Method for preparing unburned slag wall bricks by utilizing household garbage burned slag

A technology for domestic waste incineration and wall bricks, which is applied in the field of high-efficiency resource utilization of domestic waste incineration slag to prepare slag-free wall bricks, which can solve problems such as the influence of clinker, and achieve easy operation control, strong technical flexibility, and reduced Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

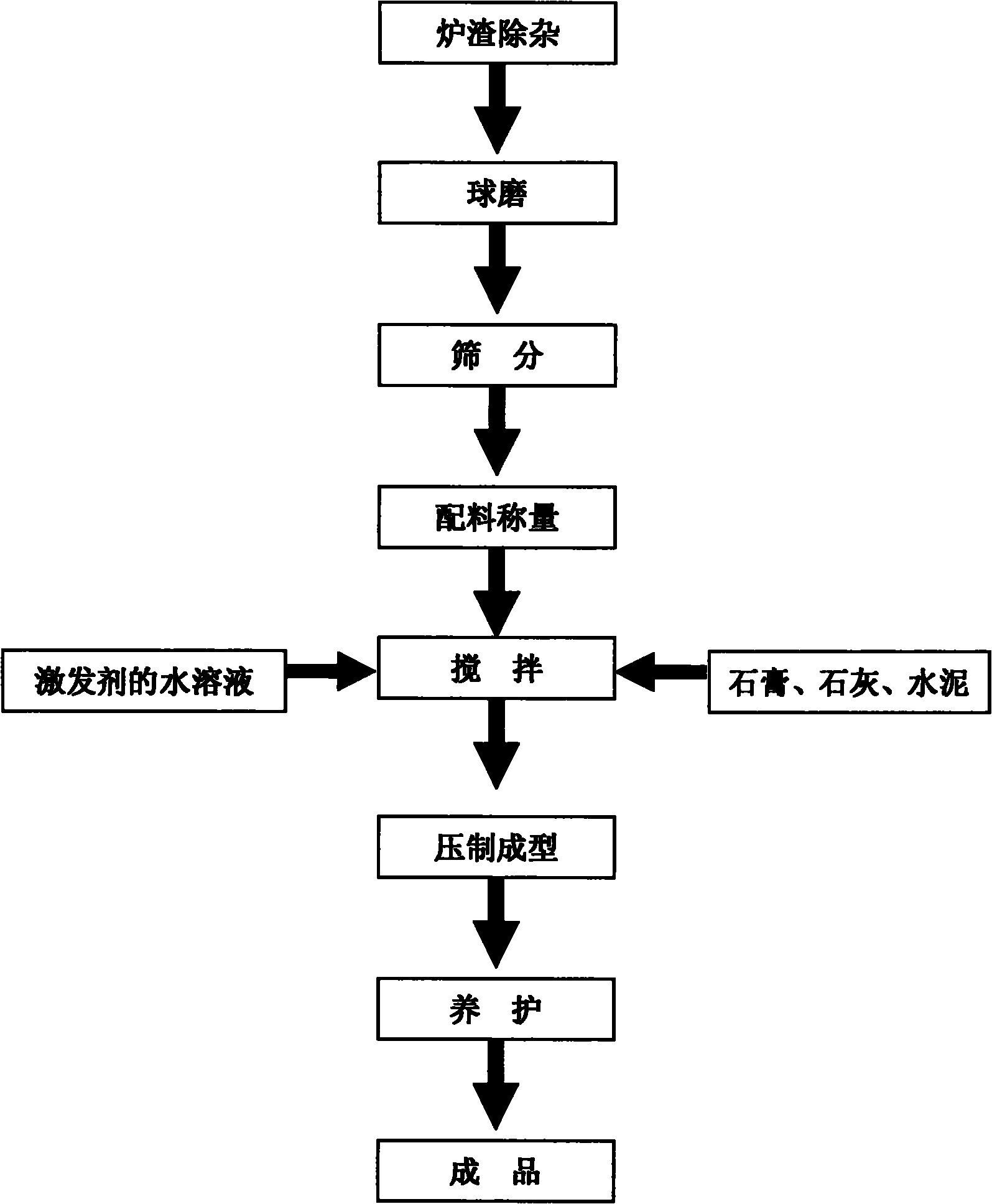

[0039] Embodiment 1 (process flow such as figure 1 shown)

[0040] (1) Raw material treatment: first, dry, deodorize, and pass through a 3cm sieve to remove impurities from the domestic waste incinerator slag of Guangzhou Likeng domestic waste incineration power plant, and then perform ball milling. Ball milling is dry ball milling, and the ball milling time is 2 to 5 minutes. After ball milling, the slag is sieved and passed through 0.15cm, 0.3cm, 0.6cm, and 1.18cm sieves respectively. According to the particle size of 0~0.15cm, it accounts for 40% (mass) , 0.15cm-0.3cm accounted for 30% (mass), 0.6-1.18cm accounted for 30% (mass), the slag was mixed.

