Lightweight porous thermal insulation material and preparation method thereof

A thermal insulation and light-weight technology, which is applied in the production of ceramic materials, clay products, ceramic products, etc., can solve the problems of ineffective hazard reduction, threat to life safety, suffocating atmosphere, etc., and achieve obvious economic and environmental benefits , low thermal conductivity, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

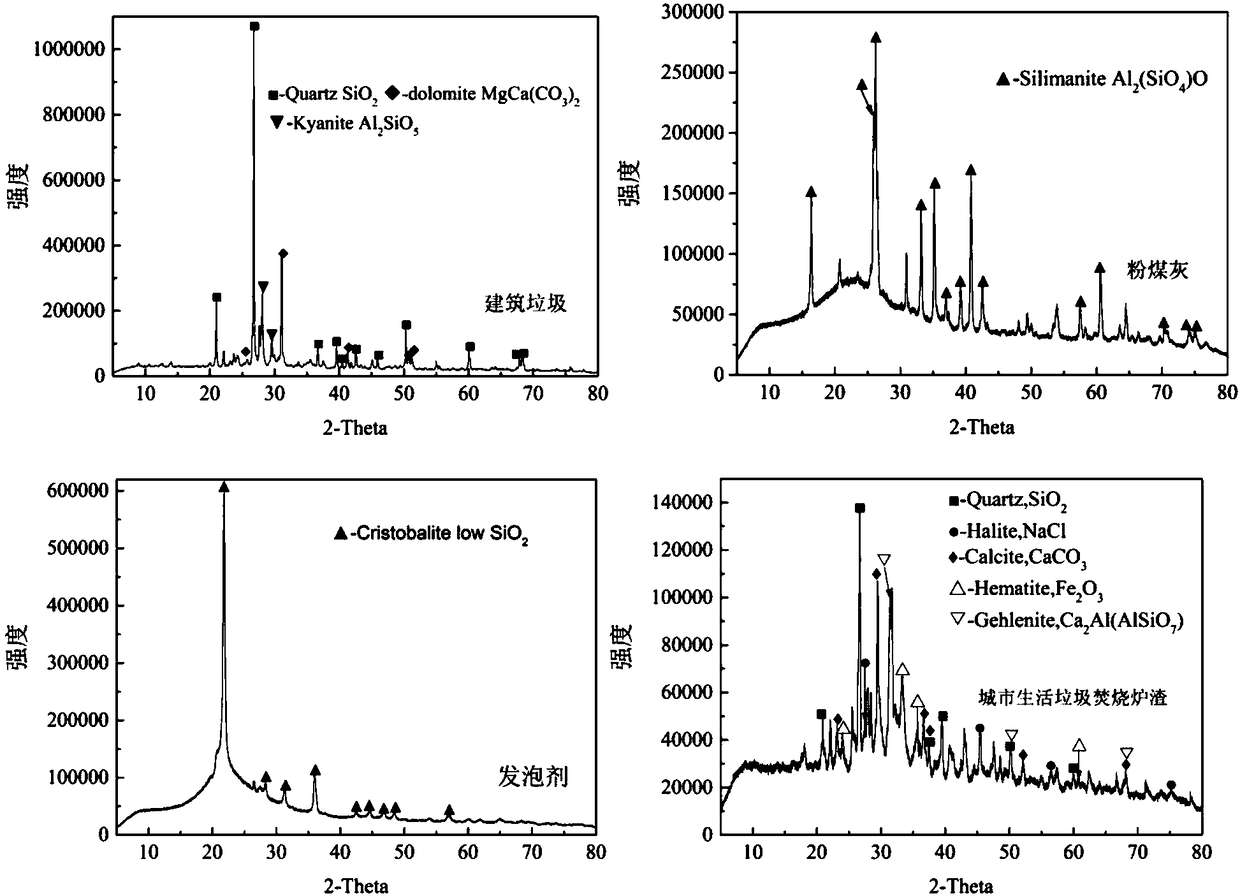

[0036] This embodiment provides a lightweight porous thermal insulation material, the components of which are calculated by weight percentage as follows:

[0037] Construction waste: 45% to 80%; the preferred range is 48 to 75%.

[0038] Municipal solid waste incineration slag; 5-40%; the preferred range is 8-35%.

[0039] Fly ash: 5-40%; the preferred range is 5-35%.

