Patents

Literature

33 results about "Municipal solid waste incinerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

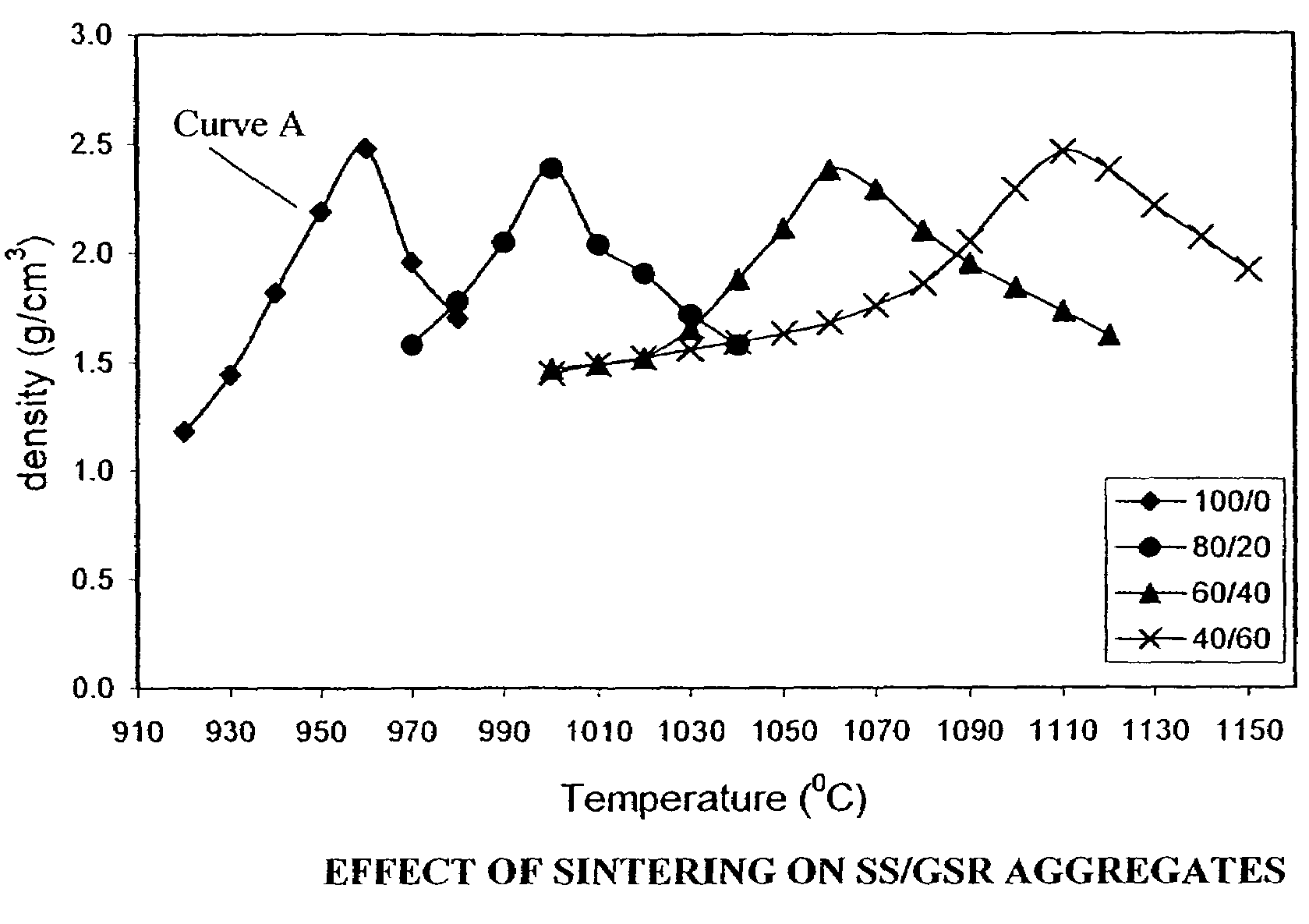

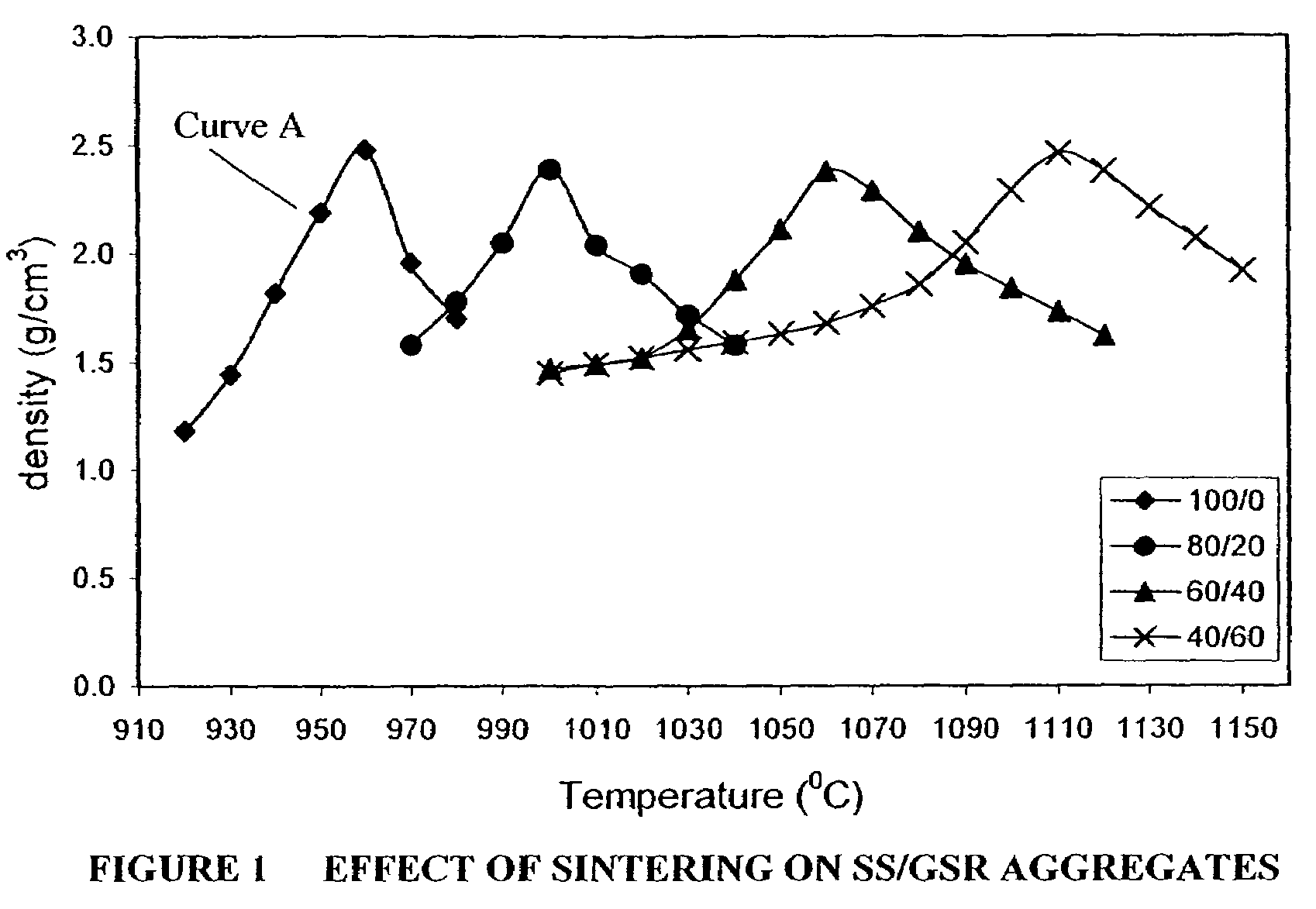

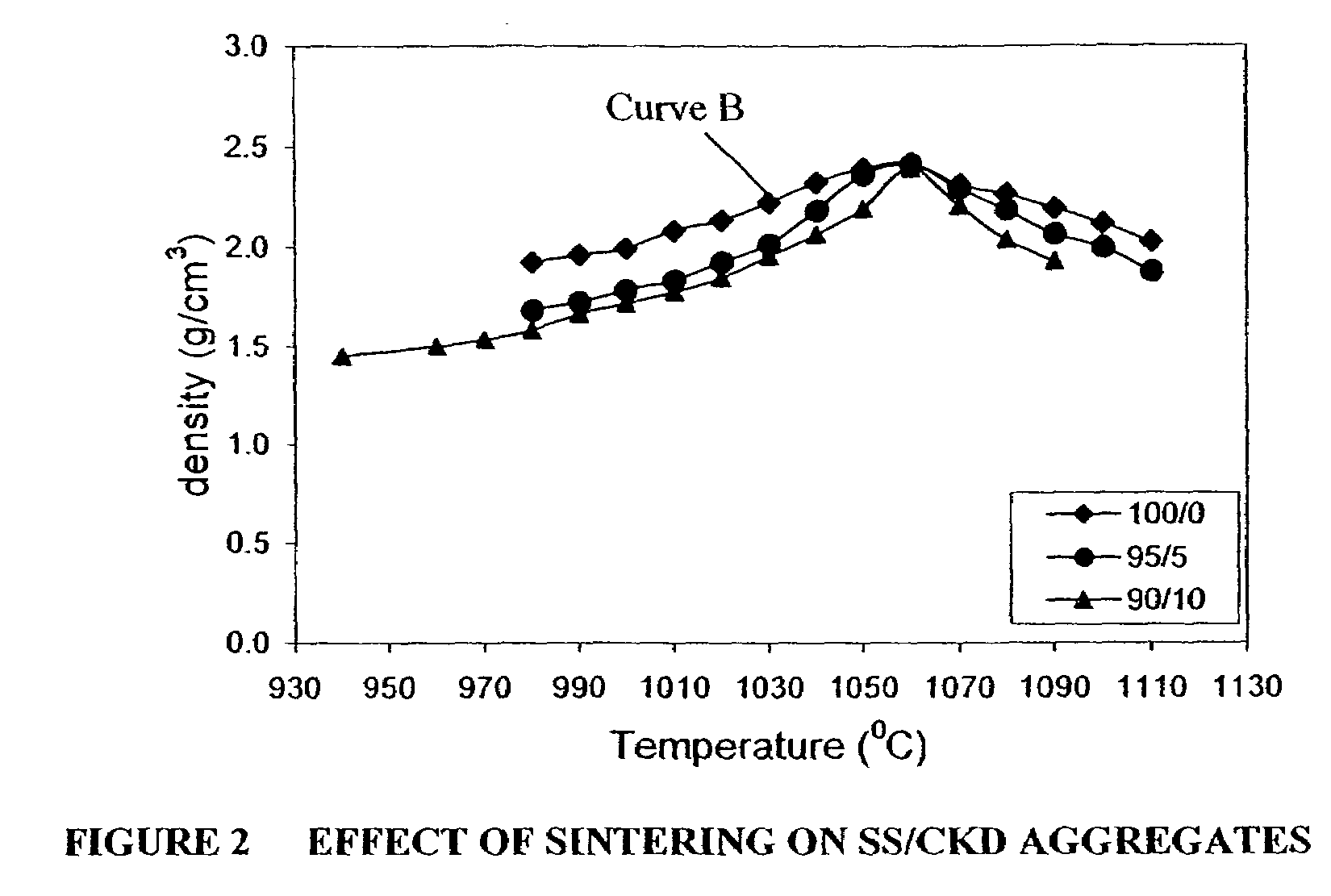

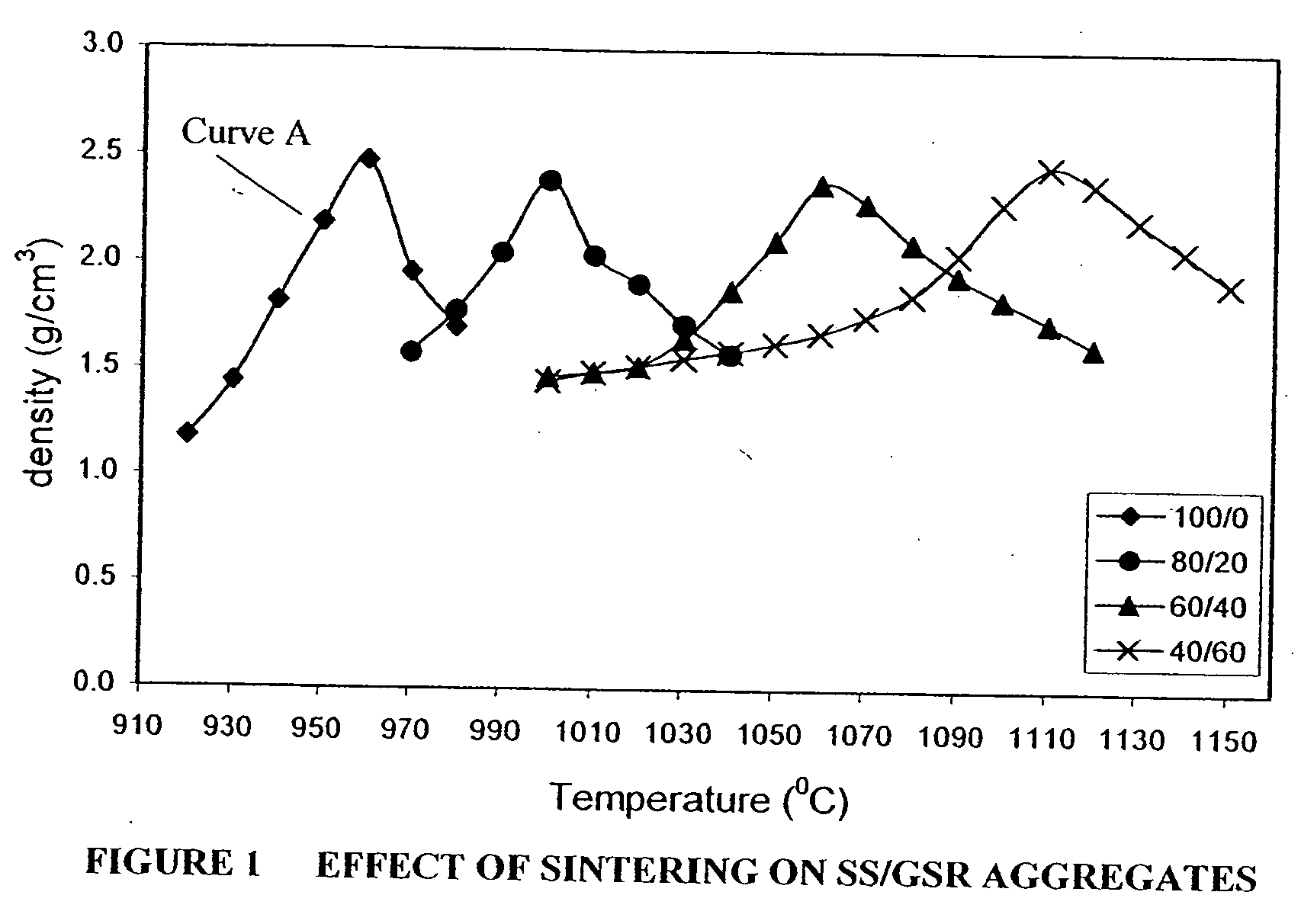

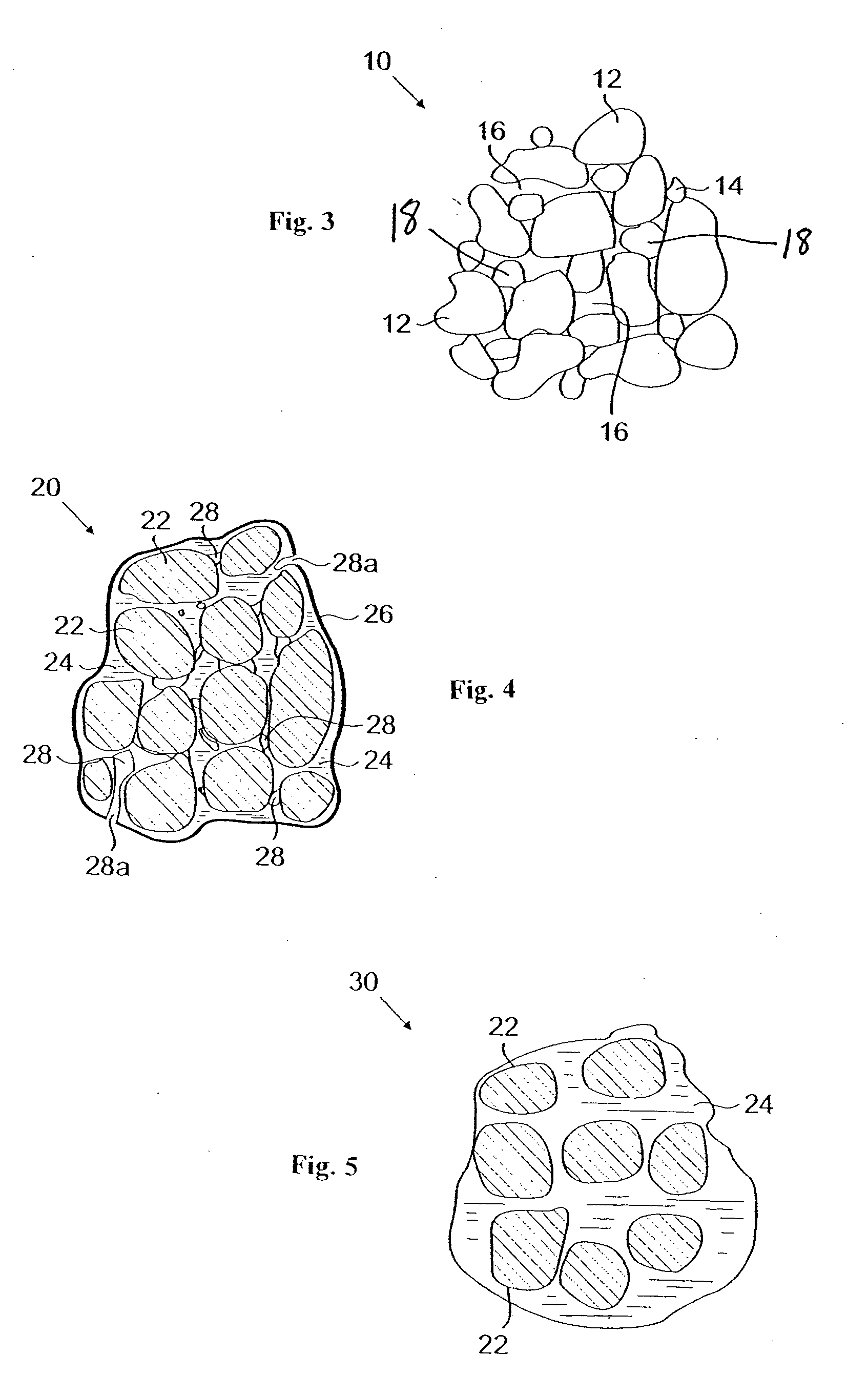

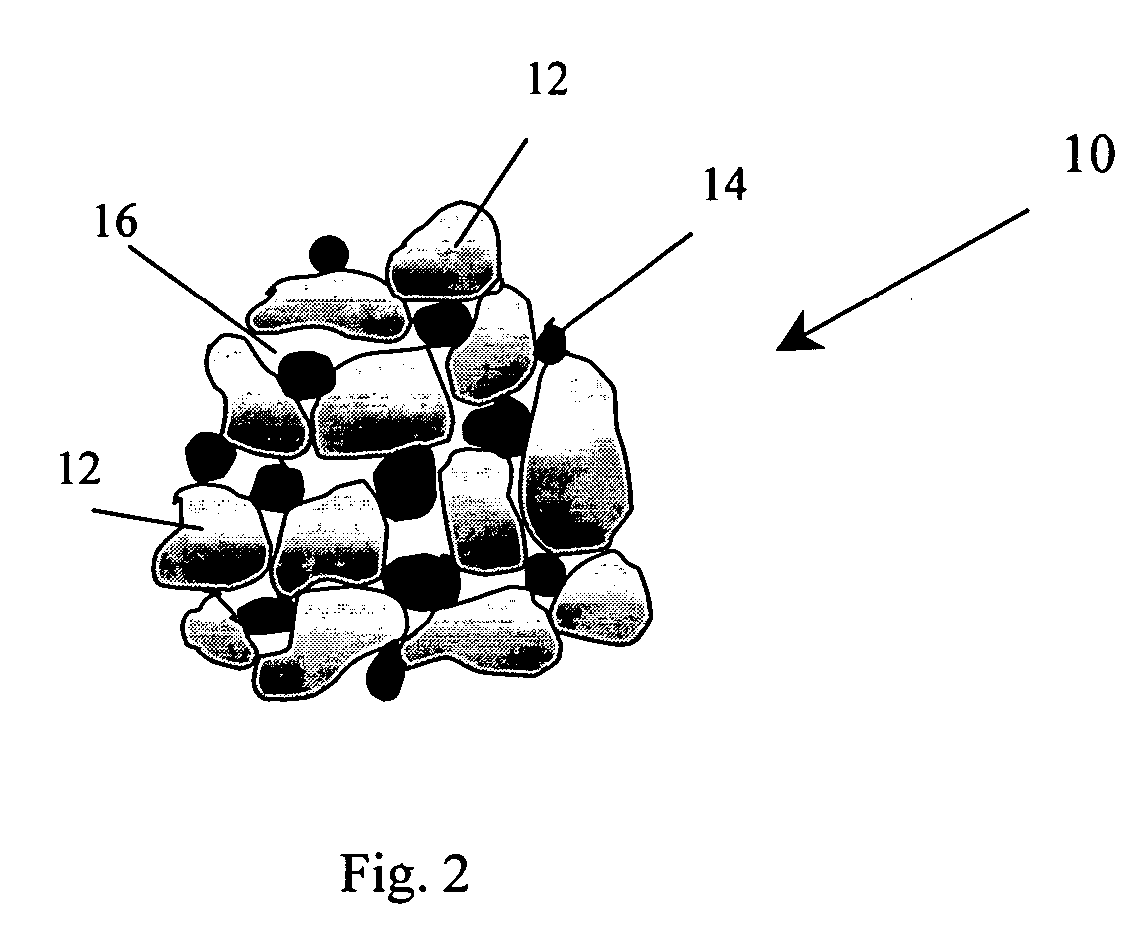

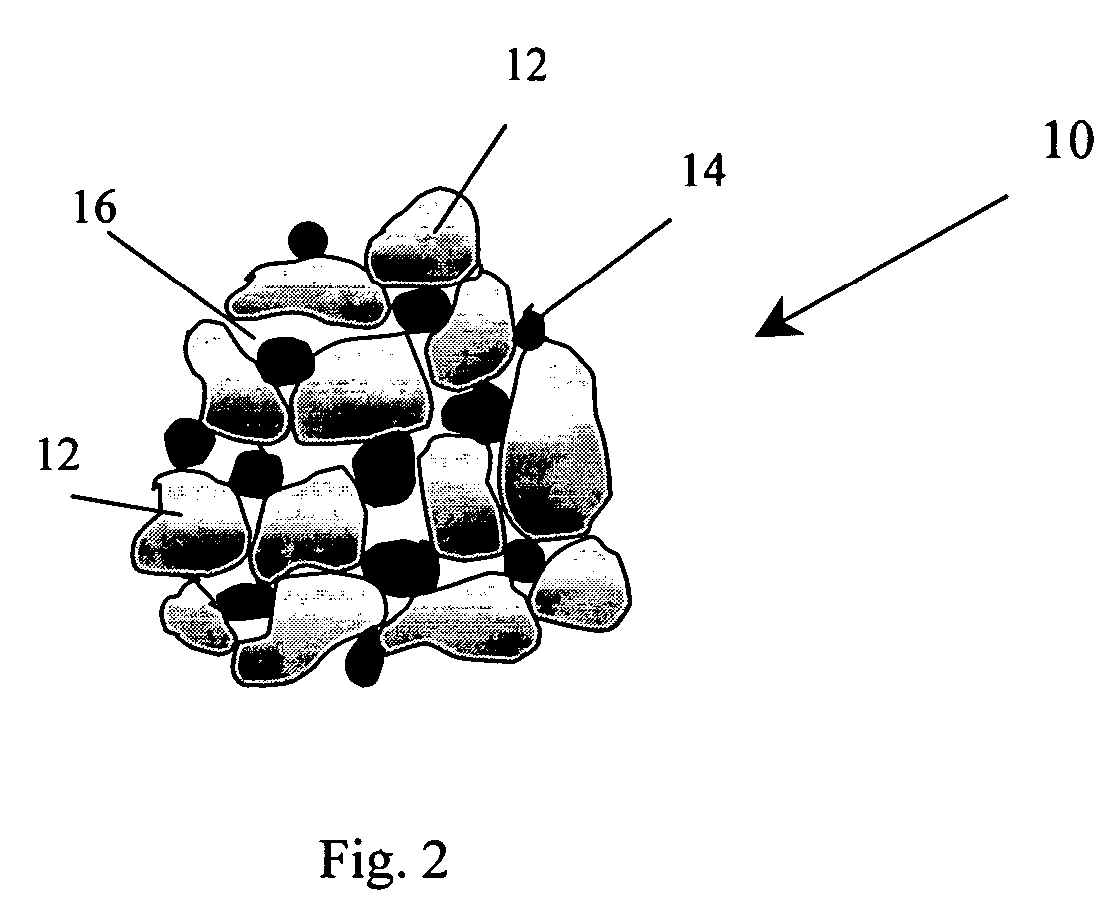

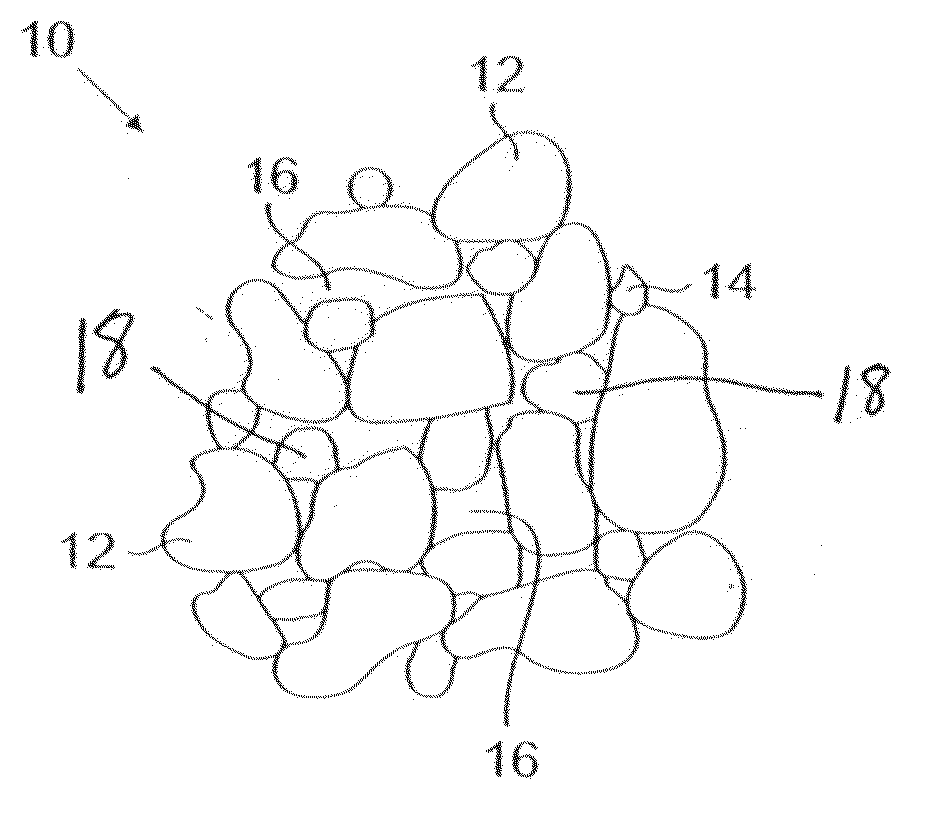

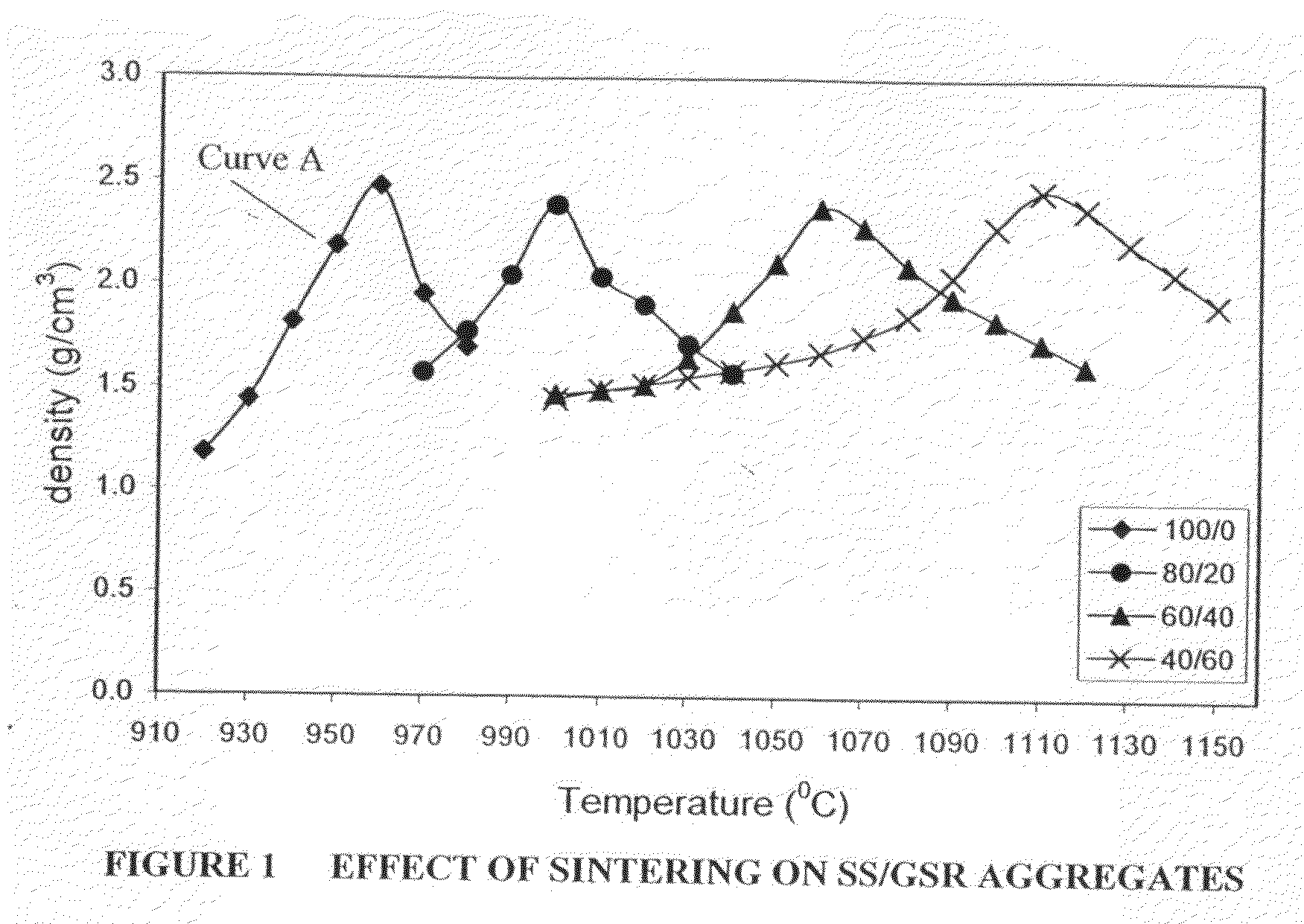

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

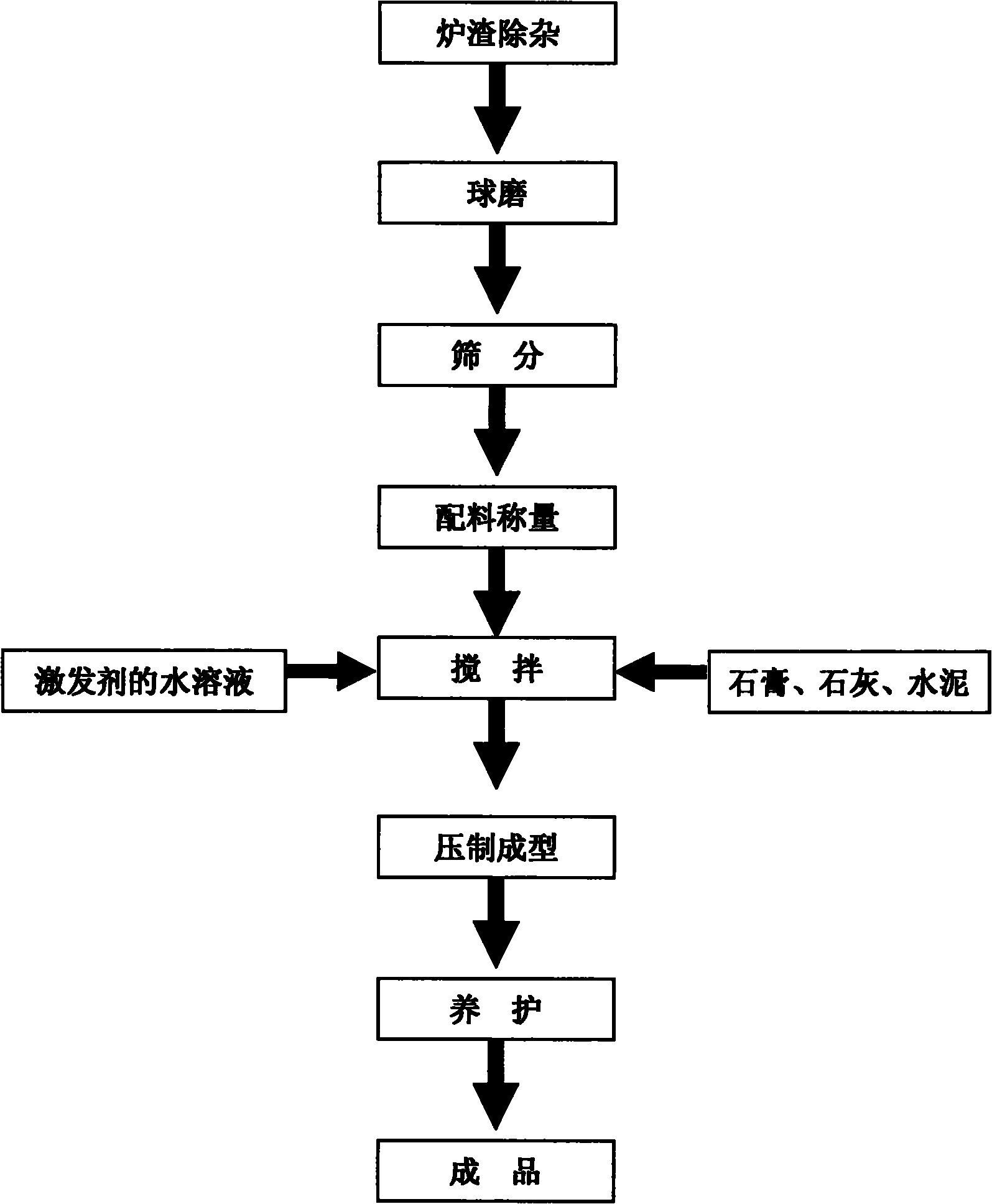

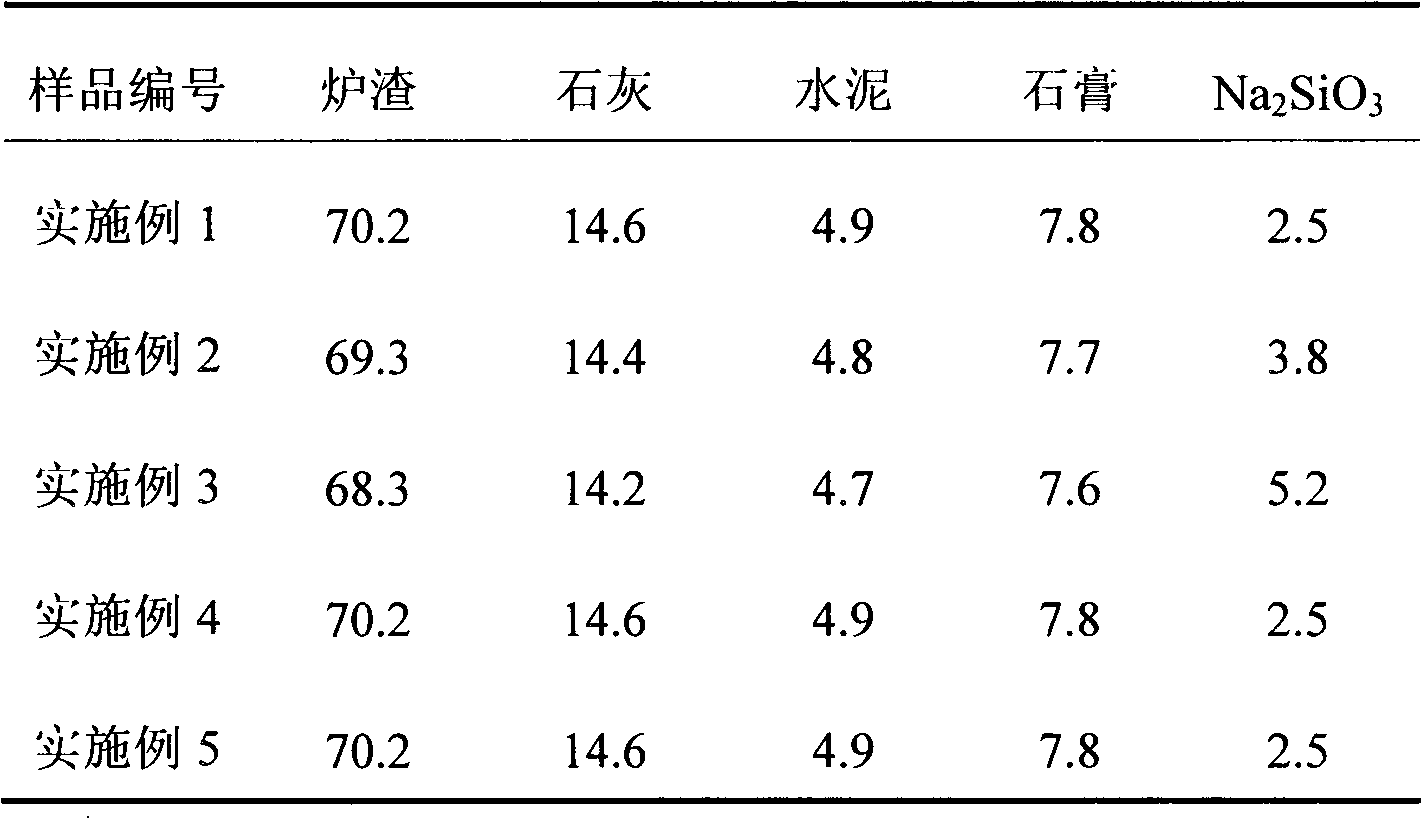

Method for preparing unburned slag wall bricks by utilizing household garbage burned slag

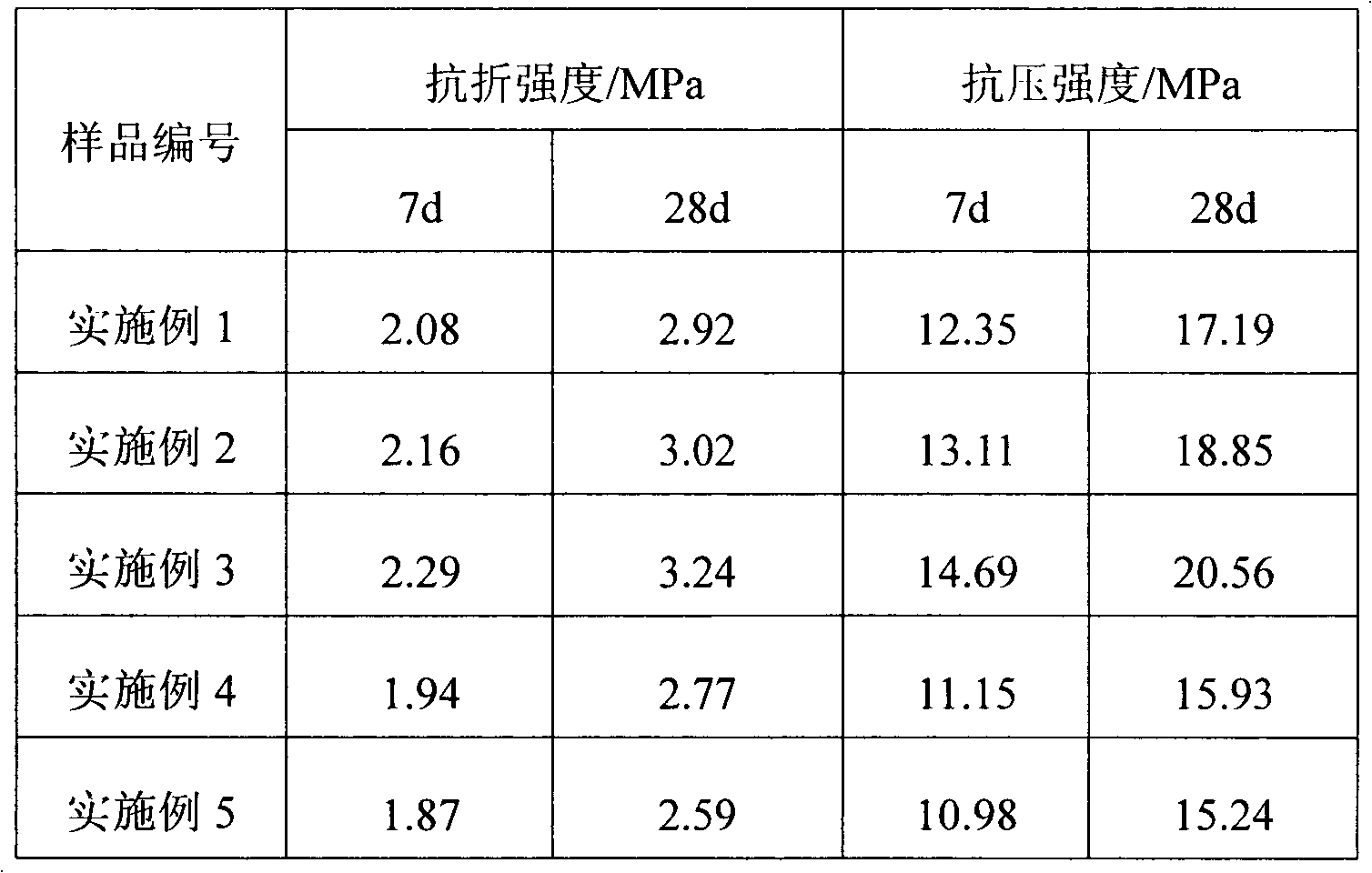

The invention discloses a method for preparing unburned slag wall bricks by utilizing household garbage burned slag. The method comprises the following steps of: proportioning the following raw materials in percentage by mass: 37.9 to 70.2 percent of household garbage burned slag, 4.7 to 19.0 percent of lime, 4.7 to 23.7 percent of cement, 7.6 to 19.0 percent of gypsum and 2.5 to 5.2 percent of excitant; preparing the excitant into aqueous solution and mixing the aqueous solution and other components in the raw materials to make the water content of the raw materials reach 8 to 12 percent; and pressing, molding, and curing to obtain the unburned slag wall bricks. The method can not only solve the problem of the treatment of current municipal household garbage burned slag to realize the resource utilization of the slag, but also reduce the discharge of the municipal household garbage burned slag so as to reduce the environmental pollution caused by the accumulation and the landfill of the municipal household garbage burned slag; and the method has the advantages that: the slag waste material has high resource utilization rate, the process is simple, the method is convenient to operate, the operating cost is low and the like.