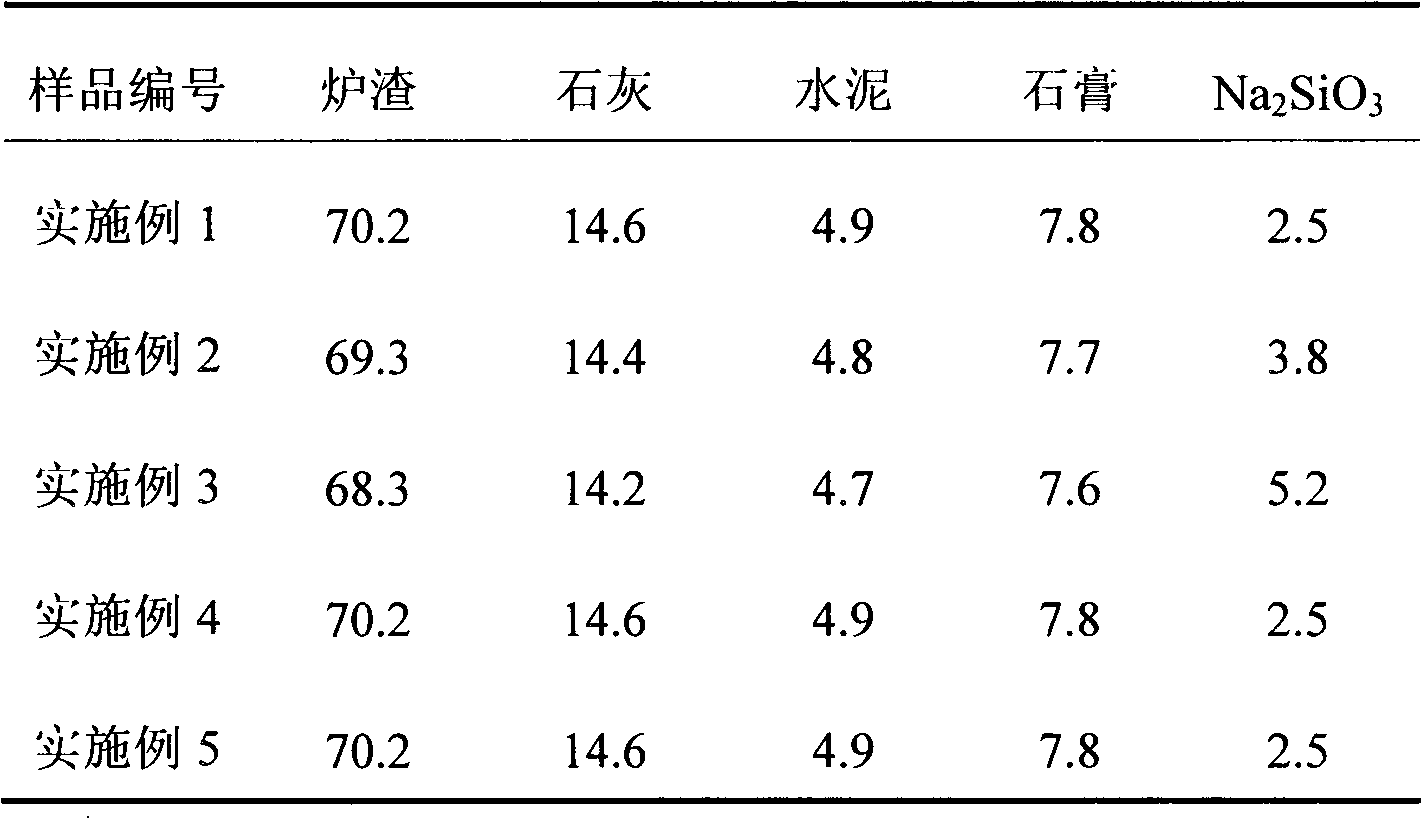

[0041] (2) Powder preparation: first add 70.2kg of slag, 14.6kg of lime, 7.8kg of gypsum and 4.9kg of cement into the mixing tank according to the formula in Table 1, and then add the activator Na 2 SiO 3 Mix 2.5kg with 10kg of water to make Na 2 SiO 3 Add the aqueous solution to the stirring tank and stir to make the mix...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] (2) Powder preparation: first add 69.3kg of slag, 14.4kg of lime, 7.7kg of gypsum and 4.8kg of cement into the mixing tank according to the formula in Table 1, and then add the activator Na 2 SiO 3 Mix 3.8kg with 9kg of water to make Na 2 SiO 3 Add the aqueous solution to the stirring tank and stir to make the mixture uniform and make the water content about 8.2% (by mass). Generally, it is better to hold it to form a ball, and to loosen it with a light touch.

