Municipal solid waste incinerator temperature forecasting method

A municipal solid waste and incinerator technology, applied in the field of municipal solid waste incinerator furnace temperature prediction, can solve problems such as complex network structure and poor model generalization ability, reduce model complexity and computational complexity, and ensure generalization The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

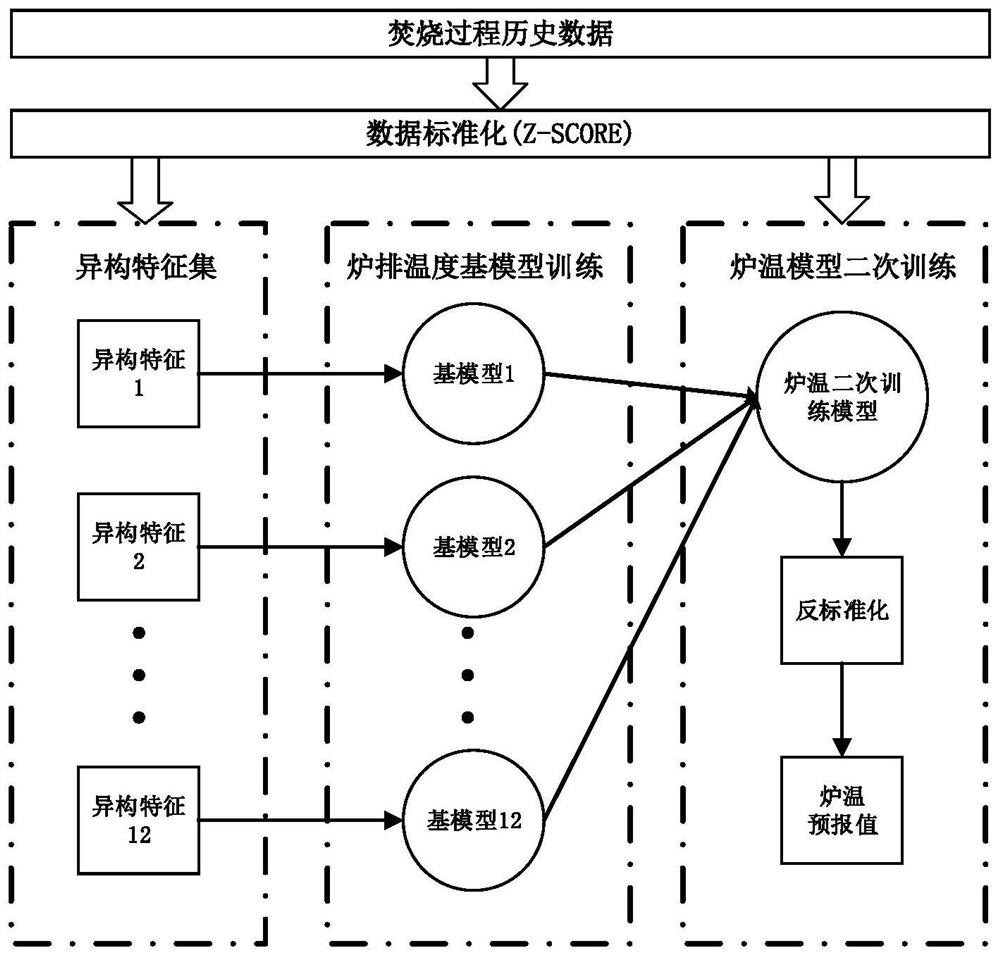

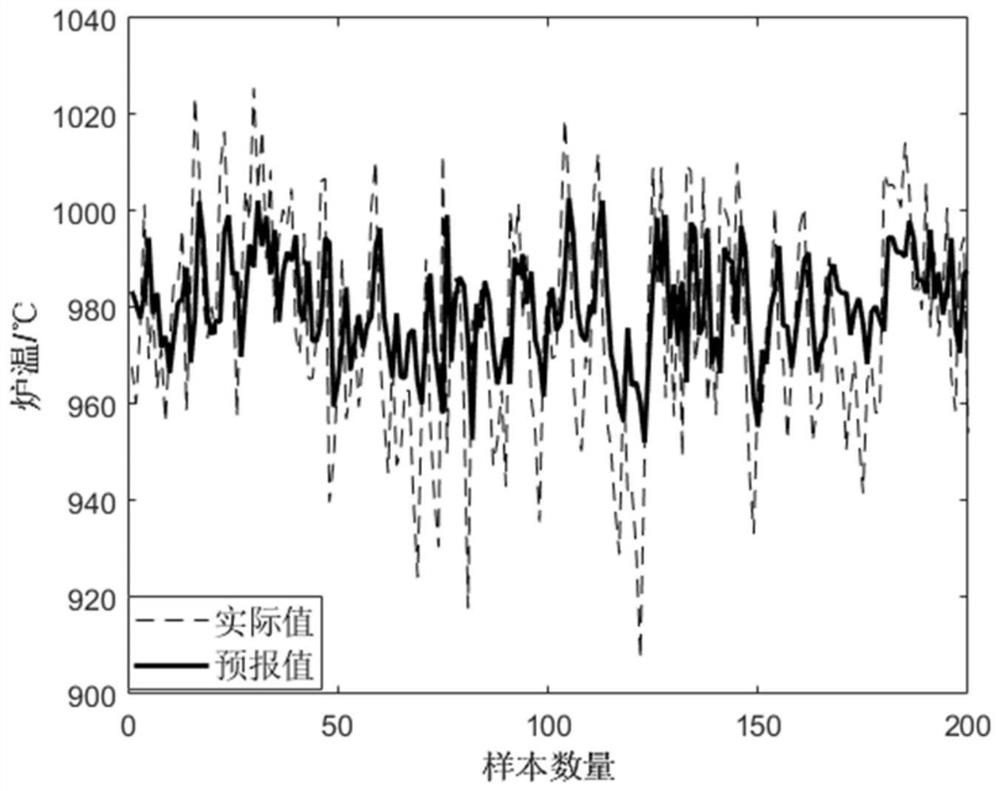

[0047] The sample data comes from 900 sets of data generated during the incineration process of a municipal solid waste incineration power plant, including 700 training samples and 200 test samples, with a sample time interval of 5 minutes. Combine below figure 1 The specific implementation manners of the present invention will be further described.