Owner:SOUTH CHINA UNIV OF TECH

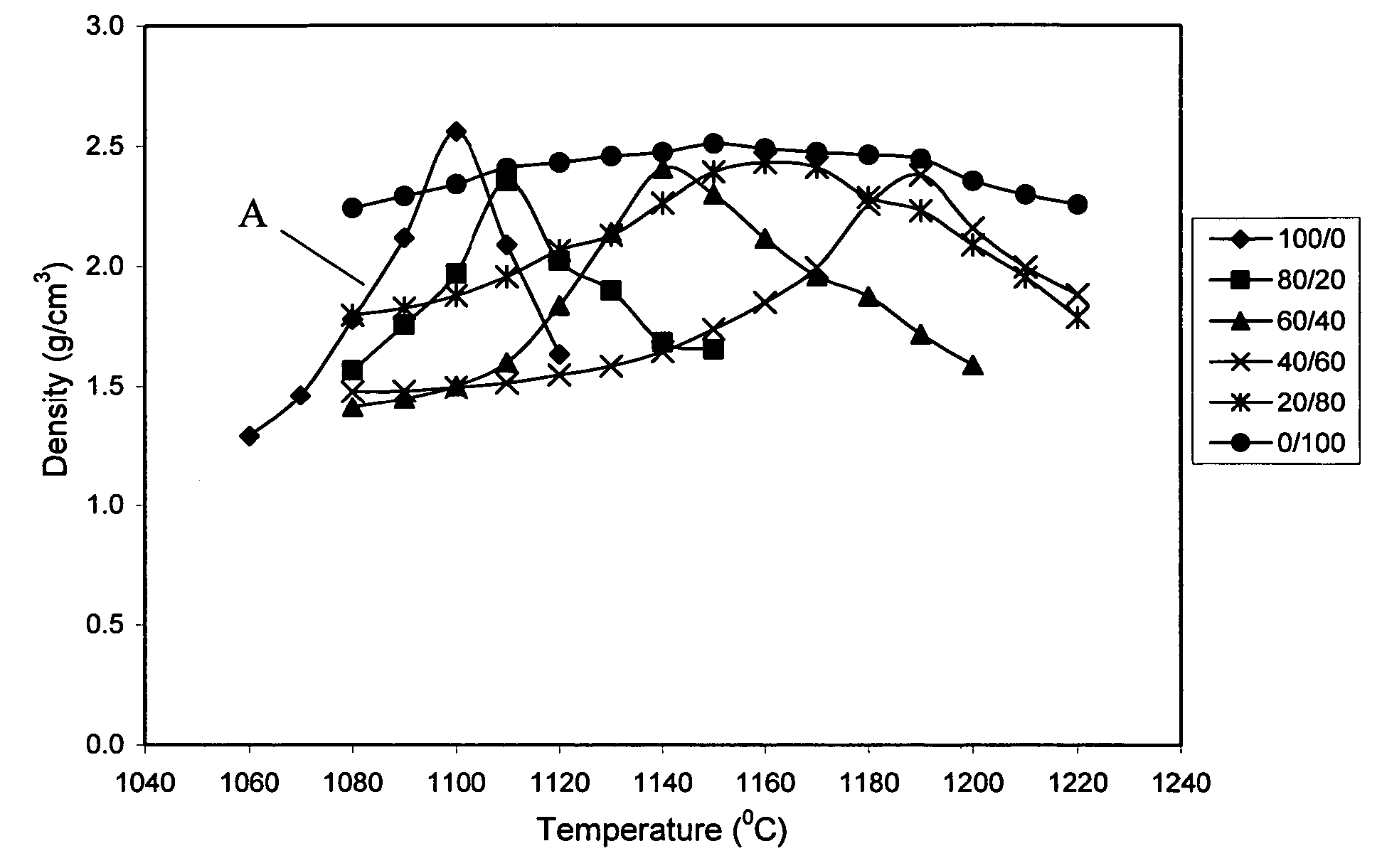

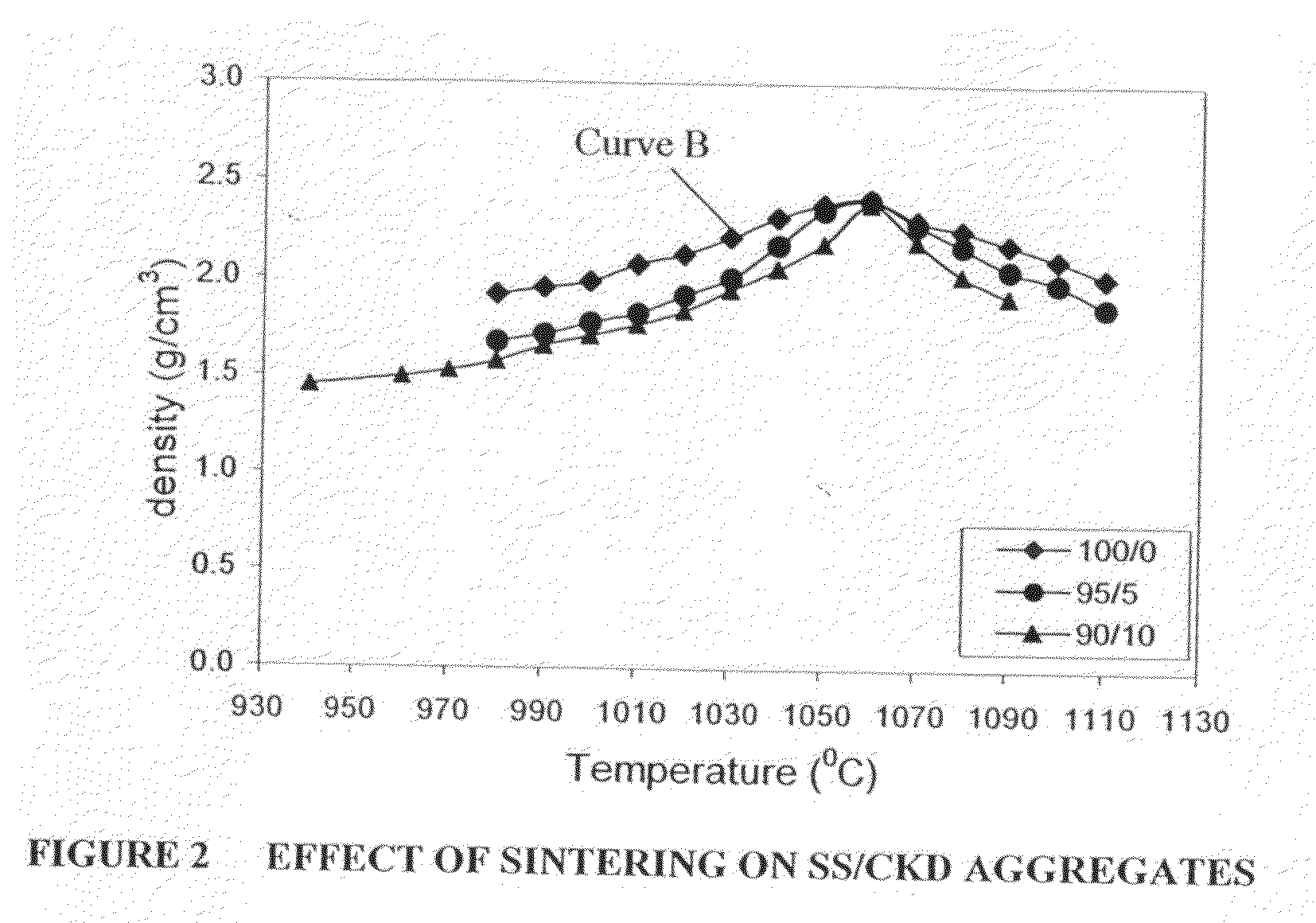

Pyroprocessed aggregates comprising IBA and PFA and methods for producing such aggregates

InactiveUS20060162618A1Low melting pointPyroprocessing behavior unpredictablePigmenting treatmentSolid waste managementPorosityPulverized fuel ash

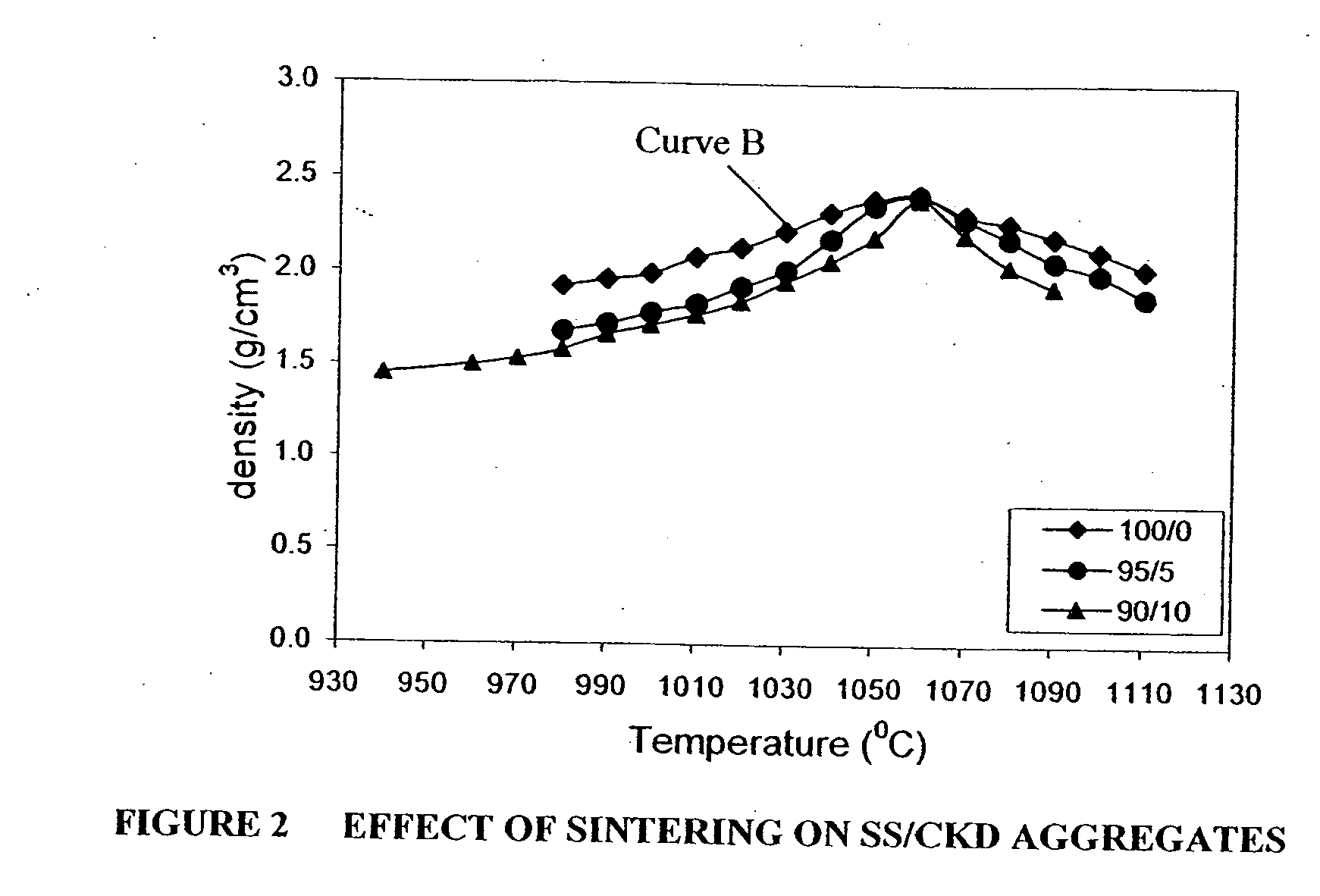

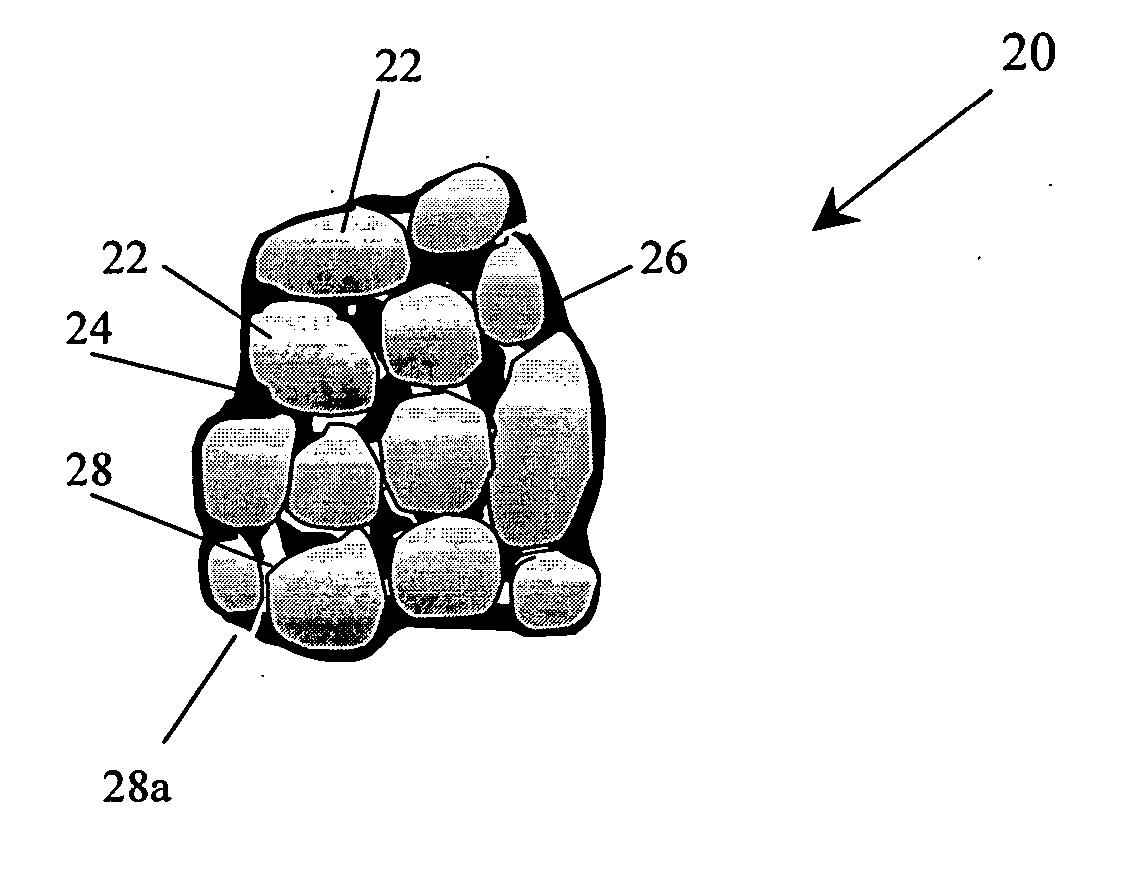

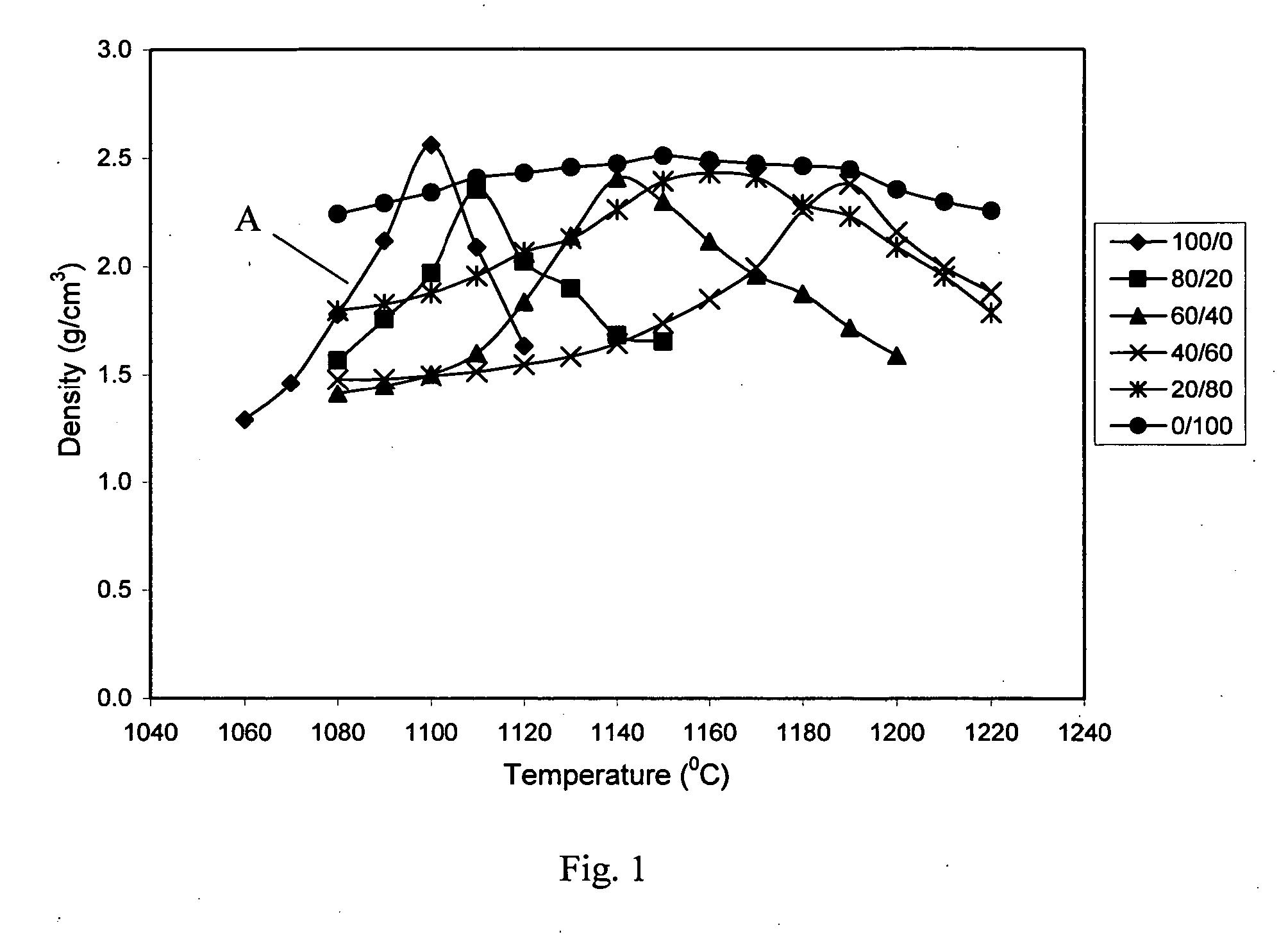

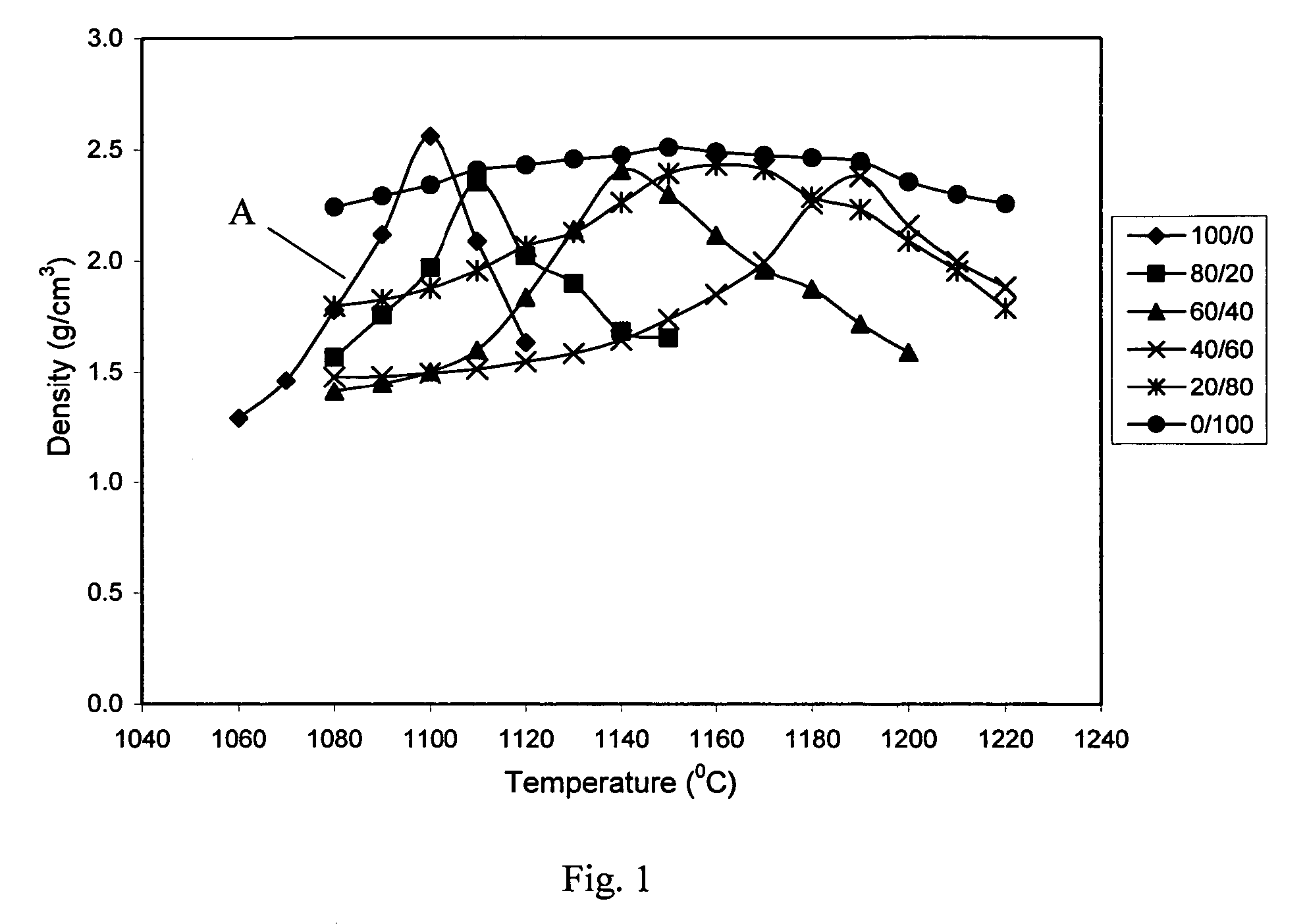

In accordance with an embodiment, a method for producing an aggregate is disclosed comprising mixing incinerator bottom ash (“IBA”) from a municipal solid waste incinerator and pulverized fuel ash (“PFA”) from coal combustion. The method further comprises agglomerating the mixture, such as by pelletizing, and pyroprocessing the agglomerates, such as by sintering or vitrification, to form the aggregate. The addition of PFA to IBA has been found to facilitate production of lightweight and normal weight aggregates. Preferably, the IBA or the mixture of IBA and PFA is wet milled prior to agglomerating. A preferred proportion of IBA to PFA is 40% / 60%. The agglomerates may be coated with an inorganic material to create a surface layer on the aggregate. Organic material may be included in the mixture to increase the porosity of the aggregate. A lightweight sintered aggregate comprising IBA and PFA and an aggregate comprising IBA and PFA are also disclosed.

