Composite ground granulated blast furnace slag for concrete

A technology of blast furnace slag powder and granulated blast furnace slag, which is applied in the field of construction, can solve the problems of low early strength, difficulty, and poor grindability of fly ash, achieve good social and economic benefits, improve workability, and improve mechanical properties Effects on Performance and Durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

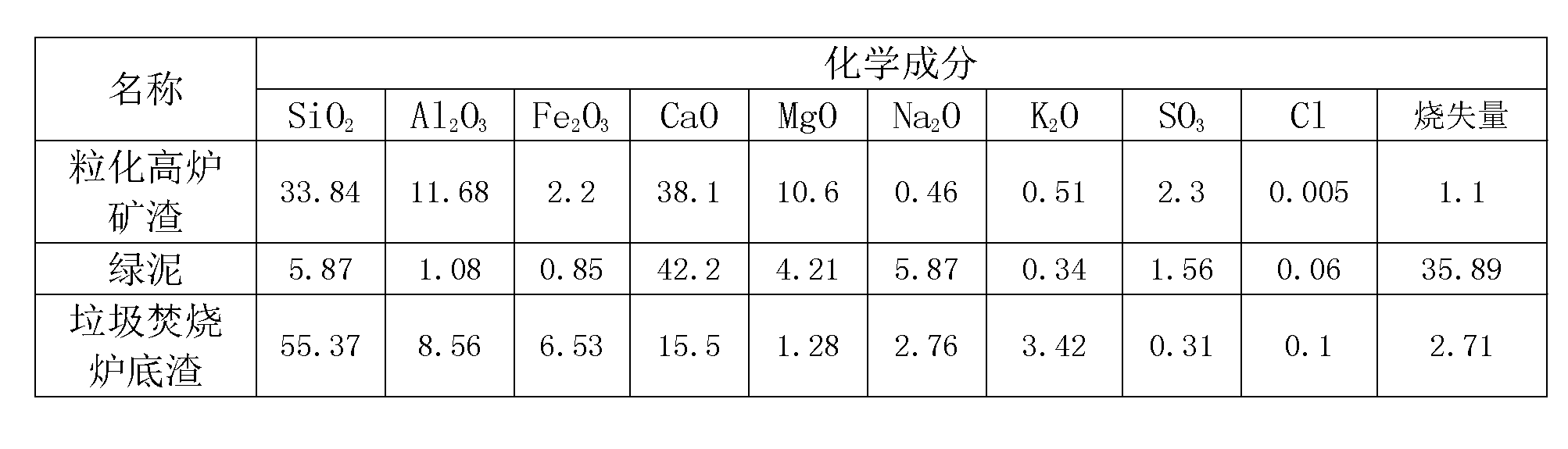

[0016] The chemical compositions of granulated blast furnace slag, domestic waste incineration bottom slag and green mud are shown in Table 1:

[0017] Table 1 Chemical composition of various components

[0018]

[0019] Weigh 85 kg of granulated blast furnace slag, 5 kg of domestic waste incinerator bottom slag, 5 kg of combined material and 5 kg of active activator according to the formula ratio and mix them into the ball mill system for grinding processing. The surface area of the milled powder is controlled at 450m 2 / kg~550m 2 / kg, during the grinding process, the fluidized furnace is used to convey hot air to dry the incoming grinding materials, and at the same time, in order to ensure the normal storage and transportation of the outgoing grinding materials, it is necessary to ensure that the moisture content of the outgoing grinding materials is less than 0.5%.

Embodiment 2

[0021] The chemical compositions of the granulated blast furnace slag, the domestic waste incineration bottom slag and the green mud are the same as in the first embodiment.

[0022] Weigh 68 kg of granulated blast furnace slag, 20 kg of domestic waste incinerator bottom slag, 10 kg of combined material and 2 kg of active activator according to the formula ratio and mix them into the ball mill system for grinding processing. The surface area of the milled powder is controlled at 450m 2 / kg~550m 2 / kg, during the grinding process, the fluidized furnace is used to convey hot air to dry the incoming grinding materials, and at the same time, in order to ensure the normal storage and transportation of the outgoing grinding materials, it is necessary to ensure that the moisture content of the outgoing grinding materials is less than 0.5%.

Embodiment 3

[0024] The chemical compositions of the granulated blast furnace slag, the domestic waste incineration bottom slag and the green mud are the same as in the first embodiment.

