Composite household garbage incinerator bottom slag coal ash for concrete

A technology of domestic waste incineration and bottom slag, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of affecting the performance of concrete, difficult to ensure the quality of compounded concrete, and difficult to transport the slurry, etc. It can improve the microstructure and strengthen the interface transition zone, which is beneficial to environmental protection, energy saving and emission reduction, and improves the mechanical properties and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

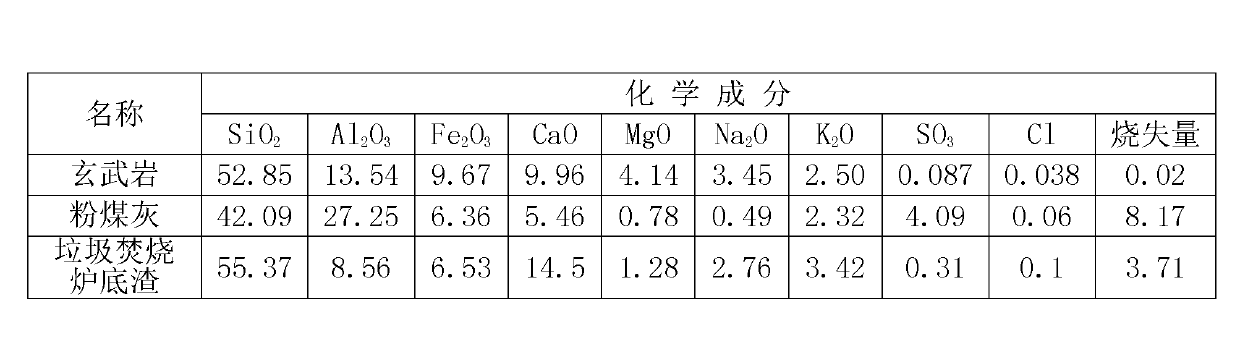

[0015] The chemical composition of basalt, wet-drained fly ash and bottom slag of domestic waste incineration is shown in Table 1:

[0016] Table 1 Chemical composition of various components

[0017]

[0018] Take 75 kg of basalt and break it into crushed stones below 60 mm, then add 18 kg of basalt crushed stones and 18 kg of wet-discharge fly ash with a moisture content of 21% into 5 kg of domestic waste incinerator bottom slag and 2 kg of composite active activator in proportion, After mixing, it enters the ball mill system for grinding processing. The fineness of the milled powder is controlled at 45 micron square hole sieve and less than 15%. The storage and transportation of the milled powder should ensure that the moisture content of the milled powder is less than 0.5% to obtain composite fly ash for concrete.

Embodiment 2

[0020] The chemical composition of the basalt, the wet discharge fly ash, and the bottom slag of domestic waste incineration are the same as in Example 1.

[0021] Take 41 kg of basalt and crush it into gravel below 60 mm, then add 45 kg of domestic waste incinerator bottom slag and 4 kg of composite active activator in proportion to basalt gravel and 10 kg of wet-discharge fly ash with a moisture content of 23% After entering the ball mill system for grinding processing, the fineness of the milled powder is controlled at 45 micron square hole sieve and the sieve is less than 15%. The storage and transportation of the mill powder should ensure that the moisture content of the mill powder is less than 0.5%, so as to obtain the composite fly ash for concrete.

Embodiment 3

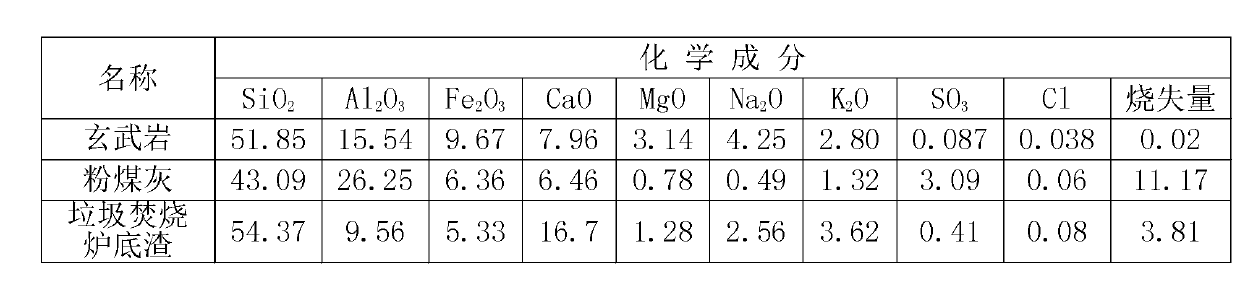

[0023] The chemical composition of basalt, wet discharge fly ash and domestic waste incinerator bottom slag are shown in Table 2:

[0024] Table 2 Chemical composition of various components

[0025]

[0026] Take 10 kg of basalt and crush it into crushed stones below 60 mm, then put basalt crushed stones, 45 kg of wet-discharge fly ash with a moisture content of 21%, 39 kg of domestic waste incinerator bottom slag, and 6 kg of composite active activator into the ball mill respectively The system carries out the grinding process, and the fineness of the milled powder is controlled at a 45-micron square hole sieve of less than 15%. It is necessary to ensure that the moisture content of the milled powder is less than 0.5%, and then mix it in proportion to obtain composite fly ash for concrete.

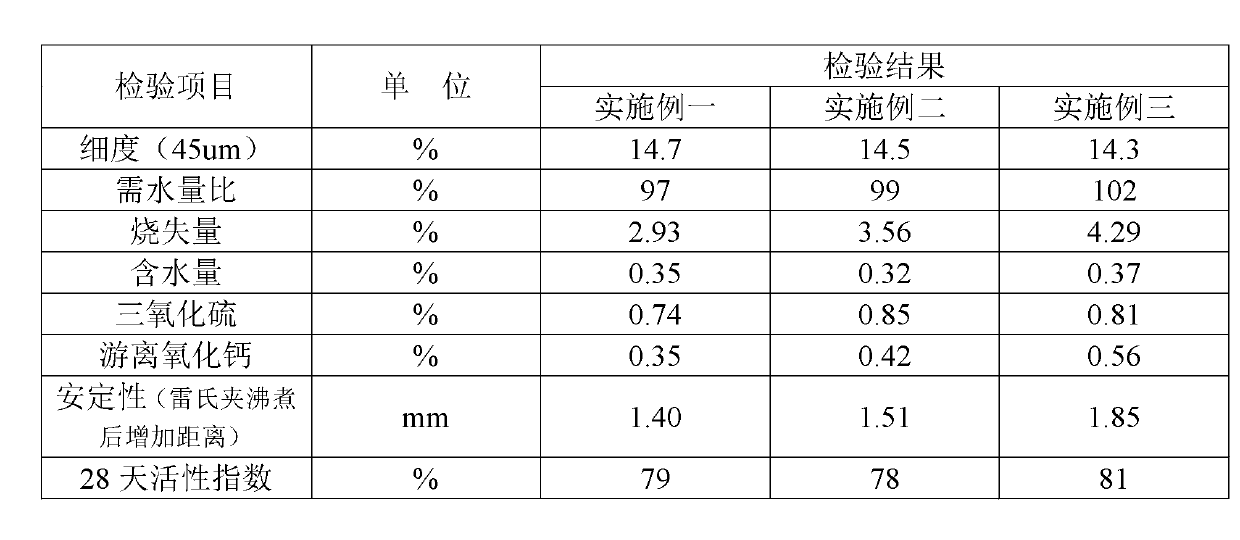

[0027] The composite fly ash obtained in Examples 1, 2, and 3 was taken respectively for testing, and its various performance indicators are shown in Table 3.

[0028] Table 3 Perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com