Owner:ALKEMY

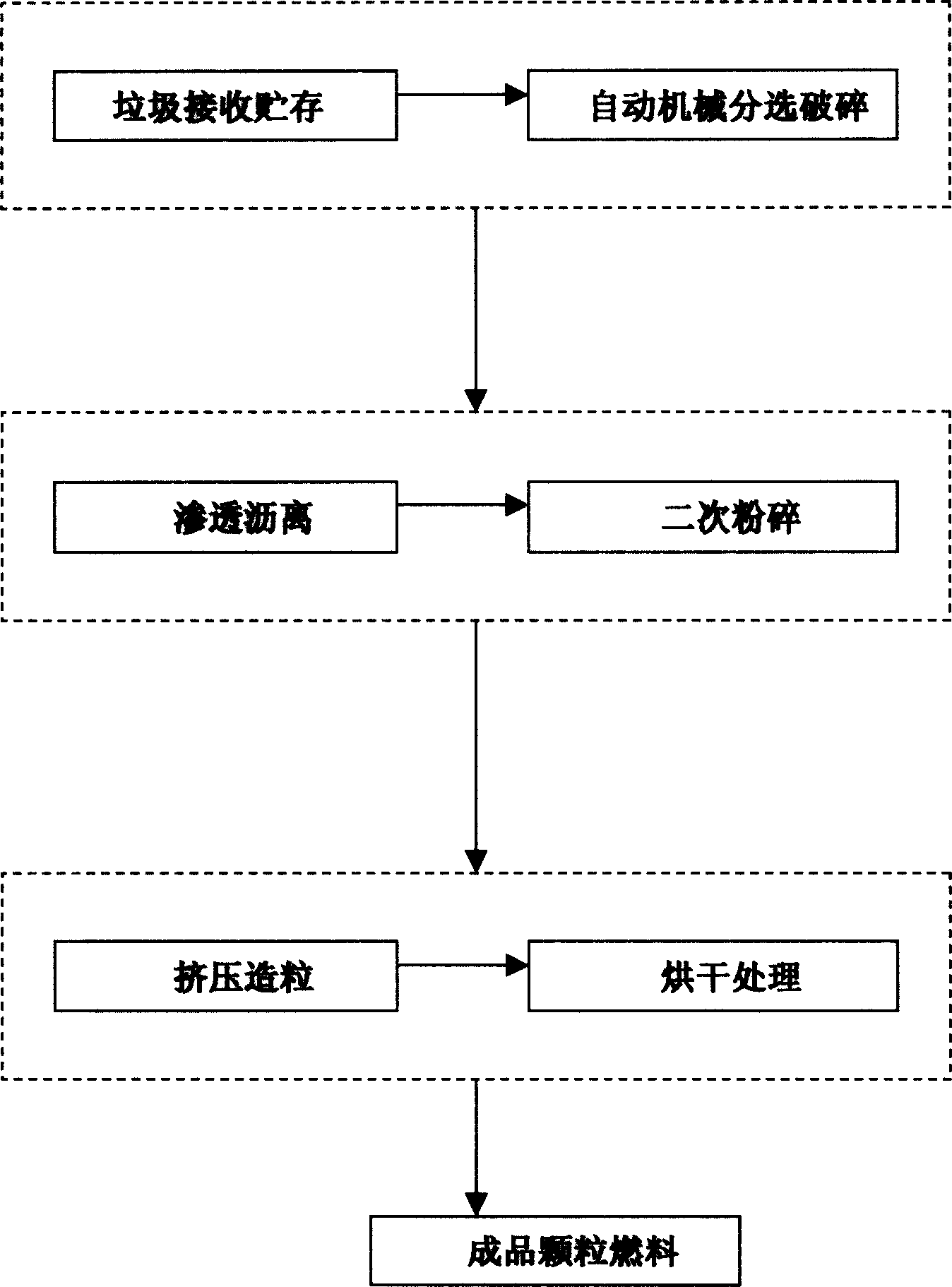

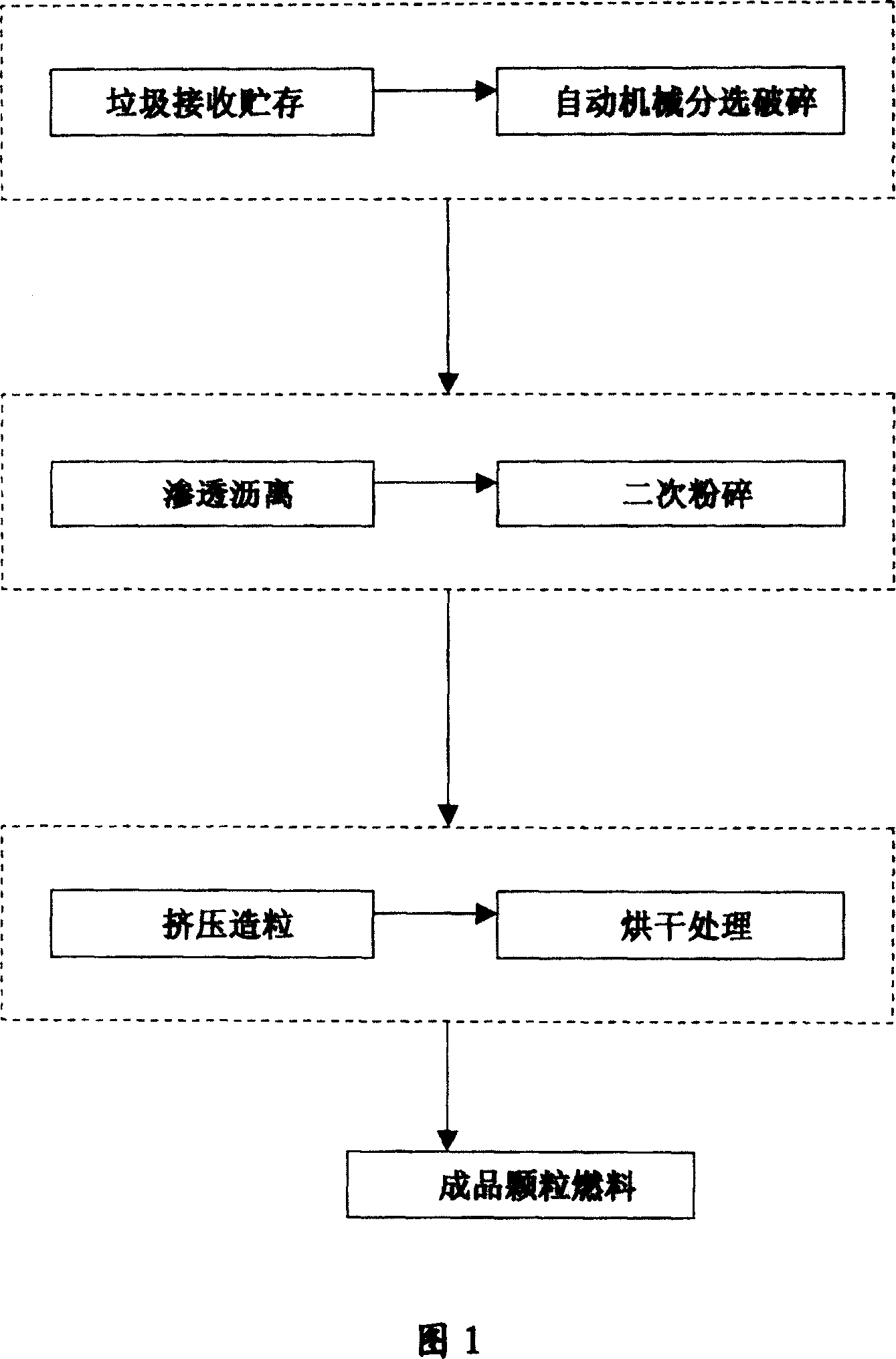

Preparation method of city refuse incineration furnace granular fuel

The invention discloses a produce method for grain fuel used in municipal refuse incinerator, which comprises: separating, breaking, draining, evaporating, secondary breaking, granulating and drying. This invention reduces the require to material, heat value and moisture, enlarges scope of application, cuts energy consumption and cost, decreases pollution greatly, and can be used to restart stop-production incinerator.

Owner:雷丰源

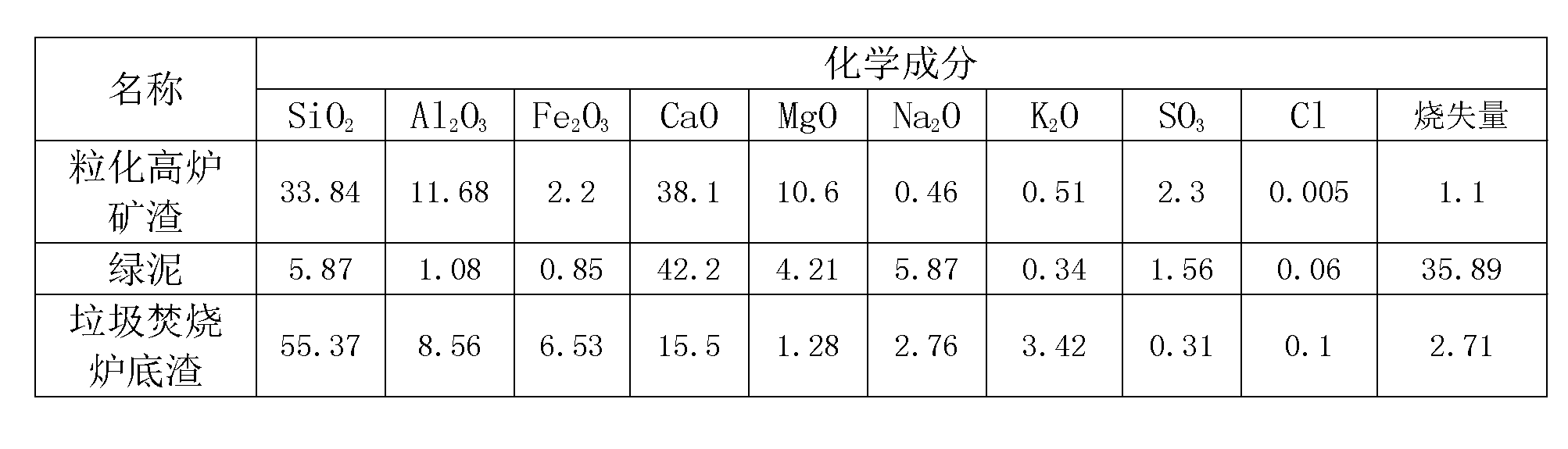

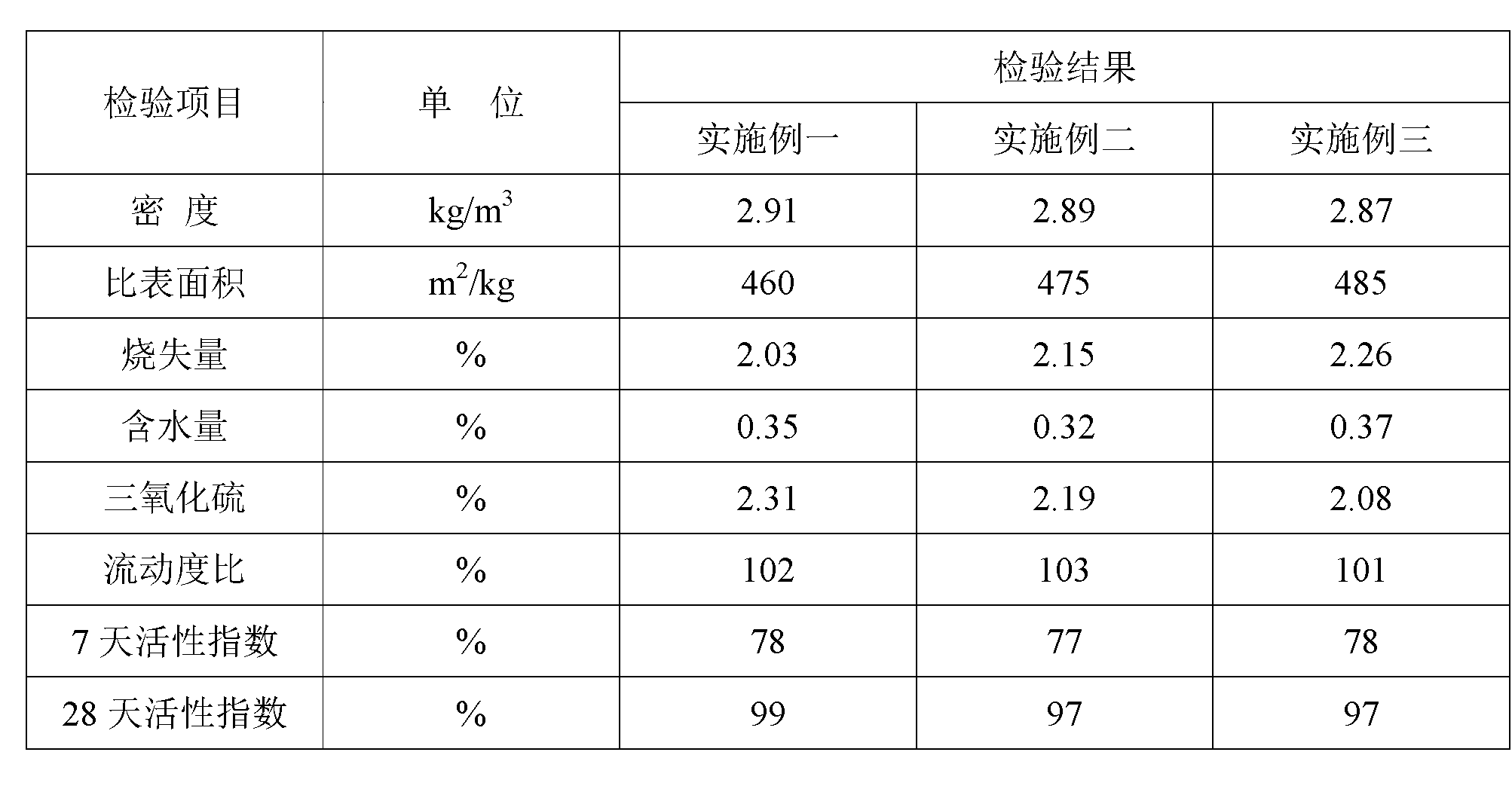

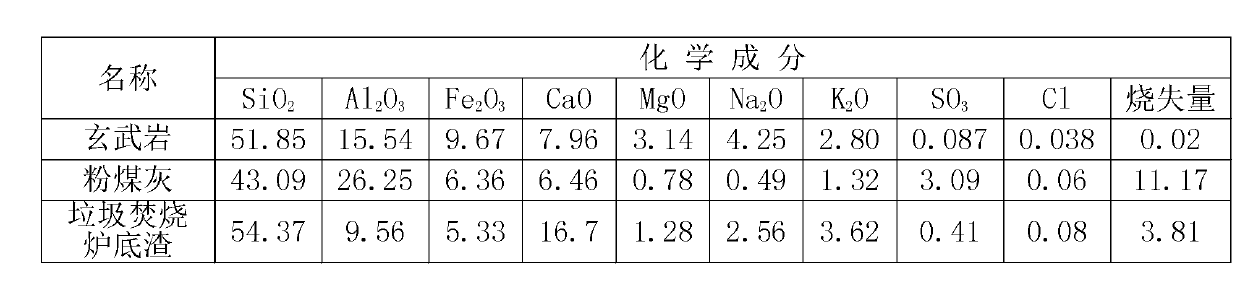

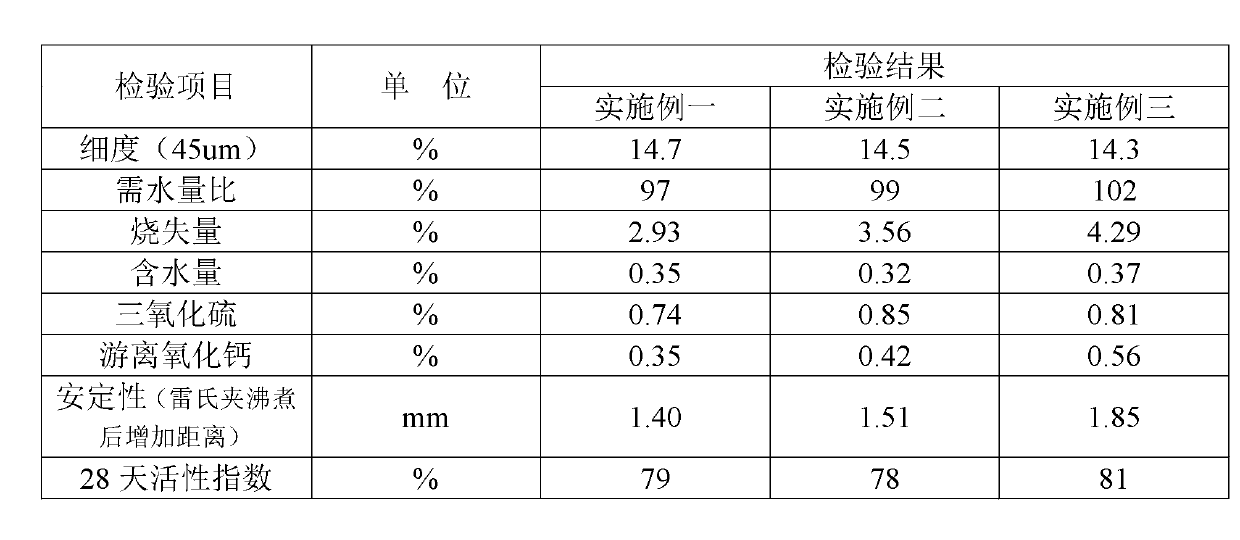

Composite ground granulated blast furnace slag for concrete

InactiveCN103304162AReduce moisture contentImprove microstructureCement productionResource utilizationEconomic benefits

The invention relates to a composite ground granulated blast furnace slag for concrete. The slag is prepared by grinding utilizing grinding equipment and then uniformly mixing household garbage incinerator bottom slag, granulated blast-furnace slag, mixed materials and an activity activator, the specific surface area of the slag is 450m<2> / kg-550m<2> / kg, and the water content is less than 0.5%. The production technology is simple, industrial wastes such as the household garbage incinerator bottom slag, the granulated blast-furnace slag and green mud which can be greatly and easily obtained as main raw materials, the optimal superimposed effects and grain composition of all the components can be fully exerted through optimal compounding, and the obtained composite ground granulated blast furnace slag can be used for substituting part cement in concrete, so that resources and energy sources are saved, the industrial production is benefited, environmental protection, energy saving and emission reduction are benefited, a new method is developed for the resource utilization of the municipal solid waste incinerator bottom slag, and the slag has a good social effect and a good economic benefit.

Owner:HAINAN LANDAO ENVIRONMENTAL PROTECTION IND

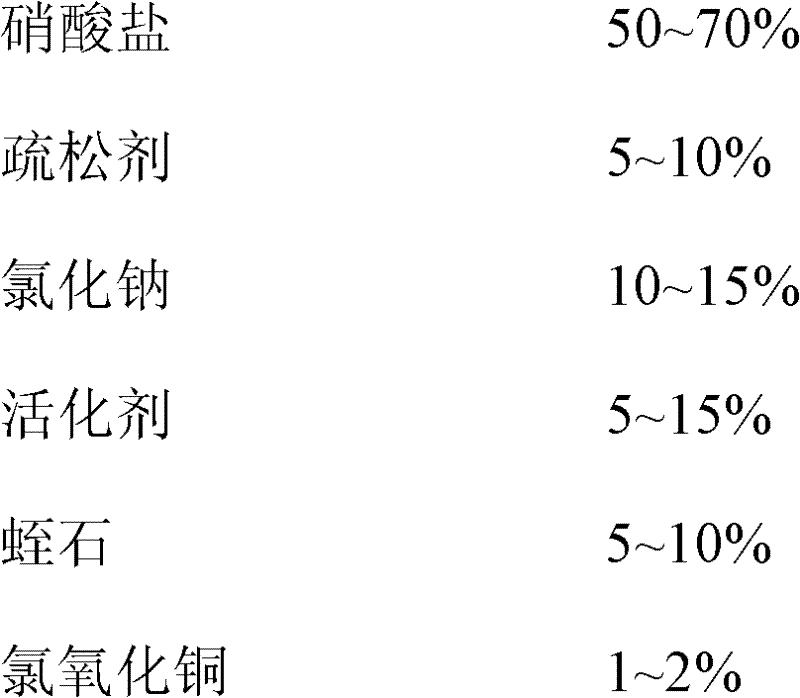

Preparation of ash-cleaning and coke-removing agent for city domestic refuse incinerator

InactiveCN101338237AImprove dust accumulation and slaggingImprove efficiencyFuel additivesIncinerator apparatusSlagCupric nitrate

The invention discloses an ash and burnt removal agent composition for rural domestic waste incinerator. The ash and burnt removal agent comprises the components with the following weight portions of 50-70 percent of nitrates, 5-10 percent of loosening agent, 10-15 percent of sodium chloride, 5-15 percent of activator, 5-10 percent of vermiculite and 1-2 percent of cupric oxychloride. The nitrates are cupric nitrate and sodium nitrate. The loosening agent refers to borax. The activator refers to ammonium nitrate, carbon powder and sulfur powder. The ash and burnt removal agent is applied in ash and burnt removal field of the rural domestic waste incinerator, which has good effect for improving the ash and slag in the waste incinerator.

Owner:XI AN JIAOTONG UNIV

Pyroprocessed aggregates comprising IBA and PFA and methods for producing such aggregates

InactiveUS7704317B2Low melting pointPyroprocessing behavior unpredictablePigmenting treatmentOther chemical processesPorosityPulverized fuel ash

Owner:ALKEMY

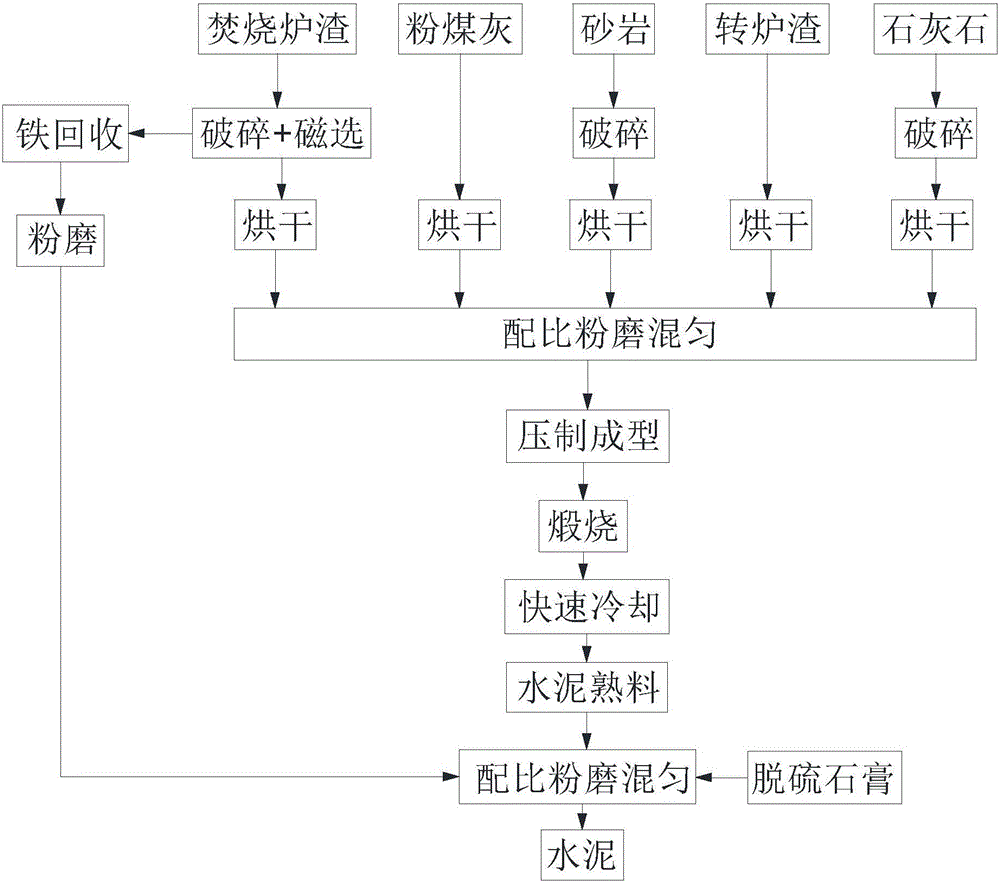

Method for preparing cement from municipal solid waste incineration furnace slag

The invention discloses a method for preparing cement from municipal solid waste incineration furnace slag.According to the method, the municipal solid waste incineration furnace slag substitutes raw materials of the cement to make cement raw meal, portland cement clinker is fired, and safety use of the cement is guaranteed.In the actual cement production process, a bypass air discharging system is arranged, normal operation of a cement kiln is guaranteed, the crusting and blocking phenomena of volatile components which are wrapped and carried by the raw materials to a cement kiln system caused by the circular enrichment rule are eliminated, and quality of a cement product can be guaranteed.By means of the method, waste materials can be changed into things of value, the municipal solid waste incineration furnace slag is adopted as the substitute raw material in the cement production process, on one hand, the effect that the incineration furnace slag is reutilized can be achieved, and on the other hand, the demand for natural raw materials of the cement can be reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

