Method for preparing quick-hardened cement-based adhesive by utilizing refuse-incinerated fly ash

A waste incineration fly ash, cement-based technology, used in adhesives, cement production, inorganic adhesives and other directions, can solve problems such as easy accidents, tile falling off, unpredictable tile falling off, etc., to ensure product performance and good economy. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

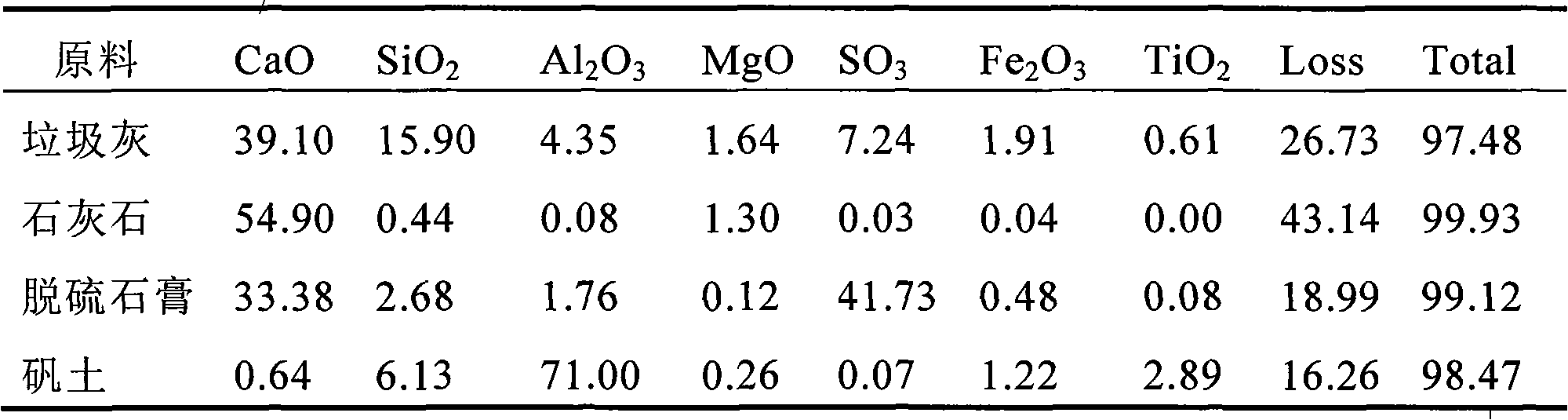

[0020] The main raw materials are desulfurization gypsum, waste incineration fly ash, limestone, bauxite. The main chemical components of the raw materials are shown in Table 1.

[0021] Table 1 Chemical Composition / wt% of Raw Materials

[0022]

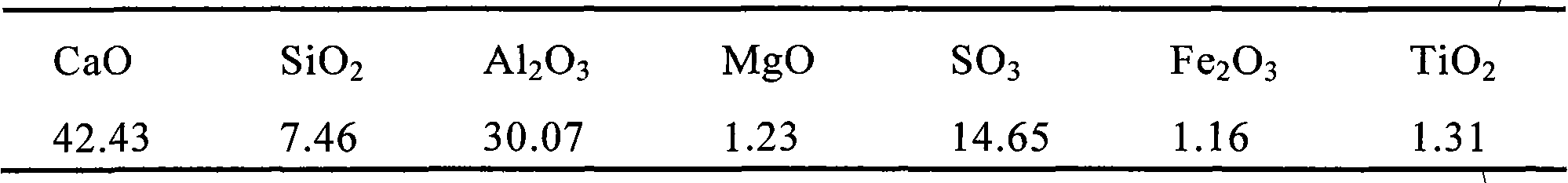

[0023] Calculated according to the designed mineral clinker composition: garbage ash: 15%; limestone: 36%; desulfurized gypsum: 19%; bauxite: 30%. The raw materials in the above ratio were calcined in an electric furnace at 1200° C. for 1 hour at a heating rate of 30° C. / min, and then taken out for rapid cooling. The chemical composition of the sulfoaluminate clinker is shown in Table 2.

