Fixing method of carbon dioxide in flue gas of municipal solid waste incinerator

A technology of domestic waste incineration and fixation method, which is applied in the field of fixing carbon dioxide in flue gas of domestic waste incineration plants, can solve the problems of strict flue gas temperature requirements, small treatment scale, slow absorption rate, etc., so as to avoid scaling problems and cost. low, demand-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

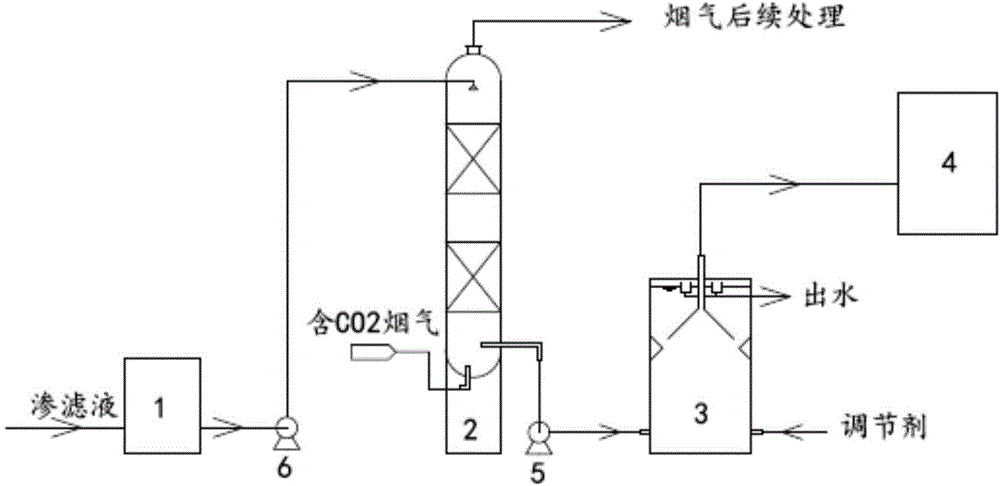

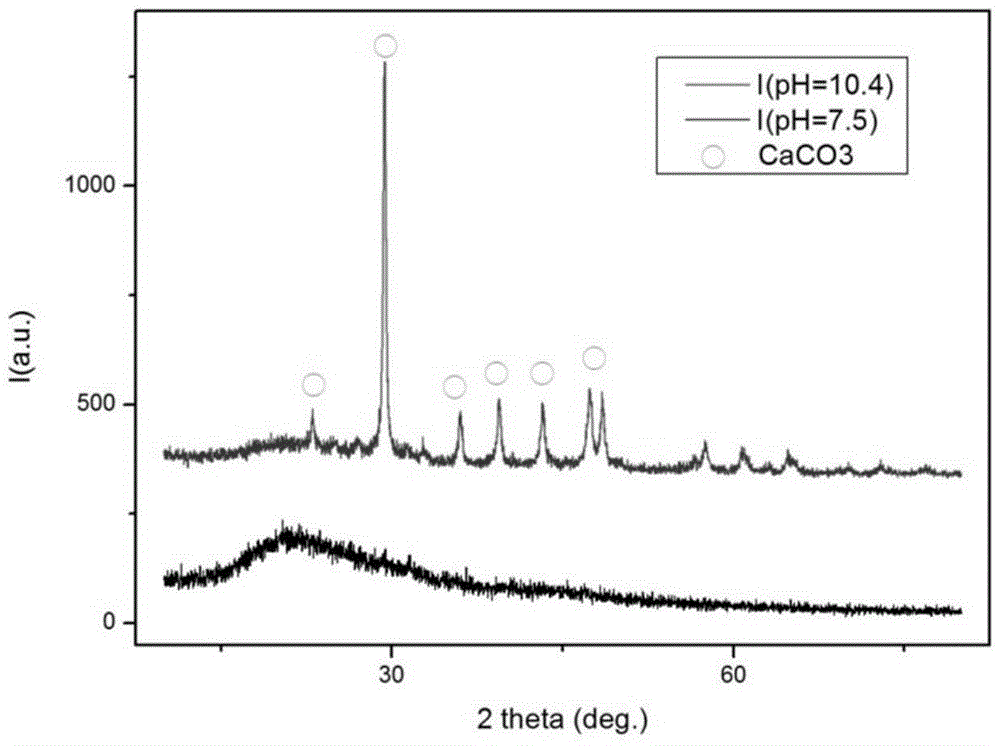

[0045] With pure CO 2 As a simulated gas, continuously inject such as 147mL / min figure 1 The absorption device, the incineration plant leachate comes from the landfill leachate stock solution of Jiangqiao Waste Incineration Plant as an absorbent, and its Ca 2+ The content is 3492mg / L, Mg 2+ The content is 897mg / L, the alkalinity is 14121mg / L, the pH is adjusted to 9.7 with sodium hydroxide and boric acid, the reaction temperature is 200°C, and the gas flow rate is at a gas-liquid ratio of 0.5m 3 / L; when the reaction is over, the content of Ca ions is 526mg / L, the pH of the leachate is 7.5, and the CO in the tail gas 2 Concentration 2 Separation, CaCO 3 get precipitated by figure 2 It can be seen that the precipitate contains a large amount of calcium carbonate and magnesium carbonate.

Embodiment 2

[0047] With 10.53% CO 2 As a simulated gas, continuously inject such as 152mL / min figure 1 The absorption device, the leachate comes from the leachate stock solution of the Shanghai Laogang Landfill as the absorbent, and its Ca 2+ The content is 2937mg / L, Mg 2+ The content is 682mg / L, the alkalinity is 18379mg / L, the pH is adjusted to 11 with sodium hydroxide and boric acid, the reaction temperature is 100°C, and the gas flow rate is at a gas-liquid ratio of 0.1m 3 / L, the running time is 9h; when the reaction ends, Ca 2+ The content is 451mg / L, the pH of the leachate is 7.0, and the CO in the tail gas 2 Concentration 2 Separation, CaCO 3 get precipitated by figure 2 It can be seen that the precipitate contains a large amount of calcium carbonate.

Embodiment 3

[0049] With 8% CO 2 As a simulated gas, continuously inject such as 152mL / min figure 1 The absorption device, the leachate of the incineration plant comes from the raw liquid of the landfill leachate of the Jiangqiao Waste Incineration Plant as an absorbent, and the Ca in the leachate 2+ The content is 3492mg / L, Mg 2+ The content is 897mg / L, the alkalinity is 14121mg / L, the pH is adjusted to 6.5 with sodium hydroxide and boric acid, the reaction temperature is 20°C, and the gas flow rate is at a gas-liquid ratio of 0.3m 3 / L; when the reaction is over, the Ca ion content in the leachate is 451mg / L, the pH of the leachate is 7.0, and the CO in the tail gas 2 Concentration 2 Separation, CaCO 3 get precipitated by figure 2 It can be seen that the precipitate contains a large amount of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com