Method for producing alinite cement by utilizing municipal solid waste incinerator fly ash

A technology of waste incineration fly ash and alnit, applied in cement production, clinker production, etc., to achieve huge social benefits, reduce consumption, and reduce additional disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

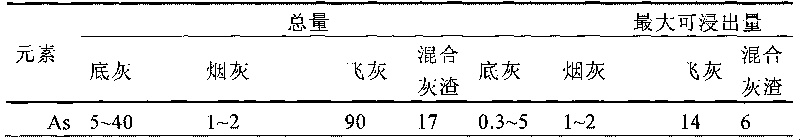

[0033] The main raw material waste incineration fly ash used in the test comes from Suzhou Waste Incineration Plant, with an average particle size of 11.25um and a moisture content of 1.5%. The main components of other raw materials such as fly ash and limestone are shown in Table 4. Grind the prepared raw meal to the same fineness as ordinary portland cement raw meal, then calcinate at 1200°C, heat it for 60 minutes, quench it and grind it until it passes through a 200-mesh sieve. The cement properties are shown in Table 5.

[0034] Table 4 main raw material chemical composition (wt.%)

[0035]

[0036]Choose three formulas (mass percentage) of burning Alinite cement clinker:

[0037] ① Waste incineration fly ash: 25%; fly ash: 6%; limestone: 60%; calcium chloride: 9%;

[0038] ②Waste incineration fly ash: 30%; fly ash: 10%; limestone: 55%; calcium chloride: 5%;

[0039] ③ Waste incineration fly ash: 40%; fly ash: 12%; limestone: 45%; calcium chloride: 3%.

[0040] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com