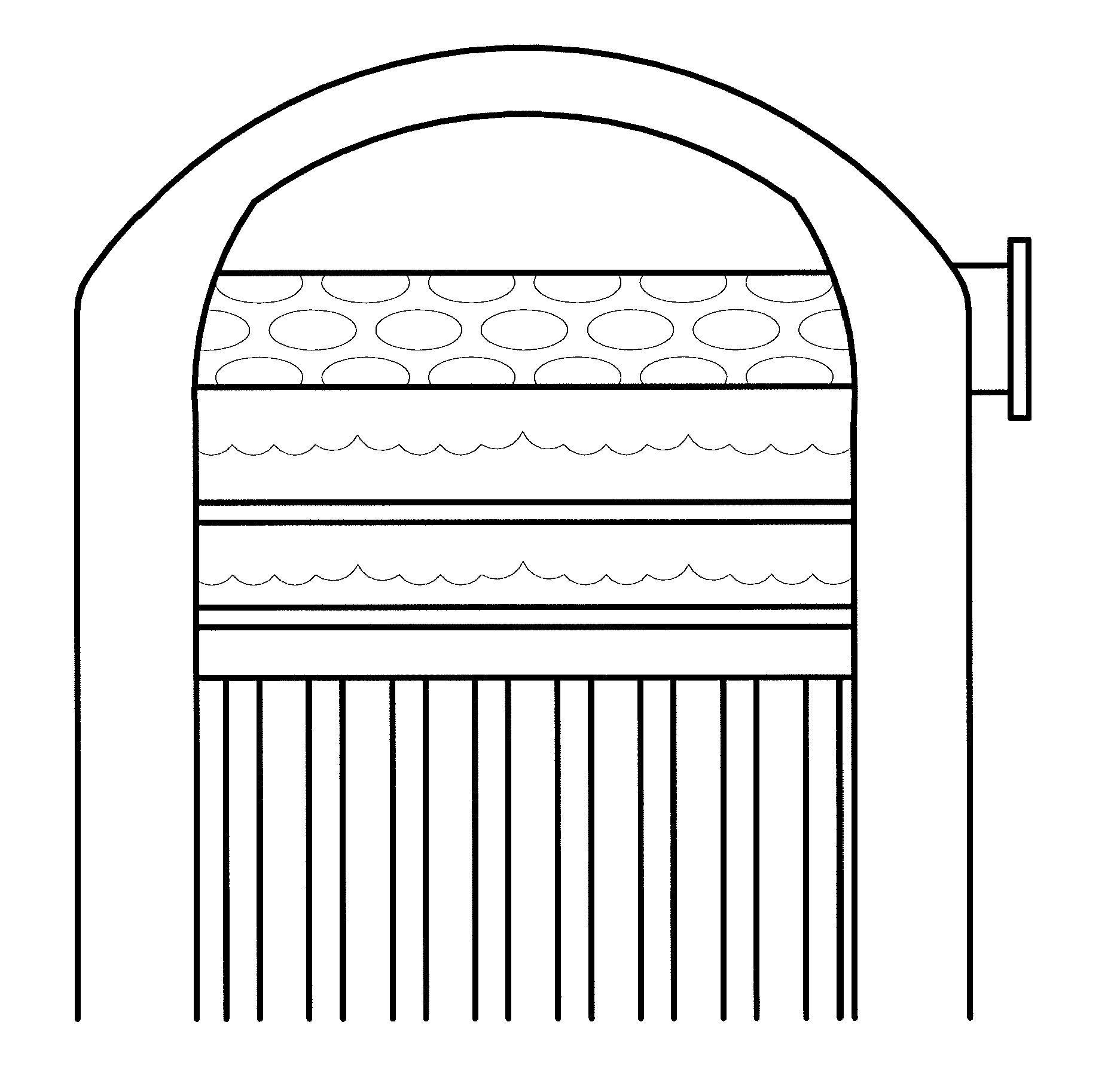

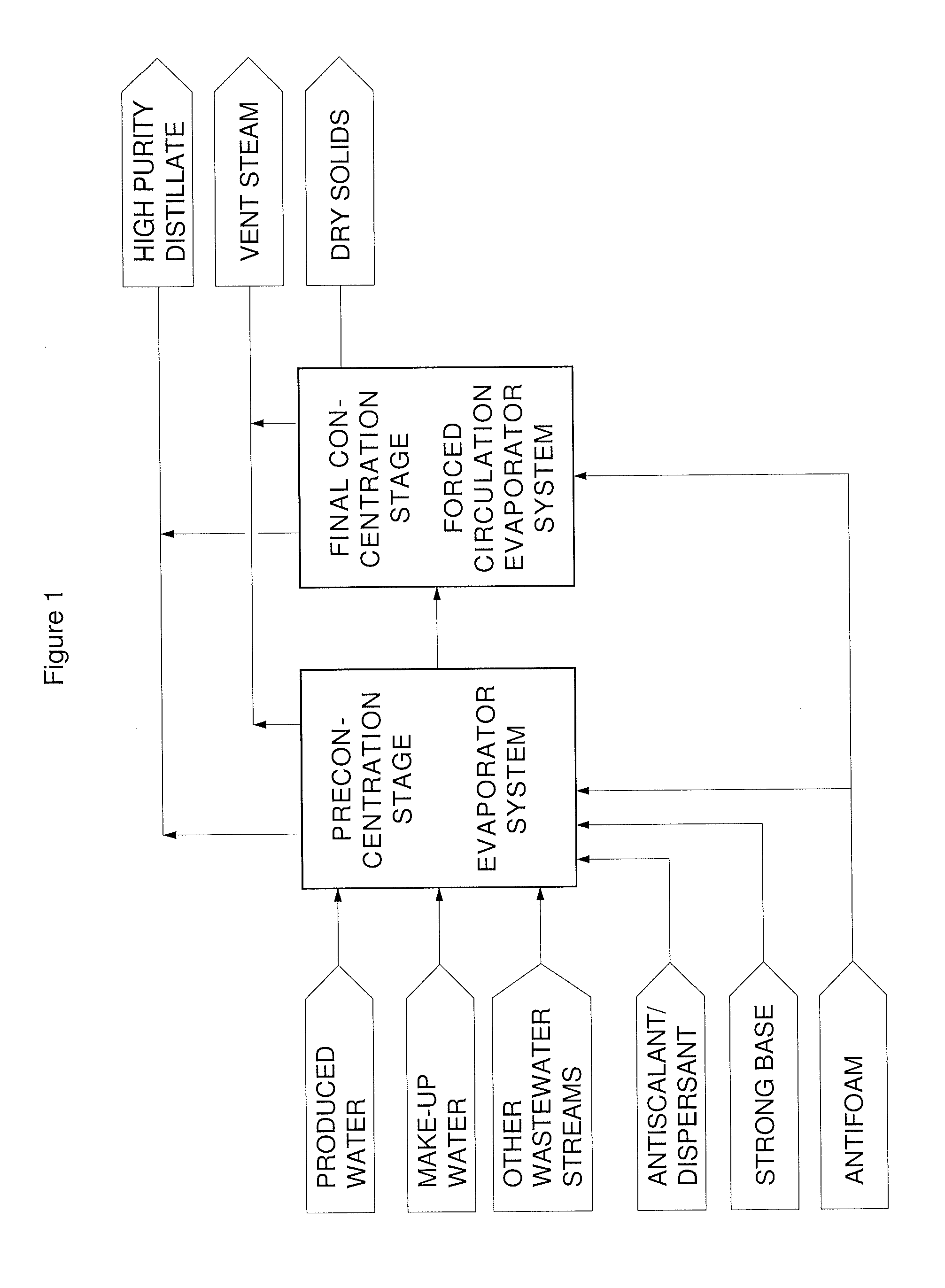

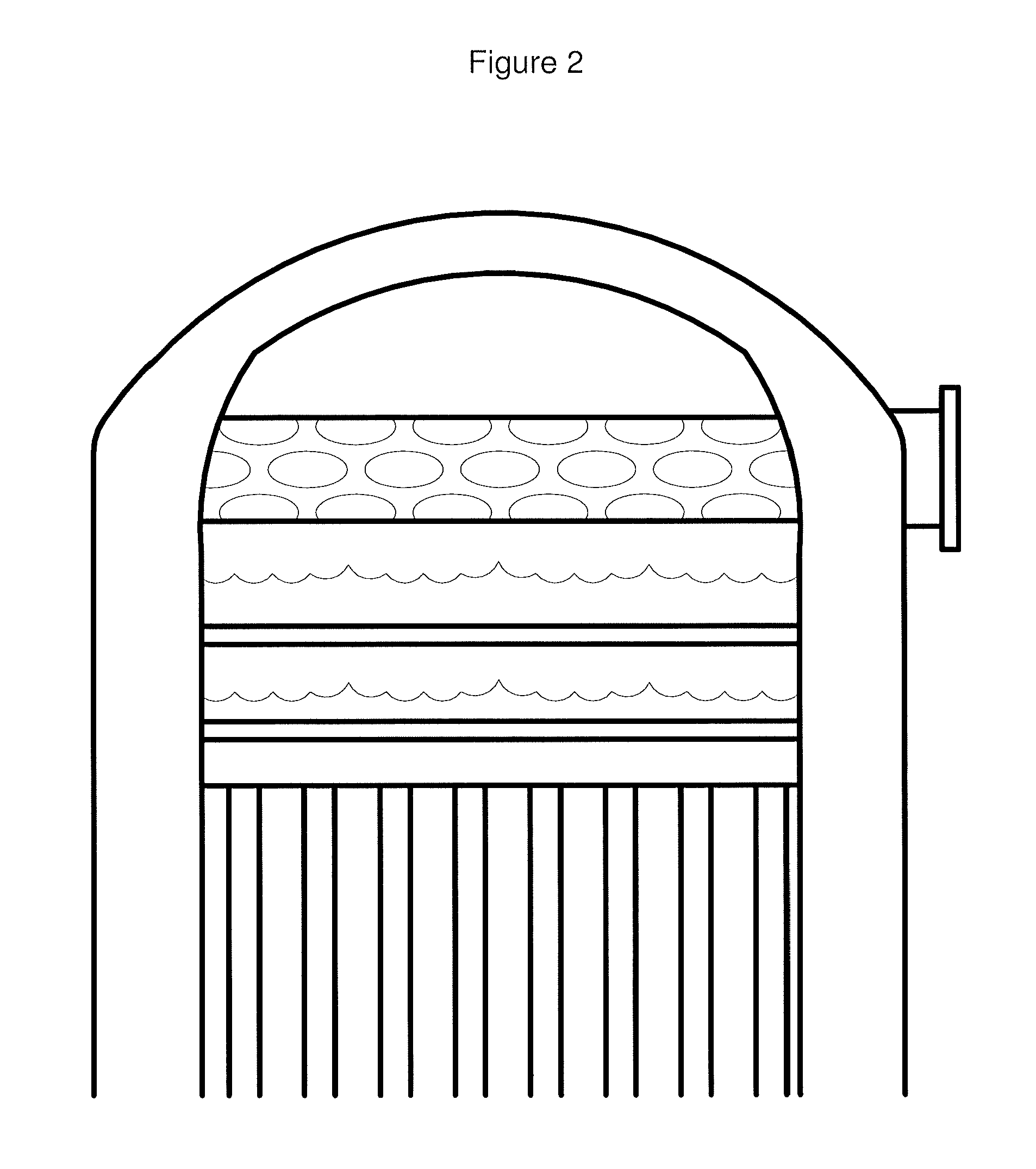

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20110061867A1High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEvaporationEngineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle>98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

