Method of purifying urban household waste incinerator residues step by step

A technology for municipal solid waste and waste incineration slag, which is applied in the direction of combustion methods, chemical instruments and methods, incinerators, etc., can solve the problems of long time consumption, high energy consumption, and lack of comprehensive use, so as to reduce the content of free carbon , The steps are simple and easy, and the effect of improving the leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

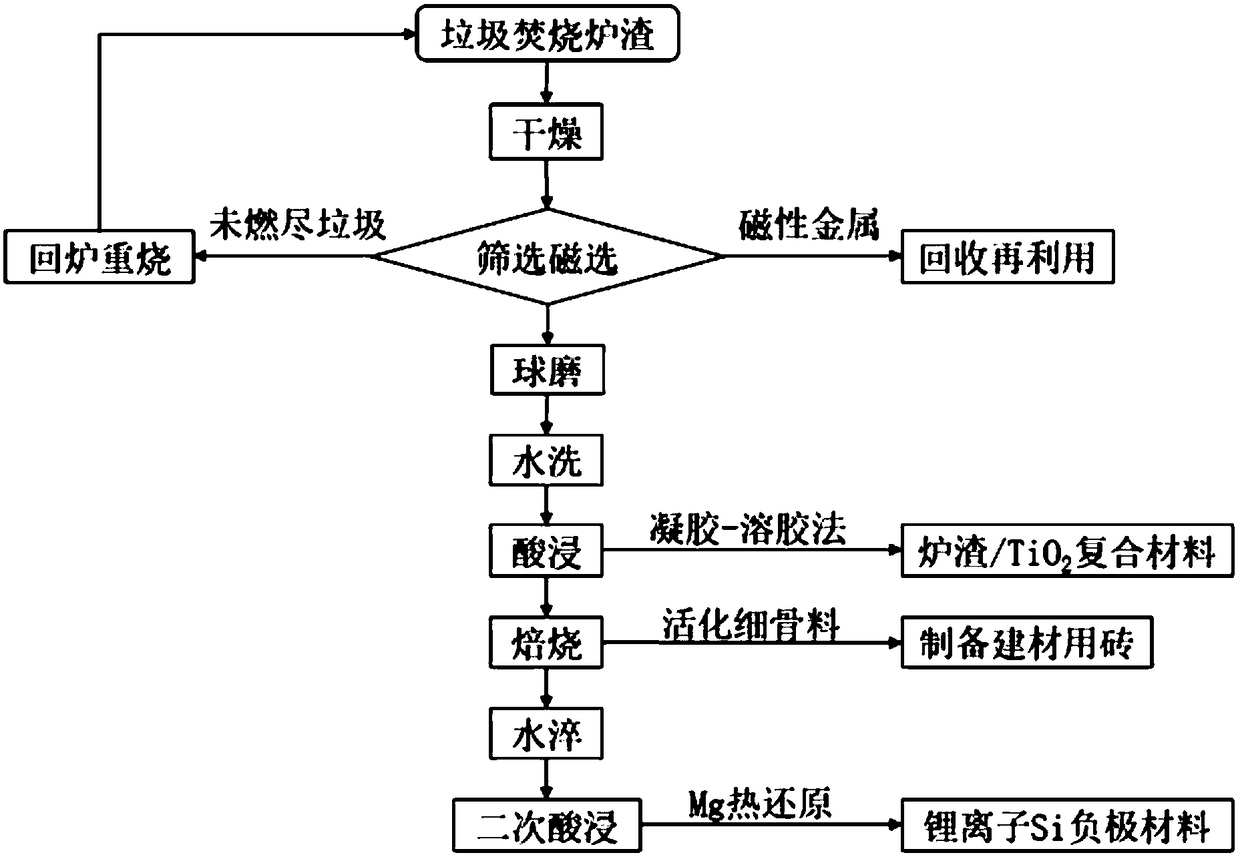

[0028] A method for step-by-step purification of municipal solid waste incinerator slag, such as figure 1 shown, including the following steps:

[0029] a. First, put an appropriate amount of waste incineration slag in an electric blast drying oven for 4 hours at 100°C.

[0030] b. Place the dried slag on a vibrating sieving machine for 10 minutes. The apertures of the sieve are 10, 20, 50, 100, and 200 mesh from top to bottom. burnt-out trash, and use magnets to circle each screen 3 times to recover magnetic metals.

[0031] c. Put the above-mentioned slag in a ball mill for 30 min to obtain a particle size below 200 mesh.

[0032] d. Mix the slag below 200 mesh in step c with distilled water (solid-to-liquid ratio: 1g: 8mL), stir at room temperature for 30 minutes, and stir at a speed of 800 r / min. After standing for clarification, pour it out and float on the water surface Impurities, and then suction filtration under reduced pressure.

[0033] e. Mix the washed slag wi...

Embodiment 2

[0038] A method for step-by-step purification of municipal solid waste incineration slag, comprising the following steps:

[0039] a. First, put an appropriate amount of waste incineration slag in an electric blast drying oven for 4 hours at 100°C.

[0040] b. Place the dried slag on a vibrating sieving machine for 10 minutes. The apertures of the sieve are 10, 20, 50, 100, and 200 mesh from top to bottom. burnt-out trash, and use magnets to circle each screen 3 times to recover magnetic metals.

[0041] c. Put the above-mentioned slag in a ball mill for 30 min to obtain a particle size below 200 mesh.

[0042] d. Mix the slag below 200 mesh in step c with distilled water (solid-to-liquid ratio: 1g: 8mL), stir at room temperature for 30 minutes, and stir at a speed of 800 r / min. After standing for clarification, pour it out and float on the water surface Impurities, and then suction filtration under reduced pressure.

[0043] e. Mix the washed slag with 25% sulfuric acid so...

Embodiment 3

[0047] A method for step-by-step purification of municipal solid waste incineration slag, comprising the following steps:

[0048] a. First, put an appropriate amount of waste incineration slag in an electric blast drying oven for 4 hours at 100°C.

[0049] b. Place the dried slag on a vibrating sieving machine for 10 minutes. The apertures of the sieve are 10, 20, 50, 100, and 200 mesh from top to bottom. burnt-out trash, and use magnets to circle each screen 3 times to recover magnetic metals.

[0050] c. Put the above-mentioned slag in a ball mill for 30 min to obtain a particle size below 200 mesh.

[0051] d. Mix the slag below 200 mesh in step c with distilled water (solid-to-liquid ratio: 1g: 8mL), stir at room temperature for 30 minutes, and stir at a speed of 800 r / min. After standing for clarification, pour it out and float on the water surface Impurities, and then suction filtration under reduced pressure.

[0052] e. Mix the washed slag with 20% nitric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com