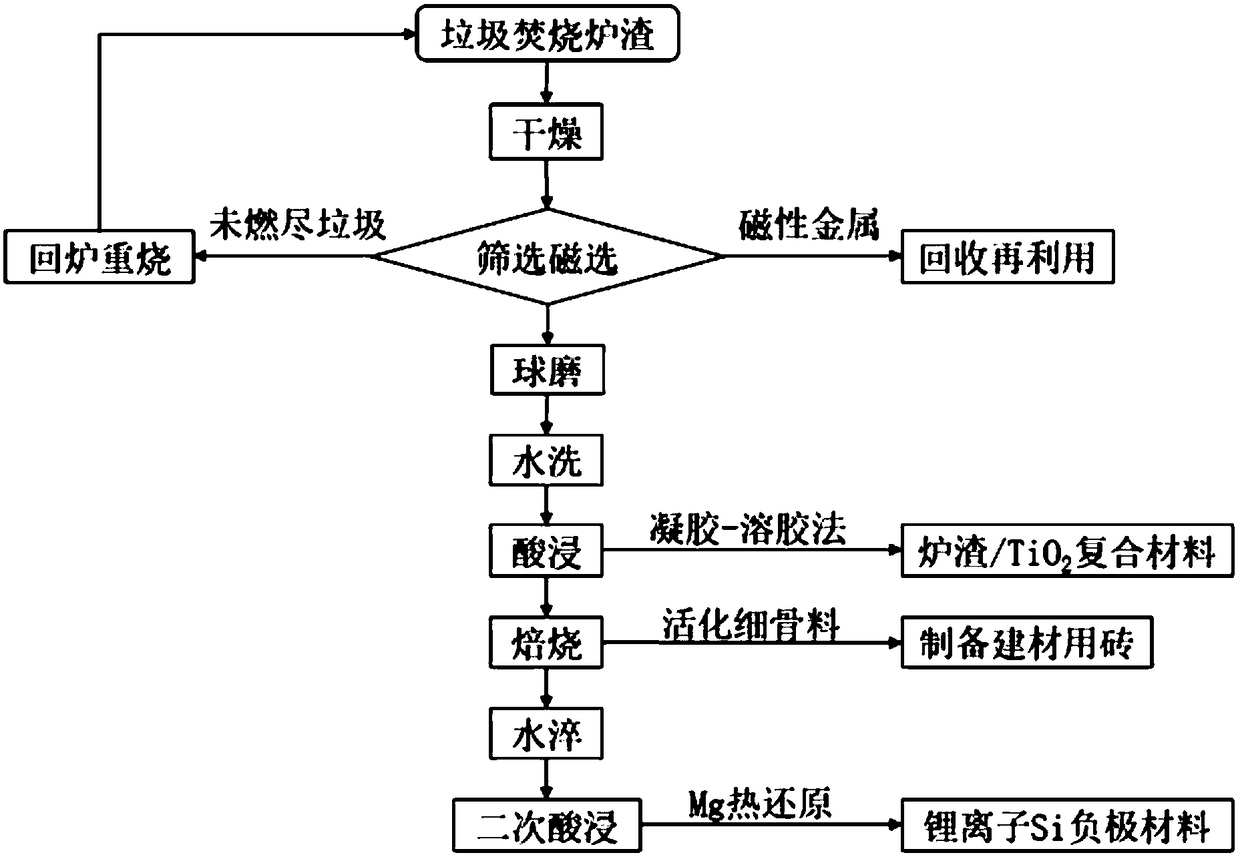

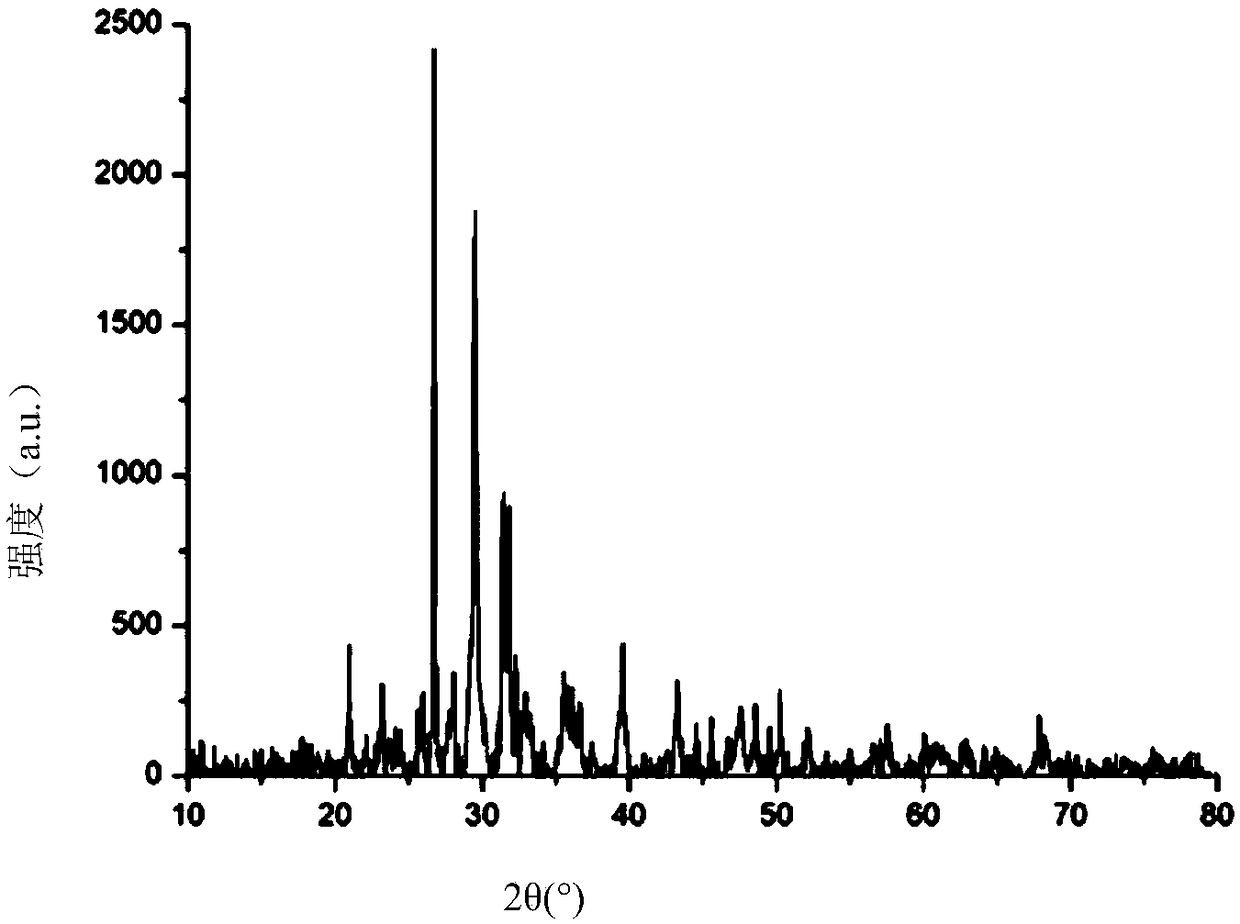

Method of purifying urban household waste incinerator residues step by step

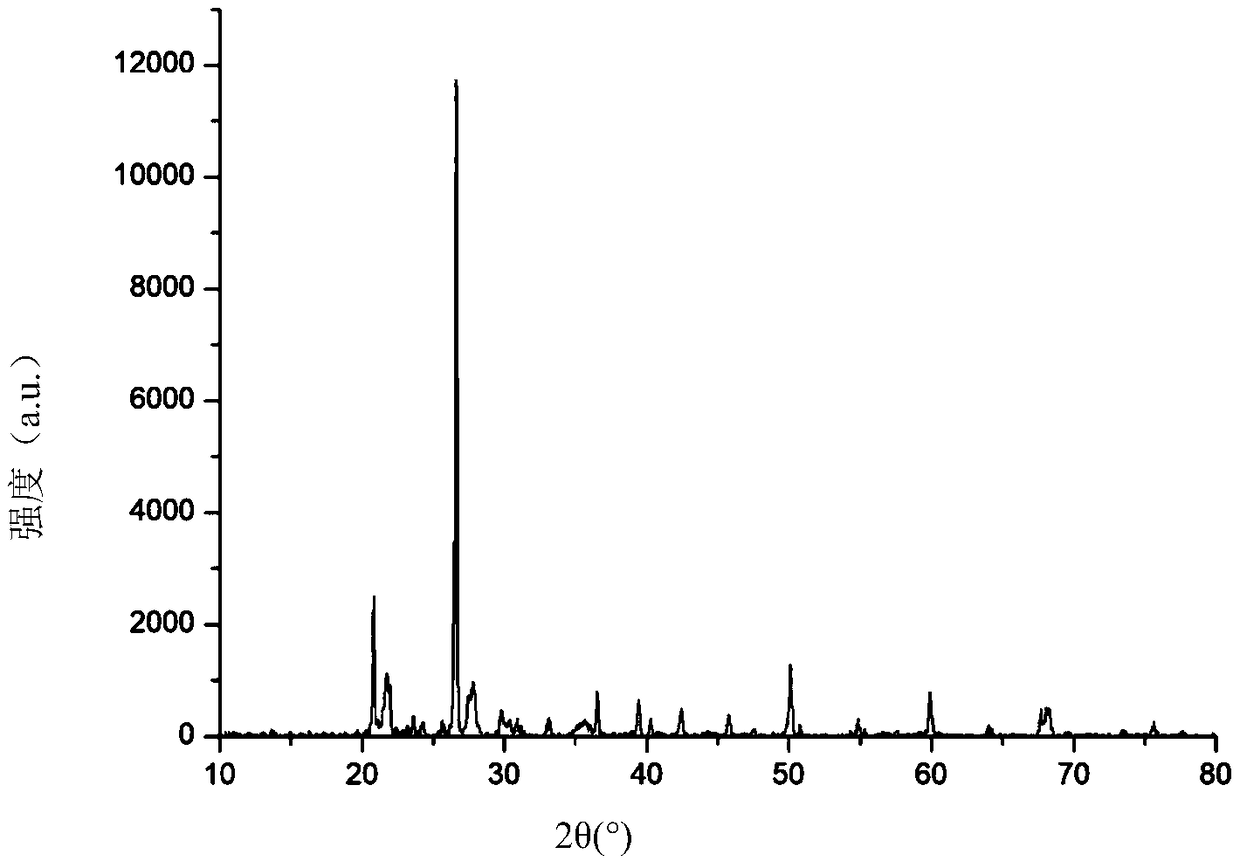

The invention discloses a method of purifying urban household waste incinerator residue step by step. The method comprises the steps of drying, screening, magnetic separation, water washing, acid leaching, roasting, water quenching, and secondary acid leaching, wherein the residue from each purification step corresponds to different morphology, physical properties and chemical composition; the residues may be applied to different fields. SiO2 is purified from the household waste incinerator residues through simple processes; the period is short; the energy consumption is low; mass impurities in the residues are effectively removed. The method herein provides another route to acquire massive silicon sources against the situation that massive waste incinerator residues are produced each yearin China; wastes are turned into wealth and are effectively reused.

Owner:YANCHENG INST OF TECH

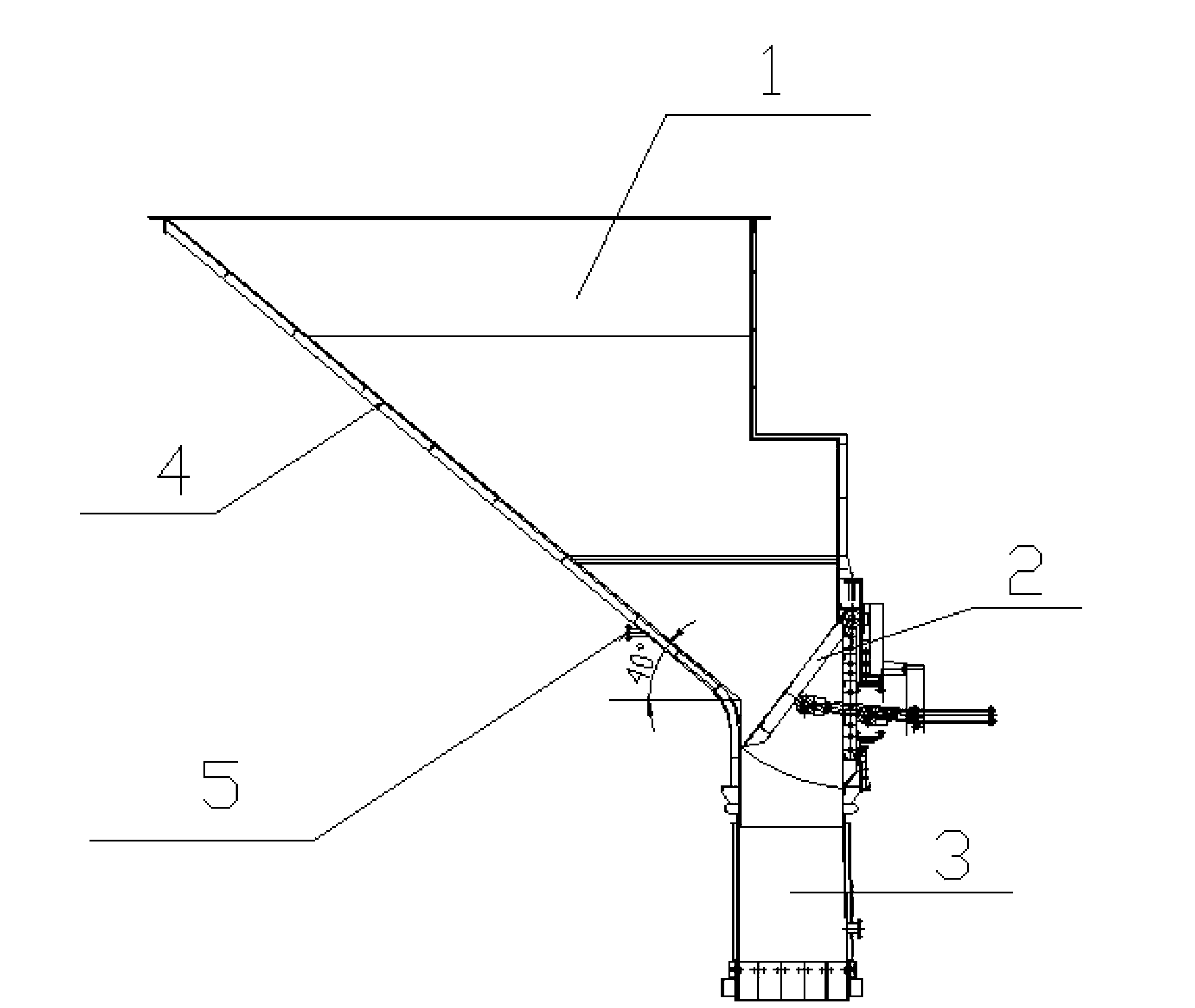

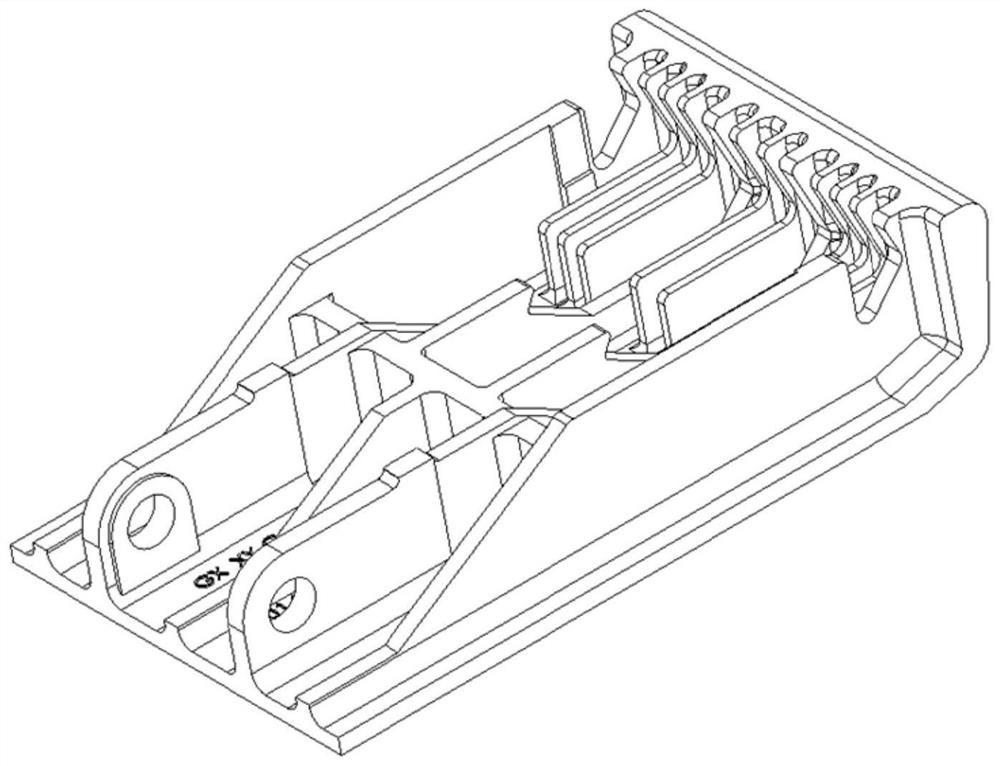

Feeding device for MSW (municipal solid waste) incinerator

InactiveCN103322577AAvoid heat damagePrevent bridgingIncinerator apparatusWater coolingMunicipal solid waste incinerator

The invention discloses a feeding device for an MSW incinerator and belongs to waste feeding devices. The feeding devices for the MSW incinerator comprises a waste hopper, a hopper door and flap bridge device, a waste sliding pipe and a water cooling clamping sleeve, wherein the upper end of the waste hopper in a feeding inlet, and the lower end of the waste hopper is a feeding outlet; the hopper door and flap bridge device is movably arranged on the wall, above the feeding outlet, of the waste hopper and can be opened inward the feeding outlet of the waste hopper along the movable joint of the wall of the waste hopper and the hopper door and flap bridge device; the waste sliding pipe is connected with the feeding outlet of the waste hopper; and the water cooling clamping sleeve is sleeved outside the wall of the waste hopper, above the feeding outlet of the waste hopper, and the waste sliding pipe. The feeding device for the MSW incinerator solves the problem of heat damage to the feeding device, which is caused by waste bridge blocking, in-incinerator heat radiation, backfire and the like, in an existing MSW incinerator feeding system.

Owner:上海绿晖环保科技有限公司

Preparation method of water dephosphorization porous ceramic filter ball

InactiveCN109665815AHigh strengthImprove plasticityOther chemical processesWater contaminantsPore distributionRed mud

The invention belongs to the technical field of environment protection and discloses a preparation method of a water dephosphorization porous ceramic filter ball. Typical solid waste is used as a rawmaterial for collaborative treatment. The method includes: pretreating a raw material, controlling raw material grain size, and grading; uniformly mixing the raw material to obtain paste; granulating,and aging; performing gradient temperature-controlled calcining, wherein the raw material is composed of, by mass, 21-65% of Bayer-process red mud, 9-38% of urban domestic waste incinerator slag, 4-23% of excitant, 3-15% of pore forming agent and 5-10% of binder. The porous ceramic filter ball prepared by the method has the advantages of high porosity, uniform pore distribution, large specific surface area, high water absorptivity, high dephosphorization ability and speed and resistance to hydraulic impact, is excellent in various physiochemical properties, can be applied in water dephosphorization and can realize solid waste cooperative treatment and recycling and reduce solid waste accumulation.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