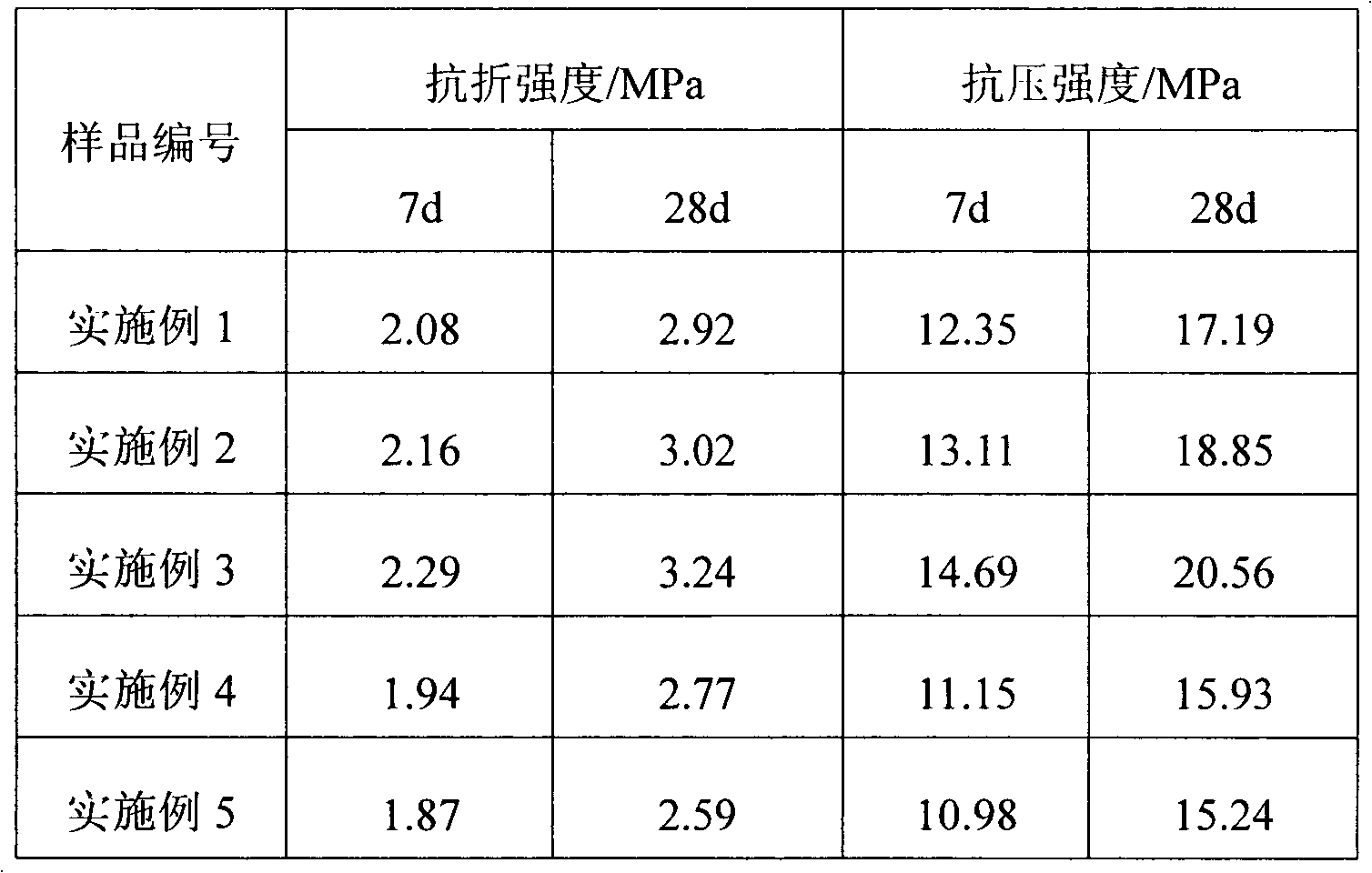

[0048] Raw material processing, compression molding, and natural curing are the same as in Example 1. The physical properties of the prepared slag-free wall bricks are shown in Table 2.

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is:

[0051] (2) Powder preparation: use a twin-shaft mixer to add 68.3kg of slag, 14.2kg of lime, 7.6kg of gypsum and 4.7kg of cement to the mixing tank according to the formula in Table 1, and then add the activator Na 2 SiO 3 Mix 5.2kg with 12kg of water to make Na 2 SiO 3 Add the aqueous solution to the stirring tank and stir to make the mixture uniform and make the water content about 11% (by mass). Generally, it is better to hold it into a ball and loosen it by light touch.

[0052] Raw material processing, compression molding, and natural curing are the same as in Example 1. The physical properties of the prepared slag-free wall bricks are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com