[0025] Weigh 50 kg of granulated blast furnace slag, 45 kg of domestic waste incinerator bottom slag, 3 kg of combined material and 2 kg of active activator according to the formula ratio and enter the ball milling system for grinding processing, and the surface area of the milled powder is controlled at 450m 2 / kg~550m 2 Between / kg, during the grinding process, the fluidized furnace is used to transport hot air to dry the incoming grinding materials. At the same time, in order to ensure the normal storage and transportation of the outgoing grinding materials, it is necessary to ensure that the moisture content of the outgoing grinding materials is less than 0.5%, and then mix them to obtain concrete. Composite blast furnace slag powder.

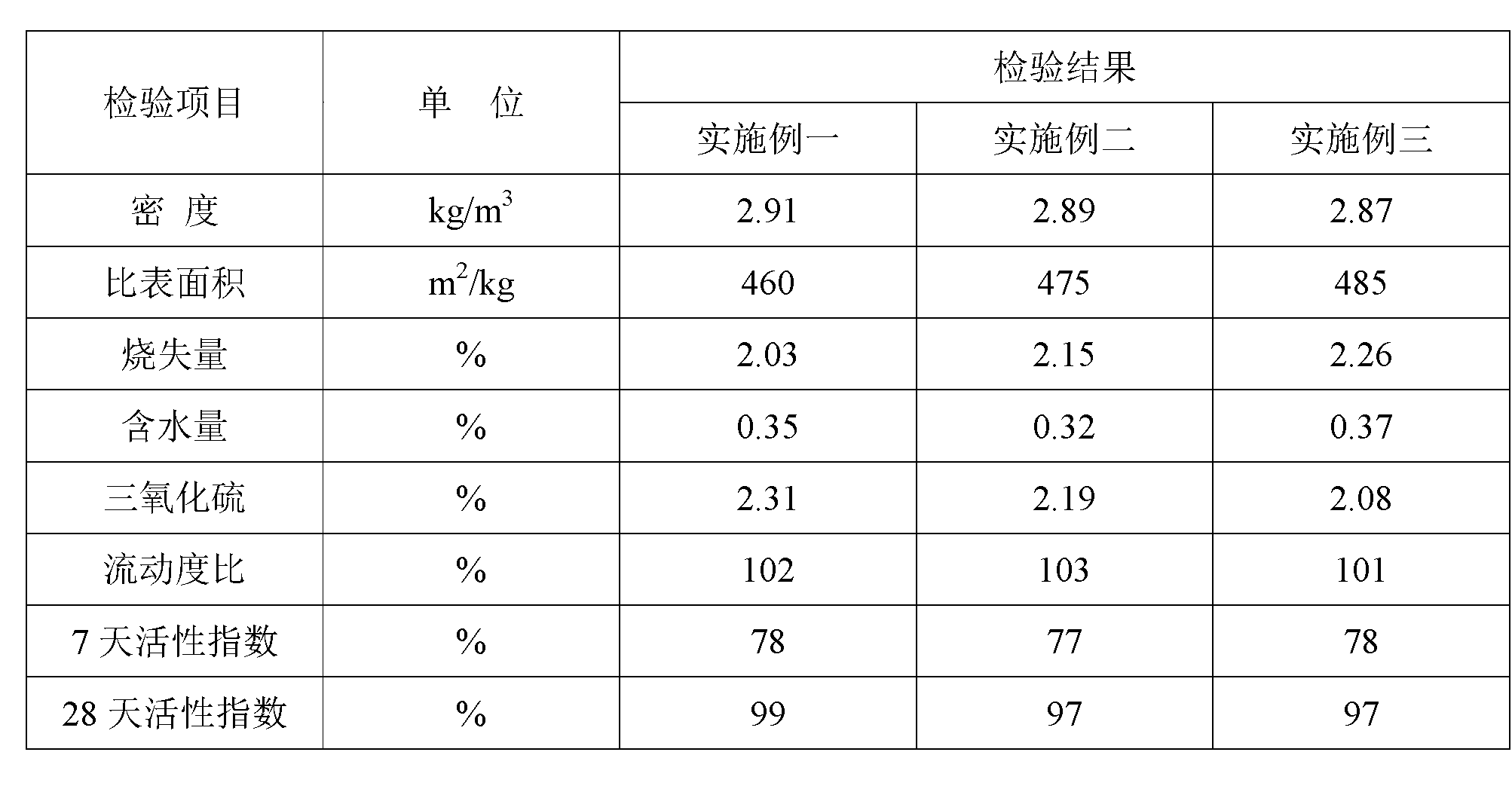

[0026] The composite micropowders obtained in Examples 1, 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com