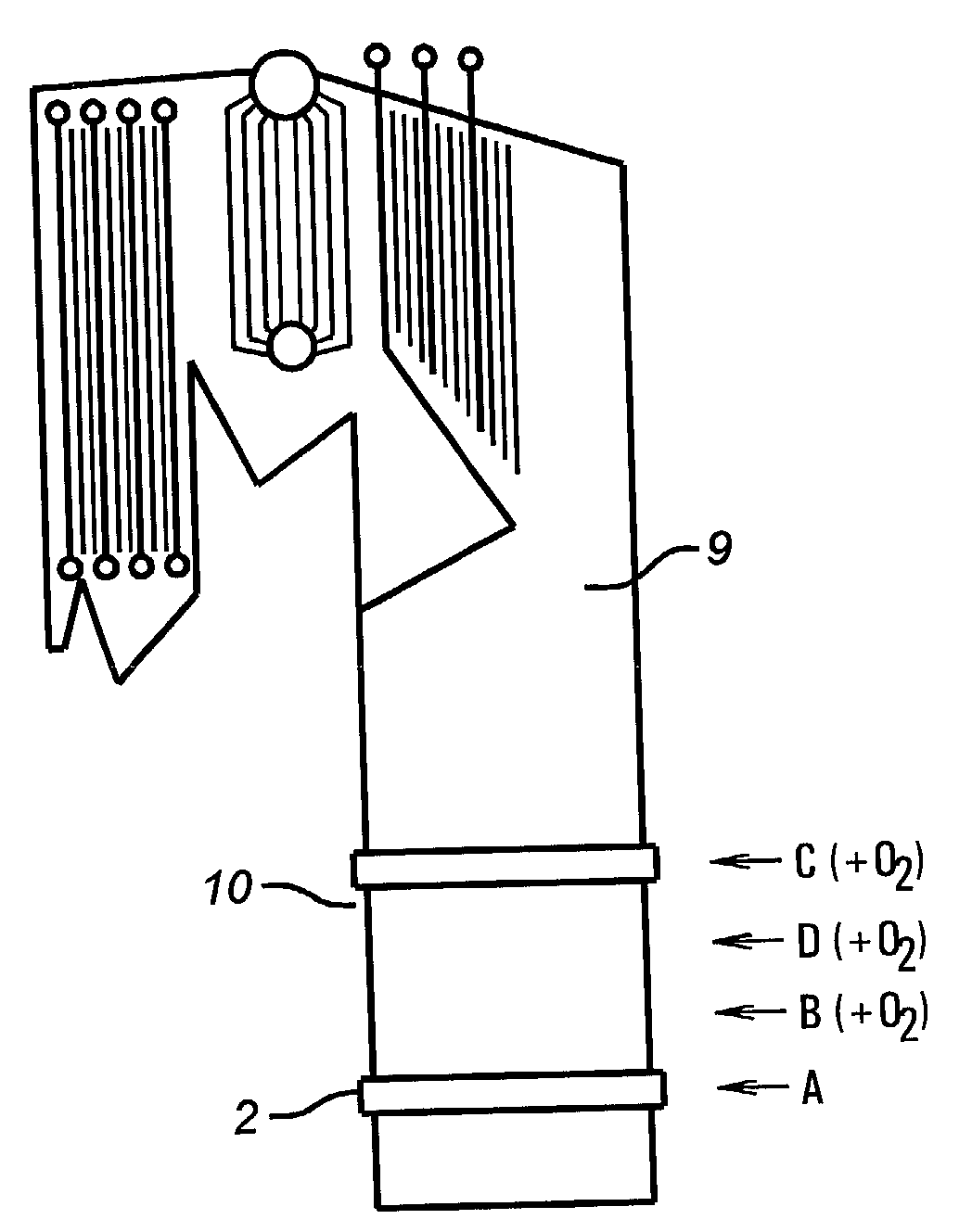

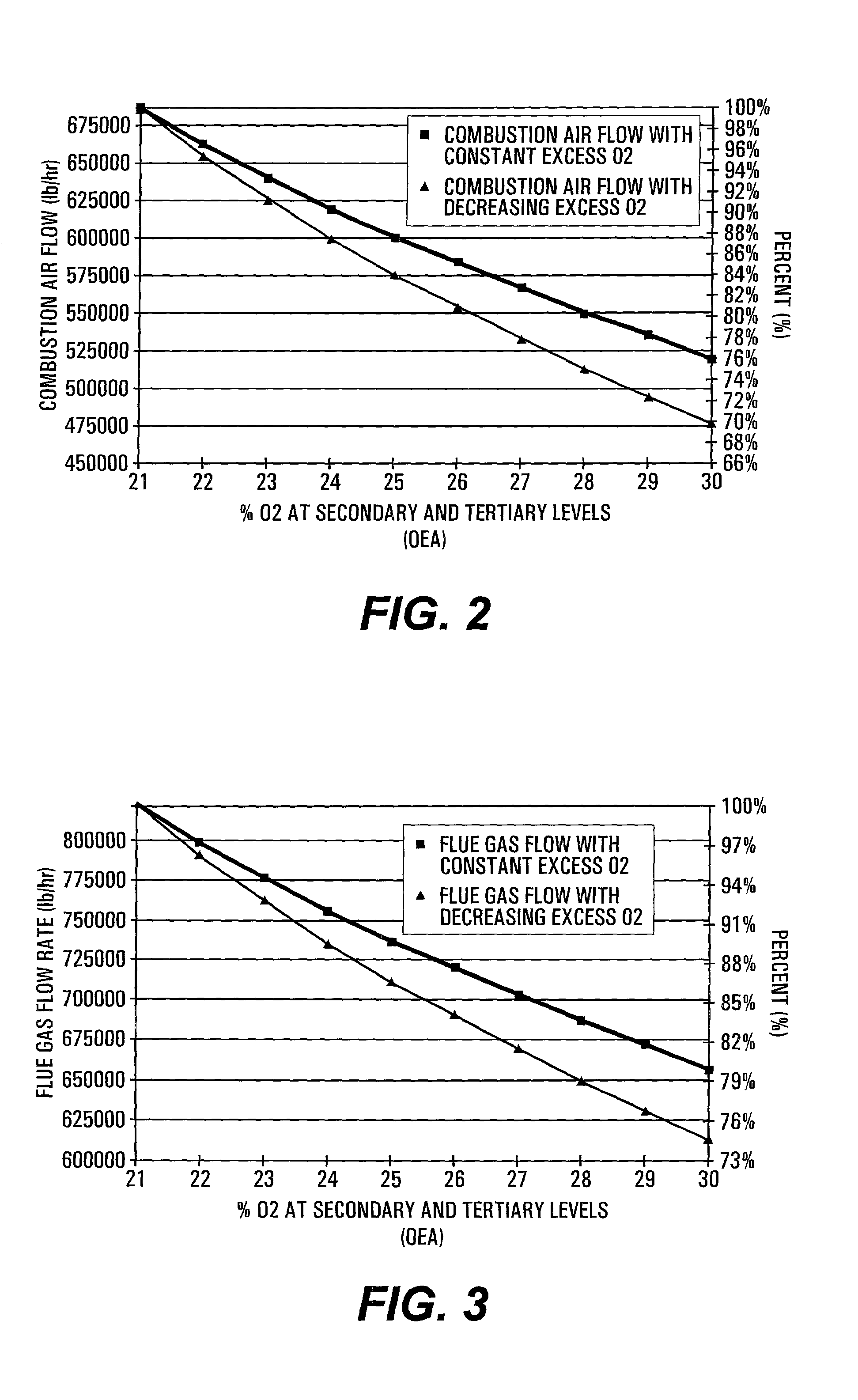

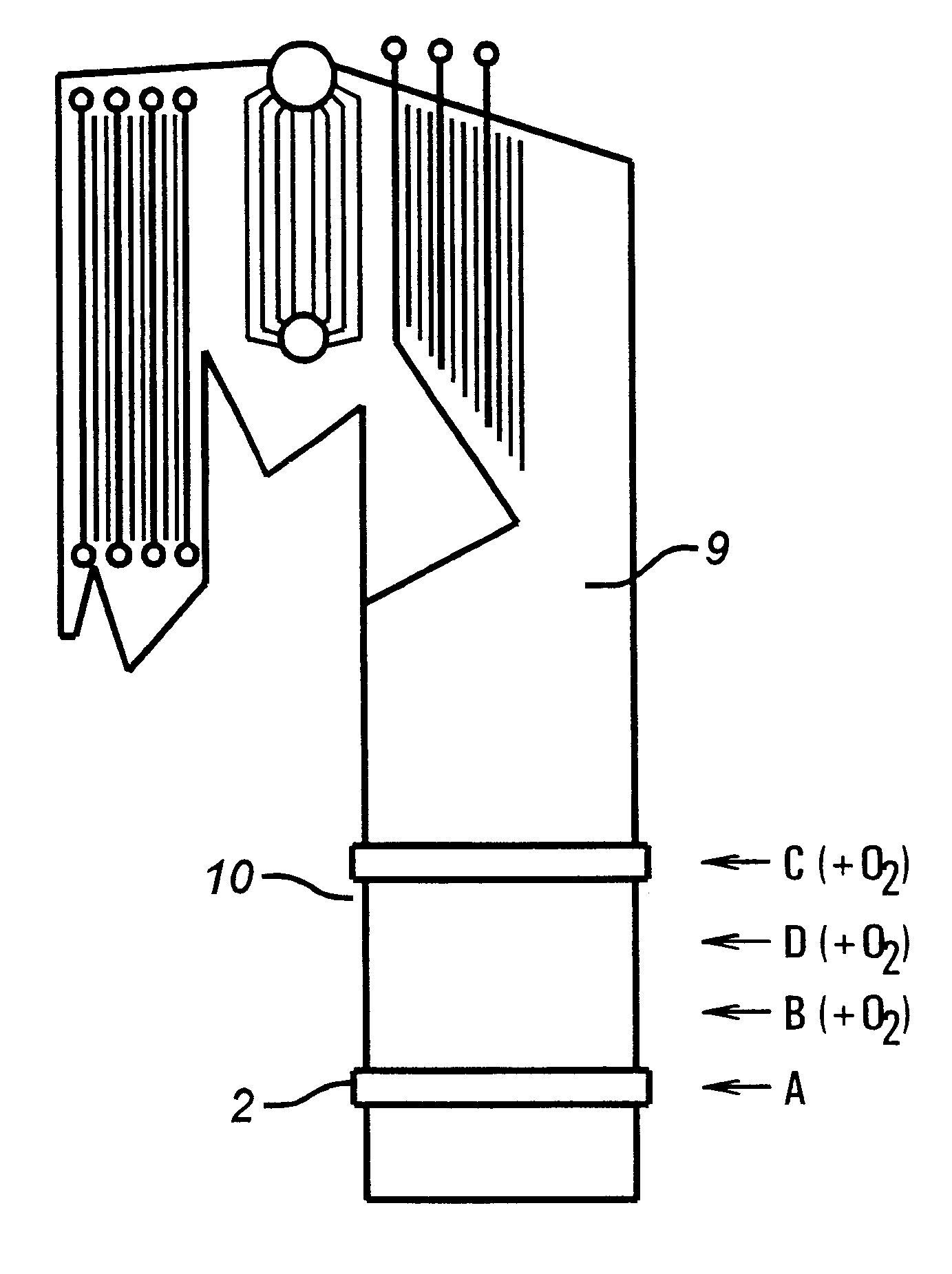

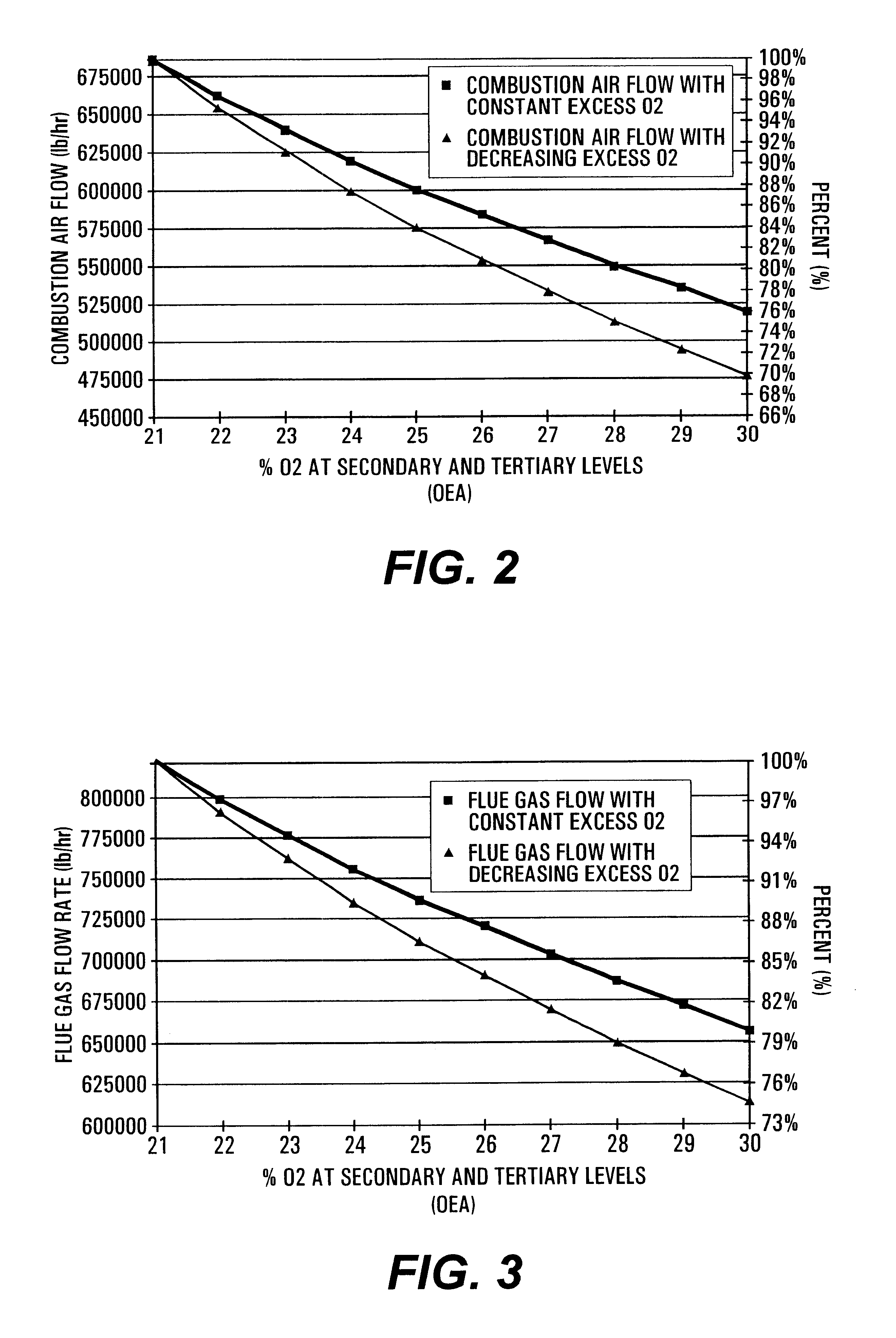

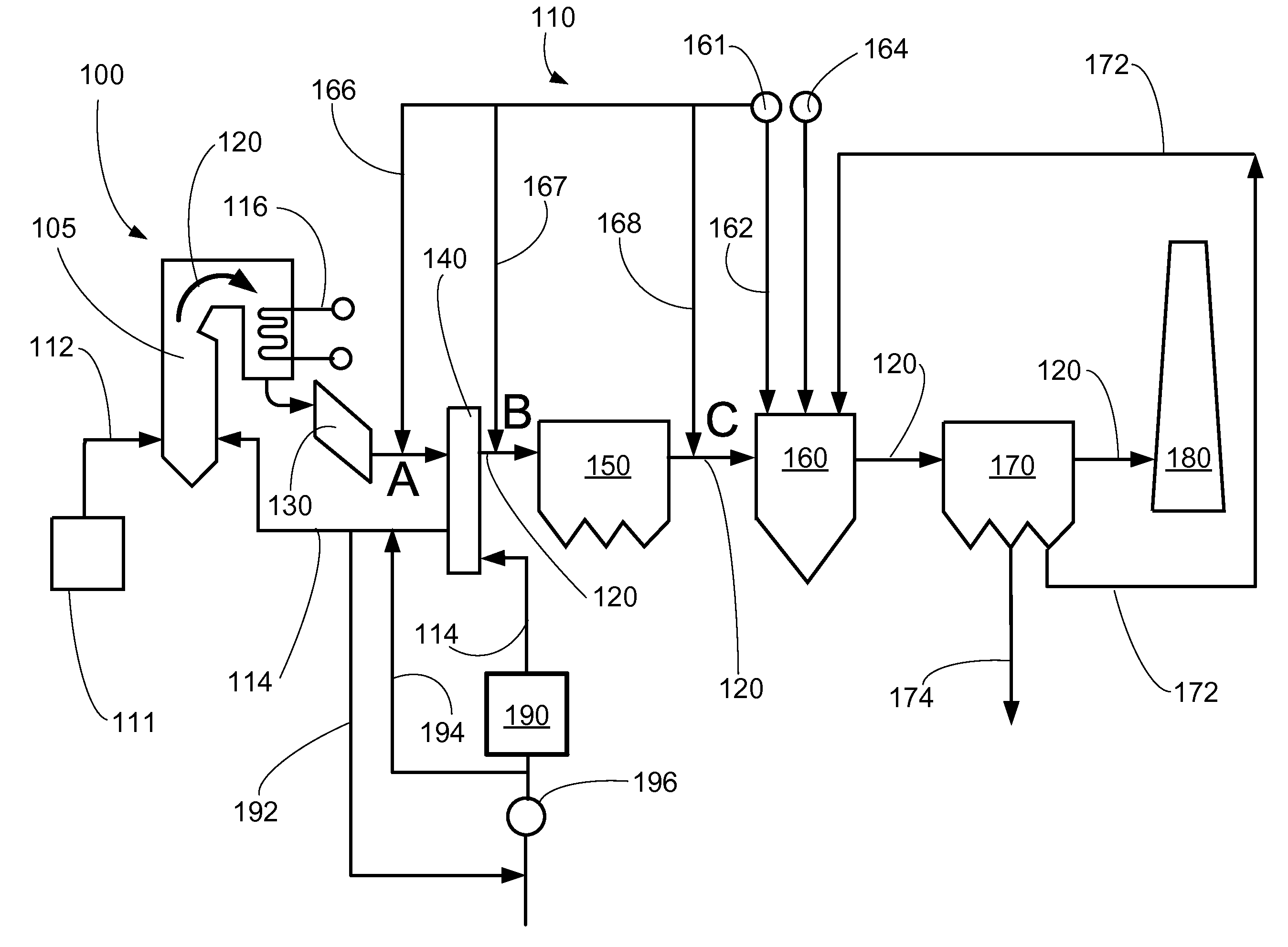

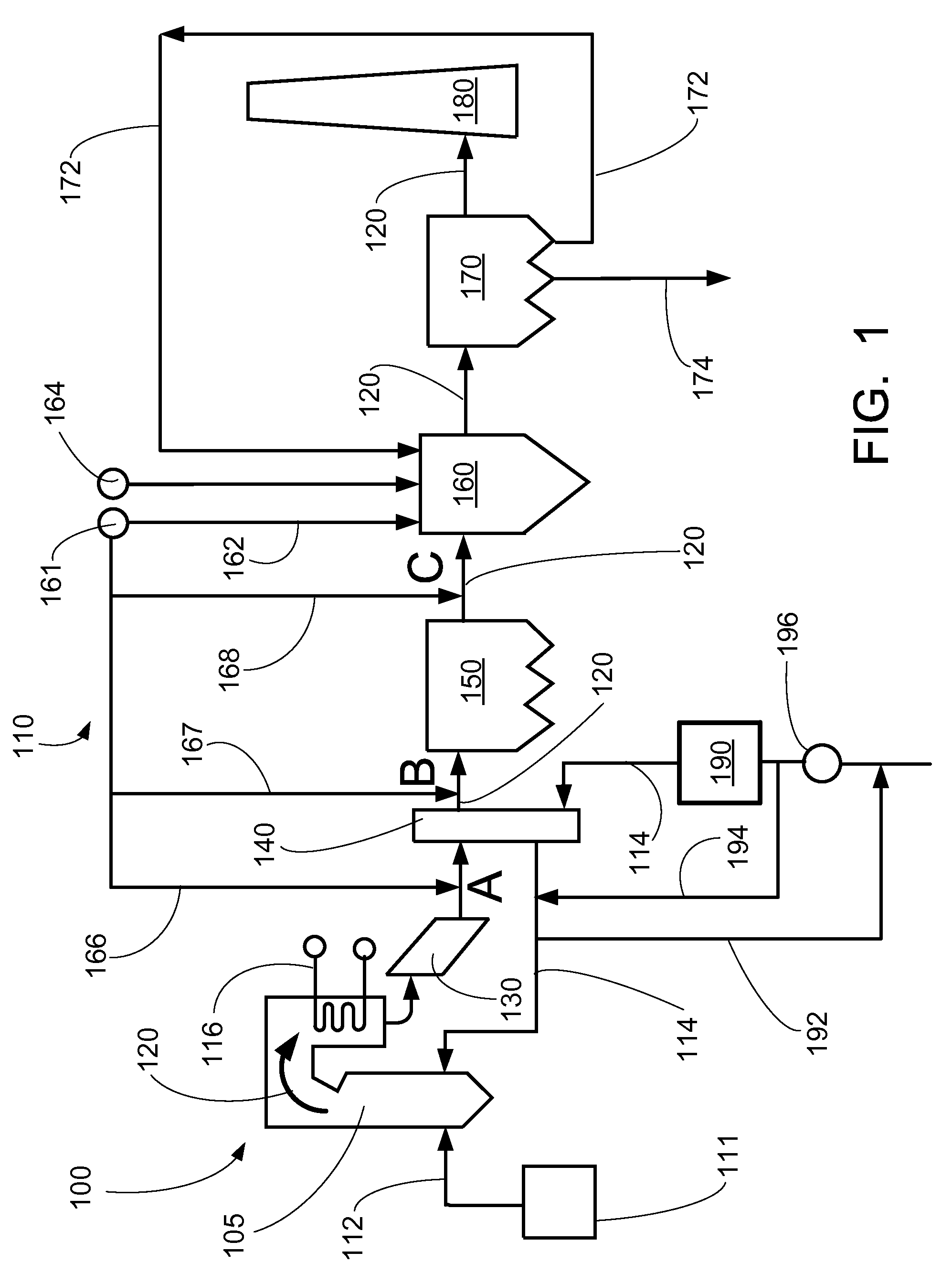

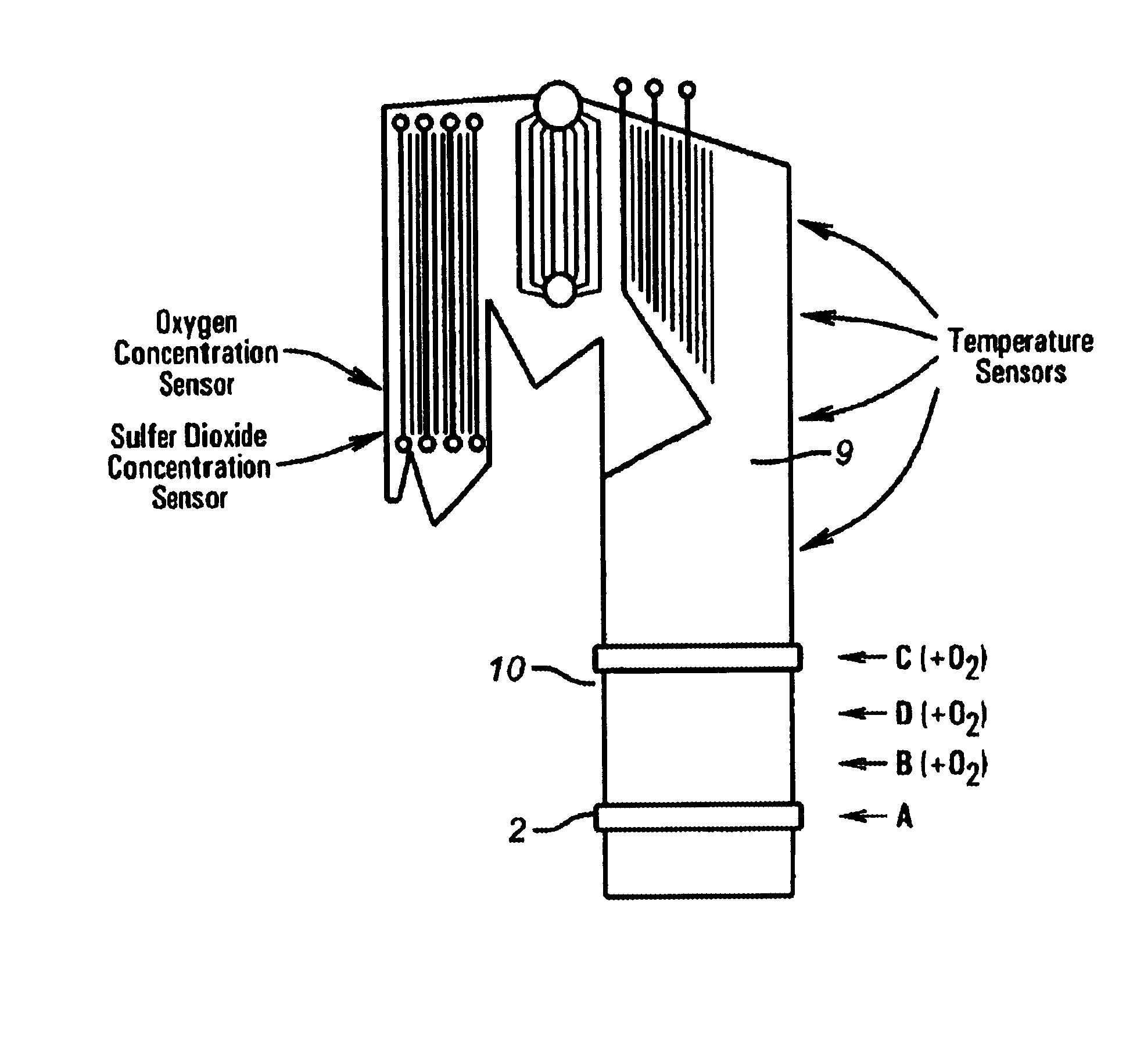

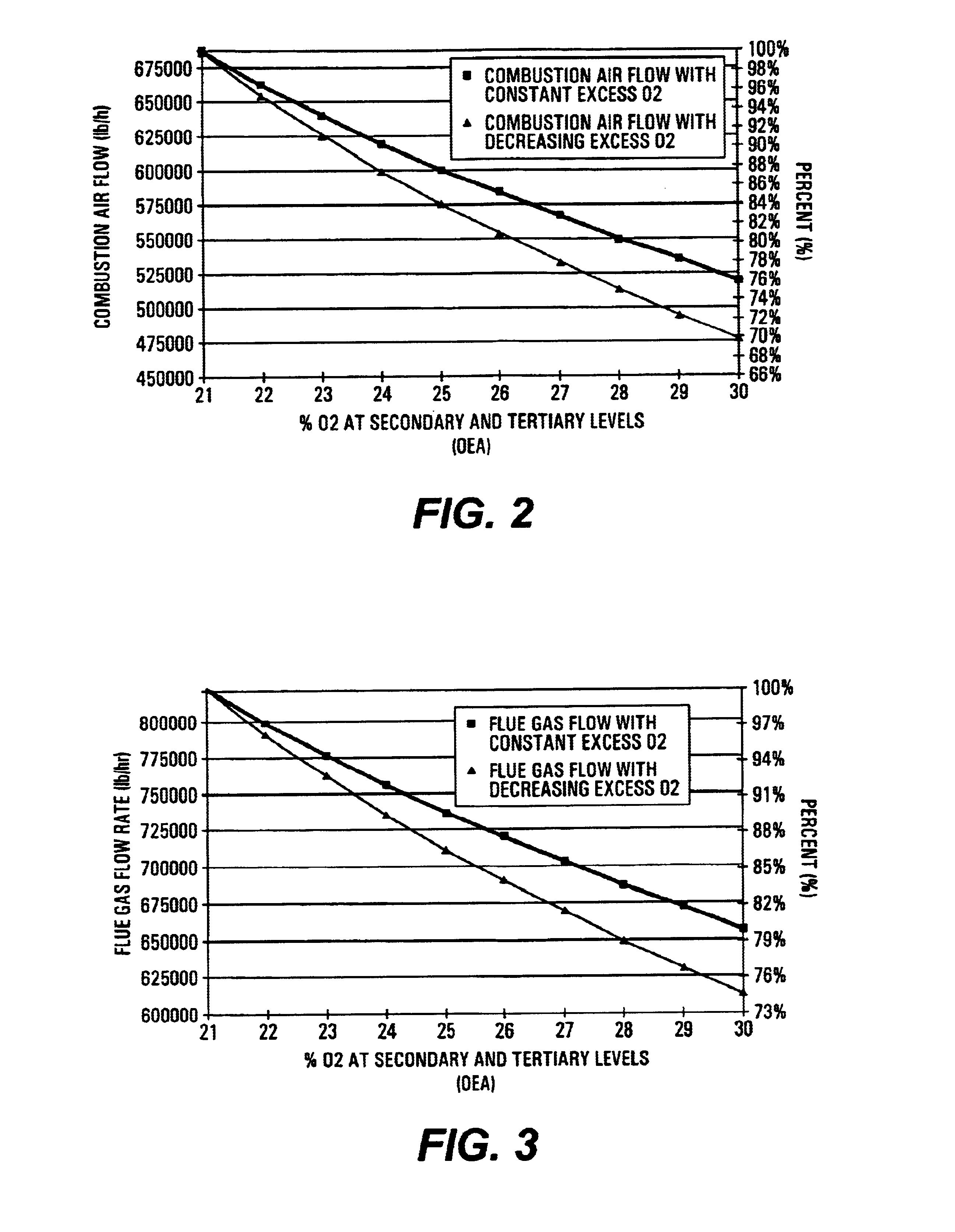

Methods of improving productivity of black liquor recovery boilers

InactiveUS20020043192A1Improve throughputImprove boiler efficiencyPulp liquors combustionSolid fuel combustionProduction rateBlack liquor

Methods of increasing the throughput of recovery boilers equipped with at least two levels of injection of air are presented, the methods improving the thermal efficiency of the boiler with oxygen enrichment of the air in at least one level of the combustion air system, at or above the secondary air level. One embodiment is a method to retrofit black liquor recovery boilers having a two level air injection system with a third level of oxidant injection below or at the same level as the original secondary air, and oxygen enrichment applied to at least the original secondary air stream and said third level. A preferred method is for the third level to be placed at or close to the same level as black liquor injector ports.

Owner:AIR LIQUIDE IND US LP

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS8469091B2High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEngineeringFuel oil

