Preparation method of city refuse incineration furnace granular fuel

A technology of municipal waste and granular fuel, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of poor exhaust emission quality, increased slag discharge, and large difference in ignition point, so as to improve exhaust emission quality and improve operation stability The effect of improving performance and heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

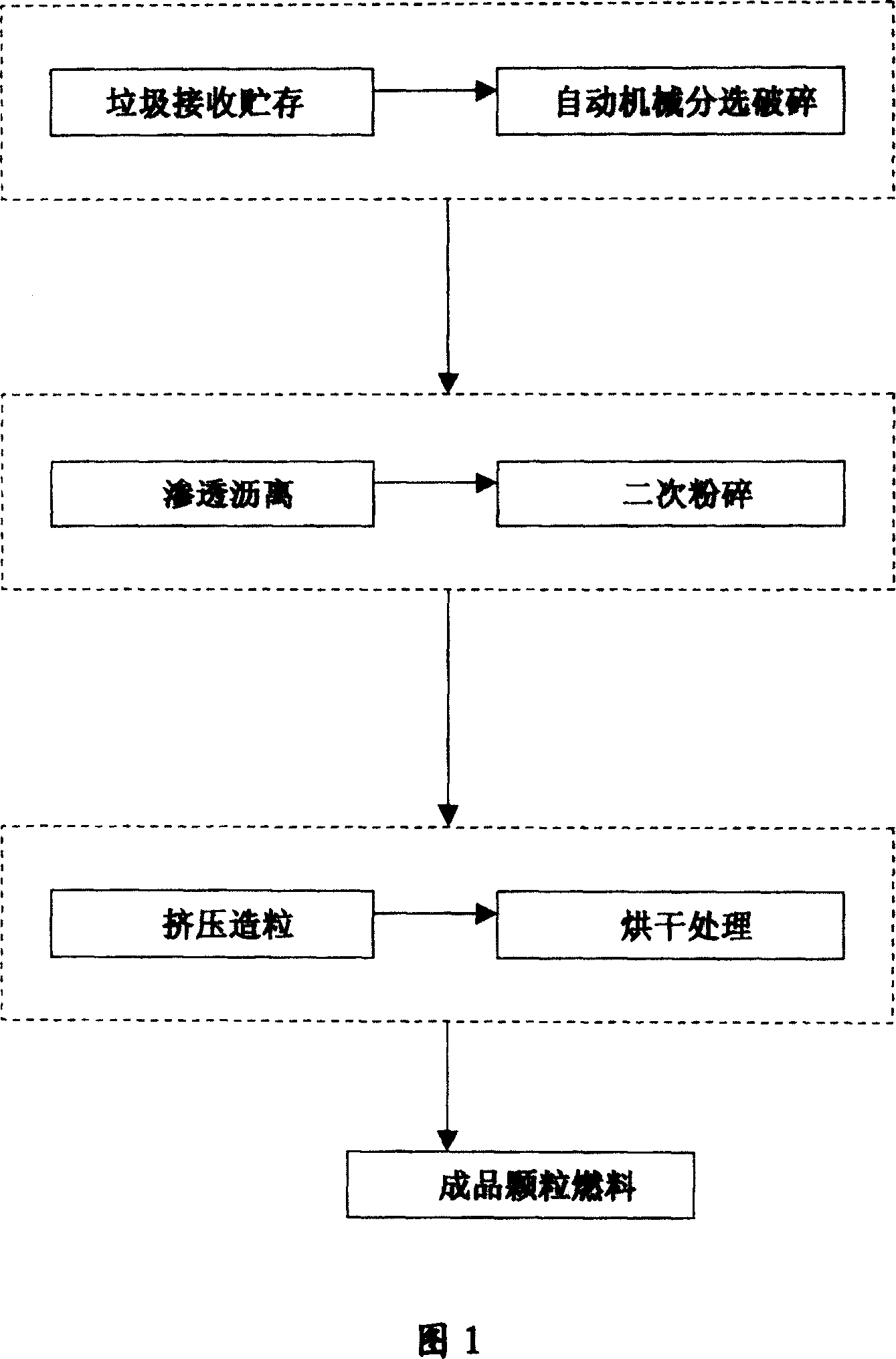

[0040] A method for preparing granular fuel for municipal refuse incinerators is characterized in that it comprises the following steps:

[0041] (1) Sorting and crushing: Sorting urban garbage, removing hard substances such as glass, pebbles, metals, bones, etc., sorting out combustible garbage, and then crushing these combustible garbage into garbage blocks with a particle size of ≤100mm, And at the same time ensure that the bag breaking rate of combustible garbage is ≥95%;

[0042] (2) Evaporation by draining: the above-mentioned rubbish blocks are mixed and drained in a leaching bin with an oxygenation pressure of 2900Pa, and the moisture in the rubbish blocks is evaporated until the water content of the rubbish blocks is ≤40%;

[0043] (3) Secondary crushing: carry out secondary crushing on the garbage blocks with a water content of ≤40% to form garbage blocks with a particle size of ≤50mm;

[0044] (4) Granulation: add calcium oxide of 3% of the weight of the waste bloc...

Embodiment 2

[0047] A method for preparing granular fuel for municipal refuse incinerators is characterized in that it comprises the following steps:

[0048] (1) Sorting and crushing: Sorting urban garbage, removing hard substances such as glass, pebbles, metals, bones, etc., sorting out combustible garbage, and then crushing these combustible garbage into garbage blocks with a particle size of ≤100mm, And at the same time ensure that the bag breaking rate of combustible garbage is ≥95%;

[0049] (2) Evaporation by draining: mixing and draining the above-mentioned rubbish blocks in a leaching chamber with an oxygenation pressure of 3300Pa, evaporating the moisture in the rubbish blocks until the water content of the rubbish blocks is ≤40%;

[0050] (3) Secondary crushing: carry out secondary crushing on the garbage blocks with a water content of ≤40% to form garbage blocks with a particle size of ≤50mm;

[0051] (4) Granulation: Add calcium carbonate with 8% of the weight of the garbage ...

Embodiment 3

[0054] A method for preparing granular fuel for municipal refuse incinerators is characterized in that it comprises the following steps:

[0055] (1) Sorting and crushing: Sorting urban garbage, removing hard substances such as glass, pebbles, metals, bones, etc., sorting out combustible garbage, and then crushing these combustible garbage into garbage blocks with a particle size of ≤100mm, And at the same time ensure that the bag breaking rate of combustible garbage is ≥95%;

[0056] (2) Evaporation by draining: mixing and draining the above-mentioned rubbish blocks in a leaching chamber with an oxygenation pressure of 3300Pa, evaporating the moisture in the rubbish blocks until the water content of the rubbish blocks is ≤40%;

[0057] (3) Secondary crushing: carry out secondary crushing on the garbage blocks with a water content of ≤40% to form garbage blocks with a particle size of ≤50mm;

[0058] (4) Granulation: Add slaked lime of 5% of the weight of the waste block to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com