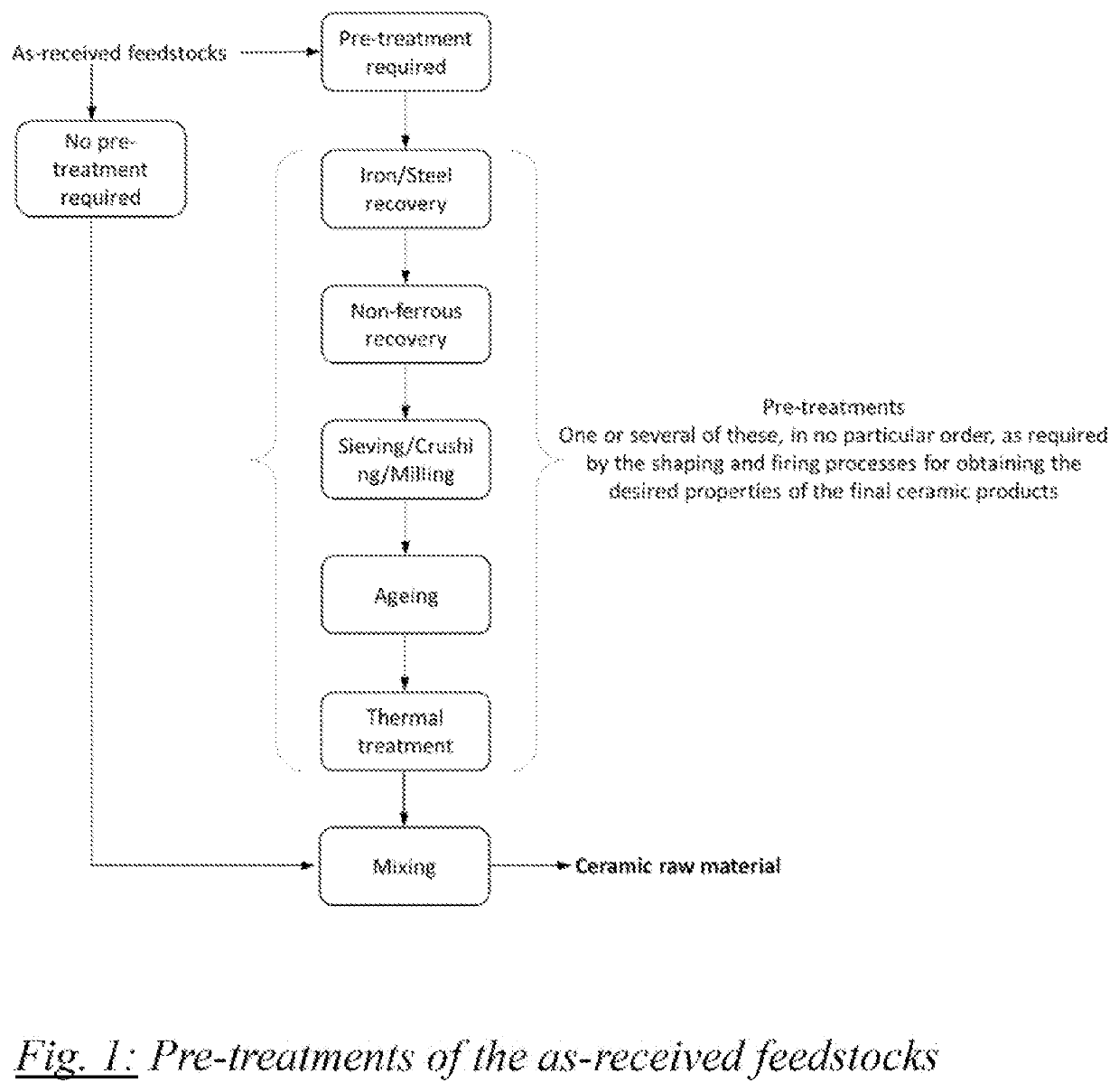

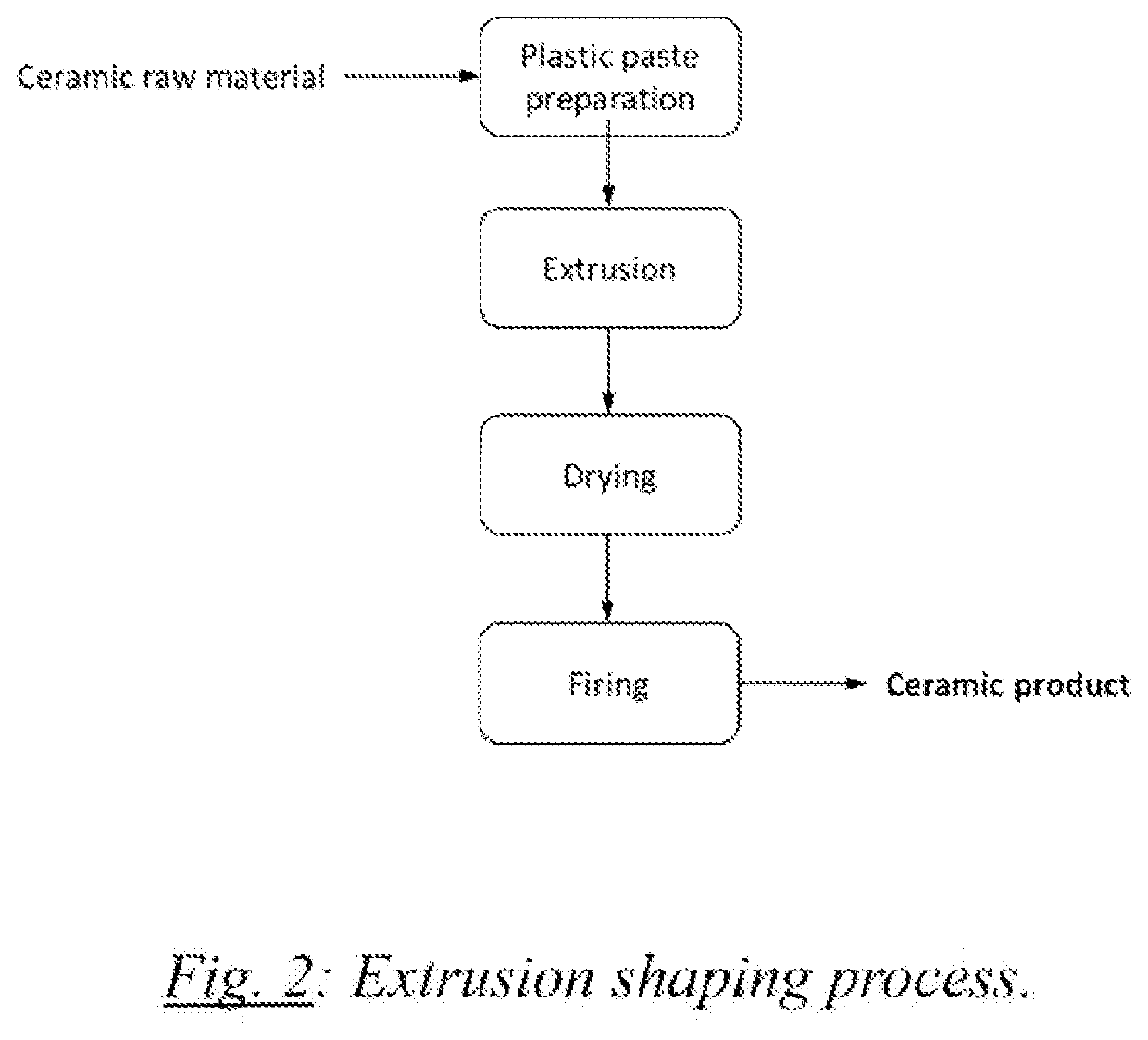

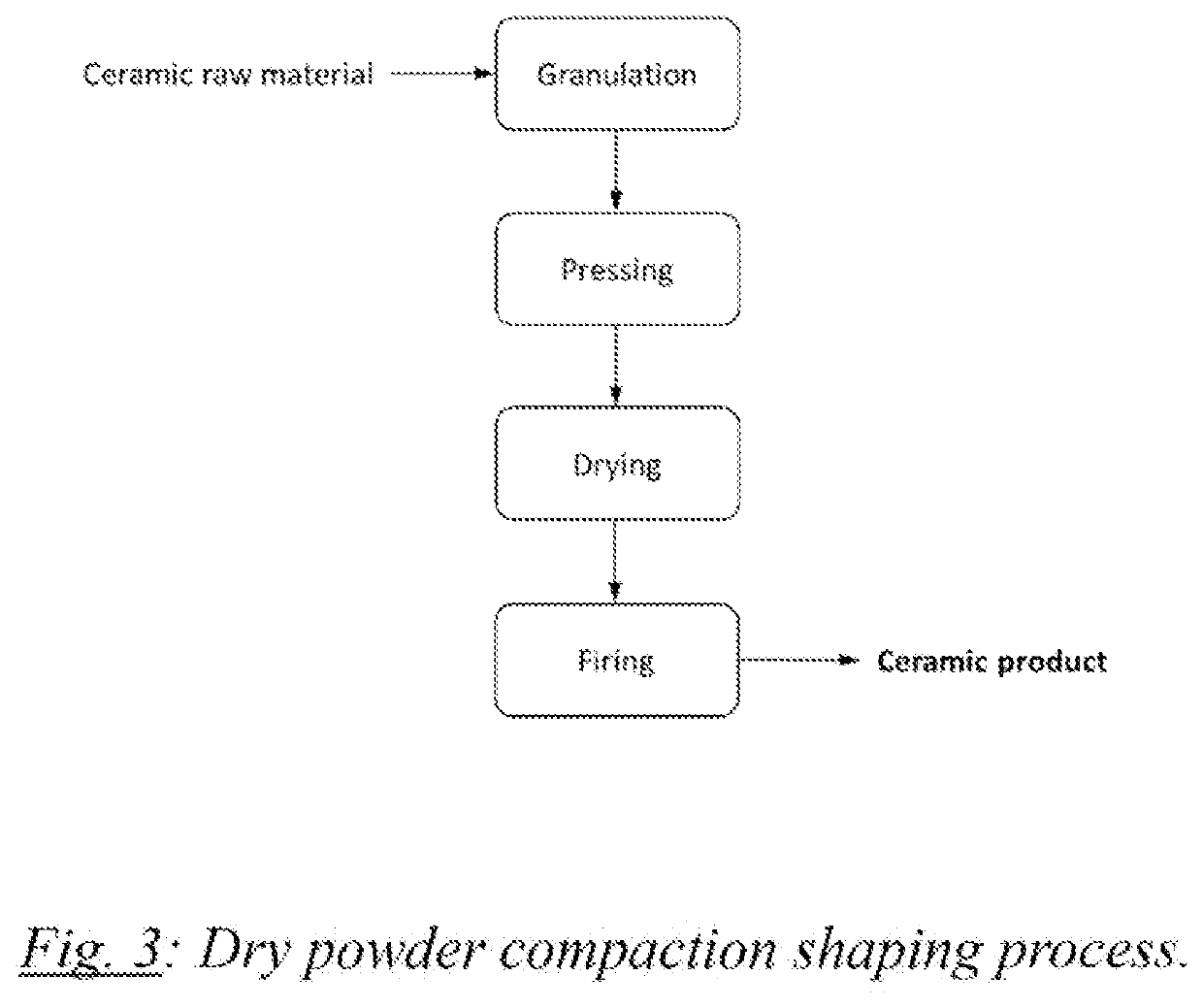

Industrial solid waste based construction and technical ceramics

A ceramic for construction or technical applications, composed of at least one of Municipal Solid Waste Incinerator Bottom Ash (MSWIBA) and other recycled industrial solid waste and different methods of forming such ceramics. Various techniques illustrate how ceramics are formed using at least one of extrusion shaping, dry powder compaction and agglomeration, any of which can be preceded by a pre-treatment process of received feedstock.

Owner:SERAMIC MATERIALS LTD

Method for producing alinite cement by utilizing municipal solid waste incinerator fly ash

InactiveCN101746975ALighten the serious burdenReduce consumptionClinker productionCoalMaterials science

The invention relates to a method for producing alinite cement by utilizing municipal solid waste incinerator fly ash. The method includes that solid waste incinerator fly ash is taken as main raw material, the raw materials including 25-40wt% of solid waste incinerator fly ash, 17-20wt% of limestone, 3-5wt% of coal ash and 3-9wt% of calcium chloride are mixed, ground into powder and made into pat, the pat is placed into a high temperature furnace and heated to 1200 DEG C, heat preservation is carried out for a period of time, and then the pat is taken out and quenched to room temperature, thus obtaining the alinite cement clinker. Compared with the prior art, the invention has the advantages of energy conservation and emission reduction as well as huge social benefit, economic benefit and environmental protection benefit.

Owner:TONGJI UNIV

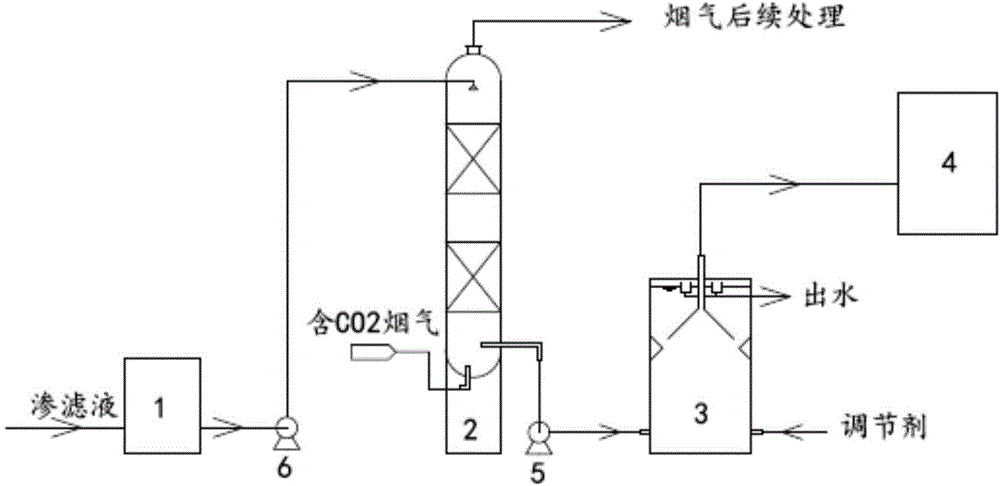

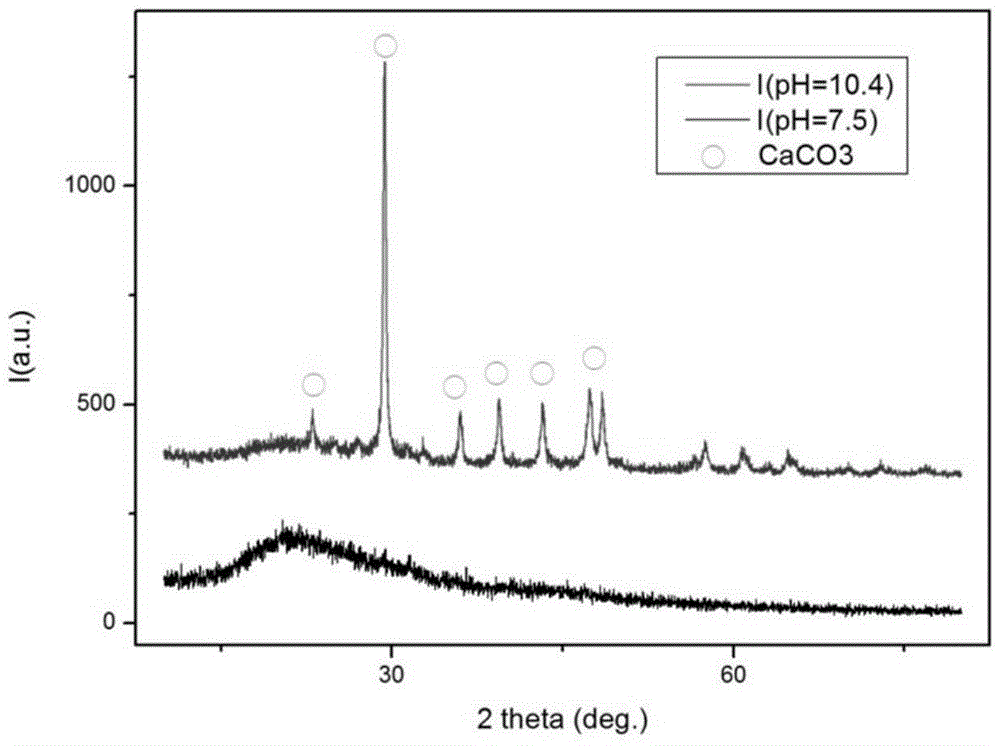

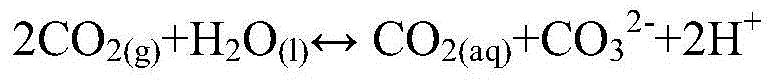

Fixing method of carbon dioxide in flue gas of municipal solid waste incinerator

InactiveCN104587819ACaptureAchieve fixationDispersed particle separationAir quality improvementPh regulationMagnesium ion

The invention discloses a fixing method of carbon dioxide in flue gas of a municipal solid waste incinerator. The fixing method comprises the following steps: by adopting absorption devices including a water regulating tank, an absorption tower, a separation tower and an absorption tank, with a leachate of the incinerator as an absorbent, introducing the flue gas containing CO2 generated by waste incineration into the leachate at a certain flow rate, carrying out rapid reaction on a great amount of ions including calcium ions and magnesium ions contained in the leachate and the CO2 in the flue gas in the absorption tower, enabling a liquid after reaction to produce a carbonate precipitate in the separation tower by virtue of pH regulation, realizing solid-liquid separation, achieving fixing and separation of the CO2 in the flue gas, absorbing released CO2 by adopting ammonia to produce an ammonium bicarbonate fertilizer, or enabling the released CO2 to reflux to the absorption tower, and trapping, separating and solid storing the CO2 in the flue gas of the municipal solid waste incinerator in an internal circulation mode. According to the fixing method disclosed by the invention, the CO2 in the flue gas of the municipal solid waste incinerator is effectively controlled by adopting the internal circulation mode; the fixing method has the advantages that the absorbent is wide in source, low in cost and high in efficiency, is capable of solving the problem of scaling of the leachate in subsequent processing and is suitable for trapping and fixing the CO2 in the flue gas of the municipal solid waste incinerator.

Owner:SHANGHAI JIAO TONG UNIV

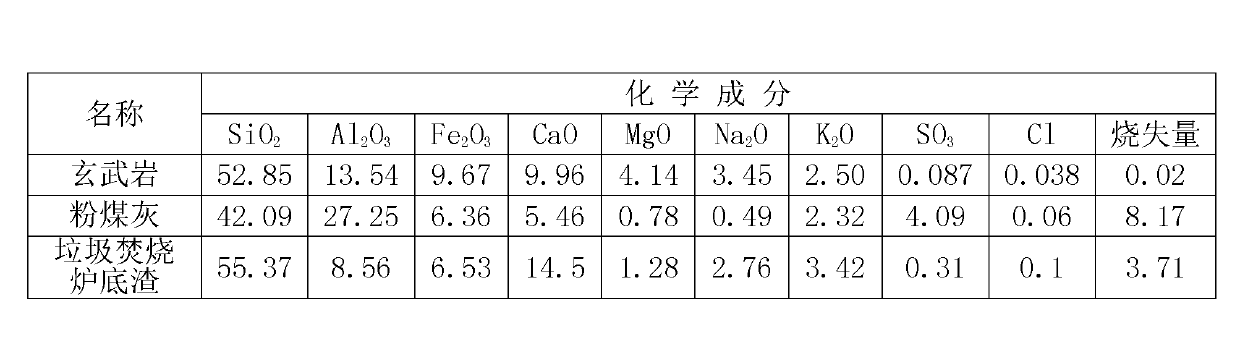

Composite household garbage incinerator bottom slag coal ash for concrete

InactiveCN103342490AImproved particle size distributionImprove microstructureSolid waste managementSlagResource utilization

The invention relates to a composite household garbage incinerator bottom slag coal ash for concrete, and the coal ash is prepared by grinding the bottom slag of a household garbage incinerator, wet discharged coal ash, basalt and composite activity excitant by virtue of grinding equipment and then mixing the materials uniformly. The fineness of the composite coal ash is controlled to be less than 15% of residues via a square hole sieve 45mm in diameter, and the water content of the coal ash is less than 0.5%. The coal ash is simple in production process, and takes easily obtained wet discharged coal ash, the bottom slag of the household garbage incinerator, waste corner material of a basalt plant and other industrial wastes as main raw materials. By virtue of optimal combination, the optimal superimposed effect and grain composition of all components are expressed fully, thus part of cement in the concrete can be replaced by the composite coal ash. The coal ash can be used for saving resources and energy source, and is beneficial to industrial production, environmental protection, energy conservation and emission reduction, can be used for developing a new way for the resource utilization of the bottom slag of the municipal household garbage incinerator, and has good social effects and economic benefits.

Owner:HAINAN LANDAO ENVIRONMENTAL PROTECTION IND

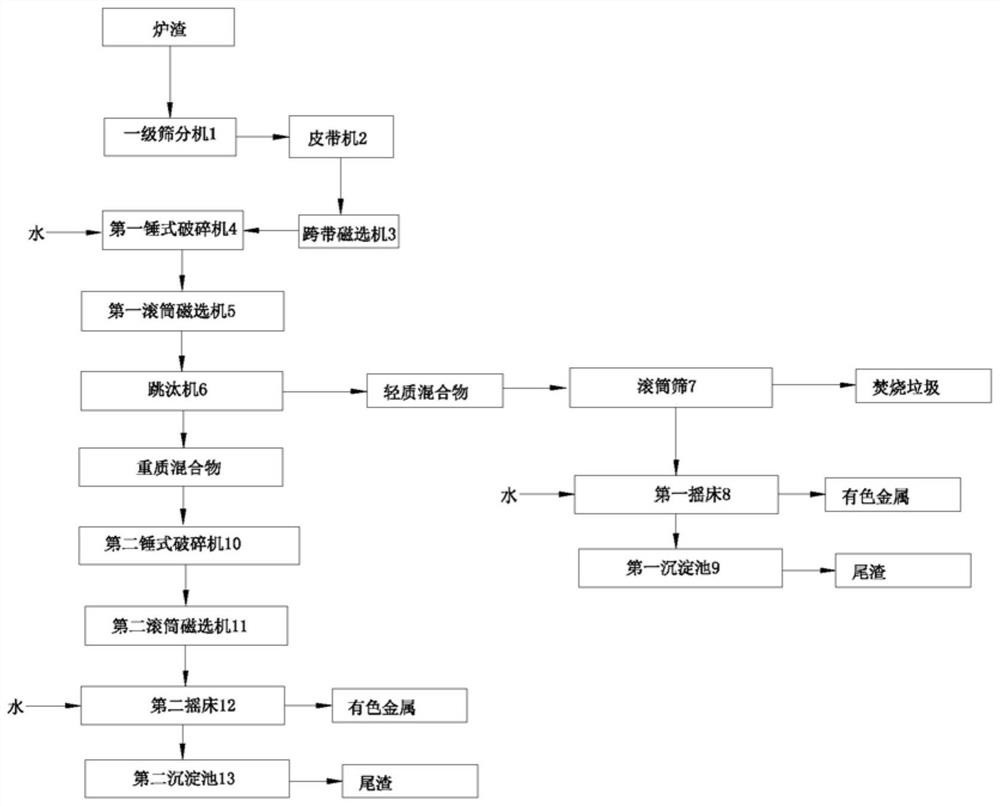

Comprehensive utilization process of municipal solid waste incineration slag

InactiveCN112792106ASolve wasteReasonable and efficient process designTransportation and packagingSolid waste disposalSlagNonferrous metal

The invention relates to the technical field of garbage treatment systems, in particular to a comprehensive utilization process of municipal solid waste incineration slag. The process realizes recovery of metal substances in the slag through production processes of primary screening, manual screening, primary magnetic separation, primary crushing, secondary magnetic separation, jigging separation, drum screening and shaking table screening. Magnetic metal and non-ferrous metal in the slag are screened and recovered in a wet recovery manner, the process design is reasonable and efficient, the metal with utilization value in the slag can be recovered to the maximum extent, and the problem of resource waste in the past is solved.

Owner:广东中翔环保建材有限公司

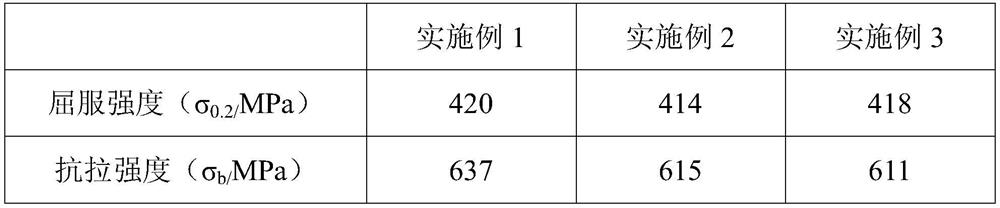

Alloy material for incinerator fire grate and preparation method of alloy material

The invention provides an alloy material for an incinerator fire grate and a preparation method of the alloy material, and belongs to the field of manufacturing and processing of special alloy materials. The alloy material for the incinerator fire grate comprises the following alloy elements in percentage by weight: 0.15 percent to 1.5 percent of carbon C, 2 percent to 3 percent of silicon Si, 0.6 percent to 1.5 percent of manganese Mn, 18 percent to 29 percent of chromium Cr, 2.5 percent to 4.0 percent of nickel Ni, 0.15 percent to 0.45 percent of molybdenum Mo, 0.1 percent to 0.8 percent of copper Cu, 0.05 percent to 0.20 percent of rare earth element RE, less than or equal to 0.03 percent of sulfur S, less than or equal to 0.04 percent of phosphorus P, 0.1 percent to 0.3 percent of nitrogen N, 0.05 percent 0.40 percent of strong carbide forming element, 0.04 percent to 0.06 percent of boron B, 0.04 percent to 0.06 percent of aluminum Al, and the balance of ferrum Fe and other inevitable impurities. The alloy material for the fire grate provided by the invention has the characteristics of high temperature resistance, corrosion resistance, carbonization resistance, wear resistance and the like, is simple in process, long in service life and good in comprehensive performance, is very suitable for materials for fire grates of large municipal solid waste incinerators in China, and has a wide application prospect.

Owner:萍乡市长峻特种材料铸造有限公司

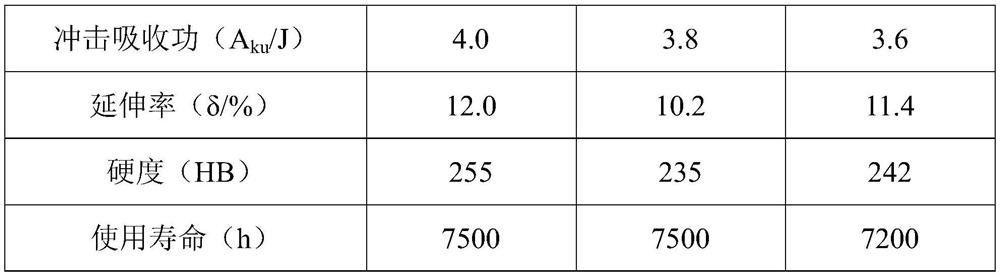

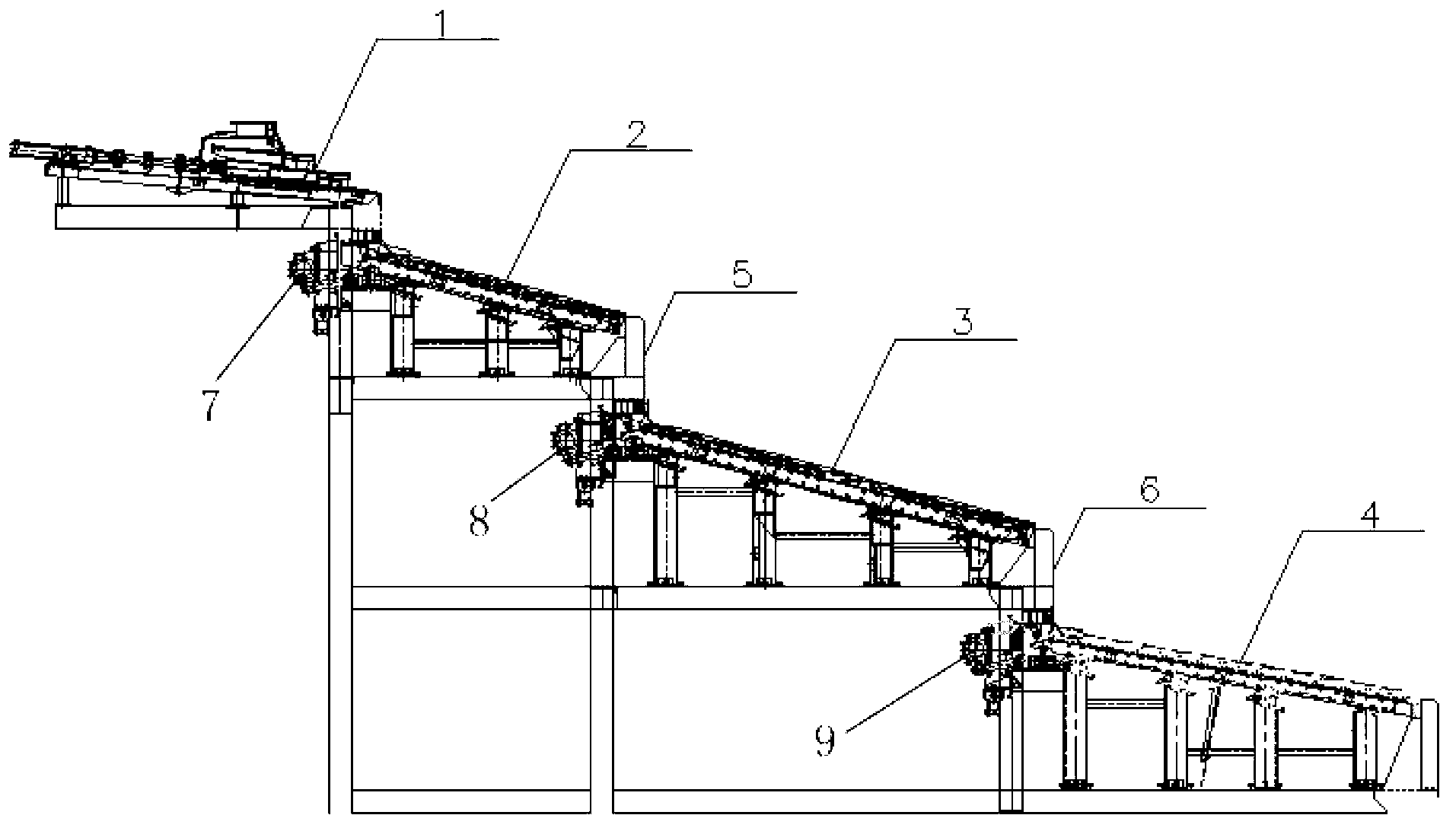

Grate device used for urban domestic garbage incinerator

The invention discloses a grate device used for an urban domestic garbage incinerator, and belongs to garbage processing equipment. The grate device used for the urban domestic garbage incinerator comprises a drying grate, a burning grate, a burnt grate and a driving device, wherein the drying grate, the burning grate and the burnt grate are sequentially connected and are arranged sequentially from top to bottom in a staged mode; the grating face of each grate is inclined downward; the drying grate, the burning grate and the burnt grate are respectively driven by the driving device to carry out reciprocating type mechanical motion in the same direction. The grate device used for the urban domestic garbage incinerator solves the problems that garbage cannot be burned completely caused by low calorific value and high ash content in existing urban domestic garbage incineration.