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

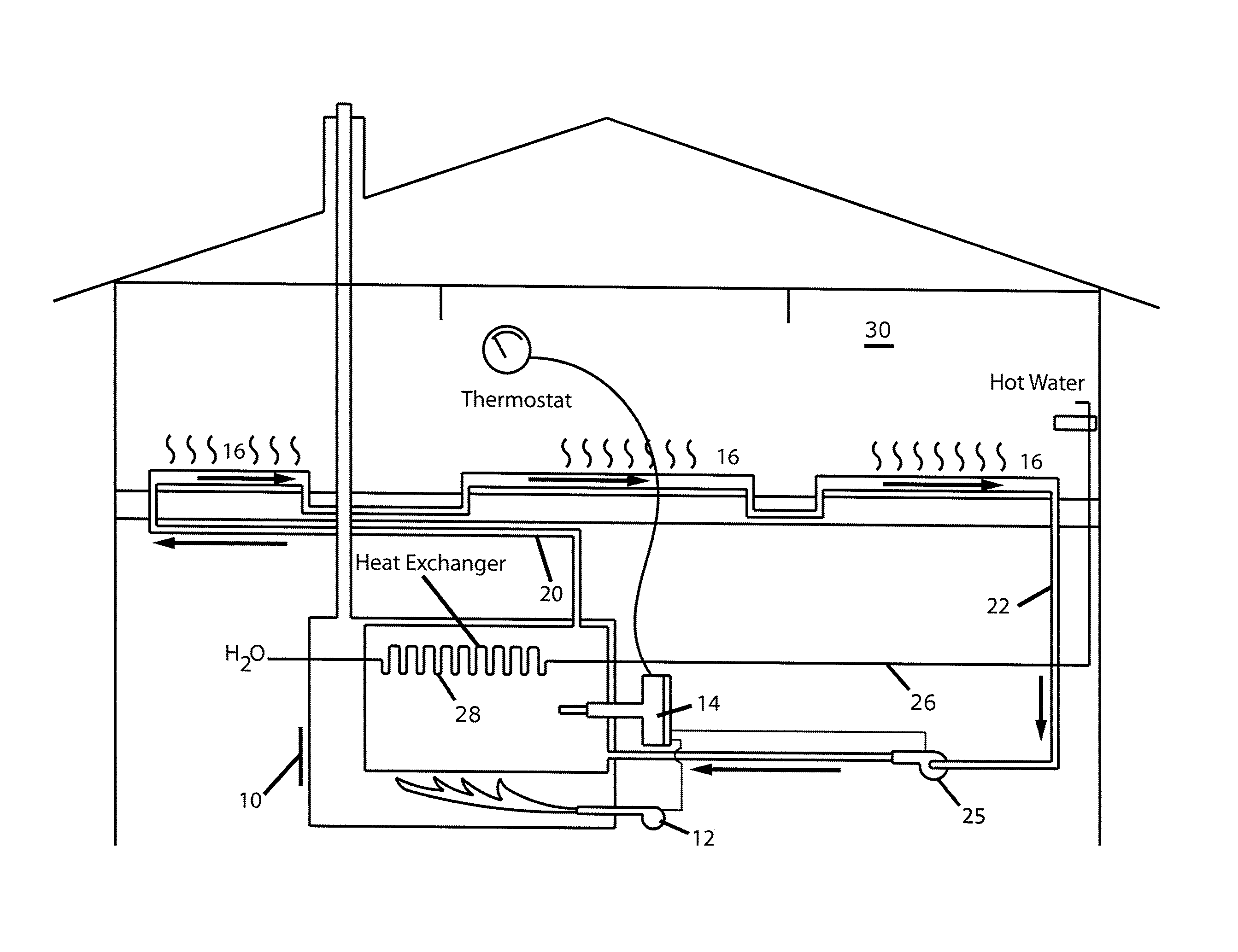

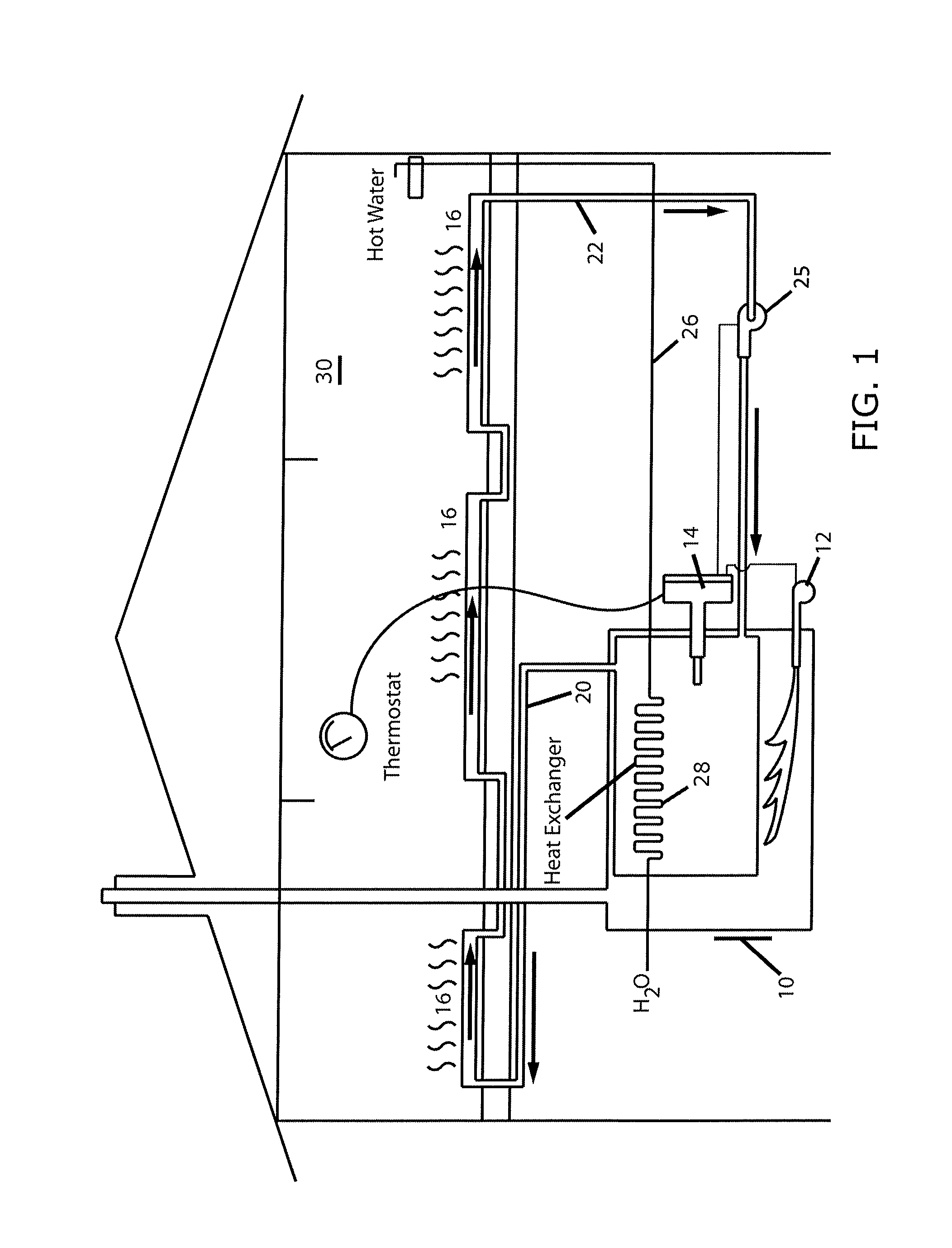

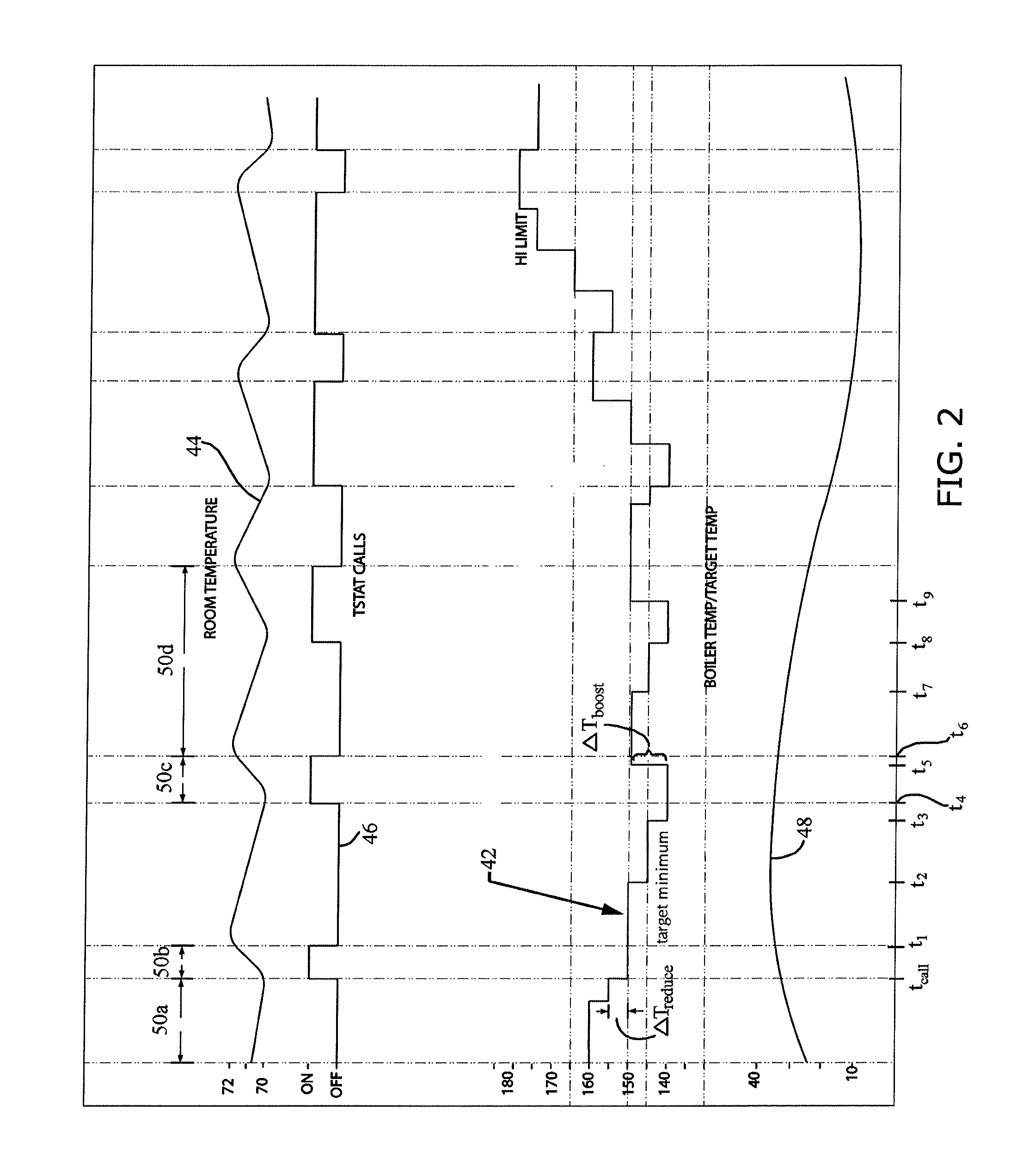

Thermal reduction through activity based thermal targeting to enhance heating system efficiency

ActiveUS8844834B1Improve efficiencyLower target temperatureSampled-variable control systemsFuel supply regulationThermal energyEngineering

Thermal targeting technology is used to continuously adjust boiler target temperature to the minimum necessary to satisfy the required heating load. Responsive to and initiated by a first call for heat, boiler target temperature is reduced by a predetermined amount upon or subsequent to the call for heat. Once the boiler temperature reaches this new target, a call timer is activated. If demand for heat is satisfied before a time set point is reached, the system ceases providing additional heat energy until the next heat demand. Responsive to and initiated by a next call for heat, the boiler target temperature is again reduced by the predetermined amount upon or subsequent to this next call for heat. Each time the heat demand is satisfied within the predetermined time interval, the boiler target temperature is reduced. If heat demand is not satisfied, a thermal boost is provided at set time intervals until the call for heat is removed.

Owner:COWLES OPERATING CO

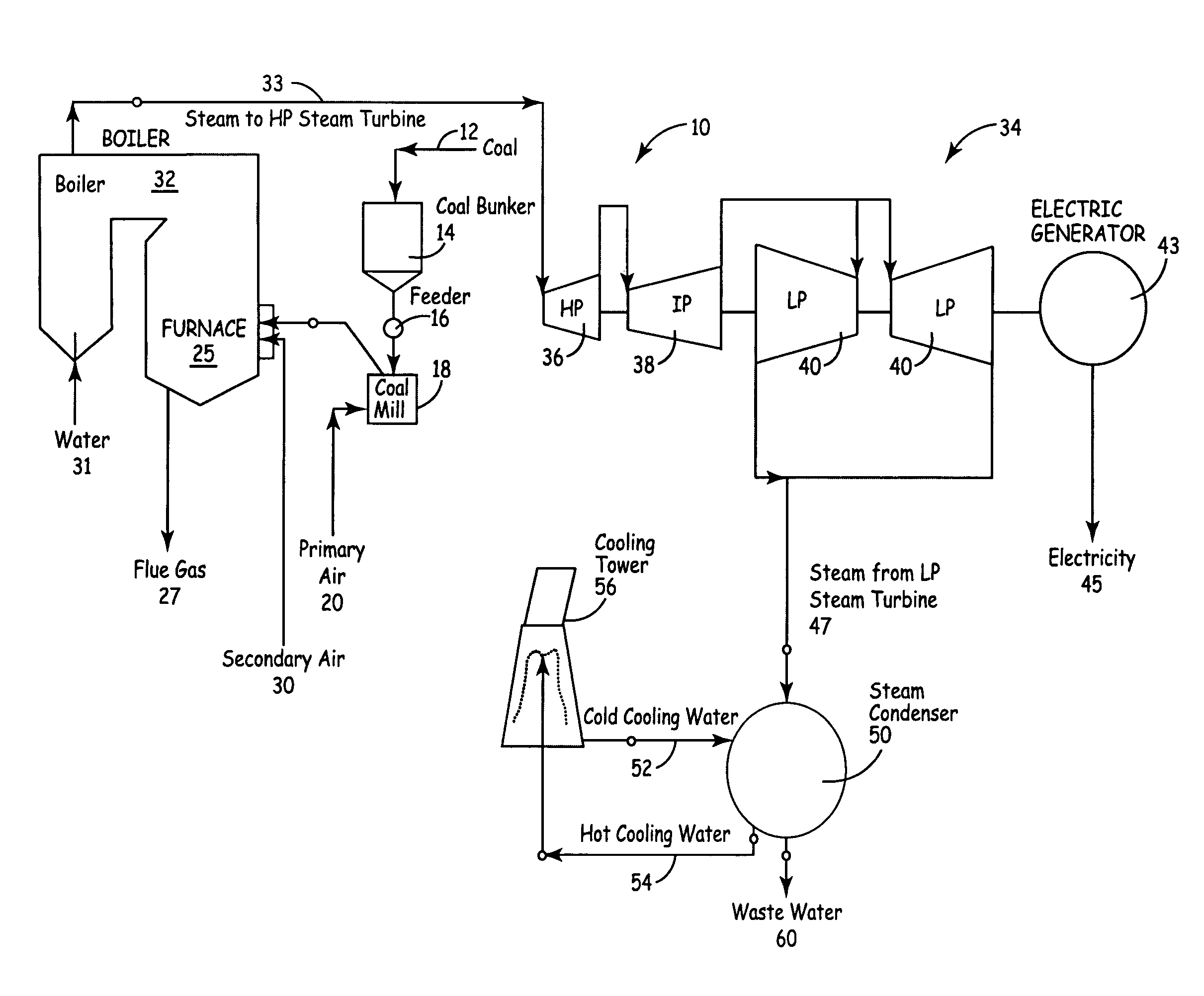

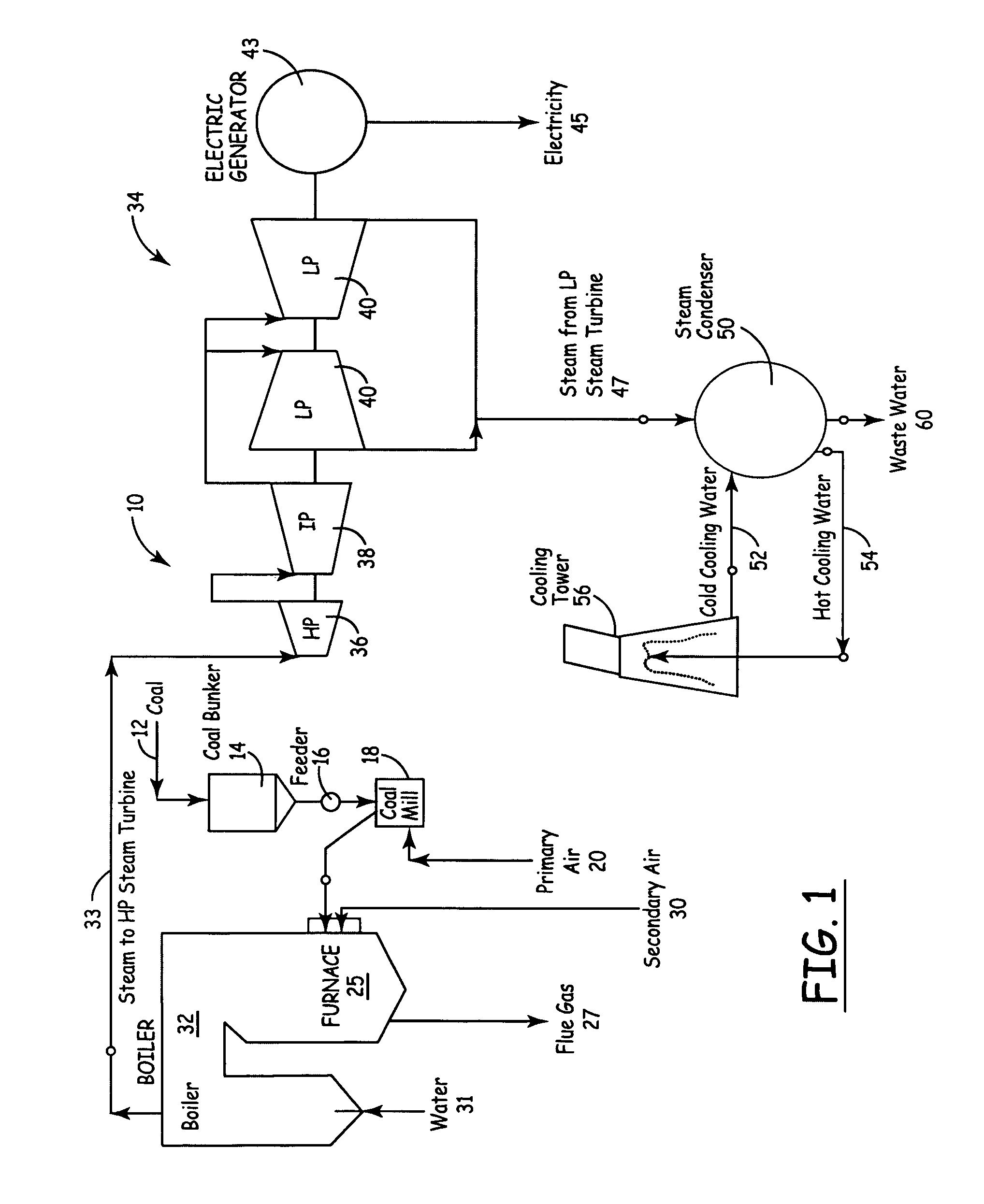

Apparatus for heat treatment of particulate materials

ActiveUS8523963B2Improve efficiencyIncrease heatDrying solid materials with heatSolid fuelsParticulatesFluidized bed drying

The present invention constitutes a heat treatment apparatus like a fluidized-bed dryer for heat treating a particulate material in a low temperature, open-air process. Preferably, available waste heat sources within the surrounding industrial plan operation are used to provide heat to the dryer. Moreover, conveyor means contained within the dryer can remove larger, denser particles that could otherwise impede the continuous flow of the particulate material through the dryer or plug the fluidizing dryer. This invention is especially useful for drying coal for an electricity generation plant.

Owner:RAINBOW ENERGY CENT LLC

Decoking and ash removing agent for urban domestic garbage incinerator and preparation method thereof

InactiveCN101787317AIncrease labor intensityImprove boiler efficiencyFuel additivesIncinerator apparatusMunicipal solid waste incineratorOxide

The invention relates to a decoking and ash removing technology for an urban domestic garbage incinerator, and discloses a decoking and ash removing agent for the urban domestic garbage incinerator and a preparation method thereof. The invention is suitable for the formula of the decoking and ash removing agent with calcium-aluminum silicate as a main component for slag formation and ash accumulation. The mass percent of the components of the decoking and ash removing agent is as follows: soda ash: 25 to 30%; zinc oxide: 25 to 30%; sodium nitrate or potassium nitrate: 20 to 25%; borax: 5 to 10%; sodium chloride: 5 to 10%; vermiculite: 1 to 4%; and copper oxychloride: 1 to 4%.

Owner:XI AN JIAOTONG UNIV

Split pass economizer bank with integrated water coil air heating and feedwater biasing

InactiveUS20130192542A1Improve thermal efficiencySmall space requirementCombustion processMachines/enginesCombustionFlue gas

An apparatus for using a water coil air heater with a single bank economizer. A boiler economizer arrangement includes an economizer bank which has separate hot pass bank and cold pass bank economizer portions in a parallel arrangement, each facing the same flow of hot flue gas. Feedwater enters the cold pass bank economizer where it is heated by the hot flue gas, and then flows to a water coil air heater away from the hot flue gas. The feedwater dissipates heat energy in the water coil air heater which may be used to heat air bound for combustion. The feedwater continues into the hot pass bank economizer portion of the economizer arrangement where it absorbs additional heat from the flue gas. The heated feedwater flows out of the economizer arrangement and may be subject to additional heating by a boiler or other heat exchanger.

