Comprehensive utilization process of municipal solid waste incineration slag

A technology for municipal solid waste and incineration slag, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as environment, soil pollution, and increased demand for landfill storage capacity, and achieve resource waste, process Reasonable and efficient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in conjunction with the following examples.

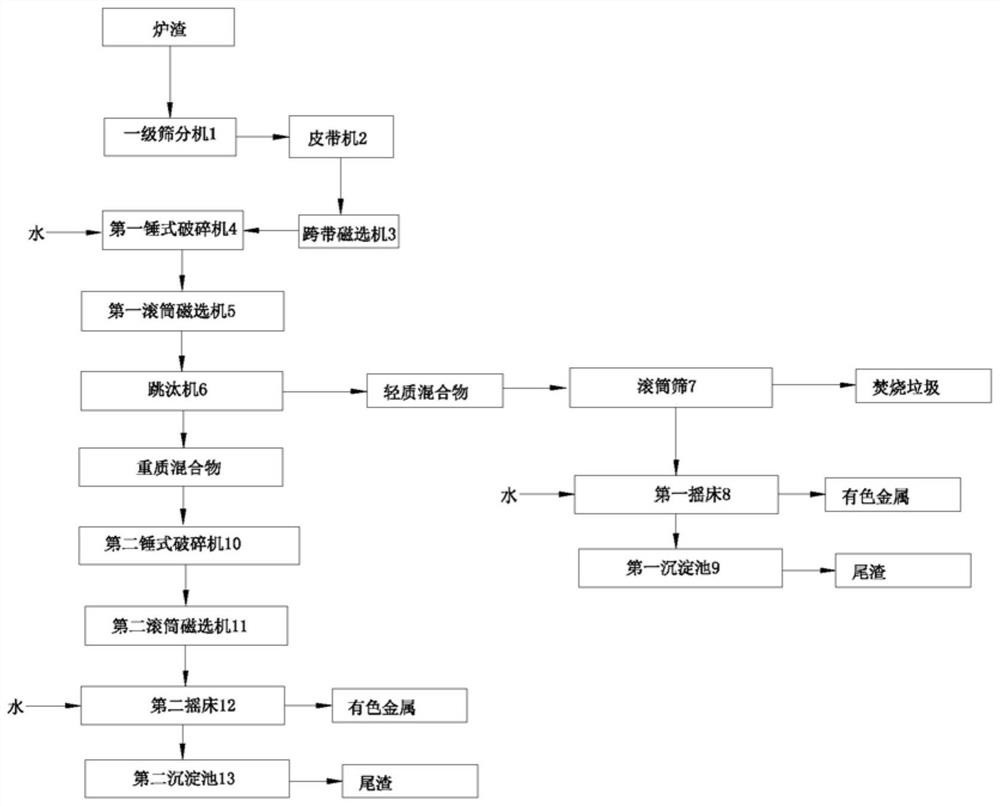

[0014] A specific embodiment of a process for the comprehensive utilization of municipal solid waste incineration slag of the present invention, as figure 1 As shown, the municipal solid waste incineration slag comprehensive utilization system includes a primary screening machine 1, a belt conveyor 2 connected to the primary screening machine 1, a cross-belt magnetic separator 3 connected to the belt conveyor 2, and a cross-belt magnetic separator 3 The connected first hammer crusher 4, the first drum magnetic separator 5 connected to the first hammer crusher 4, the jig 6 connected to the first drum magnetic separator 5, and the jig 6 are respectively connected to the drum The screen 7 and the second hammer crusher 10, the drum screen 7 is connected with the first shaker 8, the first shaker 8 is connected with the first sedimentation tank 9; the second hammer crusher 10 is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com