[0040] Foaming agent 5% to 25%; the preferred range is 6 to 18%.

[0041] And auxiliary material 0.5~2%, preferred range is 0.6~1.2%, auxiliary material comprises foam stabilizer, flux, foam stabilizer 0.2~1.5%, preferred range is 0.3~1.0%, flux 0.2~1.5%, preferably The range is 0.3 to 1.0%.

[0042] More preferably, the construction waste is construction waste with a particle size of 0-5mm after sieving; the municipal solid waste incineration slag has undergone quality-based multi-stage resource utilization and has poor utilization effects. Currently, it can only be used as a filling Buried components; the...

Embodiment 2

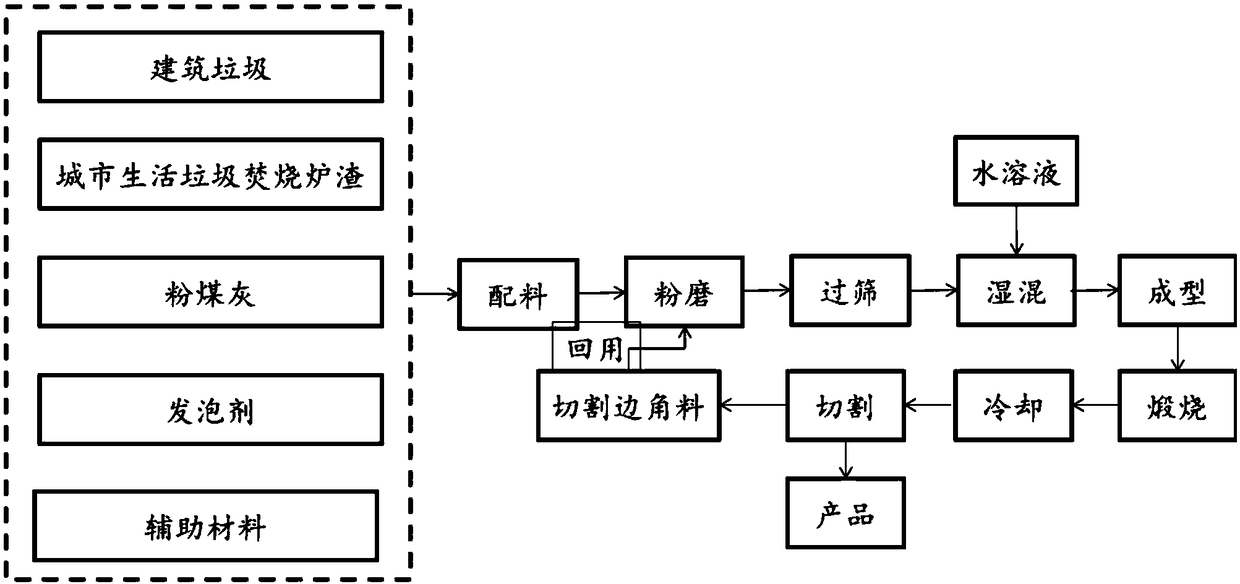

[0046] This example provides a preparation method of a lightweight porous thermal insulation material, especially the preparation of a lightweight porous thermal insulation material by using waste as a raw material through calcining synthesis, that is, the preparation of light porous thermal insulation material from all waste A thermal material method comprising the steps of:

[0047] Step S1, mixing materials: the pretreated construction waste, municipal solid waste incineration slag, fly ash, foaming agent, foam stabilizer, and fluxing agent are combined according to a certain ratio and then transferred to a ball mill for material grinding.

[0048]Step S2, forming a billet: add the material that has been ground and passed through an 80-mesh sieve into a mixer, and the wet-mixed material after adding an appropriate amount of aqueous solution is pressed into a billet under a pressure of 10MPa-50MPa to obtain a billet.