Owner:上海绿晖环保科技有限公司

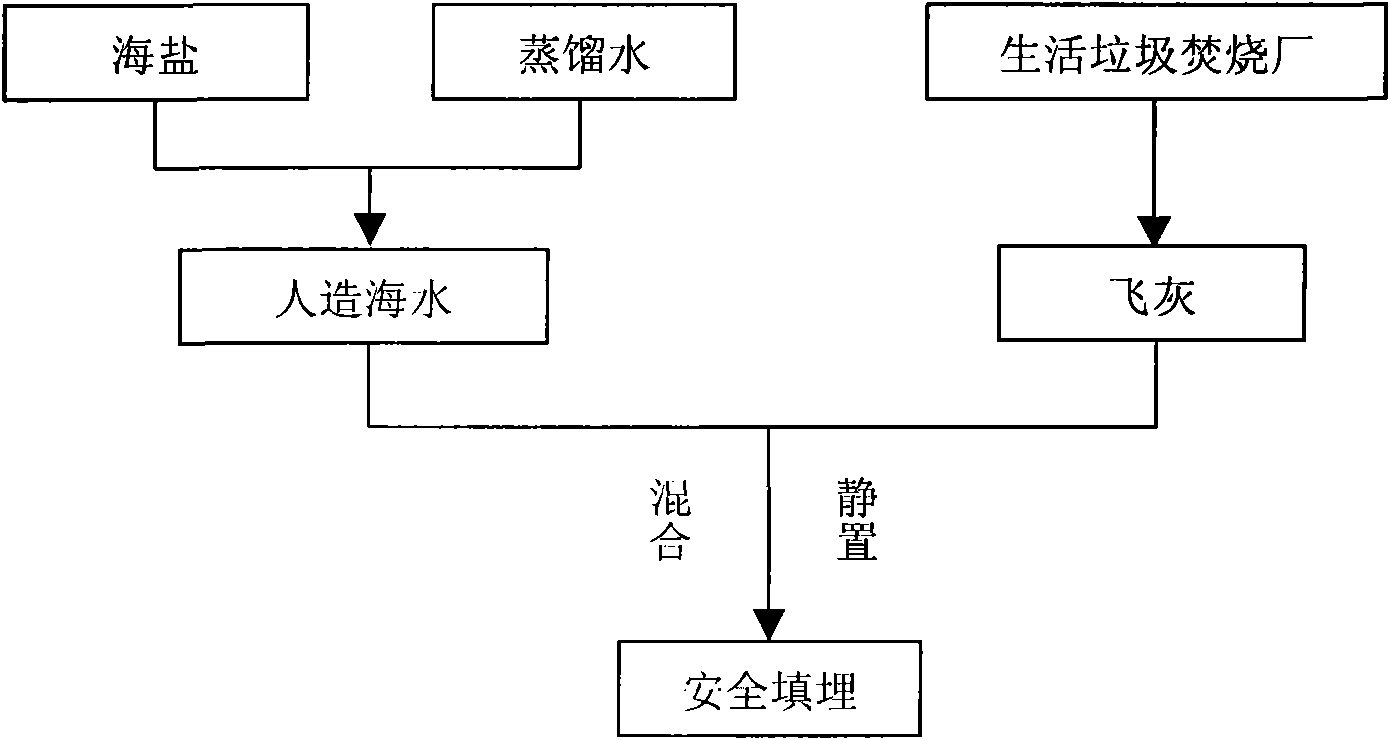

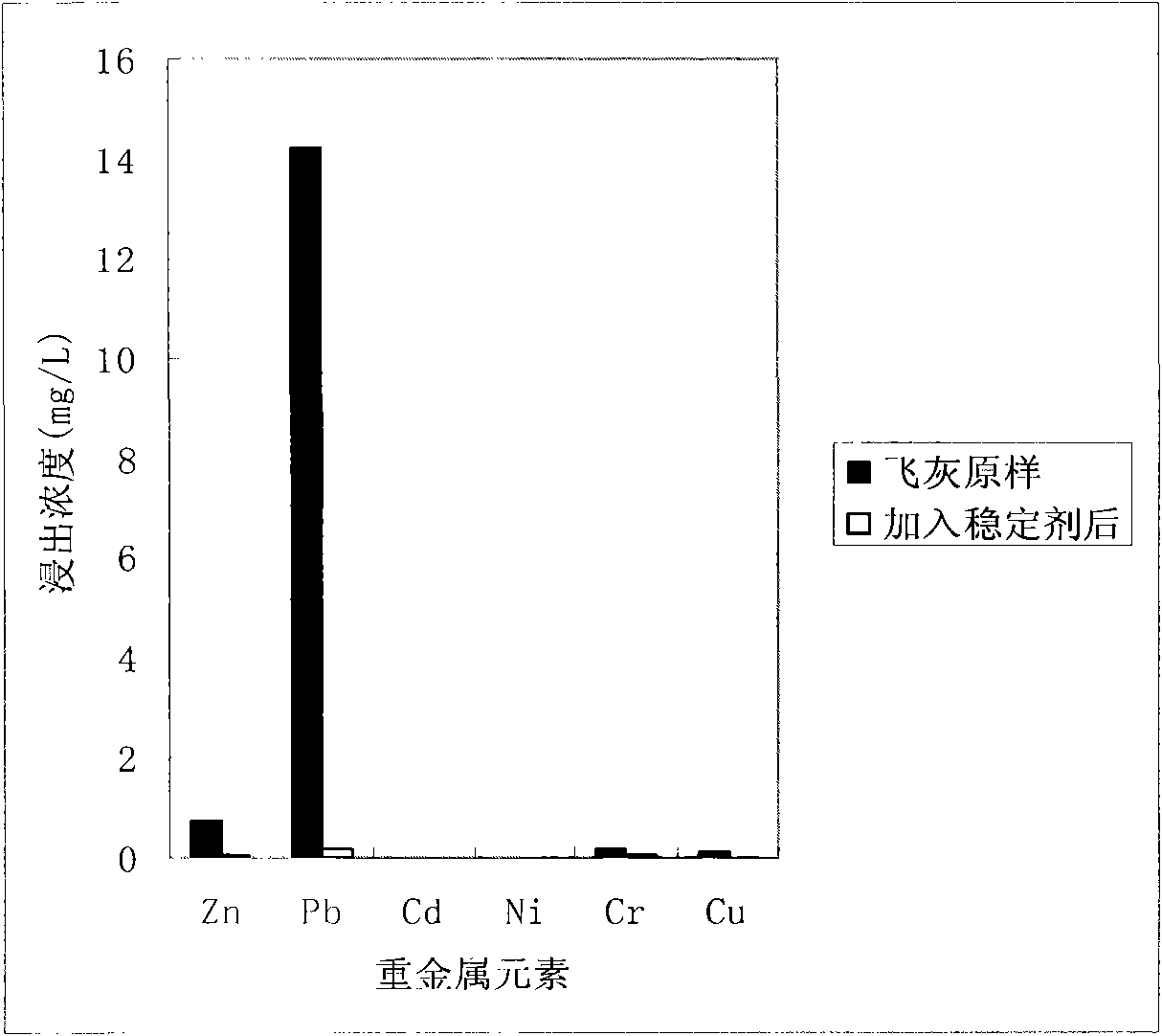

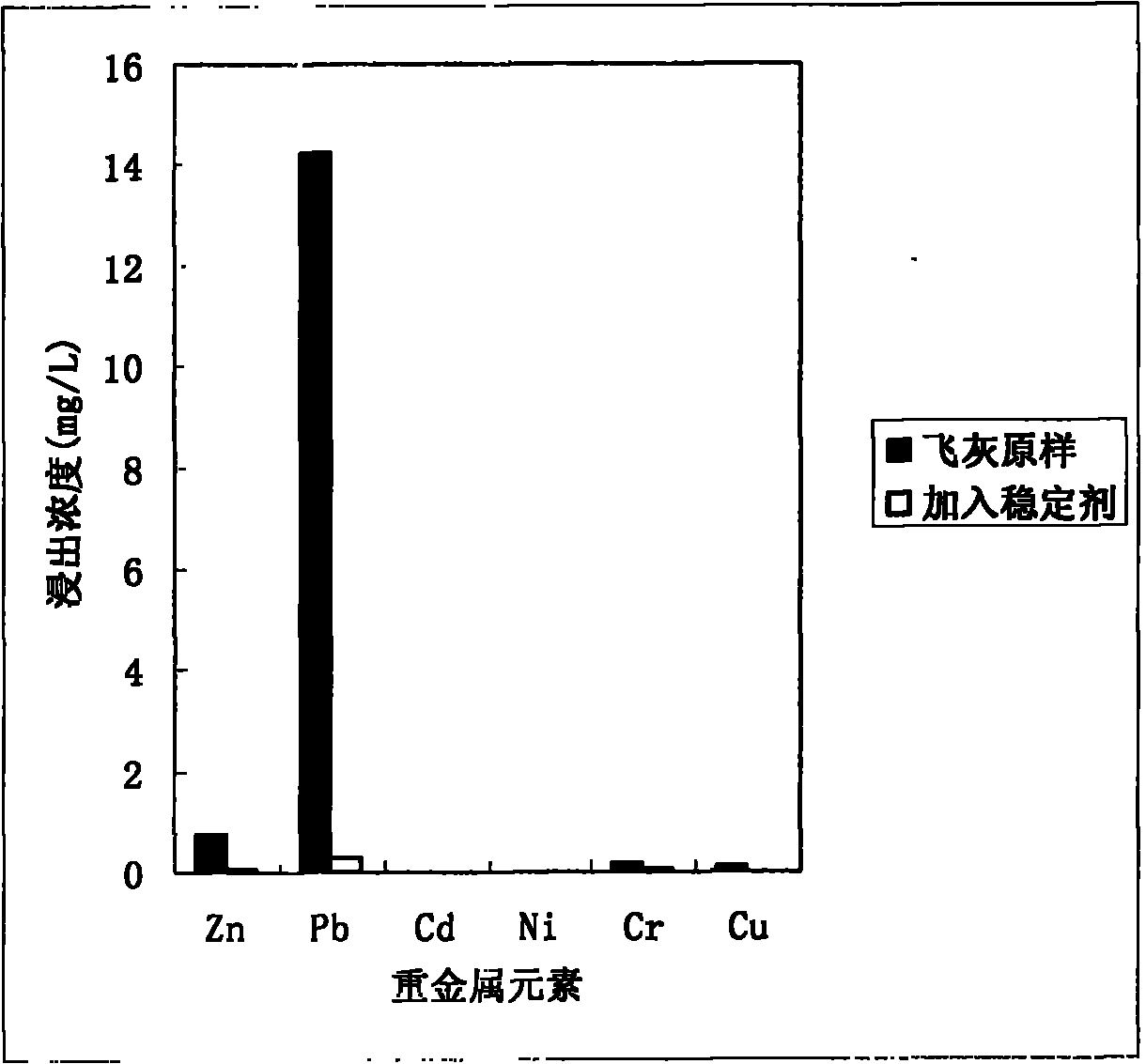

Method for stabilizing fly ash of municipal solid waste incinerator by using artificial sea water

InactiveCN102009061APlay a stimulating roleMeet the requirements of safe landfillSolid waste disposalNatural ventilationDistilled water

The invention provides a method for stabilizing fly ash of a municipal solid waste incinerator by using artificial sea water, and relates to a process for stabilizing heavy metals in the fly ash of the municipal solid waste incinerator. The method comprises the following steps of: weighing the fly ash and sea salt in a mass ratio of 1:0.01-0.5; weighing distilled water and the sea salt in the mass ratio of 30 to 1; dissolving the sea salt into the distilled water to make the artificial sea water; adding the fly ash into the artificial sea water; stirring for 10 to 30min to generate heavy mortar mixture; drying and maintaining the heavy mortar mixture for 2 to 3 days under a natural ventilating condition, and detecting that immersion of the heavy metals in the mixture meets the safe landfill requirement of 'Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity' (GB5085.3-2007). The invention has the advantages of readily available raw materials and low cost, and cannot generate secondary pollution to the environment.

Owner:TONGJI UNIV

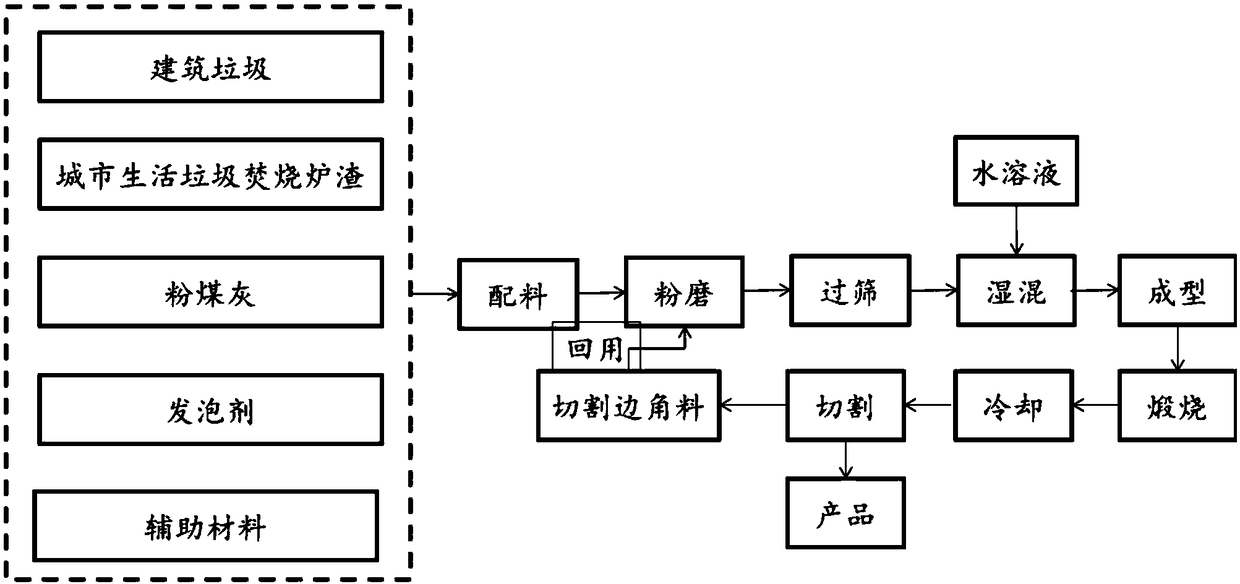

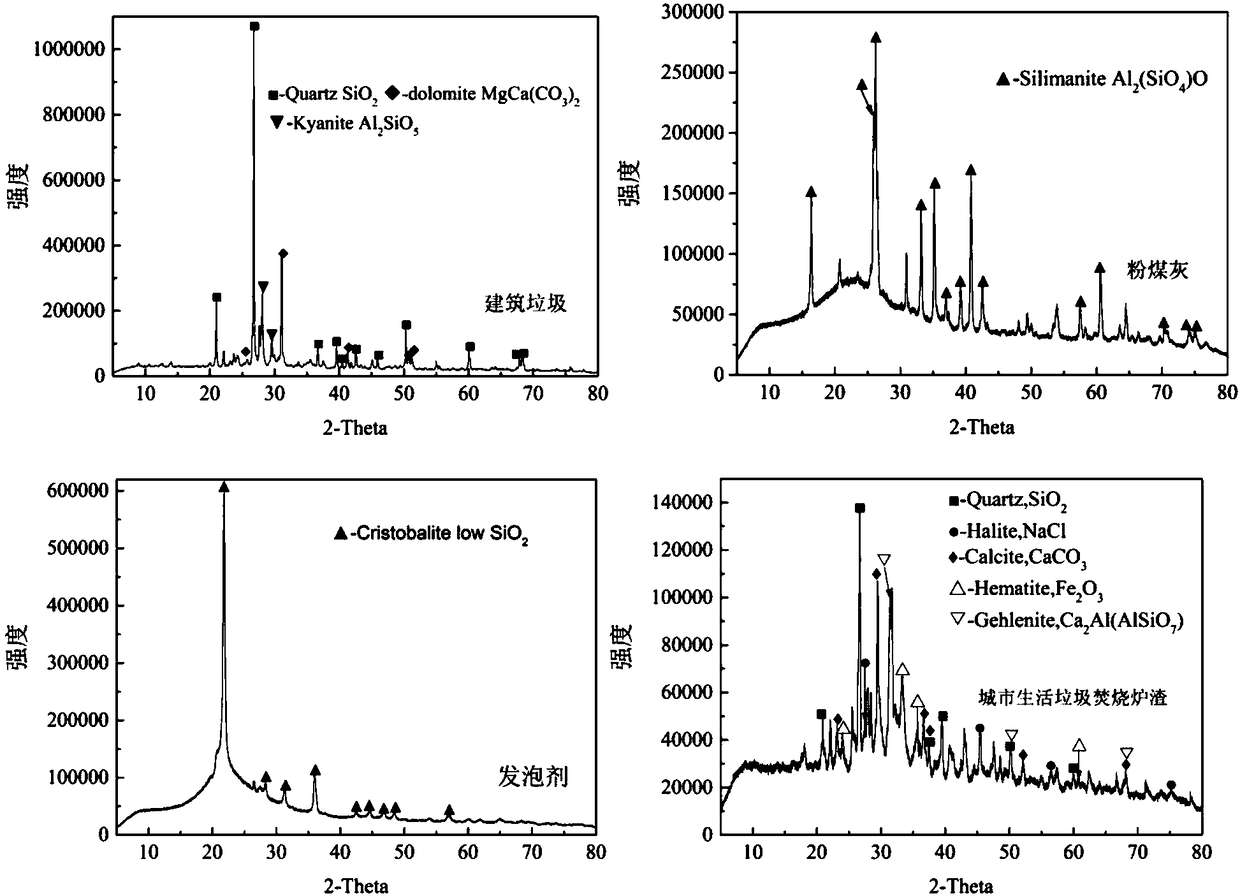

Lightweight porous thermal insulation material and preparation method thereof

ActiveCN108484119AImprove structural strengthLow water absorptionCeramic materials productionCeramicwareSlagThermal insulation

The invention discloses a lightweight porous thermal insulation material and a preparation method thereof. The lightweight porous thermal insulation material comprises the following components in weight percentage: 45%-80% of construction waste, 5%-40% of municipal solid waste incineration slag, 5%-40% of fly ash, 5%-25% of a foaming agent and 0.5%-2% of auxiliary materials, wherein the auxiliarymaterials include 0.2%-1.5% of a foam stabilizer and 0.2%-1.5% of a fluxing agent. According to the preparation method, all the raw materials of the lightweight porous thermal insulation material arewastes and are easily available, the process is simple, the cost is low, solid wastes such as construction waste, municipal solid waste incinerator slag, fly ash and agricultural straw and husk are directly used as the raw materials, and the preparation process is simple. The porous thermal insulation material has high structural strength, low water absorption rate, low density and low thermal conductivity; the production cost of the foamed porous material is effectively lowered, the environment is protected, and a waste is turned into treasure, so as to achieve obvious economic and environmental benefits.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