Owner:THE BABCOCK & WILCOX CO

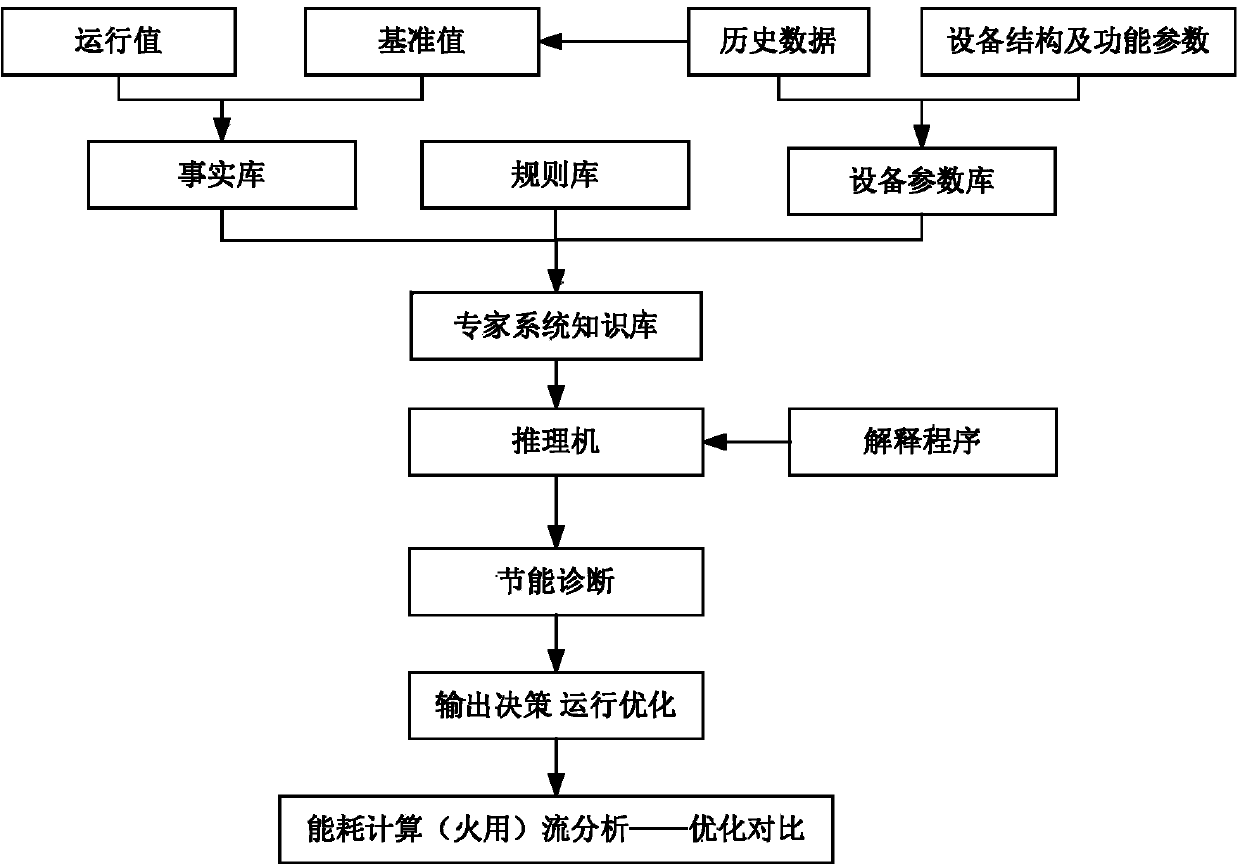

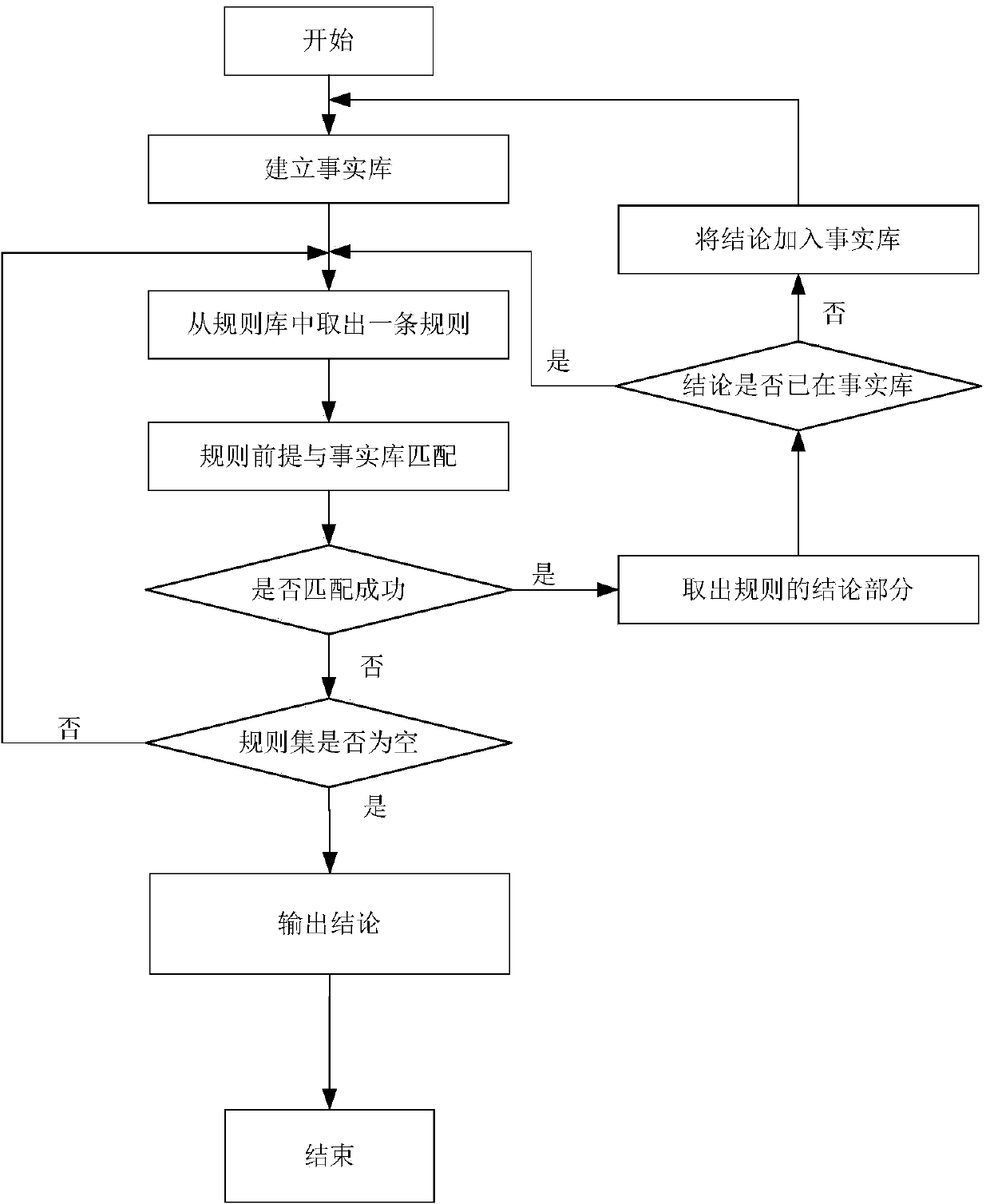

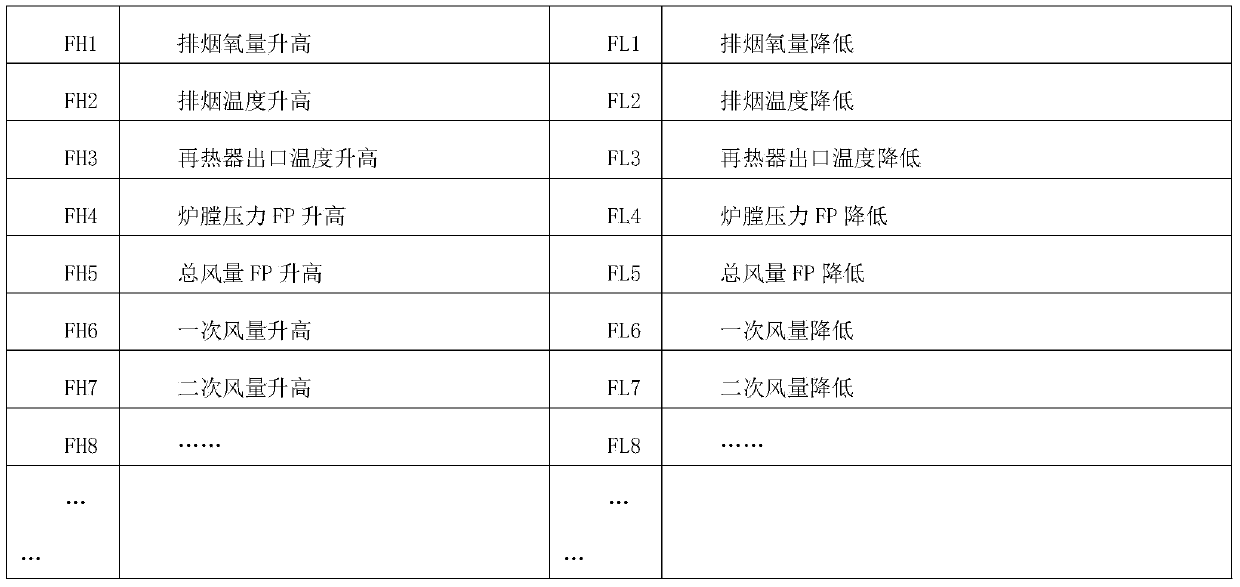

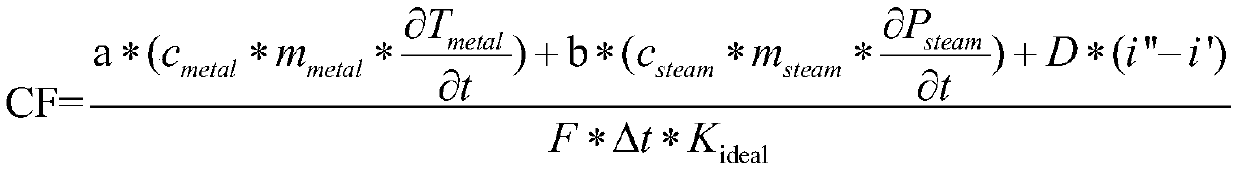

Circulating fluidized bed boiler operation optimizing method based on consumption difference analysis

ActiveCN104199290AImprove boiler efficiencyIntuitively reflect the optimization effectAdaptive controlCirculating fluidized bed boilerBoiler efficiency

The invention provides a circulating fluidized bed boiler operation optimizing method based on consumption difference analysis. According to the method, an expert system that is built based on a circulating fluidized bed boiler system can achieve simulation on energy efficiency analysis of human experts, and perform inference on boiler operation and guiding optimal operation by using expert knowledge in the industry; a critical parameter consumption difference analysis model is built, so that consumption difference computation of real-time operation critical parameters of the boiler system can be achieved, and influence of change of various parameter on boiler efficiency can be obtained; an intelligent algorithm of an expert system is used for obtaining a boiler operation optimizing strategy under a specific load working condition, and thereby boiler efficiency is improved; various losses and boiler efficiencies of the boiler system before and behind optimization are computed and compared to intuitively reflect optimizing effect of the boiler system; the platform of a knowledge base is opened that system operators correct, add or remove facts, rules and corresponding decisions and the like in real time, and thereby sensitivity and precision rate of system diagnosis are improved.

Owner:SOUTH CHINA UNIV OF TECH

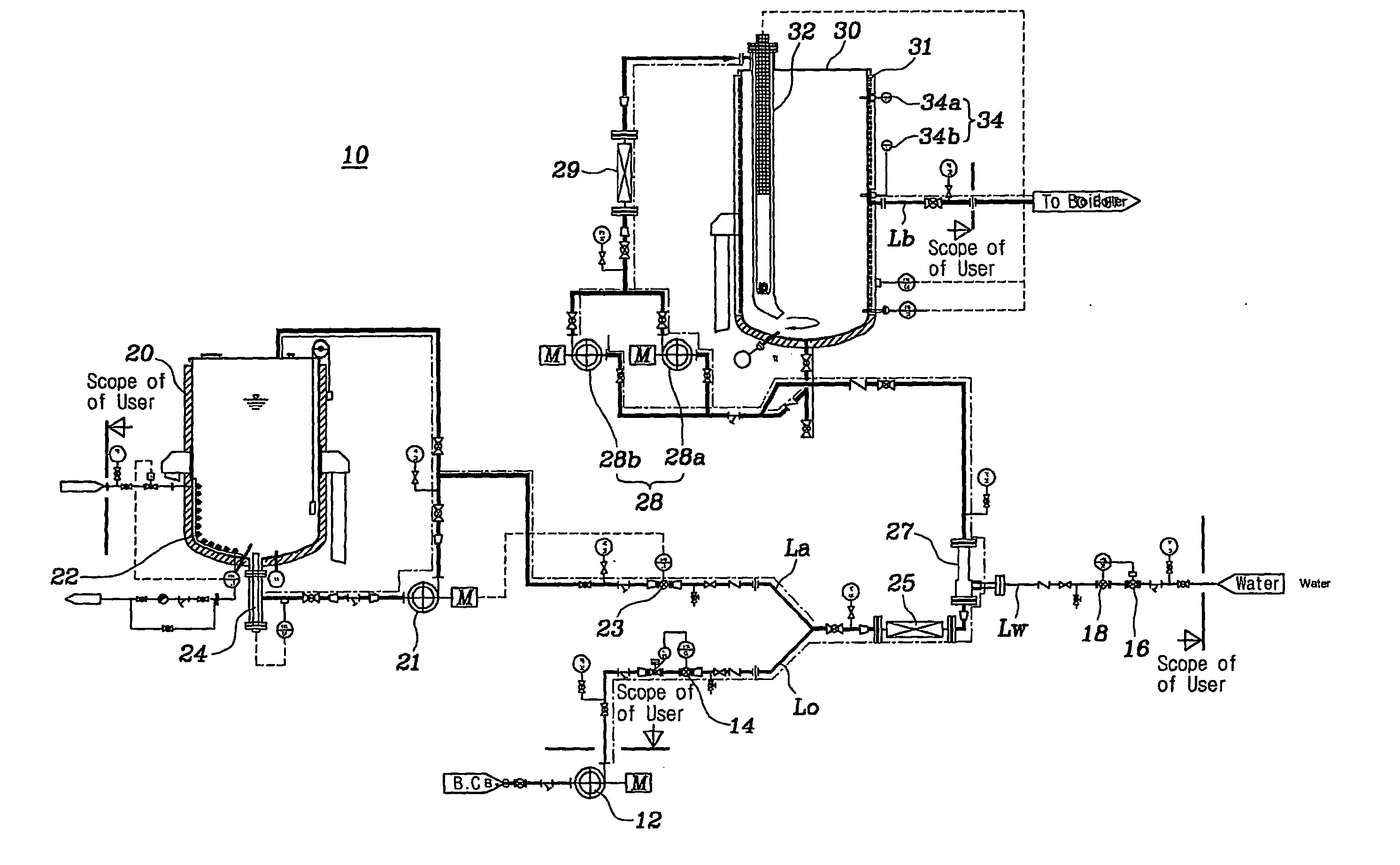

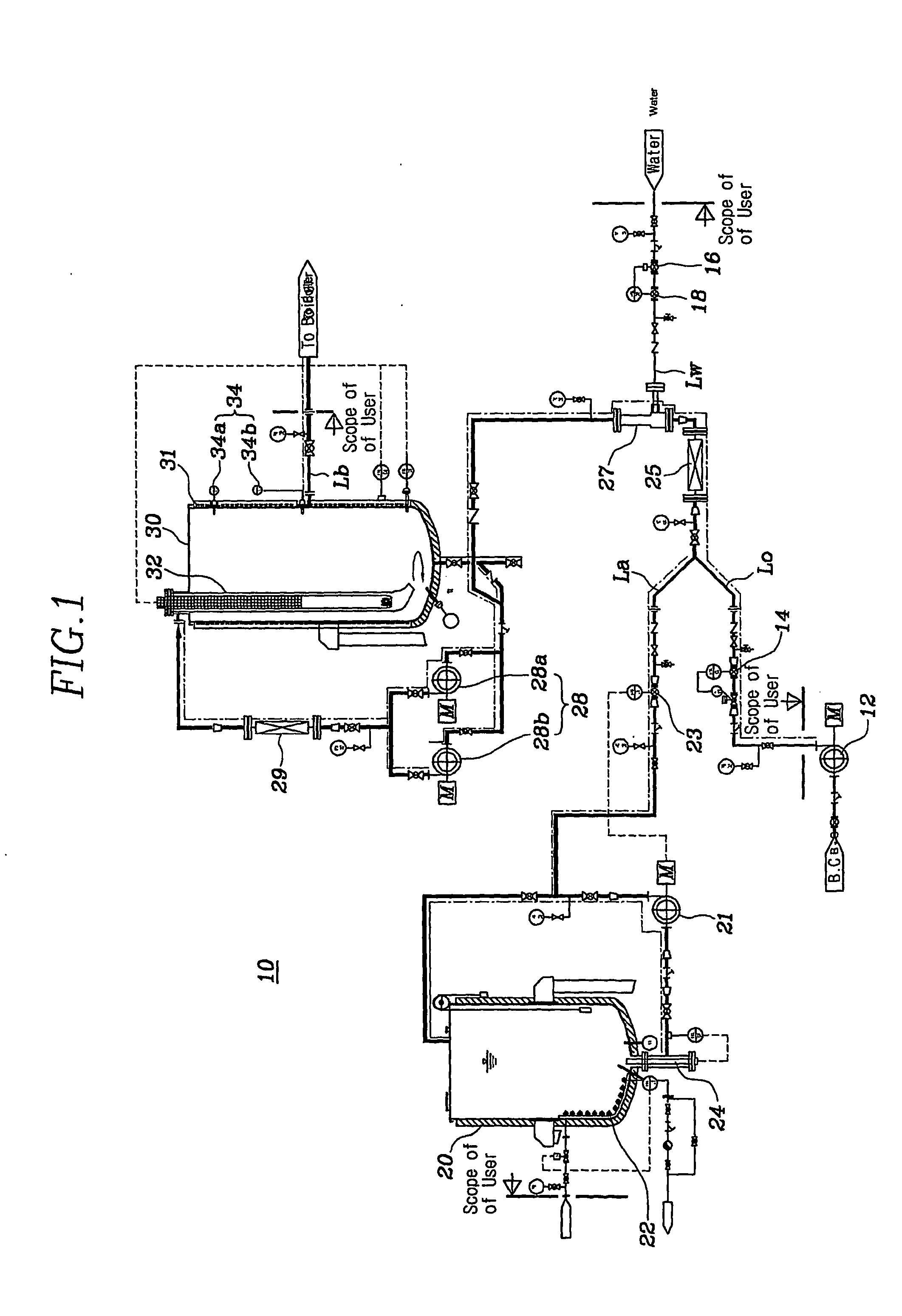

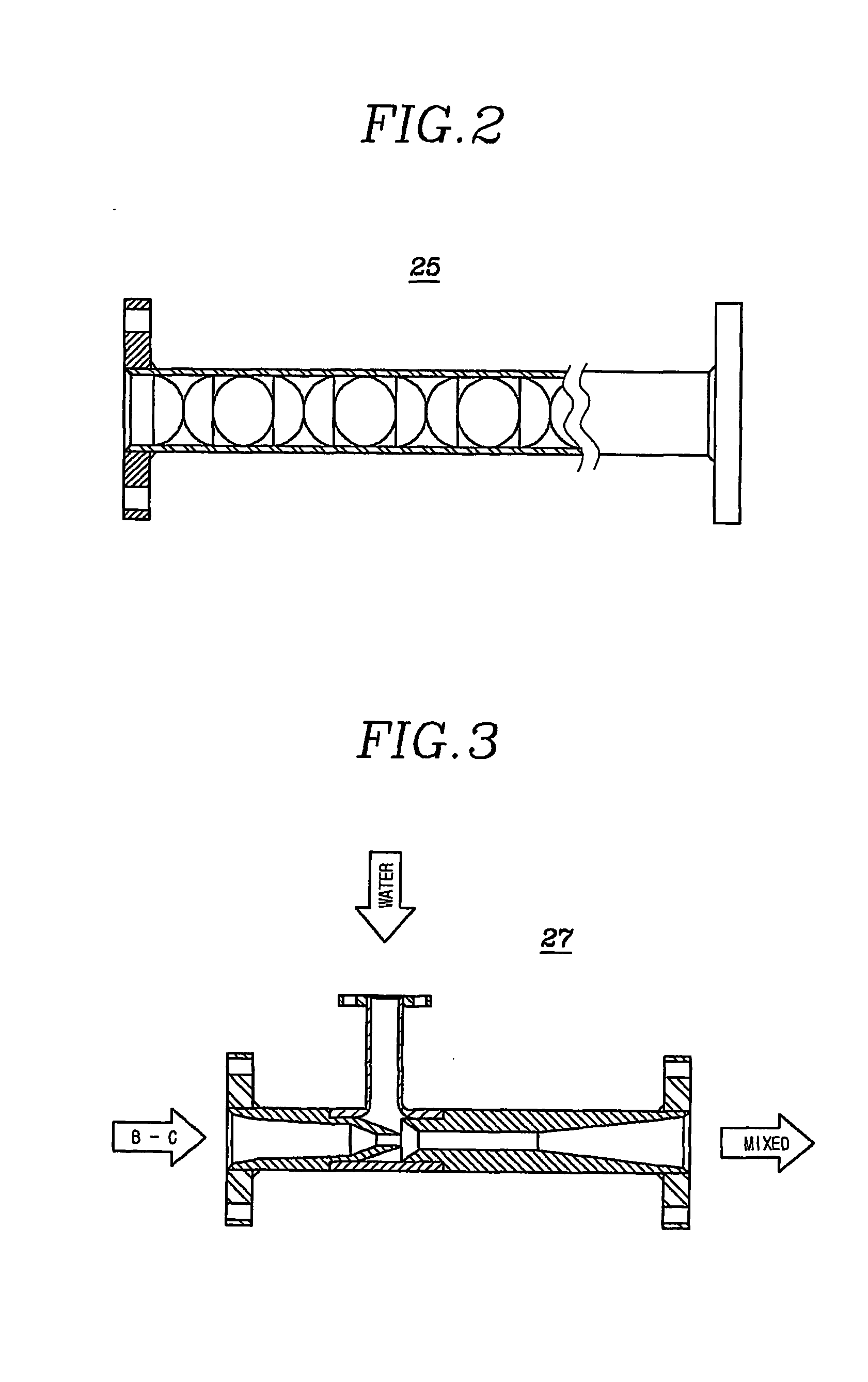

Apparatus for producing water-in-oil emulsifield fuel and supplying the same

InactiveUS20060143978A1Reduce fuel consumptionGood emulsified stateFlow mixersTransportation and packagingProcess engineeringEmulsified fuel

The present invention relates to an apparatus for producing and supplying water-in-oil emulsified fuel that supplies to a boiler water-in-oil emulsified fuel, which is emulsified by mixing an emulsifier and water in crude oil such as bunker C oil or bunker A oil. The apparatus for producing and supplying water-in-oil emulsified fuel includes an additive storage tank for storing an emulsifier; an emulsion tank for storing water-in-oil emulsified; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion. The second mixing section is realized through a circulation system that includes an emulsion tank, a mixer pump, and a double mixer. Following the supply of a predetermined amount of the raw materials, emulsified fuel mixed in the circulation system is continuously circulated even if raw material supply is stopped such that emulsified fuel that is always in a uniform state is supplied while maintaining a predetermined ratio, a predetermined moisture particle state, and a predetermined temperature.

Owner:PARK GIL WON

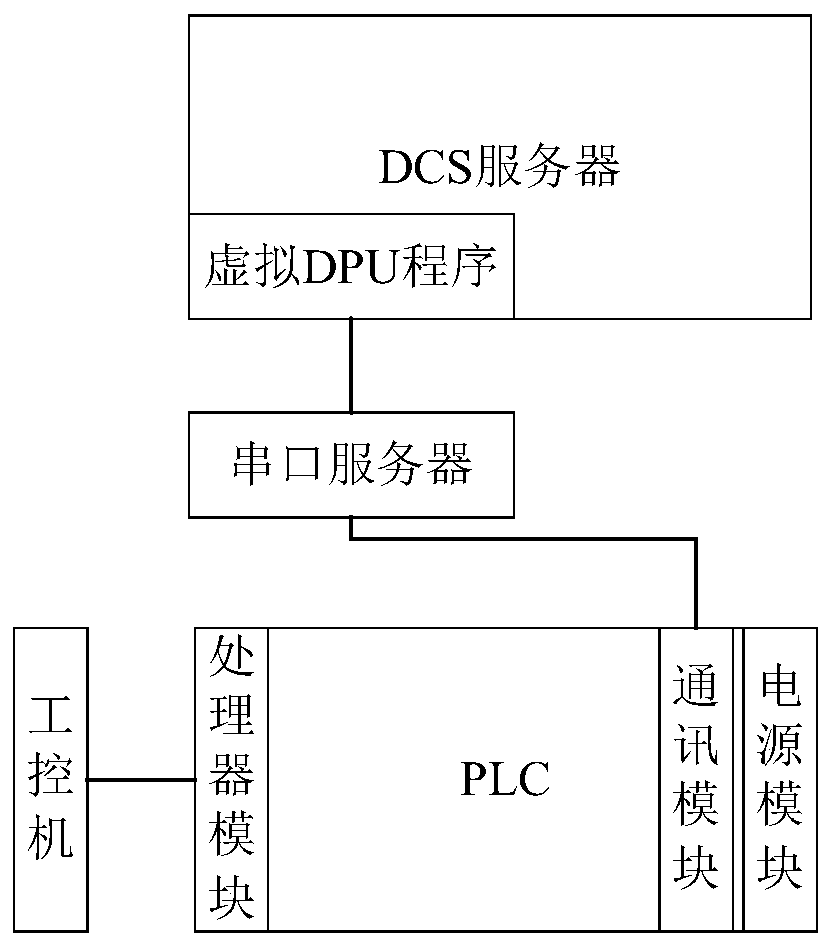

On-line monitoring system and method for accumulated dust of convection heat exchanger at tail part of coal-fired boiler

InactiveCN110578933ALow cost investmentImprove boiler efficiencyChamber safety arrangementMonitoring programNetworking cables

The invention discloses an on-line monitoring system and method for accumulated dust of a convection heat exchanger at the tail part of a coal-fired boiler. The system comprises a DCS (distributed control system) server, a serial server, a PLC (programmable logic controller) and an industrial personal computer, wherein a virtual DPU (distributed processing unit) program running on the DCS server is in TCP / IP (transmission control protocol / Internet protocol) communication with the serial server through a dynamic link communication interface program; the other end of the serial server is in communication connection with the accumulated dust monitoring PLC through an MODBUS; the PLC comprises a power module, a communication module and a processor module; the communication module is connectedwith a serial server and performs data communication through an MODBUS protocol; the processor module is connected with an industrial personal computer through a network cable to realize data communication; the power module is used for supplying power to the PLC; the industrial personal computer is used for debugging the dust deposition monitoring program and storing data; and the processor moduleis used for calculating the dust deposition degree of the convection heat exchanger at the tail part of the boiler in real time. The system is capable of characterizing the degree of dust depositionof the heat exchanger by monitoring the strength of the heat transfer process of the convection heat exchanger at the tail of the boiler in real time.

