Alloy material for incinerator fire grate and preparation method of alloy material

An alloy material and incinerator technology, which is applied in the field of special alloy material manufacturing and processing, achieves the effects of easy parameter control, easy control and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

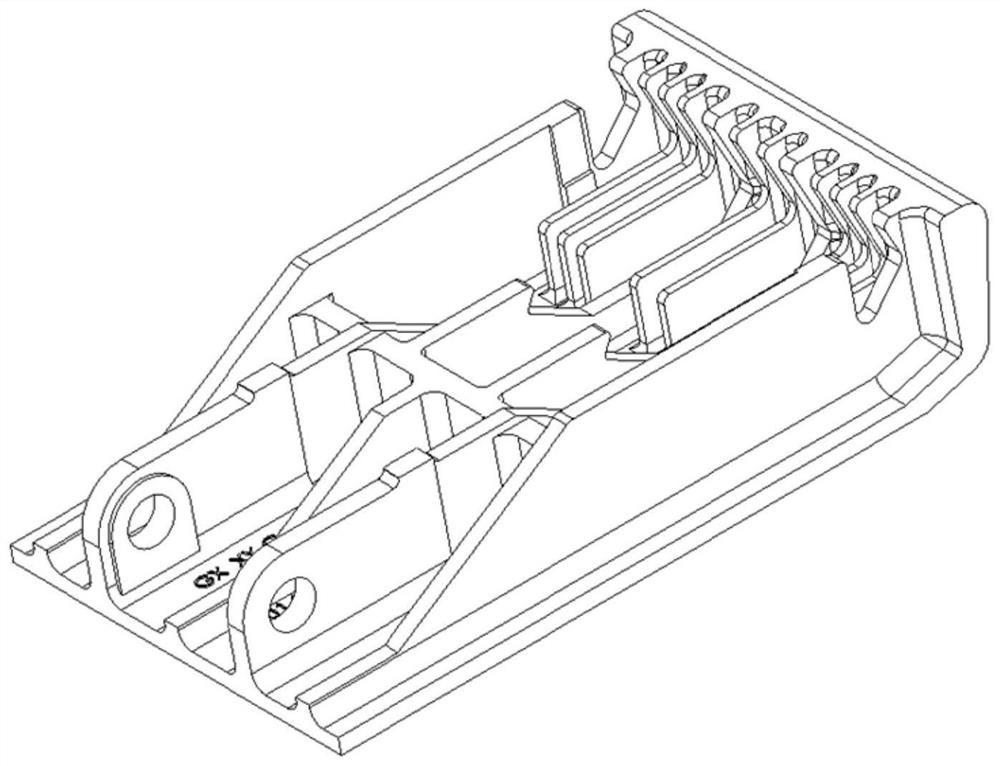

Image

Examples

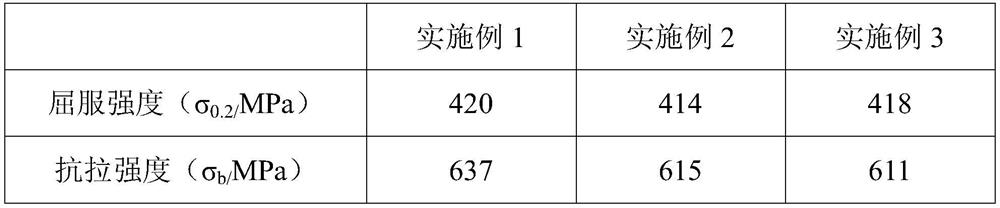

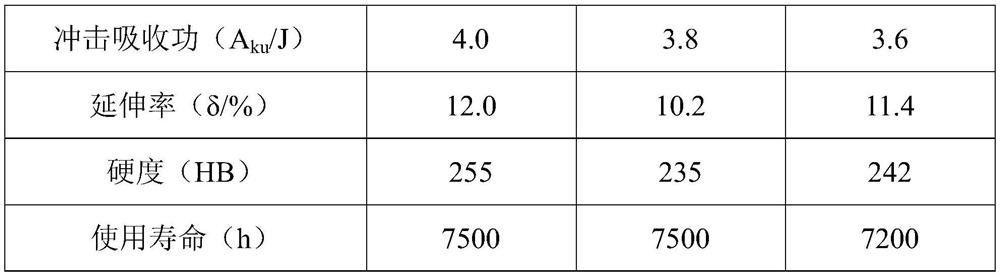

Embodiment 1

[0041] An alloy material for an incinerator grate, the composition alloy elements include:

[0042] Carbon C 0.8%, Silicon Si 2.5%, Manganese Mn 0.9%, Chromium Cr 22%, Nickel Ni 3.5%, Molybdenum Mo 0.35%, Copper Cu 0.5%, Rare Earth Element RE 0.12%, Sulfur S 0.01%, Phosphorus P 0.02 %, nitrogen N 0.2%, strong carbide forming elements 0.25%, boron B 0.05%, aluminum Al 0.05%, the balance is iron Fe and other unavoidable impurities.

[0043] Low-carbon steel scrap, ferroalloy and pure nickel are sequentially added to an intermediate frequency induction furnace for smelting by weight percentage, with a neutral lining, and the smelting temperature is 1650°C. Baking is carried out before the iron alloy is added to remove moisture, and the temperature is kept between 200-300°C. During the melting process, an appropriate amount of flux is added to form slag and cover the molten steel. After the charge is melted, samples are taken for full analysis, and the composition is adjusted acc...

Embodiment 2

[0046] An alloy material for an incinerator grate, the composition alloy elements include:

[0047] Carbon C 0.8%, Silicon Si 2.2%, Manganese Mn 0.9%, Chromium Cr 22%, Nickel Ni 3.5%, Molybdenum Mo 0.35%, Copper Cu 0.5%, Rare Earth Element RE 0.12%, Sulfur S 0.01%, Phosphorus P 0.03 %, nitrogen N 0.2%, strong carbide forming elements 0.20%, boron B 0.03%, aluminum Al 0.03%, the balance is iron Fe and other unavoidable impurities.

[0048] Low-carbon steel scrap, ferroalloy and pure nickel are sequentially added to an intermediate frequency induction furnace for smelting by weight percentage, with a neutral lining, and the smelting temperature is 1620°C. Baking is carried out before the iron alloy is added to remove moisture, and the temperature is kept between 200-300°C. During the melting process, an appropriate amount of flux is added to form slag and cover the molten steel. After the charge is melted, samples are taken for full analysis, and the composition is adjusted acc...

Embodiment 3

[0050] An alloy material for an incinerator grate, the composition alloy elements include:

[0051] Carbon C 0.9%, Silicon Si 2.8%, Manganese Mn 0.9%, Chromium Cr 22%, Nickel Ni 3.5%, Molybdenum Mo 0.35%, Copper Cu 0.6%, Rare Earth Element RE 0.10%, Sulfur S 0.02%, Phosphorus P 0.02 %, nitrogen N 0.2%, strong carbide forming elements 0.15%, boron B 0.05%, aluminum Al 0.05%, the balance is iron Fe and other unavoidable impurities.

[0052] Low-carbon steel scrap, ferroalloy and pure nickel are sequentially added to an intermediate frequency induction furnace for smelting by weight percentage, with a neutral lining, and the smelting temperature is 1640°C. Baking is carried out before the iron alloy is added to remove moisture, and the temperature is kept between 200-300°C. During the melting process, an appropriate amount of flux is added to form slag and cover the molten steel. After the charge is melted, samples are taken for full analysis, and the composition is adjusted acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com