[0048] The method for predicting the furnace temperature of a municipal solid waste incinerator is characterized in that it comprises the following steps:

[0049] (1) A heterogeneous feature set designed to establish a temperature prediction model for municipal solid waste incinerators:

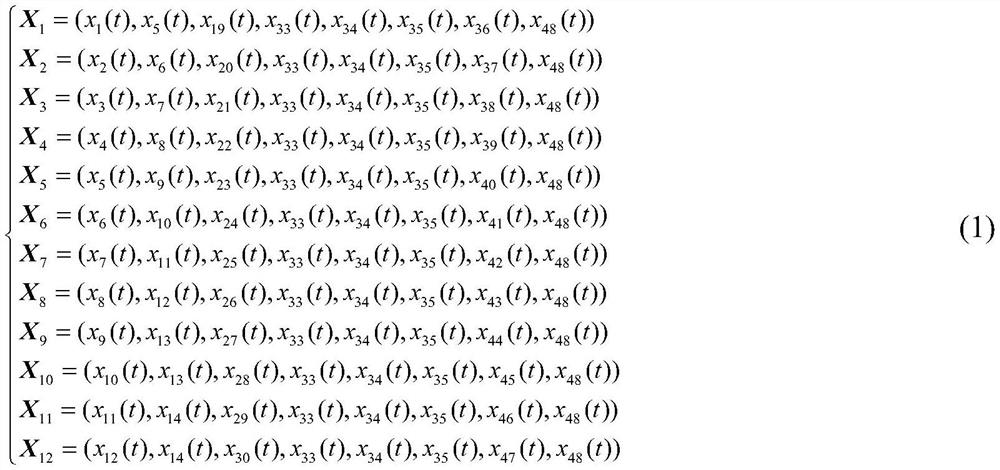

[0050] For the Tiankuma SN mechanical grate furnace, the input variables affecting the furnace temperature mainly include the following four types of input variables: grate speed x 1 -x 18 , primary air flow x 19 -x 32 , secondary air volume x 33 , fan pressure x 34 -x 35 , the details of the specific variables are shown in Table 1. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com