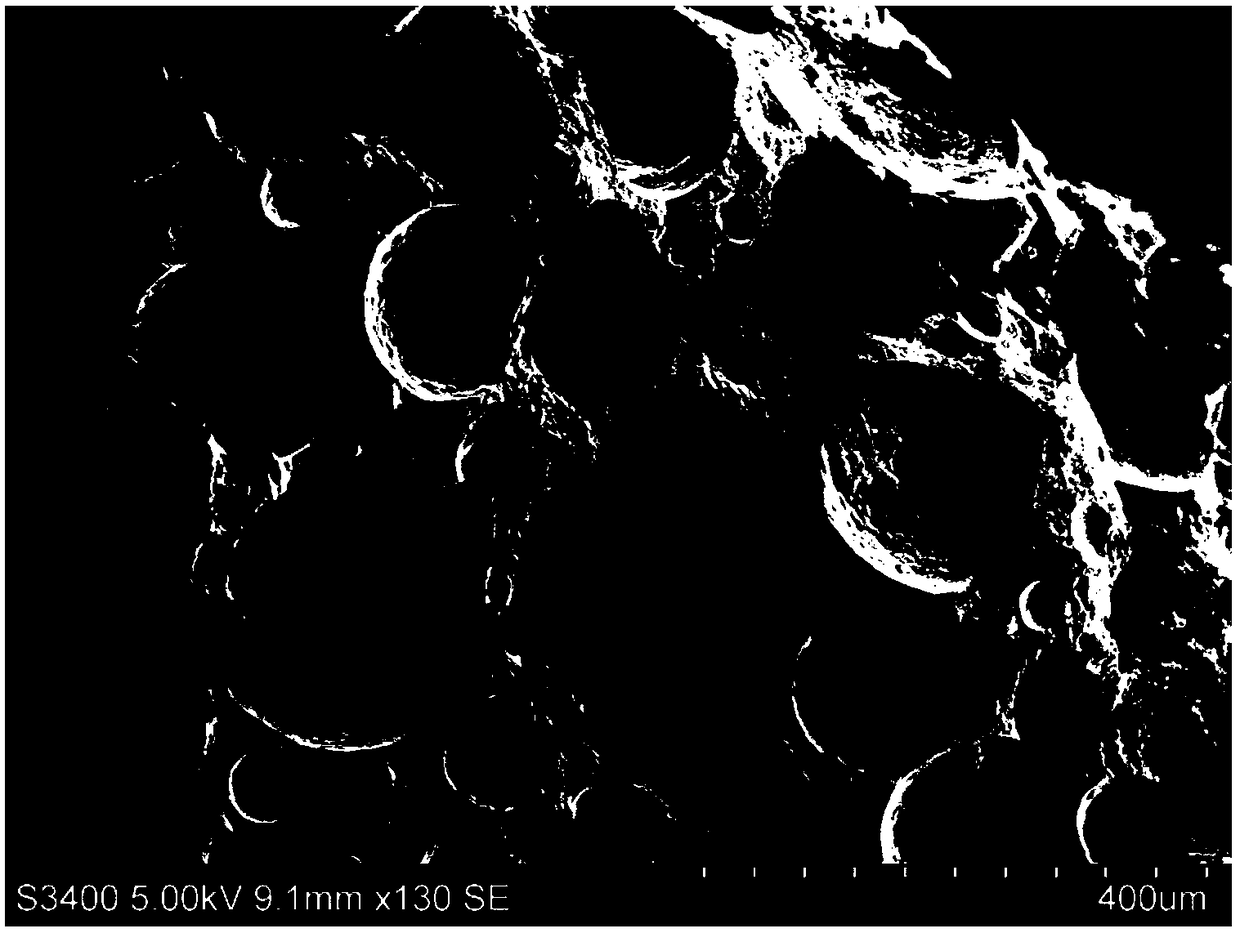

[0049] Step S3, calcination: put the body obtained in st...

Embodiment 3

[0072] This embodiment provides a method for preparing a lightweight porous thermal insulation material, comprising the following steps:

[0073] Step S1, mixing materials: pretreated construction waste, municipal solid waste incineration slag, fly ash, foaming agent, foam stabilizer, and fluxing agent according to the ratio of 65%, 20%, 5%, 9%, and 0.6% respectively %, 0.4% of the proportion of compatibility, together with the insulation material cutting scrap into the ball mill for material grinding.

[0074] Step S2, forming a billet: put the material that has been ground and passed through an 80-mesh sieve into a blender, and add an appropriate amount of tap water to the wet-mixed material to press it into a billet under a pressure of 20 MPa to obtain a billet.

[0075] Step S3, calcination: put the green body obtained in step S2 into a kiln for calcination, after calcination, the product is naturally cooled, and the calcination is as follows: from room temperature to 500°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com