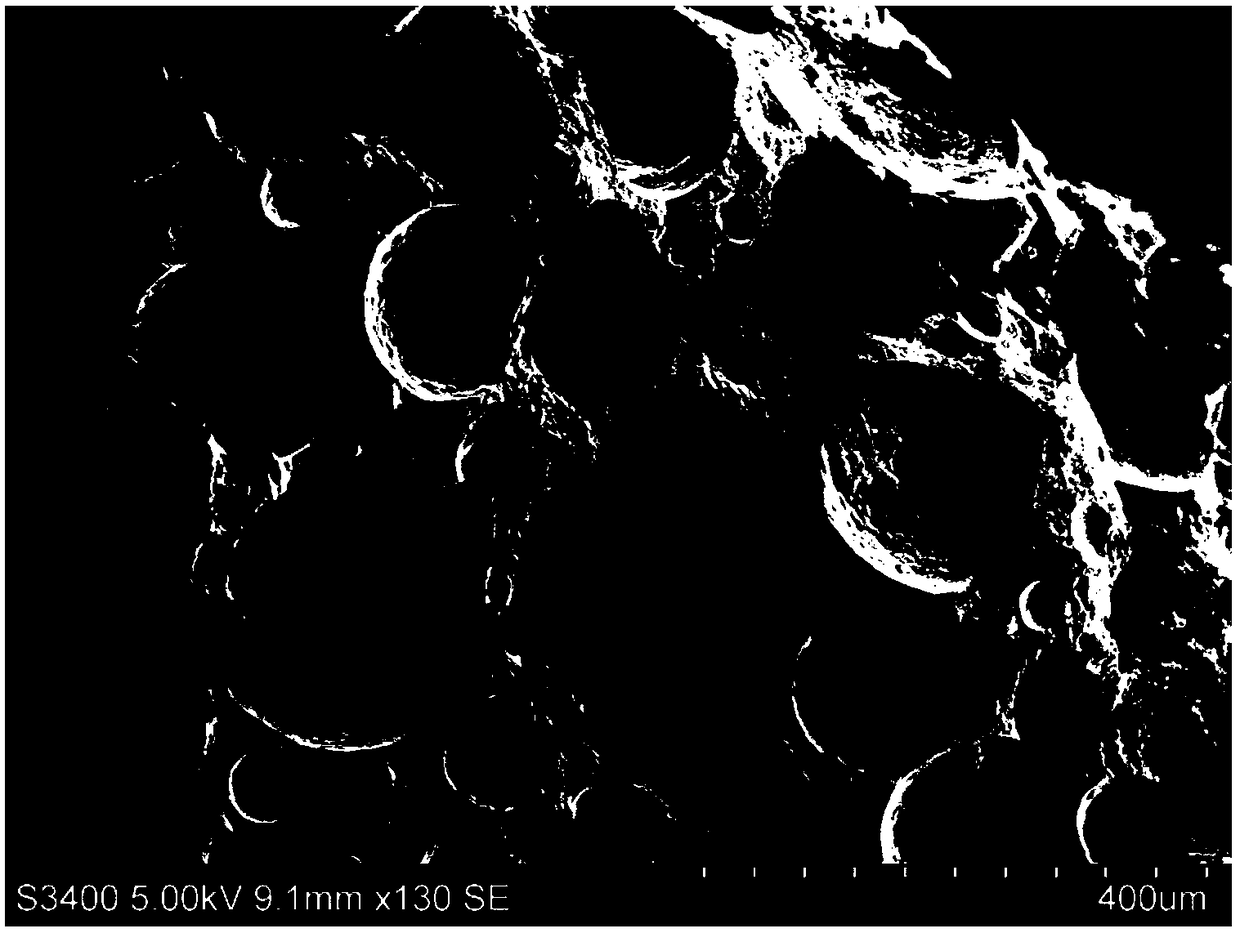

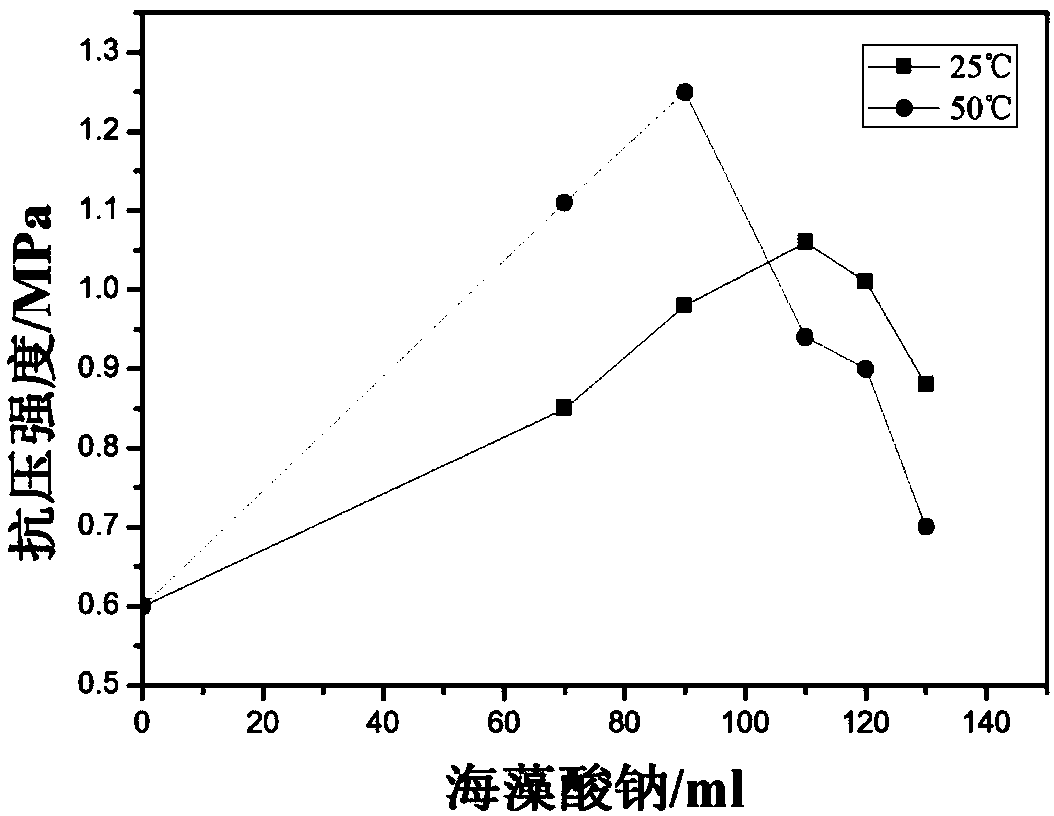

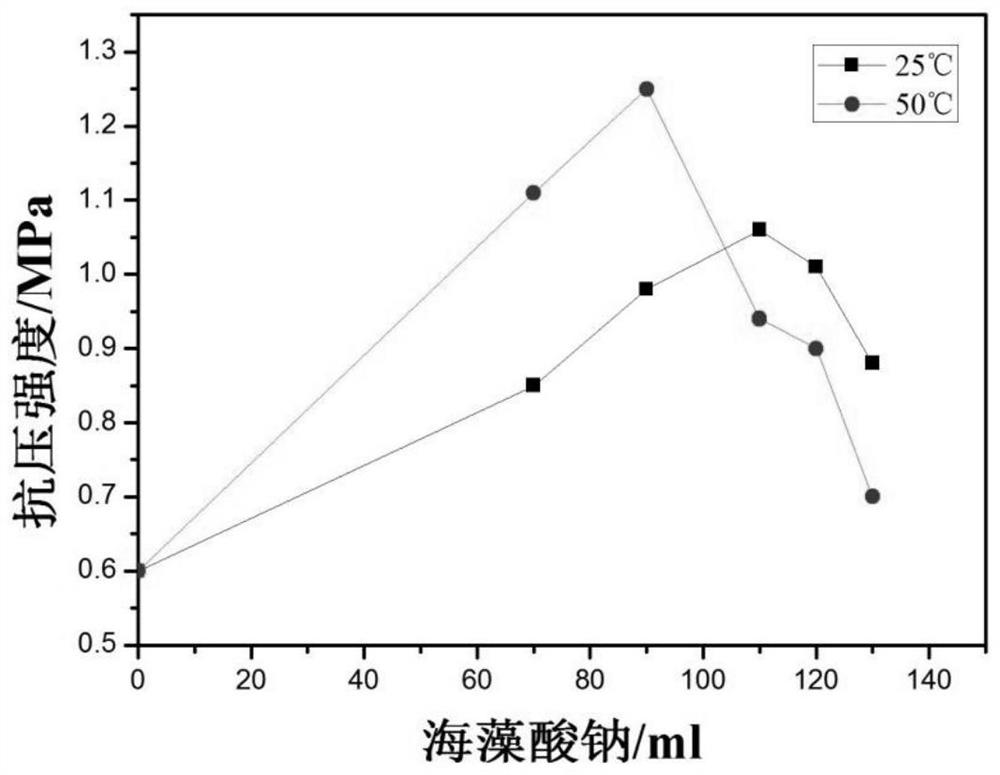

Method of using urban domestic waste incinerator residue to produce lightweight foam concrete

ActiveCN109354448AExpand the scope of engineering applicationsThe scope of engineering application is reducedCeramicwareFoam concreteEnvironmental resistance

The invention discloses a method of using urban domestic waste incinerator residue to produce lightweight foam concrete. The method comprises the steps of 1) weathering urban domestic waste incinerator residue, and washing with water; 2) pouring the materials other than a foaming agent and water, into a stirrer, and mixing well; 3) adding quantitative super-pure water and prepared sodium alginateinto the stirrer; 4) adding the foaming agent during stirring, pouring the mixed slurry immediately into a produced mold, covering the surface with a layer of preservative film, and allowing standingfor foaming; 5) removing the mold, storing the foam concrete in a curing tank for curing so as to obtain the lightweight foam concrete with good mechanical properties. The method provides a wider engineering applicable range for incinerator residue, has the advantages of environmental friendliness, low price, good simplicity and the like, and is worthy of application in the large-scale productionof lightweight foam concrete.

Owner:广东酉城环保产业有限公司

A kind of ash-removing and coking-removing agent formula for municipal solid waste incinerators

InactiveCN101338237BImprove dust accumulation and slaggingImprove efficiencyFuel additivesIncinerator apparatusCopper nitrateCopper oxide

The invention discloses a formula of ash-removing and coke-removing agent used in municipal solid waste incinerators, the composition and mass percent of which are: 50-70% of nitrate, 5-10% of bulking agent, 10-15% of sodium chloride %, activator 5-15%, vermiculite 5-10%, copper oxychloride 1-2%, nitrate is copper nitrate and sodium nitrate, loosening agent is borax, activator is ammonium nitrate, carbon powder and sulfur powder . The invention is applied to the field of ash removal and decoking of municipal solid waste incinerators, and has a good effect on improving the ash accumulation and slagging of the garbage incinerators.

Owner:XI AN JIAOTONG UNIV

Method for preparing lightweight foamed concrete by using municipal solid waste incineration slag

ActiveCN109354448BExpand the scope of engineering applicationsThe scope of engineering application is reducedCeramicwareFoam concreteFoaming agent

The invention discloses a method of using urban domestic waste incinerator residue to produce lightweight foam concrete. The method comprises the steps of 1) weathering urban domestic waste incinerator residue, and washing with water; 2) pouring the materials other than a foaming agent and water, into a stirrer, and mixing well; 3) adding quantitative super-pure water and prepared sodium alginateinto the stirrer; 4) adding the foaming agent during stirring, pouring the mixed slurry immediately into a produced mold, covering the surface with a layer of preservative film, and allowing standingfor foaming; 5) removing the mold, storing the foam concrete in a curing tank for curing so as to obtain the lightweight foam concrete with good mechanical properties. The method provides a wider engineering applicable range for incinerator residue, has the advantages of environmental friendliness, low price, good simplicity and the like, and is worthy of application in the large-scale productionof lightweight foam concrete.

Owner:广东酉城环保产业有限公司

Decoking and ash removing agent for urban domestic garbage incinerator and preparation method thereof

InactiveCN101787317BExtended safe operation periodIncrease labor intensityFuel additivesIncinerator apparatusSlagAluminum silicate

The invention relates to a decoking and ash removing technology for an urban domestic garbage incinerator, and discloses a decoking and ash removing agent for the urban domestic garbage incinerator and a preparation method thereof. The invention is suitable for the formula of the decoking and ash removing agent with calcium-aluminum silicate as a main component for slag formation and ash accumulation. The mass percent of the components of the decoking and ash removing agent is as follows: soda ash: 25 to 30%; zinc oxide: 25 to 30%; sodium nitrate or potassium nitrate: 20 to 25%; borax: 5 to 10%; sodium chloride: 5 to 10%; vermiculite: 1 to 4%; and copper oxychloride: 1 to 4%.

Owner:XI AN JIAOTONG UNIV

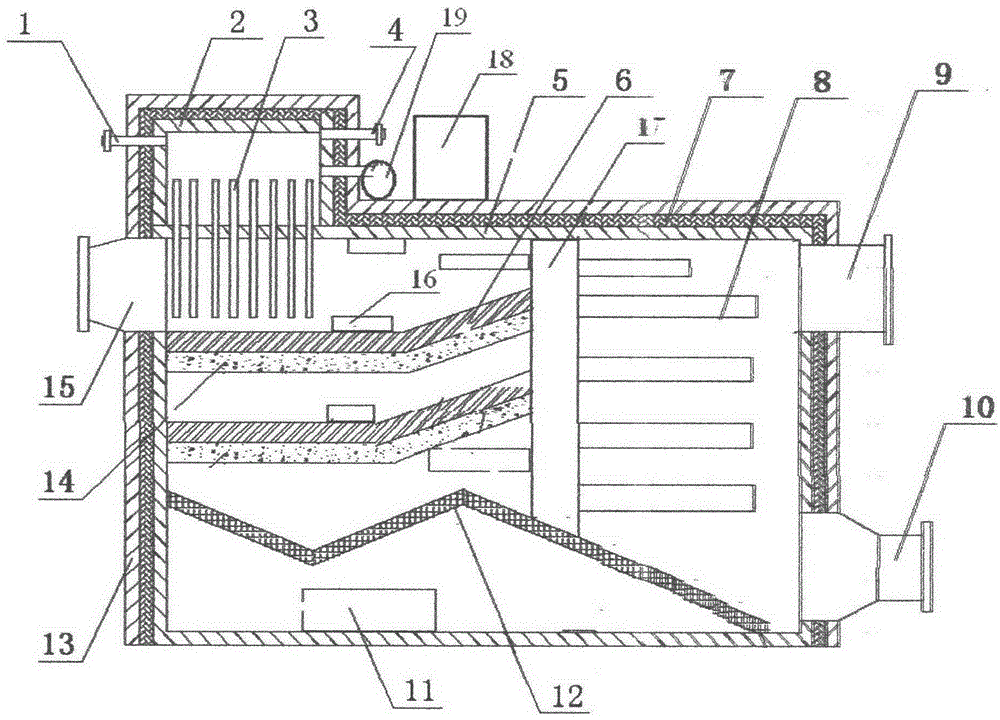

Municipal Solid Waste Incinerator

ActiveCN102889596BEffective filteringAchieve energy saving and emission reductionIncinerator apparatusControl systemSoot

The invention relates to a municipal domestic garbage incinerator. The municipal domestic garbage incinerator comprises a box body, a soot dust inlet pipe, soot dust outlet pipe, two filtering baffle plates, a granule attachment beam, a control system and a sensing system, wherein a plurality of granule attachment columns are arranged on the granule attachment beam. The control system is positioned on the upper part of the box body; a blower is arranged in a heat exchange box; a sensor is arranged on a filter screen; and the control system is connected with the sensor and the blower through signal wires. The municipal domestic garbage incinerator is provided with the granule attachment beam, and a plurality of granule attachment columns are arranged on the granule attachment beam, so that energy conservation and emission reduction are realized effectively.

Owner:青岛华泰锅炉热电设备有限公司

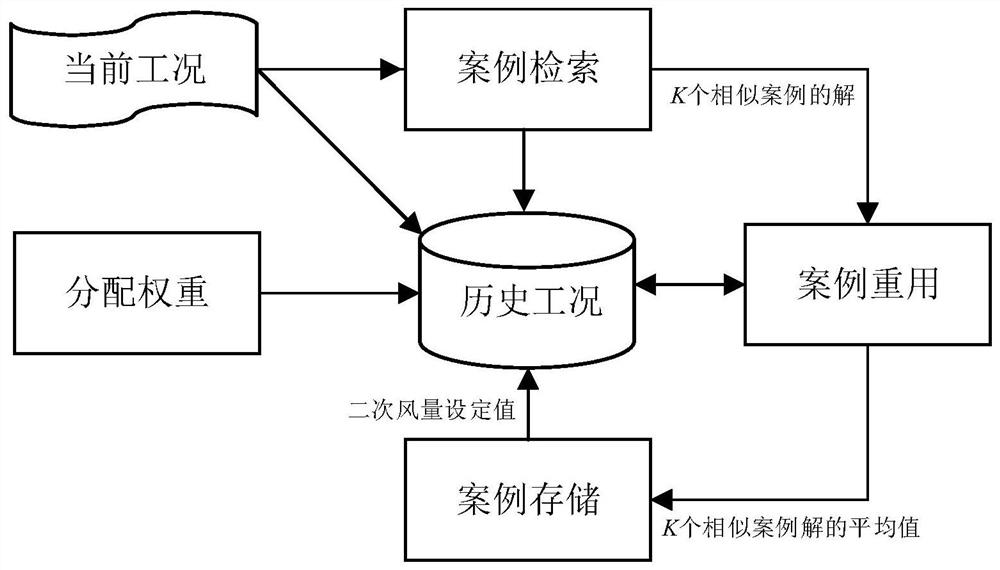

Intelligent setting method for secondary air volume in municipal solid waste incineration process

ActiveCN113154404AAvoid limitationsAvoid subjectivityArtificial lifeIncinerator apparatusAir volumeFlue gas

The invention discloses an intelligent setting method for secondary air volume in a municipal solid waste incineration process and relates to the field of parameter setting of municipal solid waste incinerators. According to the method, the oxygen content of flue gas at an outlet is maintained within an ideal range through the intelligent setting of the secondary air volume. The method mainly comprises the following steps of (1) establishing a set database according to historical data in the municipal solid waste incineration process; (2) initializing parameters; (3) distributing feature weights based on a black hole cuckoo algorithm; (4) obtaining solutions of K similar cases through a case retrieval model; (5) solving an average value of the solutions of the K similar cases through case reuse in order to obtain a set value of a solution of a target case; (6) storing a case formed by the target case and the set value of the target case in the set database; and (7) repeating step (3) to step (6) in order to achieve the intelligent setting process of the secondary air volume in the municipal solid waste incineration process.

Owner:BEIJING UNIV OF TECH

Preparation method of city refuse incineration furnace granular fuel

InactiveCN100363475CHigh calorific valueRealize the incineration operationBiofuelsSolid fuelsThermal energyLitter

The invention discloses a produce method for grain fuel used in municipal refuse incinerator, which comprises: separating, breaking, draining, evaporating, secondary breaking, granulating and drying. This invention reduces the require to material, heat value and moisture, enlarges scope of application, cuts energy consumption and cost, decreases pollution greatly, and can be used to restart stop-production incinerator.

Owner:雷丰源

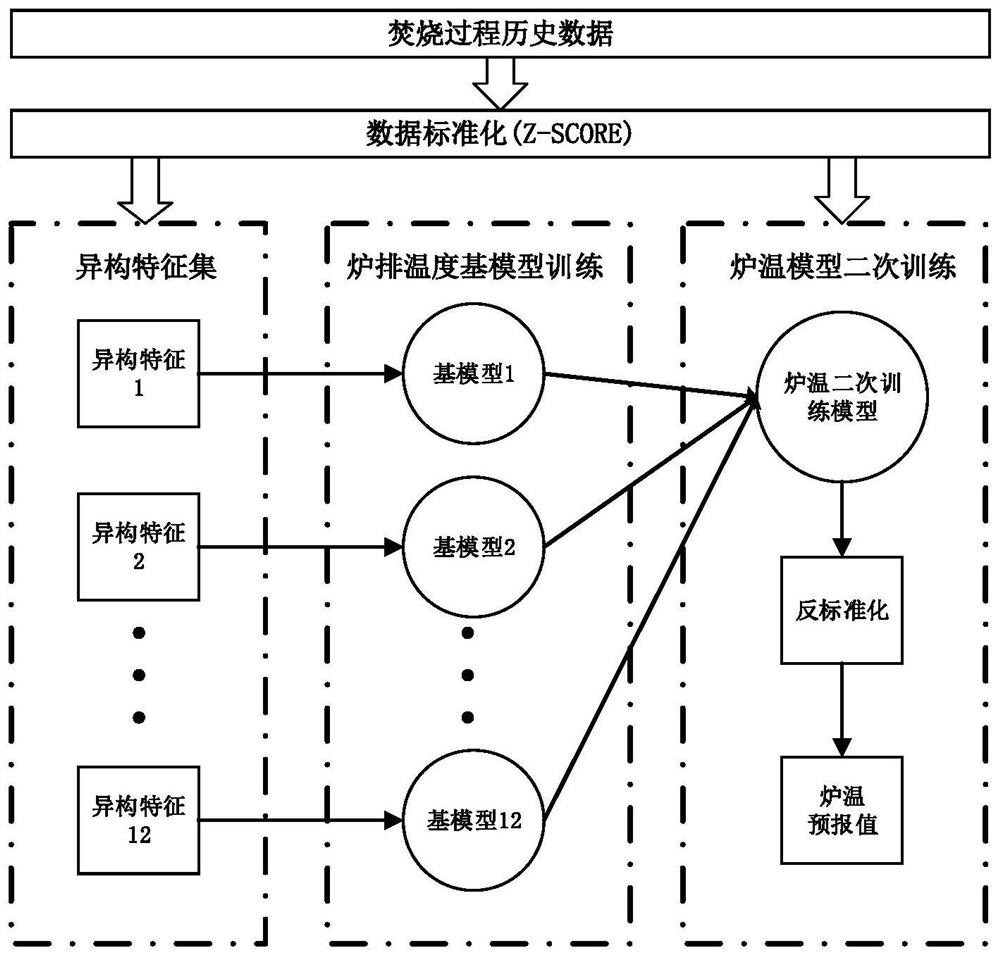

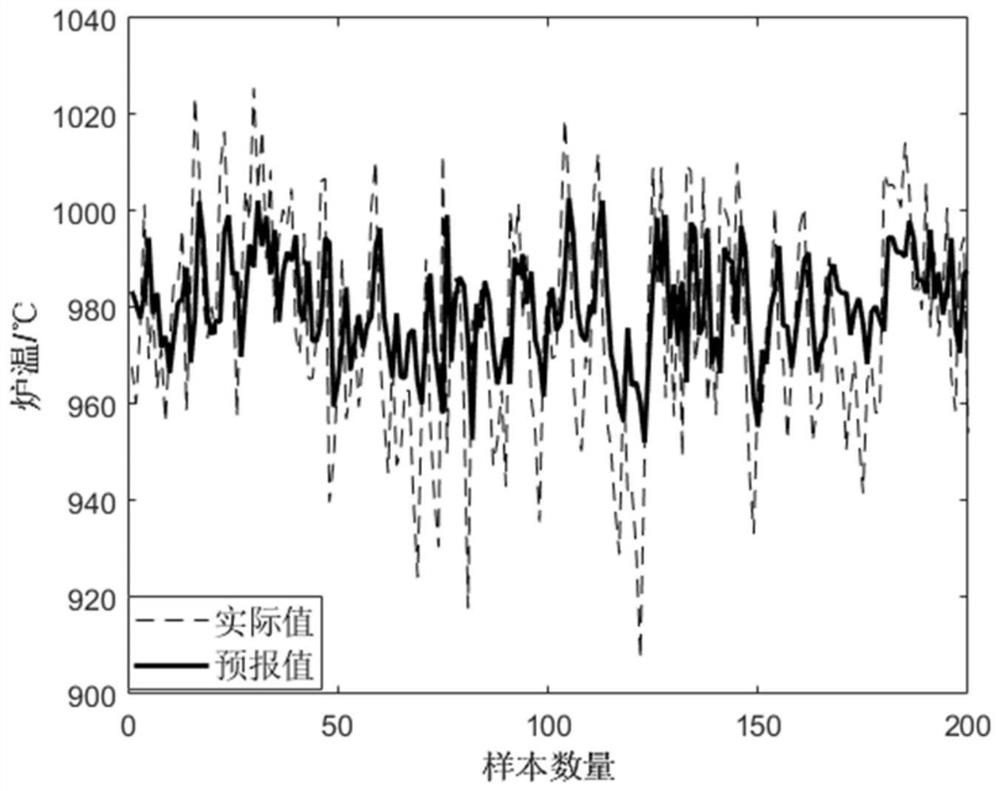

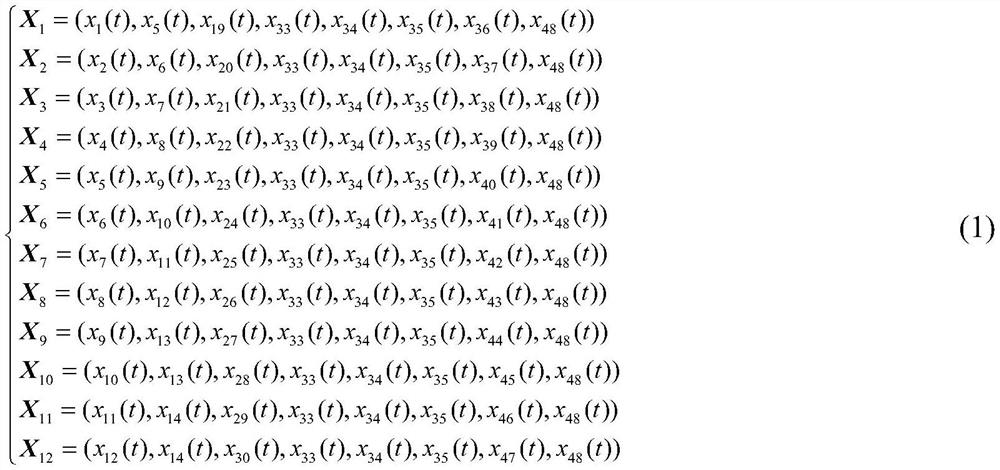

Municipal solid waste incinerator temperature forecasting method

PendingCN114297916AGuaranteed accuracyReduce complexityDesign optimisation/simulationNeural architecturesFurnace temperatureTemperature forecasting

A method for forecasting the temperature of a municipal solid waste incinerator relates to the technical field of key parameter forecasting in the municipal solid waste incineration process, and is used for forecasting the temperature of the garbage incinerator through input variables such as the speed of each section of fire grate, primary air flow, secondary air flow and fan pressure to guide field operators to timely and accurately judge the change trend of the furnace temperature. The method mainly comprises the following steps: (1) designing a heterogeneous feature set for establishing a furnace temperature forecasting model of the municipal solid waste incinerator; (2) data preprocessing; (3) dividing a training set of a fire grate temperature base model based on the heterogeneous feature set in the step (1); (4) determining a training set of a furnace temperature secondary learning model based on the step 1; (5) initializing parameters; (6) constructing a fire grate temperature base model and a furnace temperature secondary training model by adopting a regularization random configuration network algorithm; and (7) carrying out anti-standardization processing on the output of the furnace temperature secondary training model.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com