Municipal Solid Waste Incinerator

A technology for municipal solid waste and incineration devices, applied in the field of municipal solid waste incineration devices, can solve the problems that combustible gas and combustible dust particles cannot be recycled and reused, waste heat of smoke and dust cannot be recycled and utilized, and the cost of smoke and dust treatment is increased, so as to achieve favorable The effect of environmental protection, low production cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

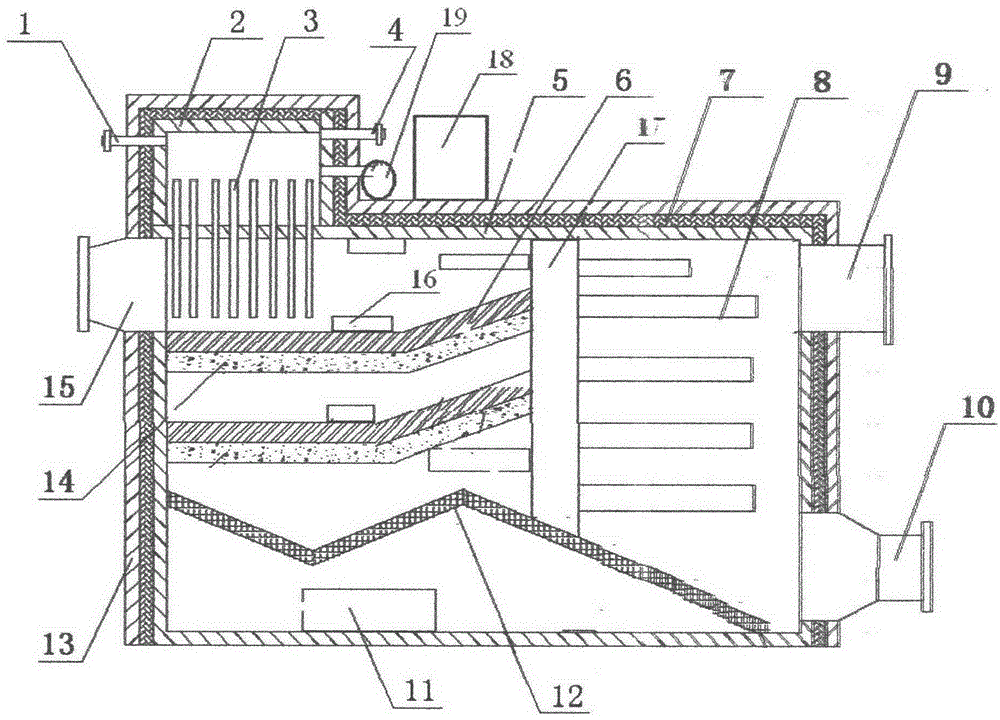

[0029] The present invention will be described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention.

[0031] Wherein, including box body 5, smoke and dust inlet pipe 9 and smoke and dust outlet pipe 15, the upper part of box body 5 is further provided with heat exchange box 2, and one end of heat exchange box 2 is provided with heat exchange medium input pipe 4, and the other end is provided with heat exchange medium. The exchange medium output pipe 1 and the box body 5 are further provided with a smoke return pipe 10 , and the heat exchange box 2 , the smoke return pipe 10 and the box body 5 are fastened and welded. The bottom of the heat exchange box 2 is provided with a smoke and dust outlet pipe 15, and the heat exchange box 2 is further provided with a plurality of superconducting conduits 3, and one end of the superconducting conduit 3 extends from the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com