Owner:HUANENG POWER INTERNATIONAL +2

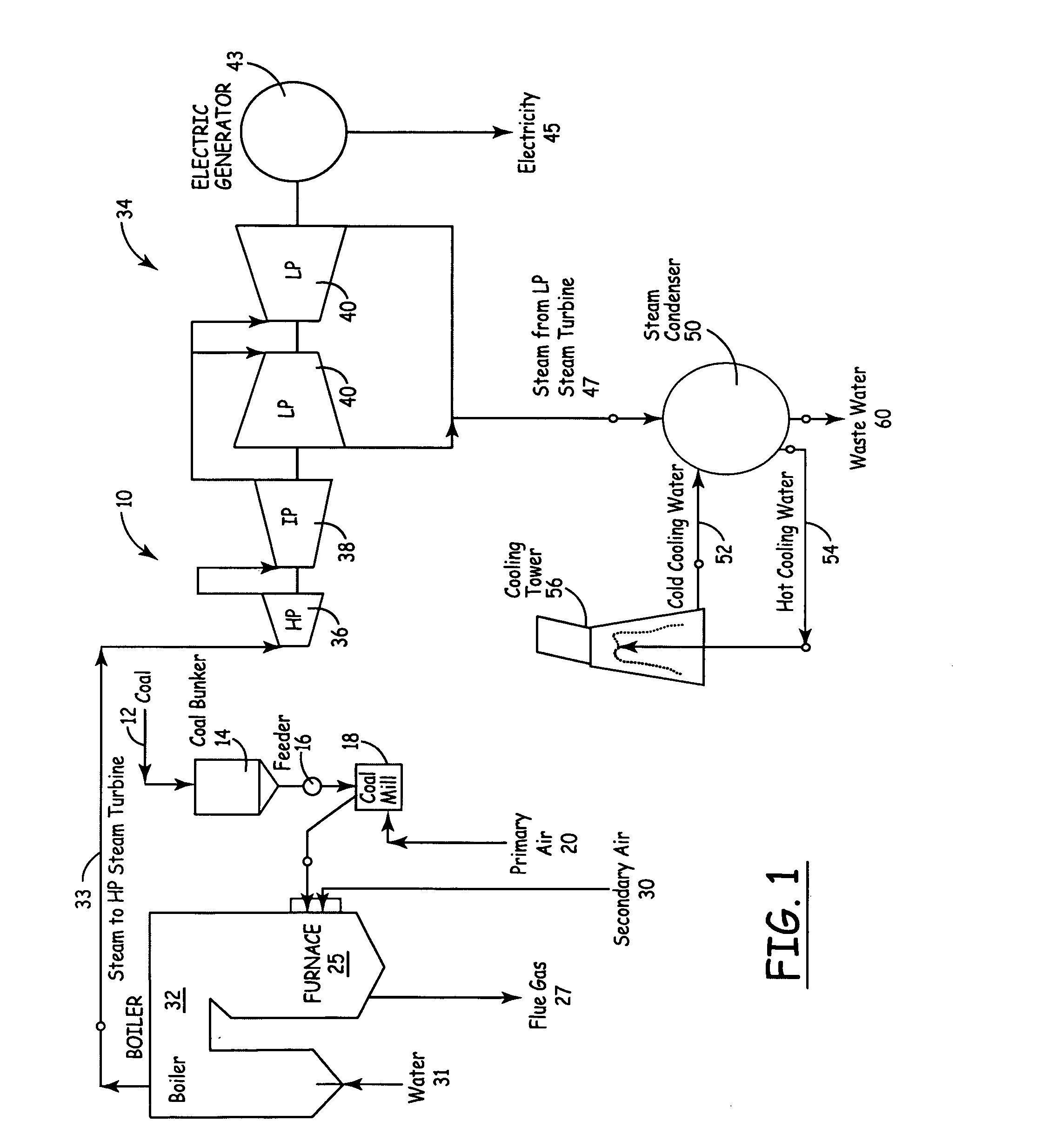

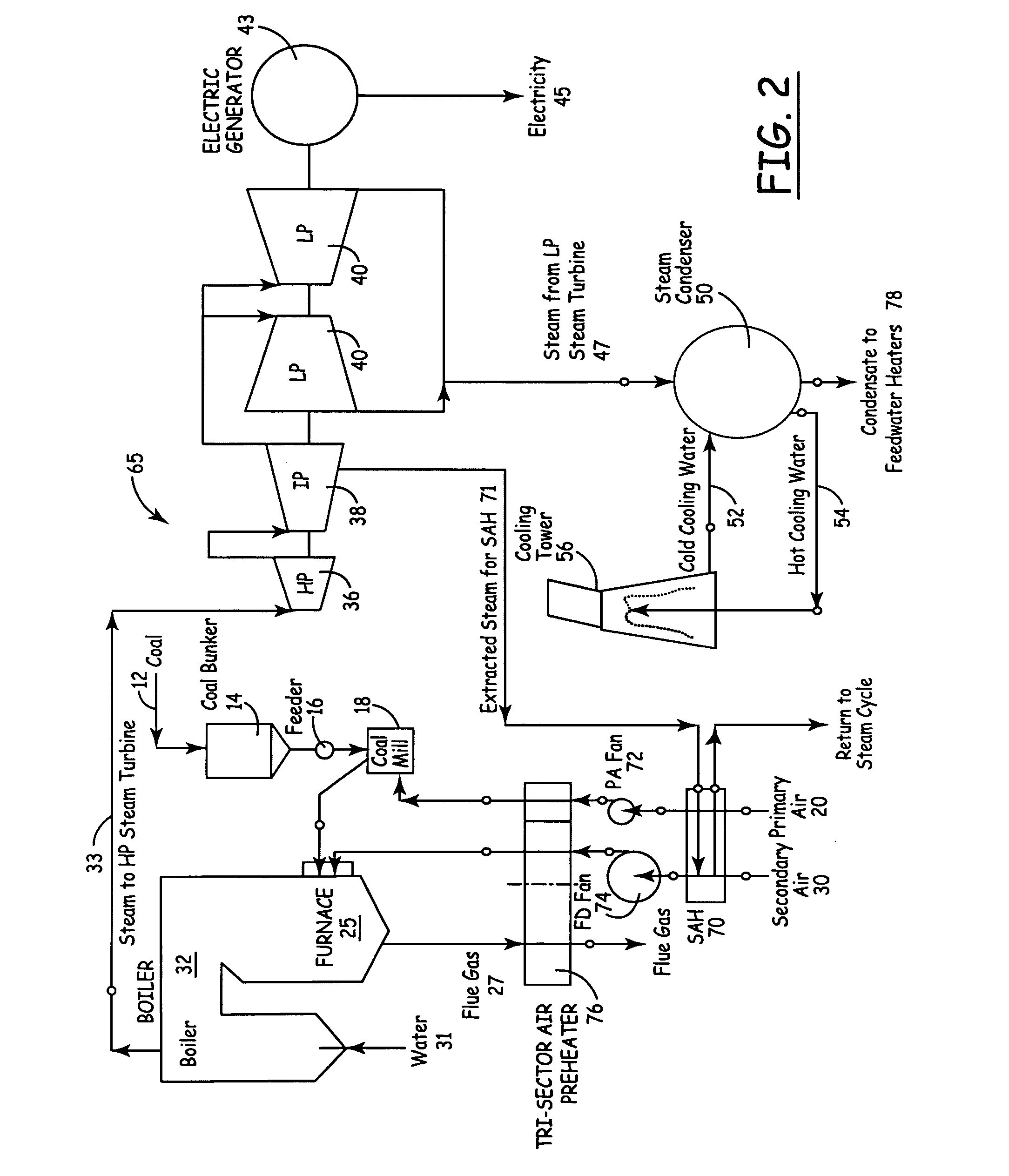

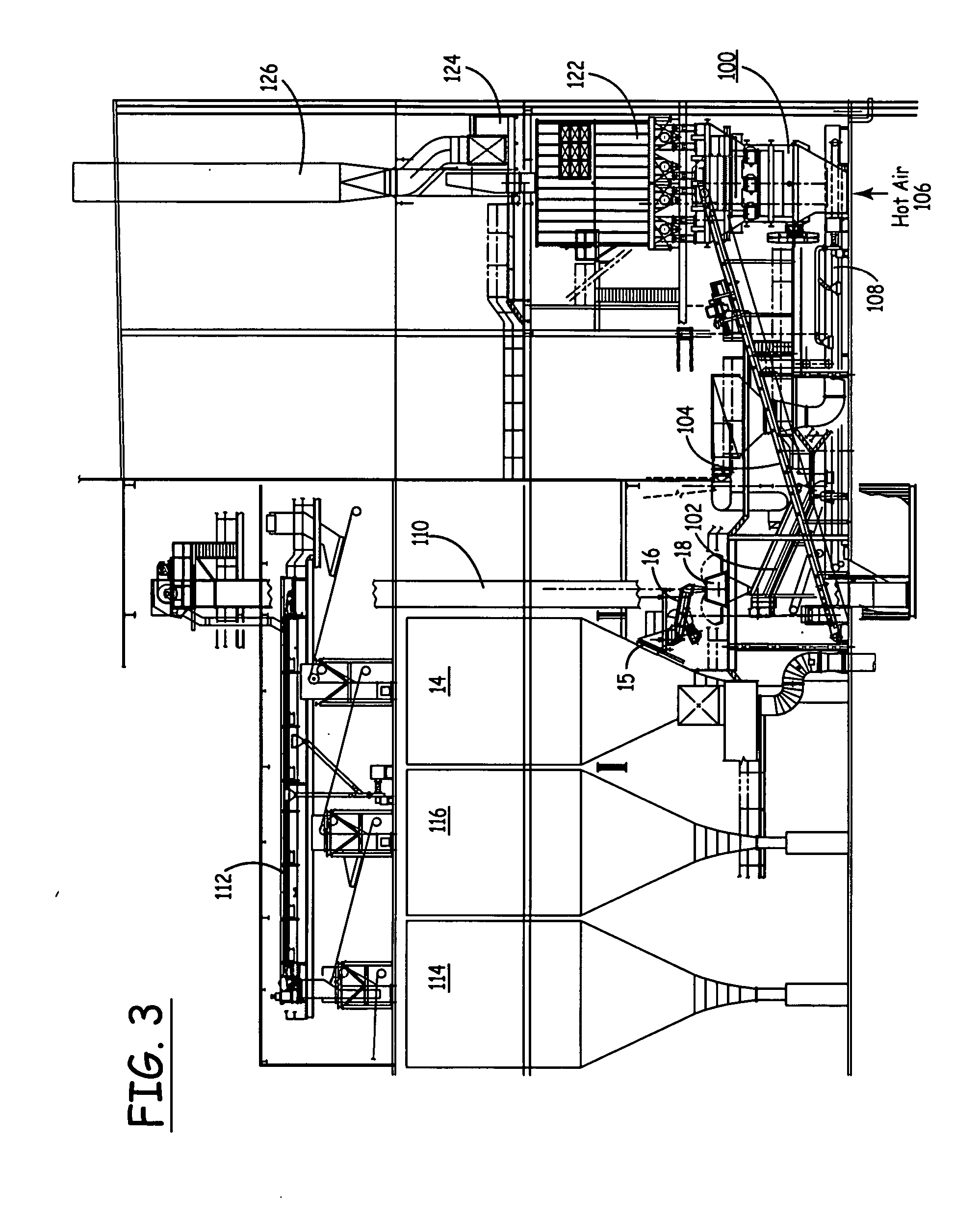

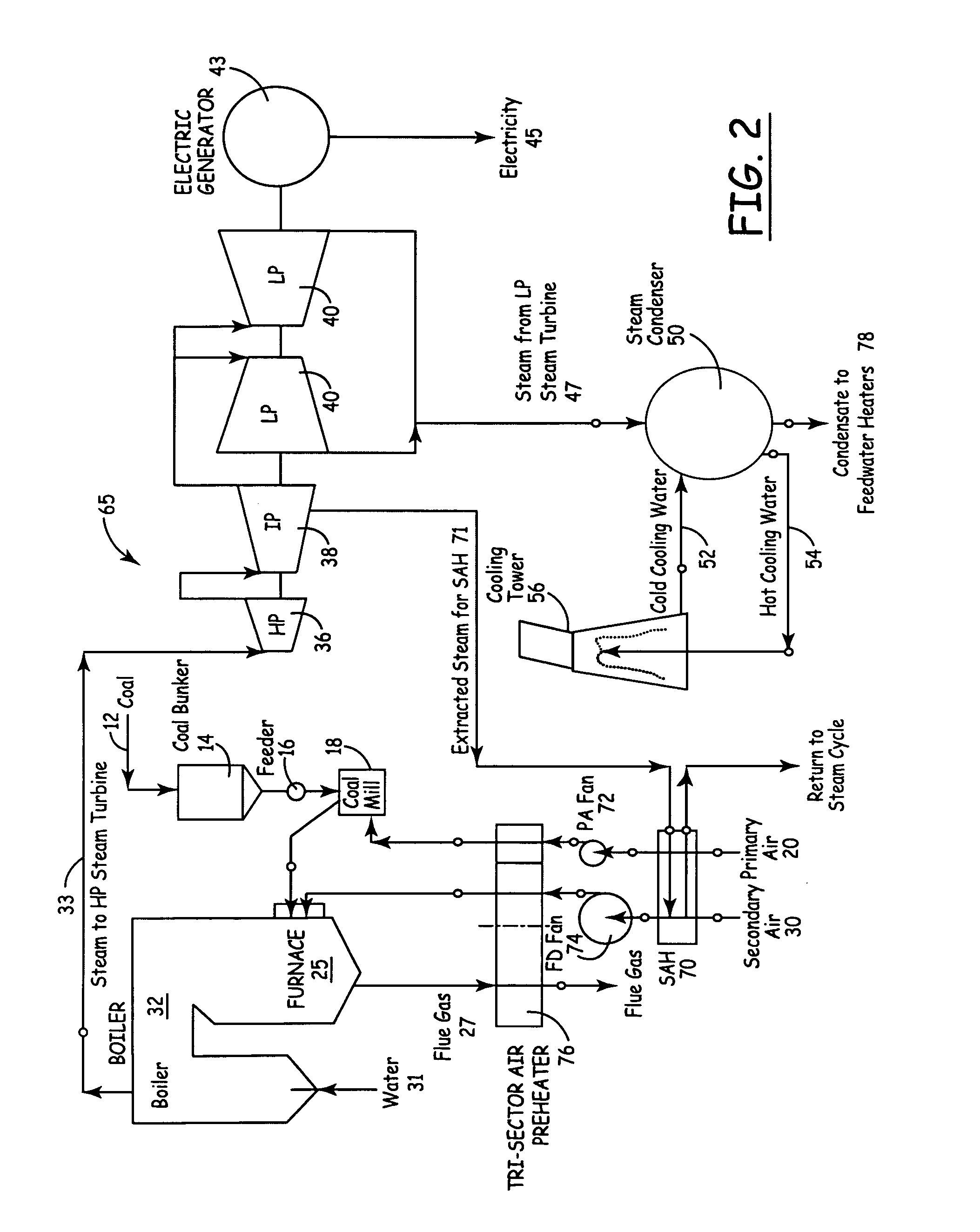

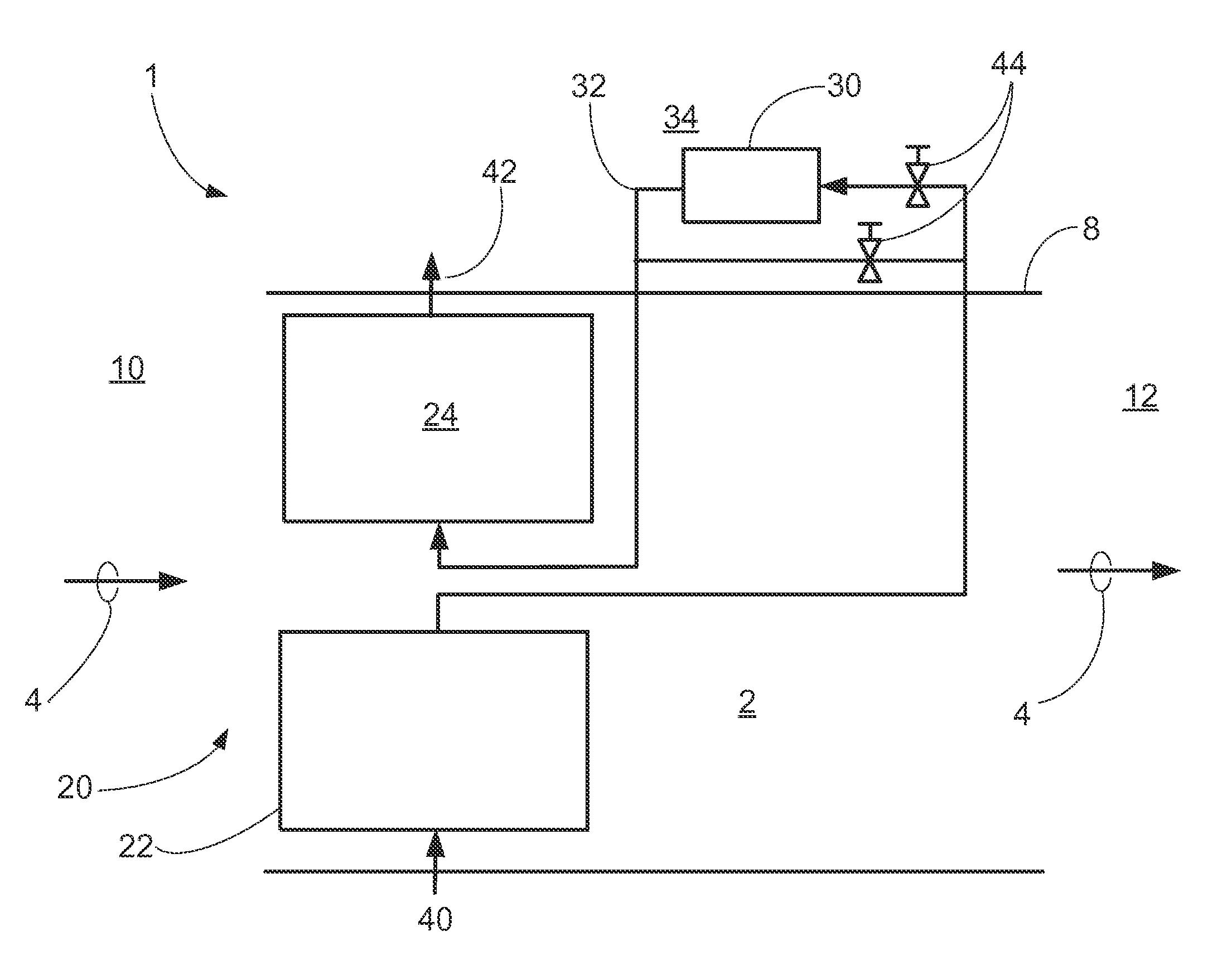

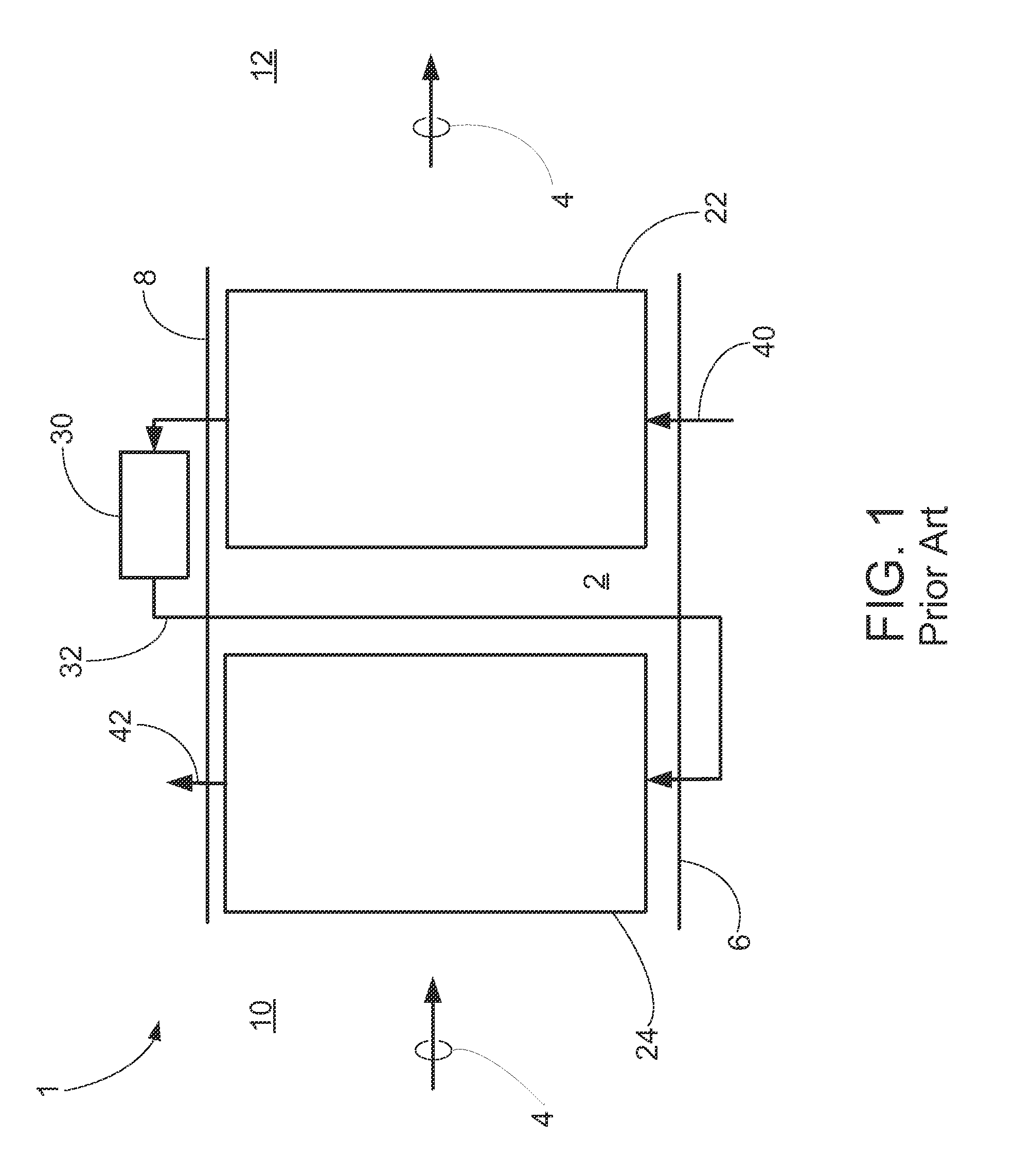

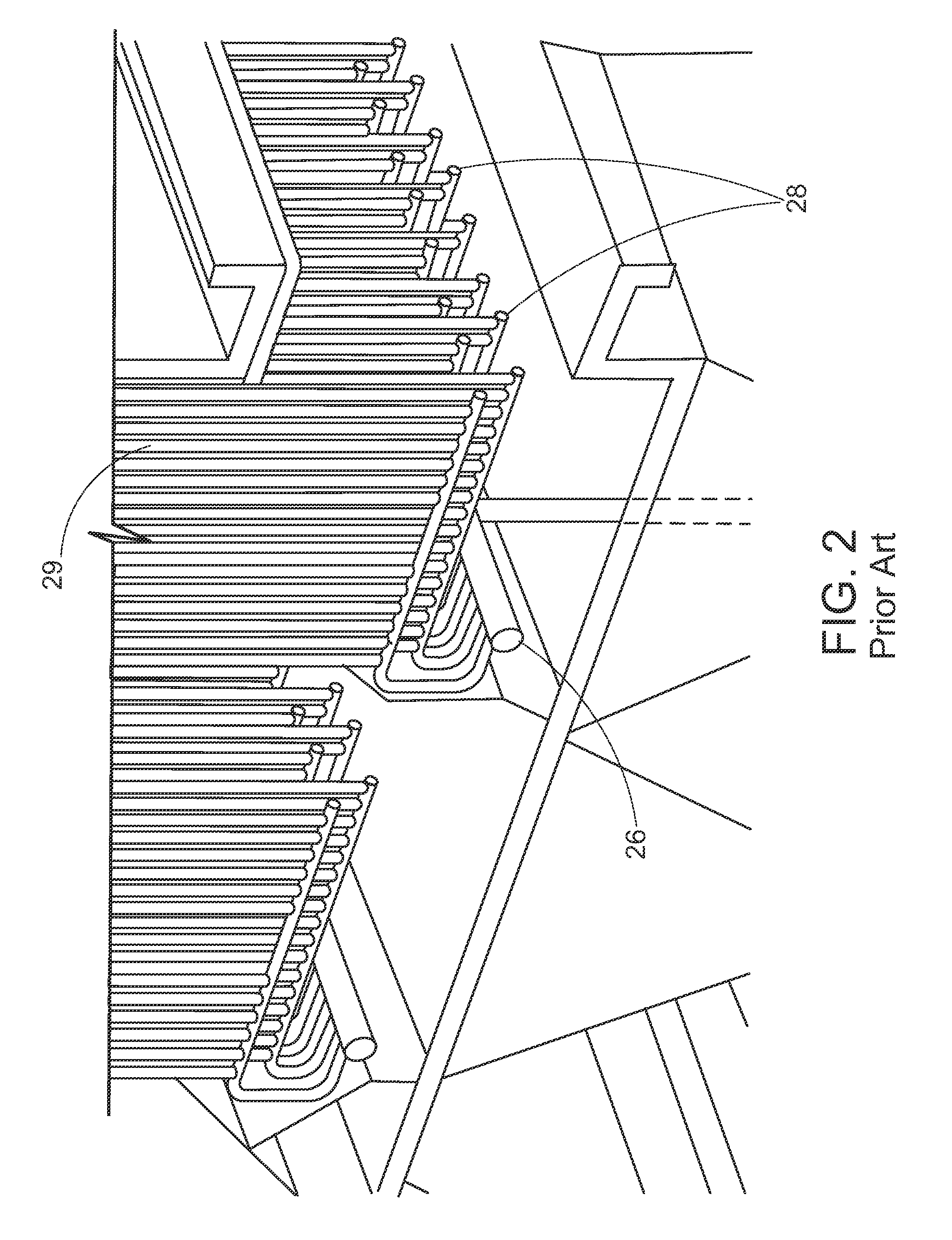

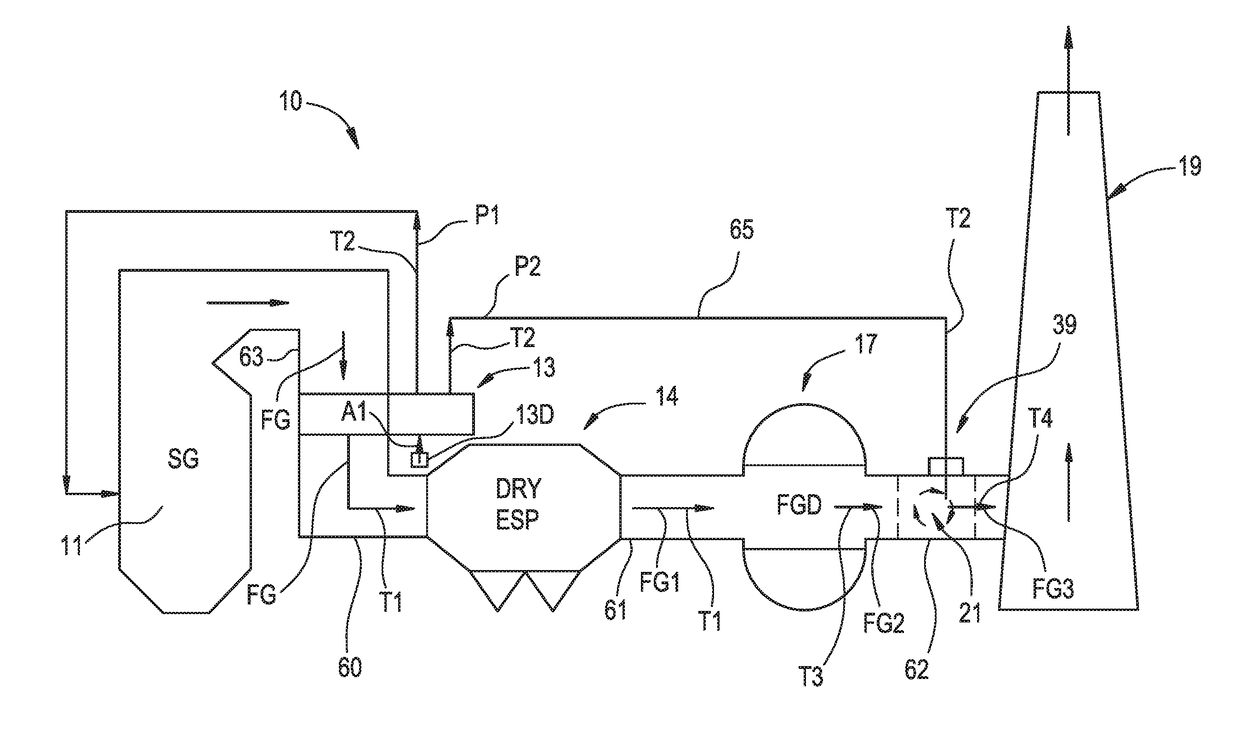

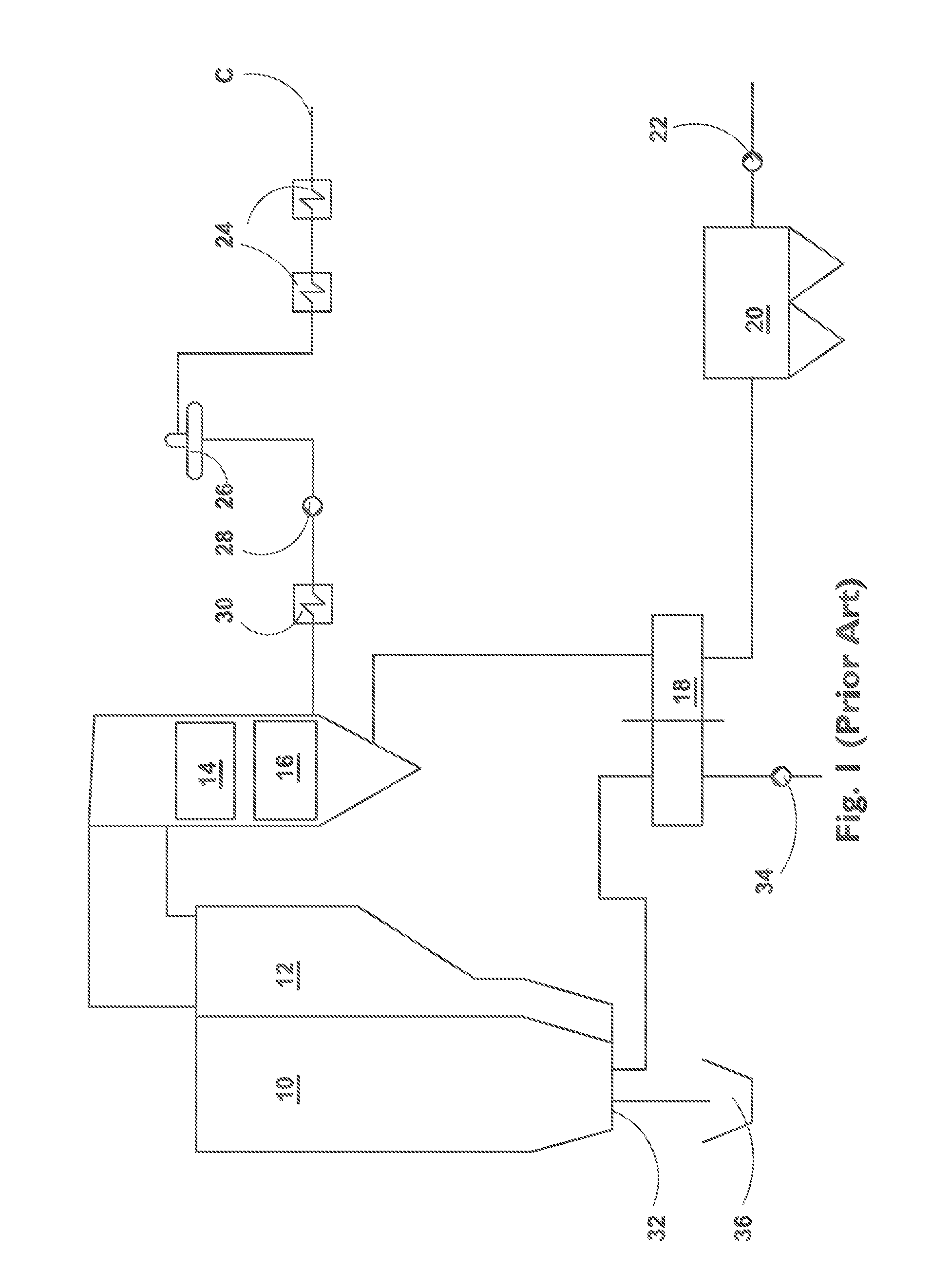

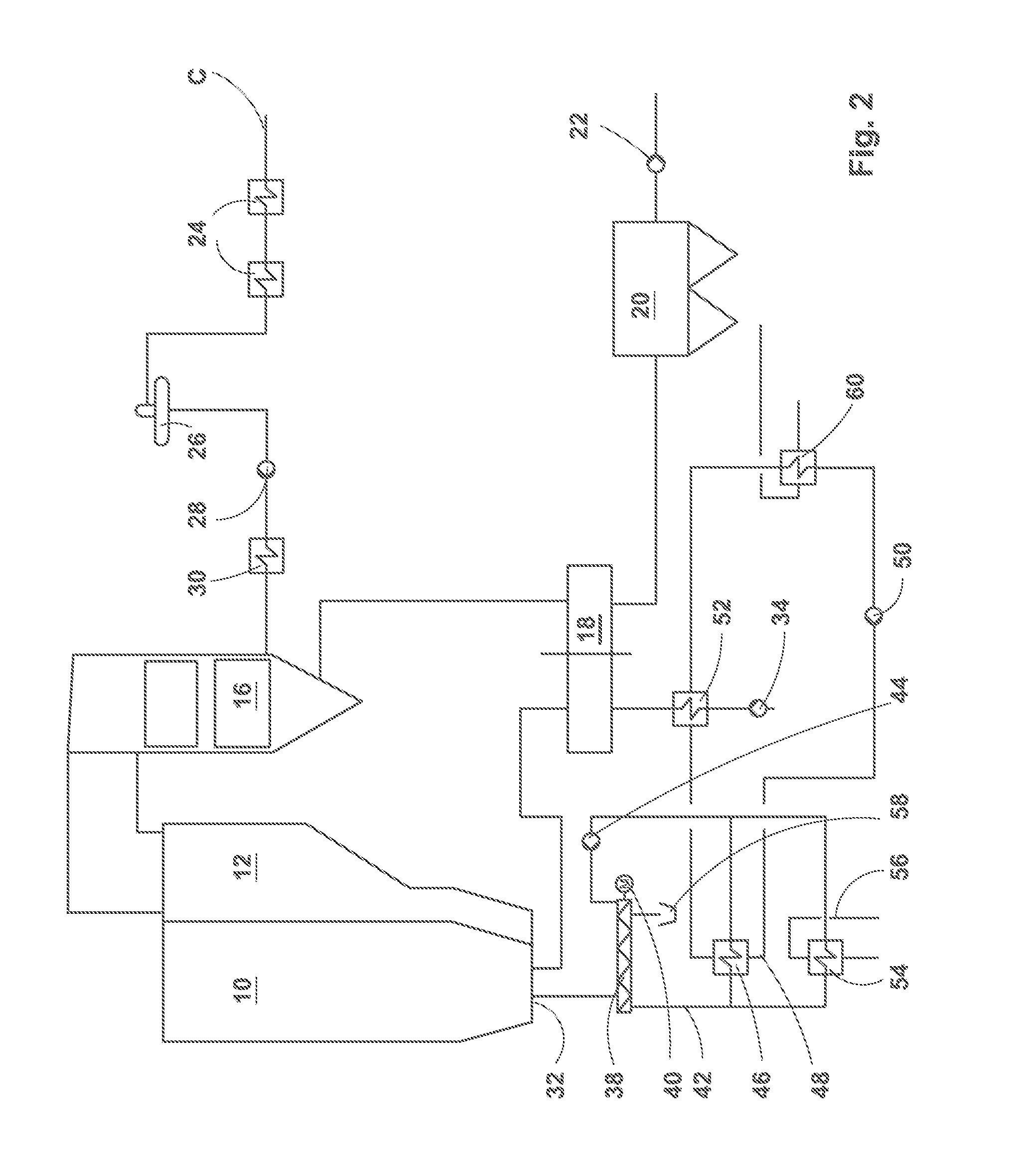

Method and system for improving boiler effectiveness

ActiveUS20180010792A1Mitigate visible plume exitingImprove efficiencyEmission preventionDispersed particle separationAir preheaterParticulates

A method for improving effectiveness of a steam generator system includes providing air to an air preheater in excess of that required for combustion of fuel and providing the air at a mass flow such that the air preheater has a cold end metal temperature that is no less than a water dew point temperature in the air preheater and such that the cold end metal temperature is less than a sulfuric acid dew point temperature. The method includes mitigating SO3 in the flue gas which is discharged directly from the air preheater to a particulate removal system and then directly into a flue gas desulfurization system. Flue gas reheat air is fed from the air preheater to heat the flue gas prior to entering a discharge stack to raise the temperature of the flue gas to mitigate visible plume exiting and to mitigate corrosion in the discharge stack.