[0024] Table 2 The main chemical components of sulphoaluminate clinker / %

[0025]

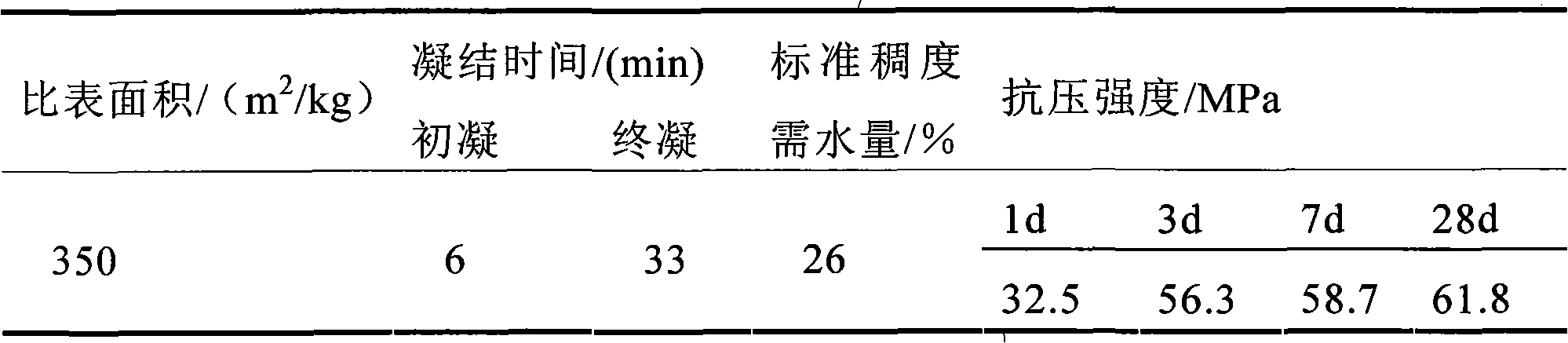

[0026] The above-mentioned calcined clinker was mixed with 5% anhydrite to make sulphoaluminate cement, and its physical properties are shown in Table 3.

[0027] Table 3 Main physical properties of sulphoaluminate cement

[0028]

[0029] Mix the abo...

Embodiment 4

[0037] A kind of method utilizing refuse incineration fly ash to prepare quick-hardening type cement-based adhesive, this method comprises the following steps:

[0038] (1) Calcination of sulphoaluminate cement

[0039] Sulphoaluminate raw meal: 18wt% of waste incineration fly ash, 15wt% of desulfurized gypsum, 35wt% of limestone, and 32wt% of bauxite were prepared in an electric furnace at a heating rate of 20°C / min to 1200°C, and then kept for 1 hour. Sulphoaluminate clinker is formed by mixing 90% of sulphoaluminate clinker with 10wt% of anhydrite to obtain sulphoaluminate cement;

[0040] The quality of sulphoaluminate clinker complies with the relevant regulations in "Sulphoaluminate Cement" (GB 20472-2006): that is, Al in clinker 2 o 3 ≥30.0%; SiO 2 ≤10.5%, the compressive strength of sulphoaluminate cement clinker 3d is ≥55MPa. The main mineral composition of sulphoaluminate clinker is as follows: 75wt%%;C 2 S15wt%; C 4 AF3wt%.

[0041] (2) Preparation of rapid...

Embodiment 5

[0044] A kind of method utilizing refuse incineration fly ash to prepare quick-hardening type cement-based adhesive, this method comprises the following steps:

[0045] (1) Calcination of sulphoaluminate cement

[0046] Sulphoaluminate raw meal: waste incineration fly ash 10wt%, desulfurization gypsum 25wt%, limestone 40wt%, bauxite 25wt%, in an electric furnace at a heating rate of 30°C / min to 1250°C, and then keep it warm for 2 hours Making sulphoaluminate clinker, mixing 95% of sulphoaluminate clinker with 5wt% of anhydrite to obtain sulphoaluminate cement;

[0047] The quality of sulphoaluminate clinker complies with the relevant regulations in "Sulphoaluminate Cement" (GB 20472-2006): that is, Al in clinker 2 o 3 ≥30.0%; SiO 2 ≤10.5%, the compressive strength of sulphoaluminate cement clinker 3d is ≥55MPa. The main mineral composition of sulphoaluminate clinker is as follows: 55wt%; C 2 S30wt%; C 4 AF6wt%.

[0048] (2) Preparation of rapid-hardening cement-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com