Owner:ARVOS LJUNGSTROM LLC

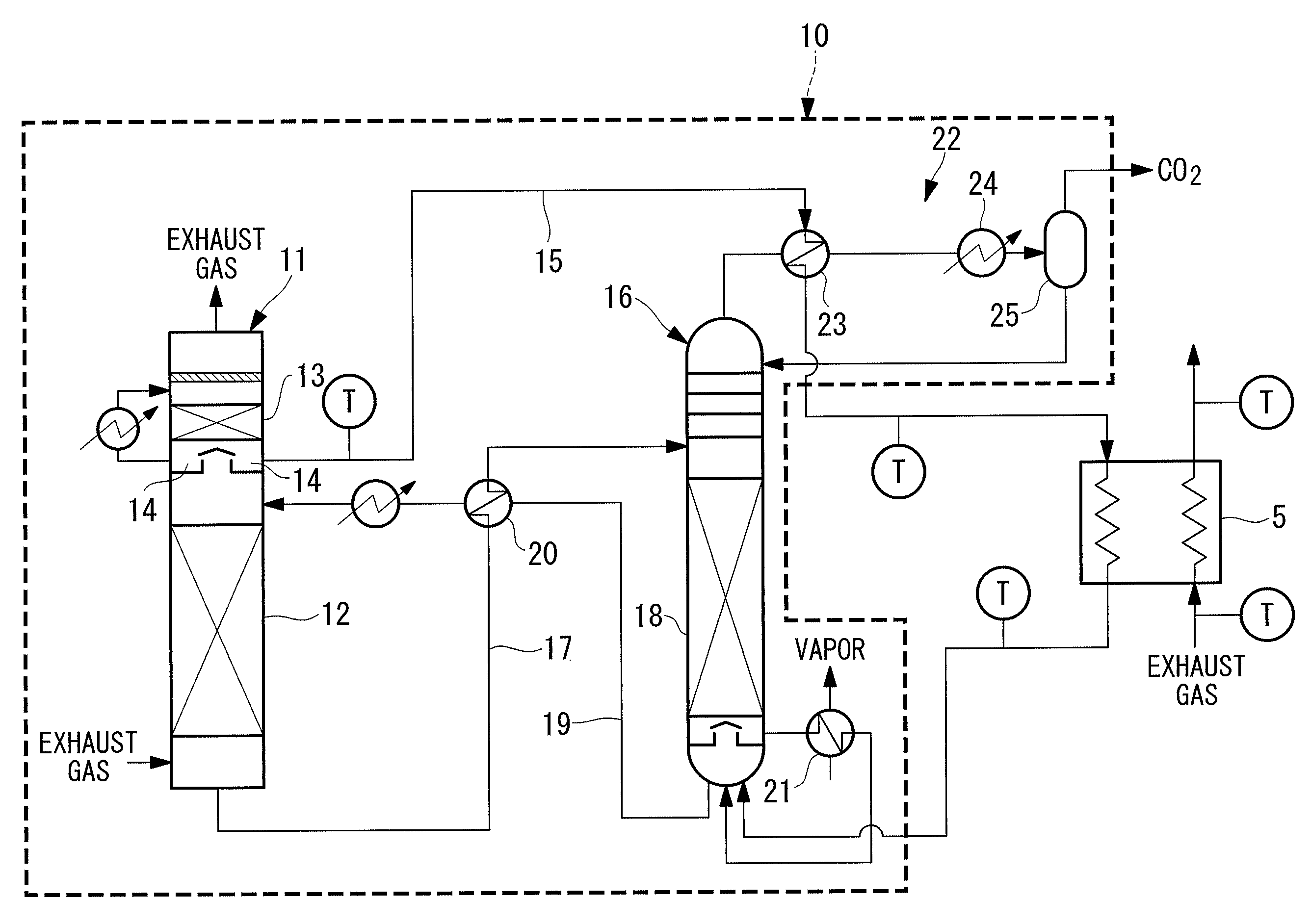

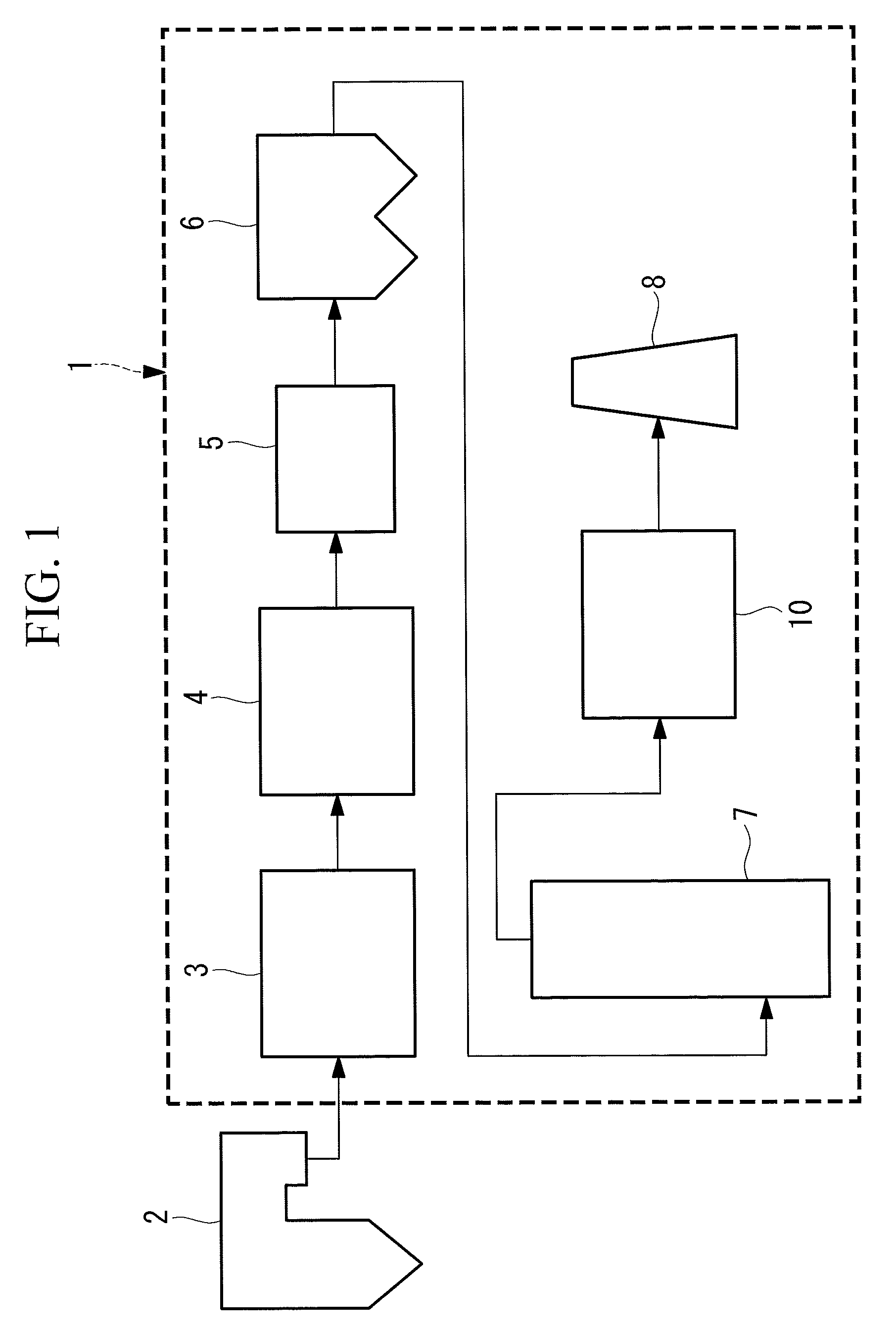

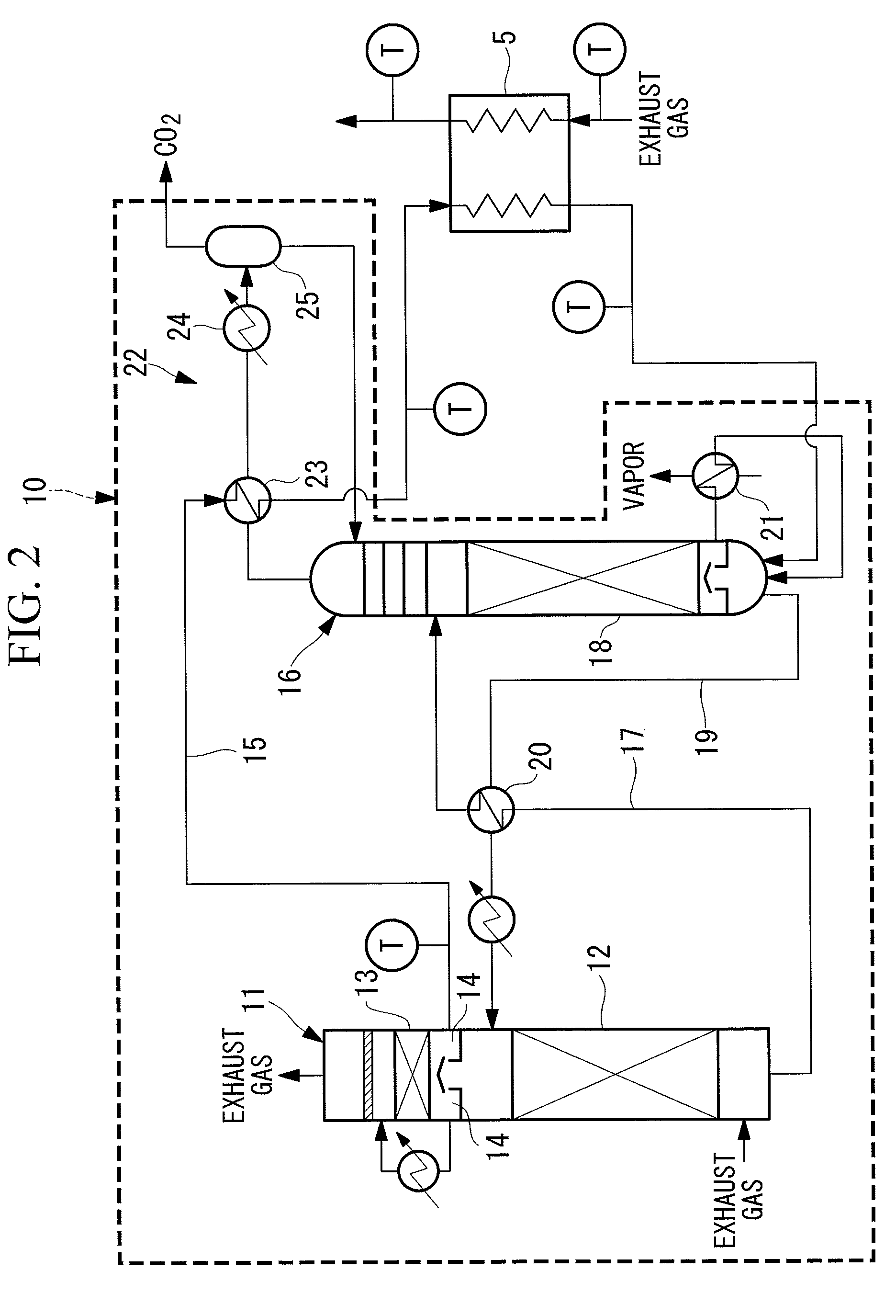

Exhaust gas treatment system

ActiveUS20130255502A1Improve thermal efficiencyImprove boiler efficiencyGas treatmentCarbon compoundsExhaust gasProcess engineering

There is provided an exhaust gas treatment system including a CO2 recovery unit with further enhanced energy efficiency. The exhaust gas treatment system (1) includes: a CO2 recovery unit (10) including a CO2 absorption column (11), an absorbing solution regeneration column (16), a condensate supply pipeline (15) for supplying condensate, which contains CO2 absorbing solution discharged from the CO2 absorption column (11) to a bottom portion of the absorbing solution regeneration column (16), and a CO2 separation section (22) for performing heat exchange, via a heat exchanger (23), between the CO2 discharged from the absorbing solution regeneration column (16) and the condensate; and an exhaust gas heat exchanger (5) provided on a gas upstream side of the CO2 recovery unit (10) for performing heat exchange between exhaust gas before flowing into the CO2 recovery unit (10) and the condensate.

Owner:MITSUBISHI HEAVY IND ENG LTD

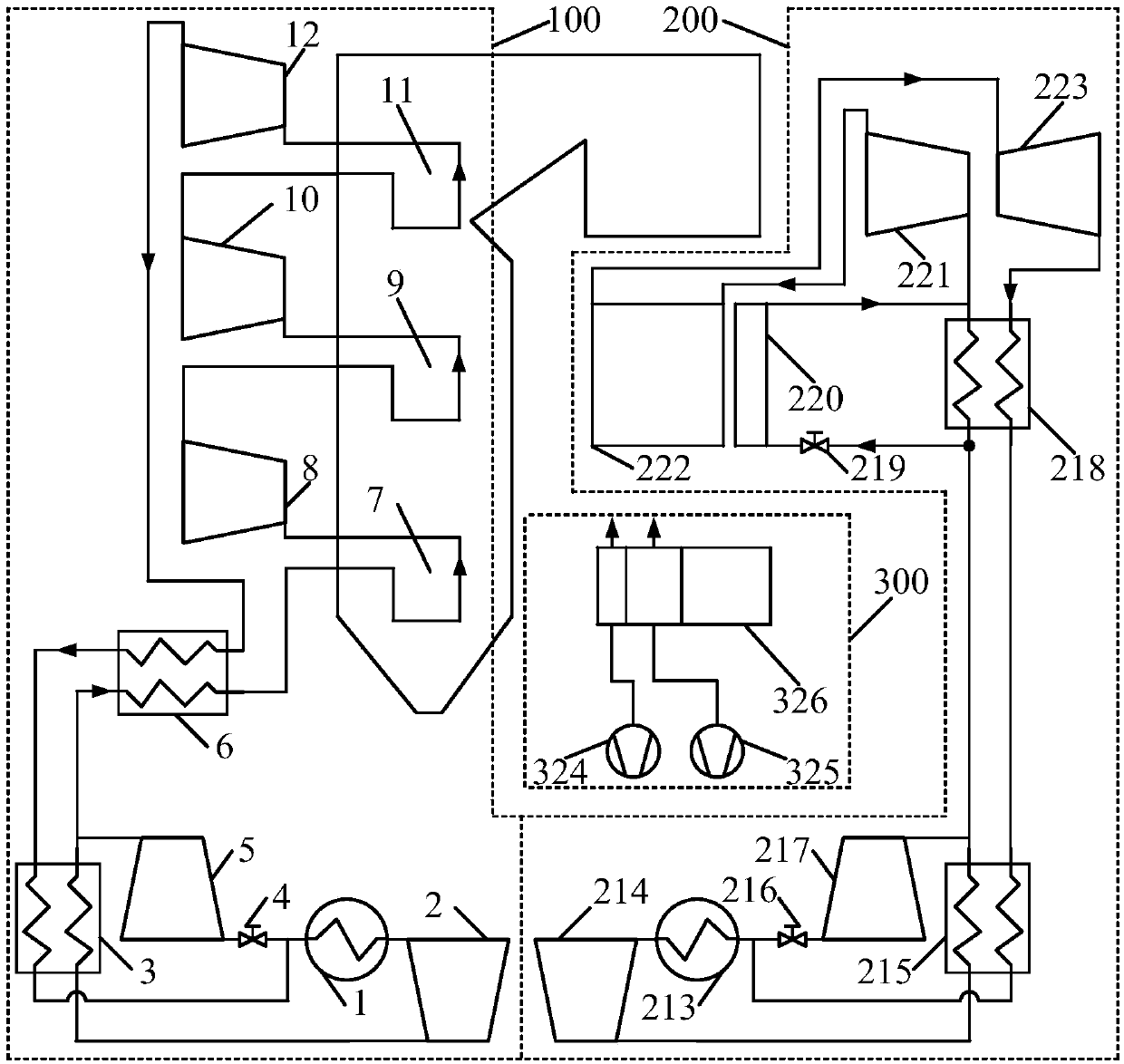

Novel supercritical CO2 compound circulation system applicable for field of coal-fired power generation

ActiveCN108678822AFully absorbedReasonable power generationLighting and heating apparatusSteam engine plantsAir preheaterCombustion

The invention discloses a novel supercritical CO2 compound circulation system applicable for the field of coal-fired power generation, and belongs to the field of high-efficiency power generation equipment. The compound circulation system is composed of a top circulation system, a bottom circulation system and an air preheater heat absorption system, and heat generated by coal combustion in a boiler is absorbed by the three systems jointly, wherein the top circulation is secondary reheating and recompression circulation; the bottom circulation is graded heating circulation, and the bottom circulation system is composed of a bottom circulation cooler, a bottom circulation first compressor, a bottom circulation low-temperature regenerator, a bottom circulation second compressor diverter valve, a bottom circulation second compressor, a bottom circulation high-temperature regenerator, a first tail flue heater diverter valve, a first tail flue heater, a bottom circulation first turbine, a second tail flue heater and a bottom circulation second turbine. Through the bottom circulation, within the inlet temperature range of 580-640 DEG C of a top circulation turbine, the compound circulation system is higher in efficiency, and the safe operation of an air preheater is ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Methods of improving productivity of black liquor recovery boilers

InactiveUS6408771B1Improve throughputImprove boiler efficiencyPulp liquors combustionSolid fuel combustionProduction rateBlack liquor

Methods are presented to increase the throughput of a recovery boiler equipped with at least primary and secondary levels of injection of air. The methods comprise operating the recovery boiler with a third level of oxidant injection below or at the same level as the secondary level, and oxygen enrichment applied to at least the secondary level and said third level.

Owner:AIR LIQUIDE IND US LP

Integrated sorbent injection and flue gas desulfurization system

ActiveUS9192890B2High energyReducing the ADP of the flue gasGas treatmentEmission preventionBaghouseSorbent

An integrated sorbent injection, heat recovery, and flue gas desulfurization system is disclosed. A dry sorbent is injected into the flue gas upstream of the air heater. This reduces the acid dew point temperature, permitting additional heat energy to be captured when the flue gas passes through the air heater. The flue gas then passes through a desulfurization unit and through a baghouse, where solids are captured. The capture of additional heat energy permits the overall boiler efficiency to be increased while safely operating at a lower flue gas temperature. The integrated system consumes no greater quantity of sorbent than conventional methods but provides the benefit of improved plant heat rate.

Owner:THE BABCOCK & WILCOX CO

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20130269934A1High work pressureIncrease vaporization rateEnergy industryFluid removalFuel oilProcess engineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle >98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

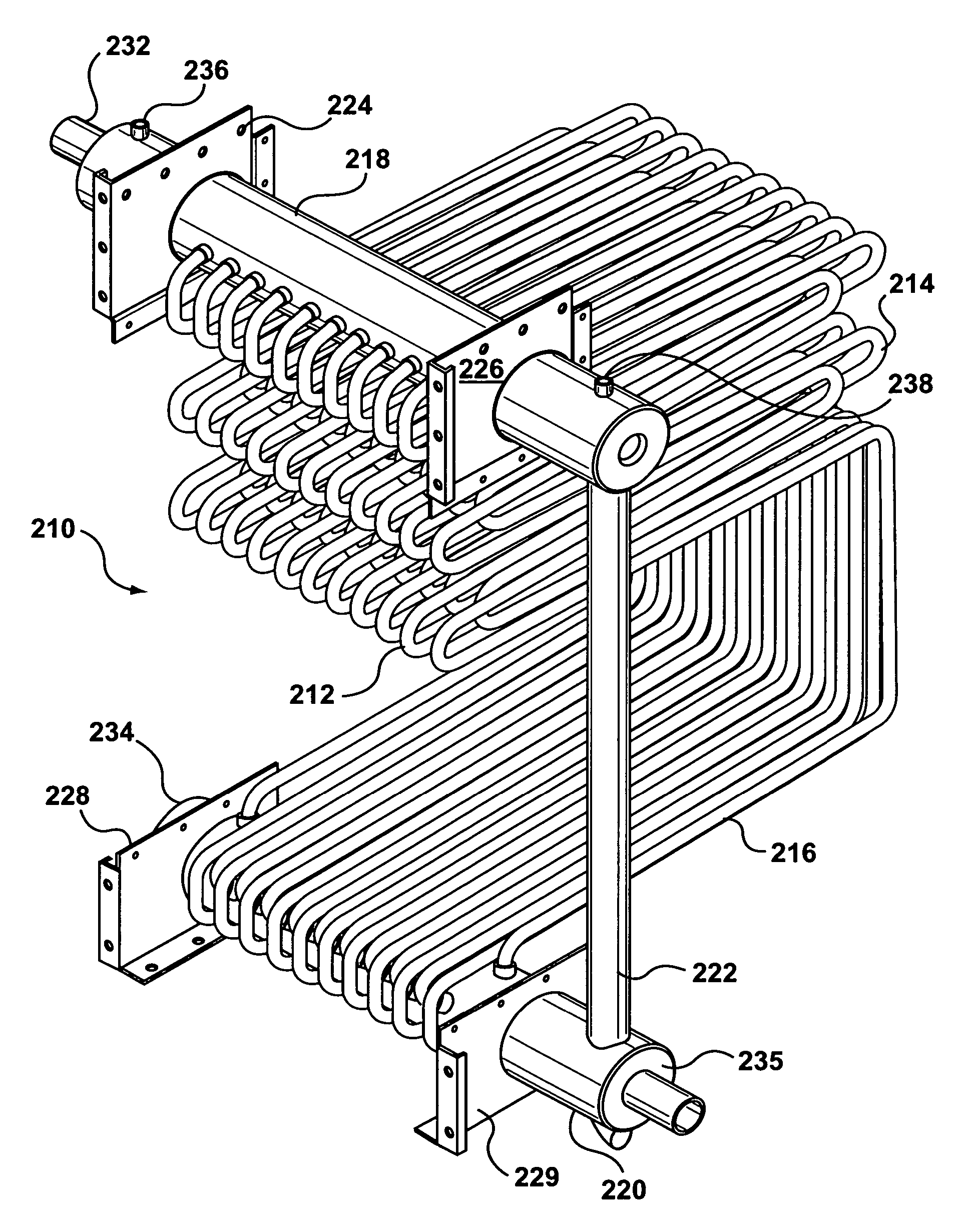

Tube assembly for a boiler

InactiveUS20060266305A1Improve boiler efficiencyGood coefficientBoiler water tubesEnergy industryFlue gasEngineering

Owner:PRIME BOILERS

Method of and Arrangement for Recovering Heat From Bottom Ash

ActiveUS20120276492A1Efficient heatingImprove boiler efficiencyFluidized bed combustionRotary drum furnacesThermal energyBottom ash

A method of recovering heat from bottom ash that is discharged from a combustion process in a furnace. Fuel and combustion air are fed into a furnace for combusting the fuel in order to generate heat energy to produce steam or hot water in a boiler arrangement, in which flue gases and bottom ash are formed. The bottom ash is discharged from the furnace. Heat is recovered from the flue gases, and heat is recovered to a bottom ash cooling water circuit from the bottom ash discharged from the furnace in order to utilize the recovered heat for preheating the combustion air in a heat exchanger.

Owner:AMEC FOSTER WHEELER ENERGIA

Powering system combining photovoltaic photo-thermal heat collector and fuel gas-steam combined circulation unit

InactiveCN103362577ALower working temperatureImprove photoelectric conversion rateSolar heating energySolar heat devicesWater dischargeCoal

A powering system combining a photovoltaic photo-thermal heat collector and a fuel gas-steam combined circulation unit comprises the fuel gas-steam combined circulation unit, a PVT heat collecting system and a drainage pump; part of condensed water discharged from a condensed water pump of the fuel gas-steam combined circulation unit enters the PVT heat collecting system to be heated, the condensed water heated by the PVT heat collecting system and the rest condensed water discharged by the condensed water pump are converged to enter a water working medium inlet of a low-pressure coal economizer of a waste heat boiler of the fuel gas-steam combined circulation unit, and the electrical energy output end of the PVT heat collecting system is connected with a load or a power grid. The PVT heat collecting system and the fuel gas-steam combined circulation unit are organically combined together, thus well solving the problems of radiating of a photovoltaic battery and the waste heat utilization, greatly improving the comprehensive utilization rate of resources, reducing the consumption of natural gas and facilitating the energy saving and emission reduction of a fuel gas-steam combined power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Methods of improving productivity of black liquor recovery boilers

InactiveUS6799526B2Improve throughputImprove boiler efficiencyPulp liquors combustionSolid fuel combustionThree levelProduction rate

Methods of increasing the throughput of recovery boilers equipped with at least three levels of injection of air with oxygen enrichment of the air in at least one air level. In one method, a black liquor recovery boiler has three levels of air injection, and oxygen enrichment is applied to at least the secondary and the tertiary air injection levels. In another method, a black liquor recovery boiler has four levels of air injection, and oxygen enrichment is applied to one or more of the tertiary or quaternary air injection levels. In another method, a black liquor boiler has three levels of air injection, with oxygen enrichment applied to at least two air injection levels. After combustion, the oxygen concentration in the resultant flue gas is sensed. The oxygen injection is then adjusted in order to maintain the sensed oxygen concentration at the previously selected oxygen set point.

Owner:AIR LIQUIDE IND US LP

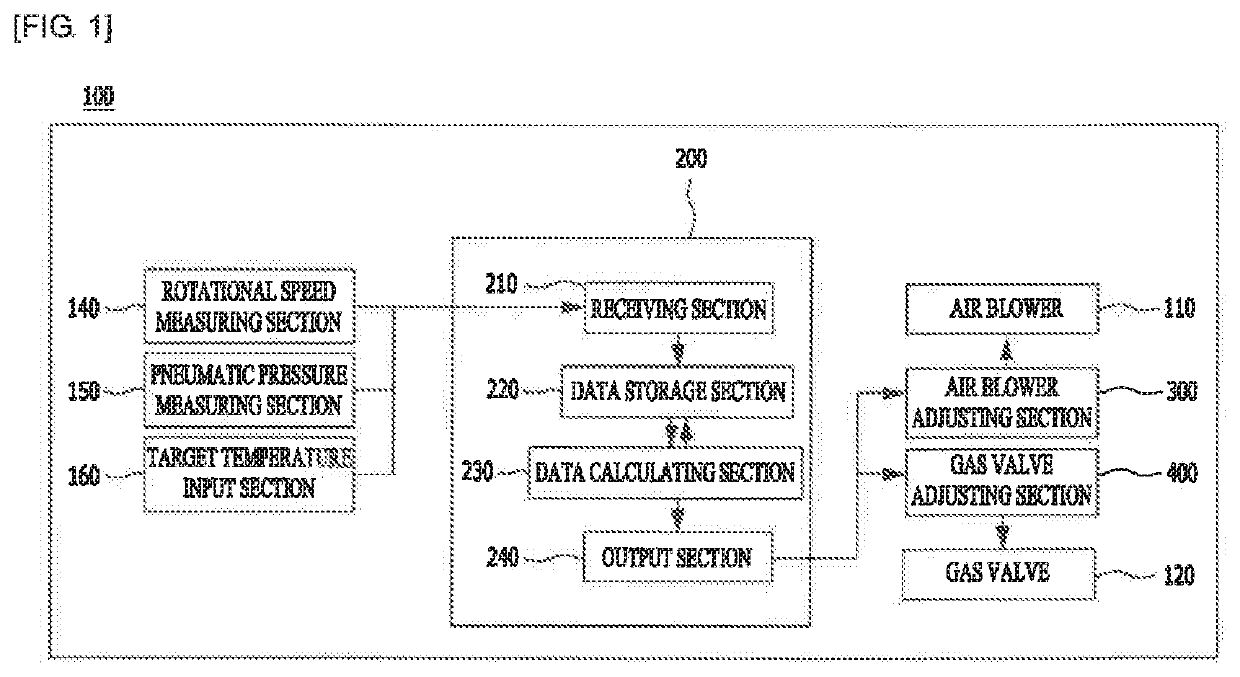

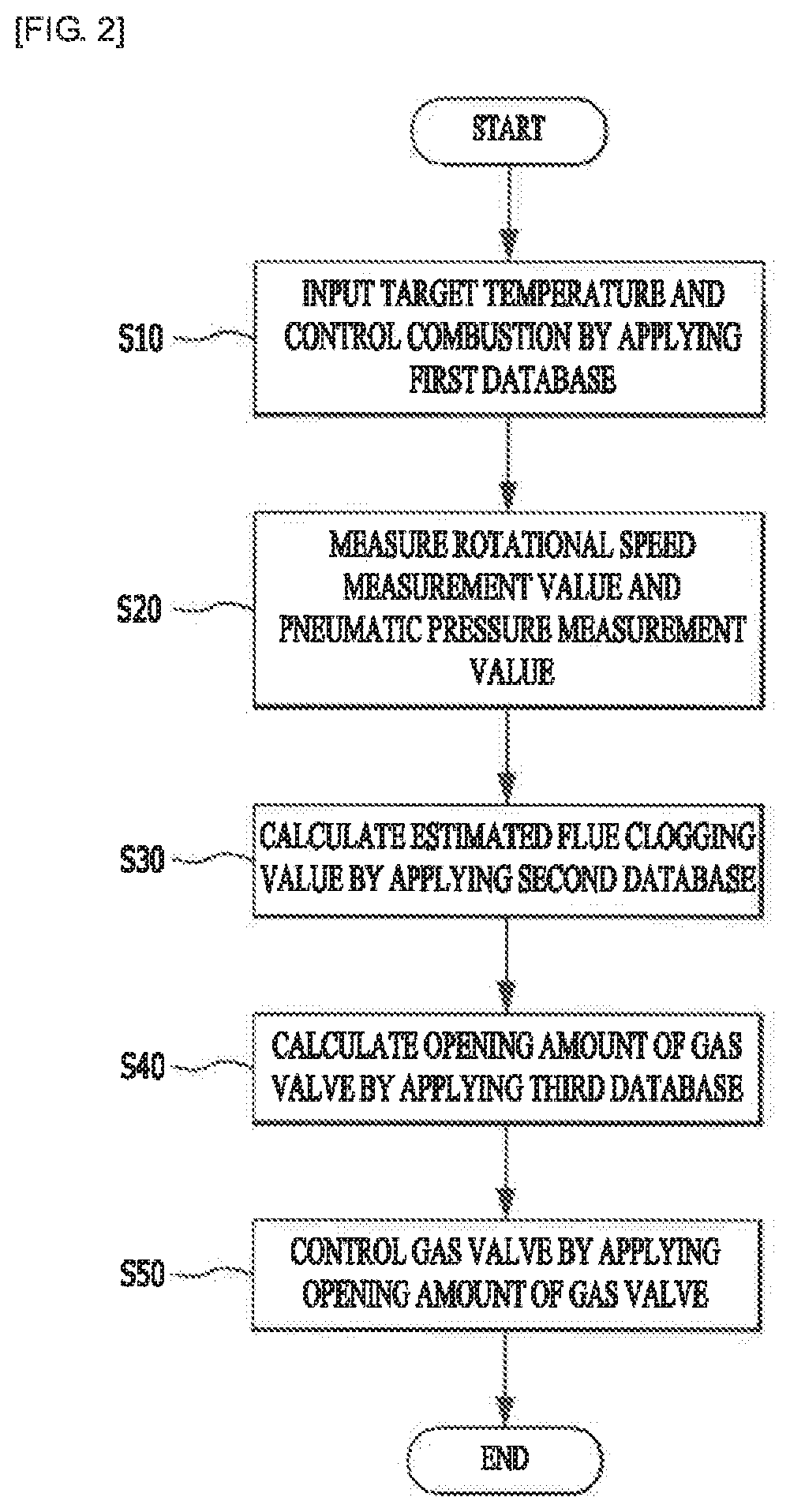

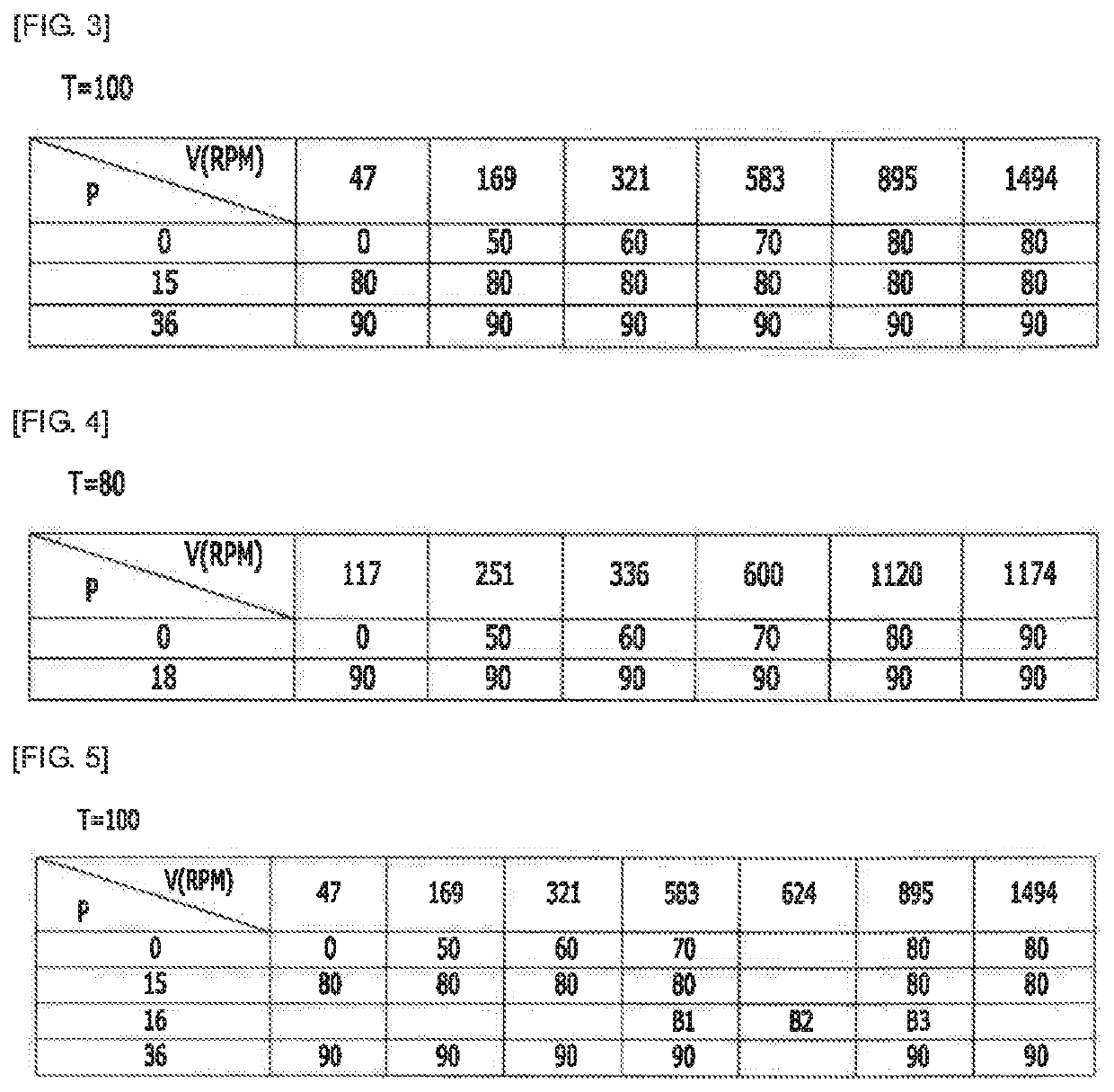

Boiler and the method for controlling combustion of the boiler

ActiveUS20200208877A1Improve boiler efficiencyMaintain combustibilityFuel supply regulationWater heatersThermodynamicsEngineering

The present invention relates to a boiler which determines a clogging degree of an exhaust flue through which combustion gas is discharged and adjusts gas supply amount to maintain its combustibility, and a combustion control method thereof, the method of the present invention including a) setting a target heat value for achieving a target temperature, b) applying a first database on the basis of the target heat value, c) measuring a rotational speed of an air blower and a pneumatic pressure of air introduced by rotation of the air blow, d) applying a second database on the basis of a rotational speed difference, a pneumatic pressure difference, and the target heat value to calculate an estimated flue clogging value according to the target heat value, and a) applying a third database according to the estimated flue clogging value to calculate an opening amount of a gas valve and control gas supply amount.

Owner:KYUNGDONG NAVIEN

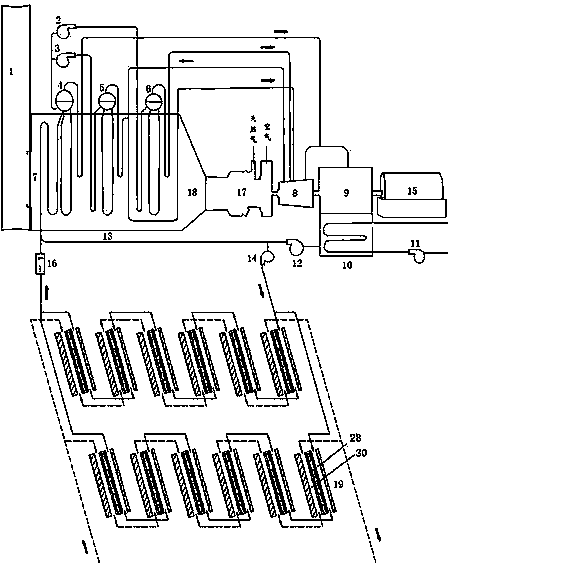

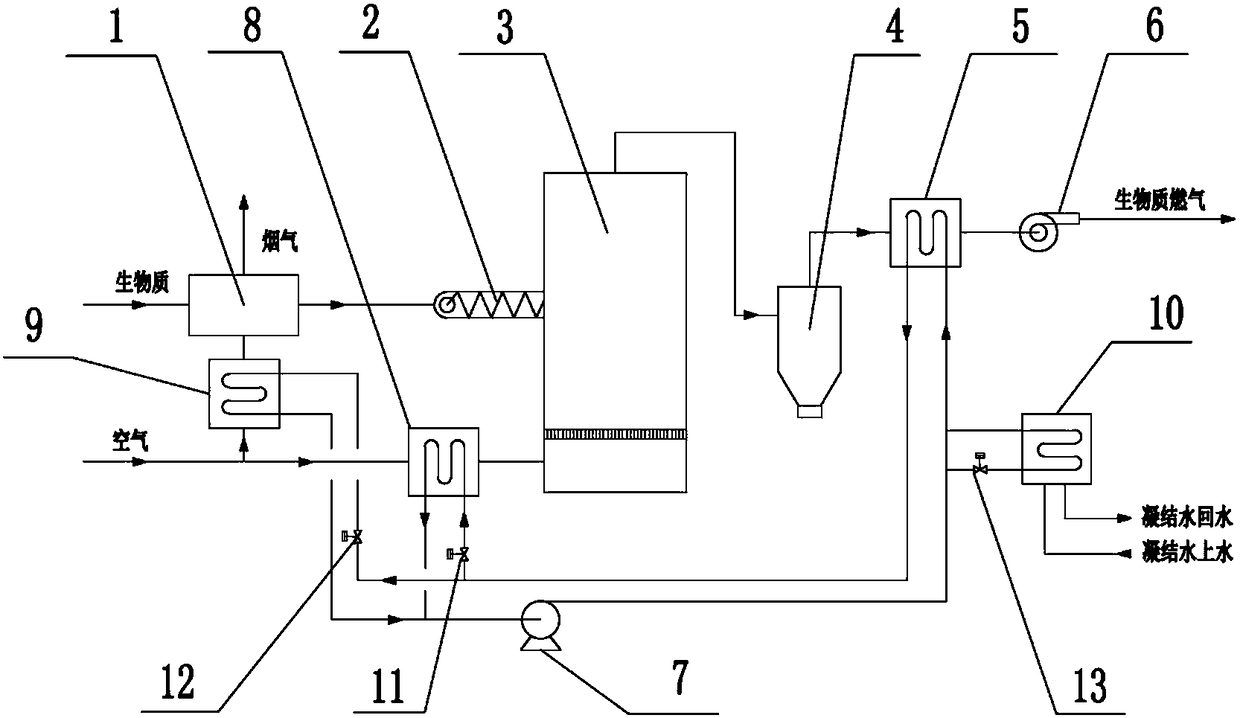

System and method for recycling sensible heat of biomass gasification gas

PendingCN108203604AUse efficientlyImprove boiler efficiencyEnergy inputGasification processes detailsThree levelAir heater

The invention provides a system and a method for recycling sensible heat of biomass gasification gas. A drying and conveying system composed of a biomass dryer and a screw feeder is used for conveyinga biomass fuel into a gasification system composed of a biomass gasifier, a cyclone dust collector and a booster fan, then synthesis gas is produced and is subsequently conveyed into a power plant boiler for generating power; a three-level sensible heat recycling system composed of a gas cooler, a circulating pump, a primary air heater, a dry air preheater and a condensation water heater is used,so that the sensible heat of the high-temperature biomass gas can be flexibly and effectively used for drying the biomass raw materials, preheating the primary air and heating the condensation waterof the power plant boiler; the energy can be effectively utilized; and the efficiency of the boiler can be improved.

Owner:HUANENG CLEAN ENERGY RES INST

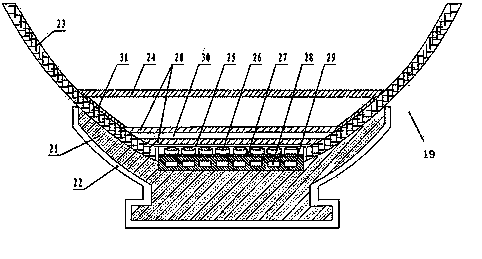

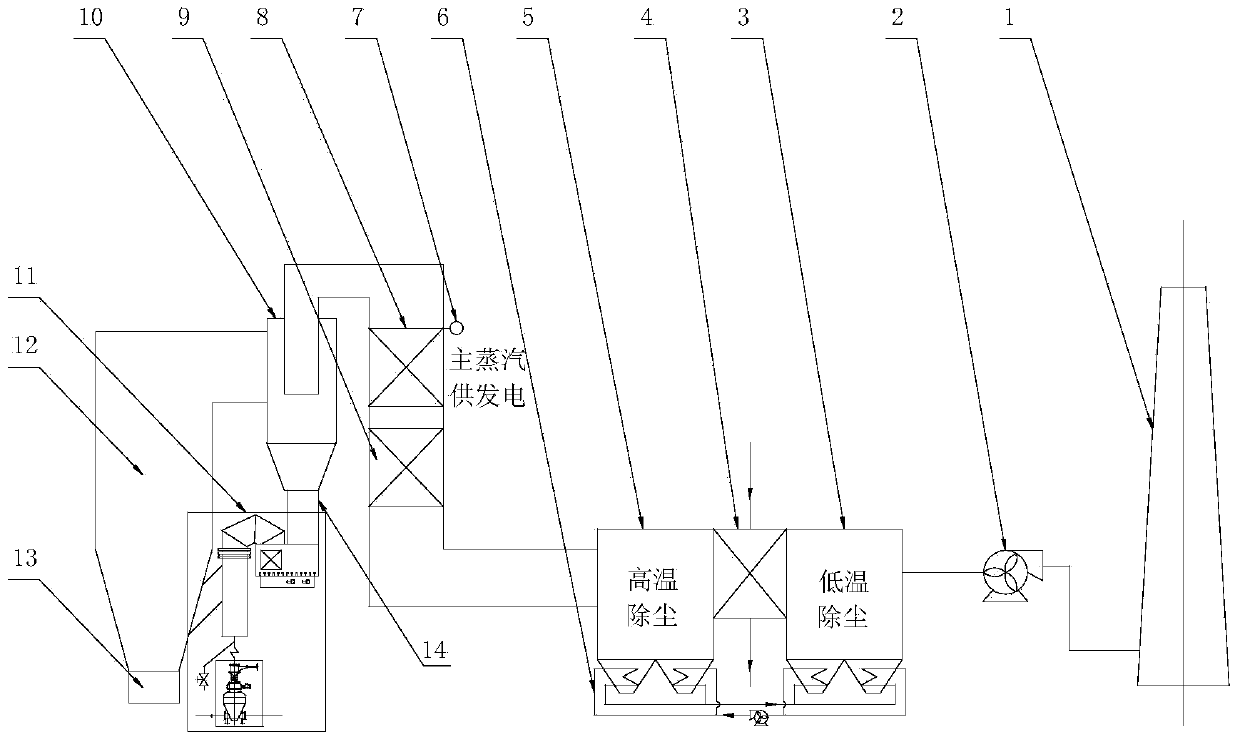

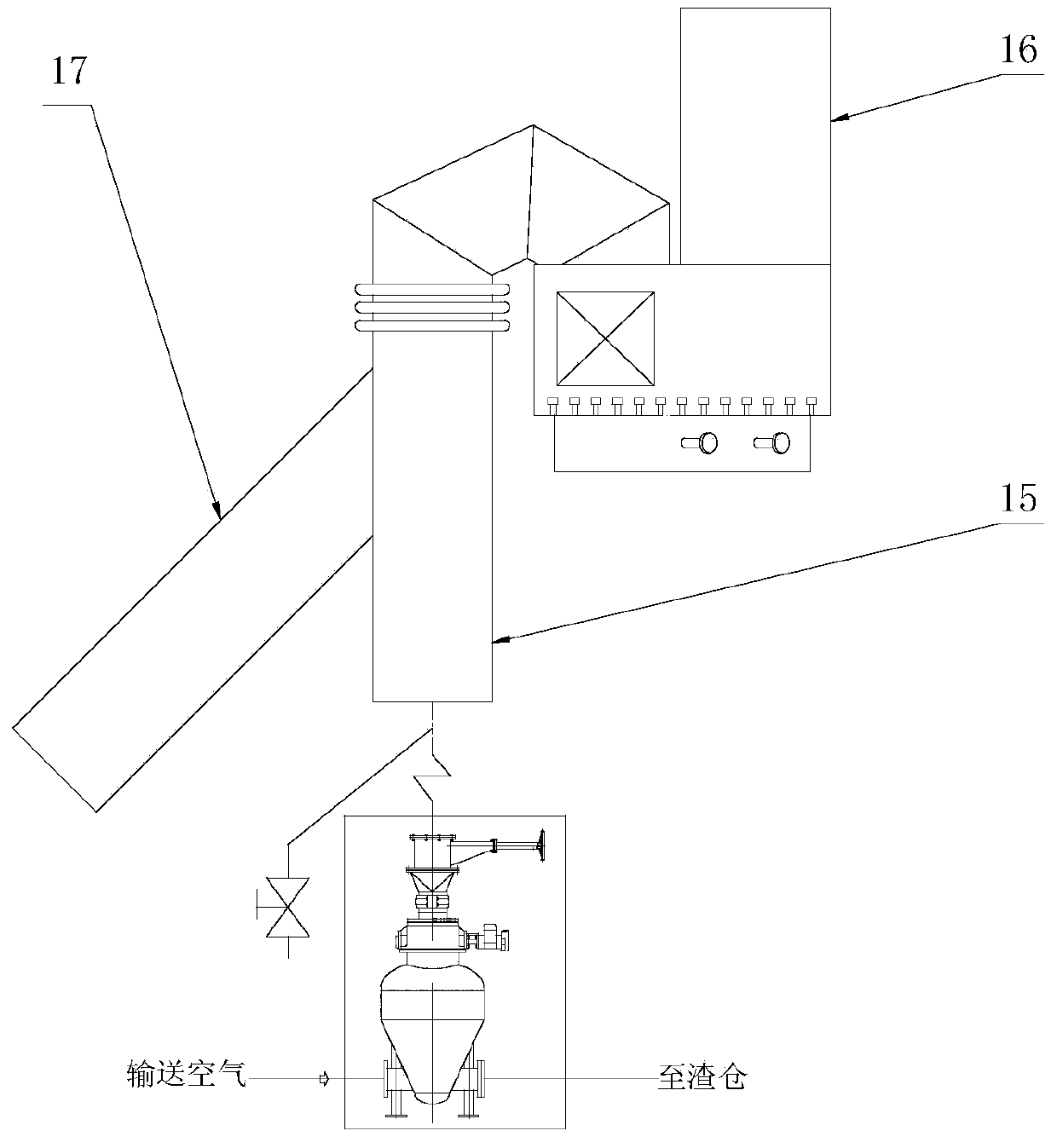

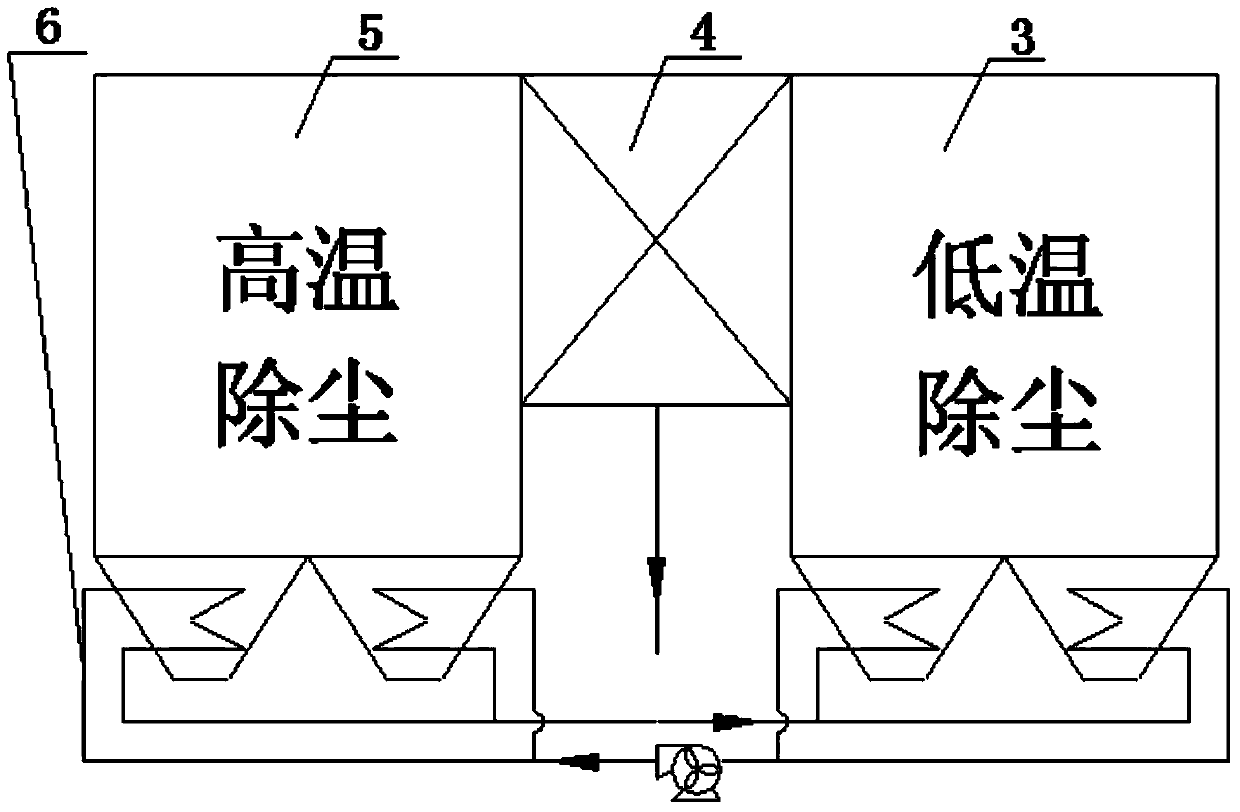

Stone coal power generation selenium extraction comprehensive utilization system and method

InactiveCN104214770ASolve the problem of low bed temperatureResolve Insufficient CombustionFluidized bed combustionSteam boilersFlueSuperheater

Disclosed are a stone coal power generation selenium extraction comprehensive utilization system and method. The system comprises a fluidized bed boiler, a superheater, an economizer, high-temperature dust removing equipment and low-temperature dust removing equipment. The superheater and the economizer are sequentially arranged in a tail flue of the fluidized bed boiler, the high-temperature dust removing equipment and the low-temperature dust removing equipment are sequentially arranged on different temperature area segments of an outlet of the tail flue of the boiler, and the fluidized bed boiler comprises a combustion chamber, a separator communicated with the top of the combustion chamber and a circulating dust discharging controller communicated with the separator and the combustion chamber. A controller dust inlet pipe on the top of the circulating dust discharging controller and a material returning device stand pipe at the bottom of the separator are used in common, or one branch is led out of the material returning device stand pipe. A material returning inclined pipe and a low-temperature dust discharging pipe are arranged on an outlet of the circulating dust discharging controller, the material returning inclined pipe is communicated with a combustion chamber dense-phase area, an outlet of the low-temperature dust discharging pipe is divided into two paths, one path is connected with a circulating dust conveying system, and the other path performs direct discharging. The stone coal power generation selenium extraction comprehensive utilization method of the system is provided. The method and system have the advantages of being low in energy consumption, high in selenium extraction efficiency, simple in system, small in selenium extraction investment scale, low in selenium escape rate, low in equipment investment and the like.

Owner:HUANENG CLEAN ENERGY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com