Apparatus for producing water-in-oil emulsifield fuel and supplying the same

a technology of emulsified fuel and apparatus, which is applied in the direction of fuels, chemistry apparatus and processes, transportation and packaging, etc., can solve the problems of water and oil breakdown, severe limited heat source use efficiency, and water and oil phase stability breakdown, etc., to reduce fuel consumption, reduce excessive oxygen concentration, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

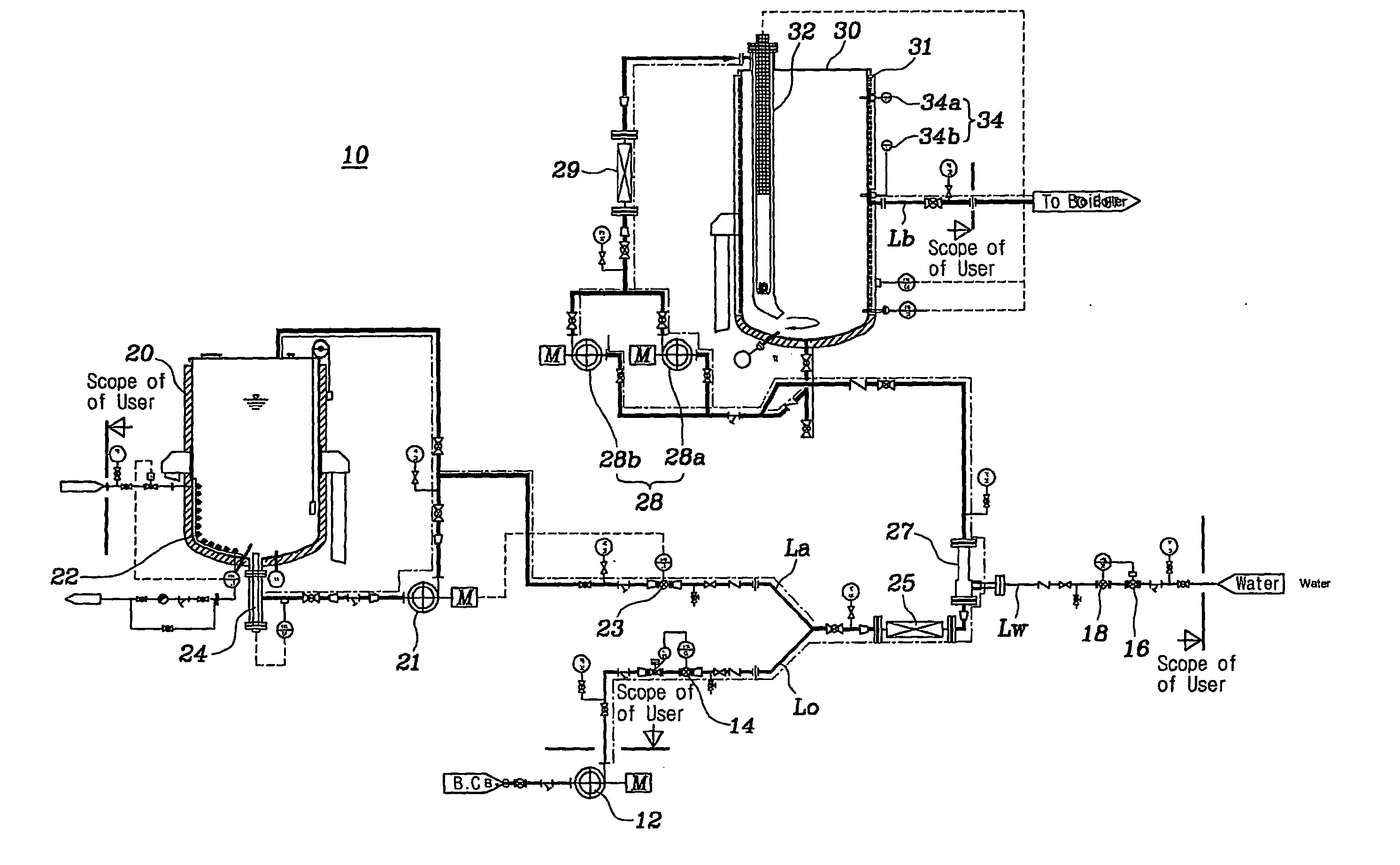

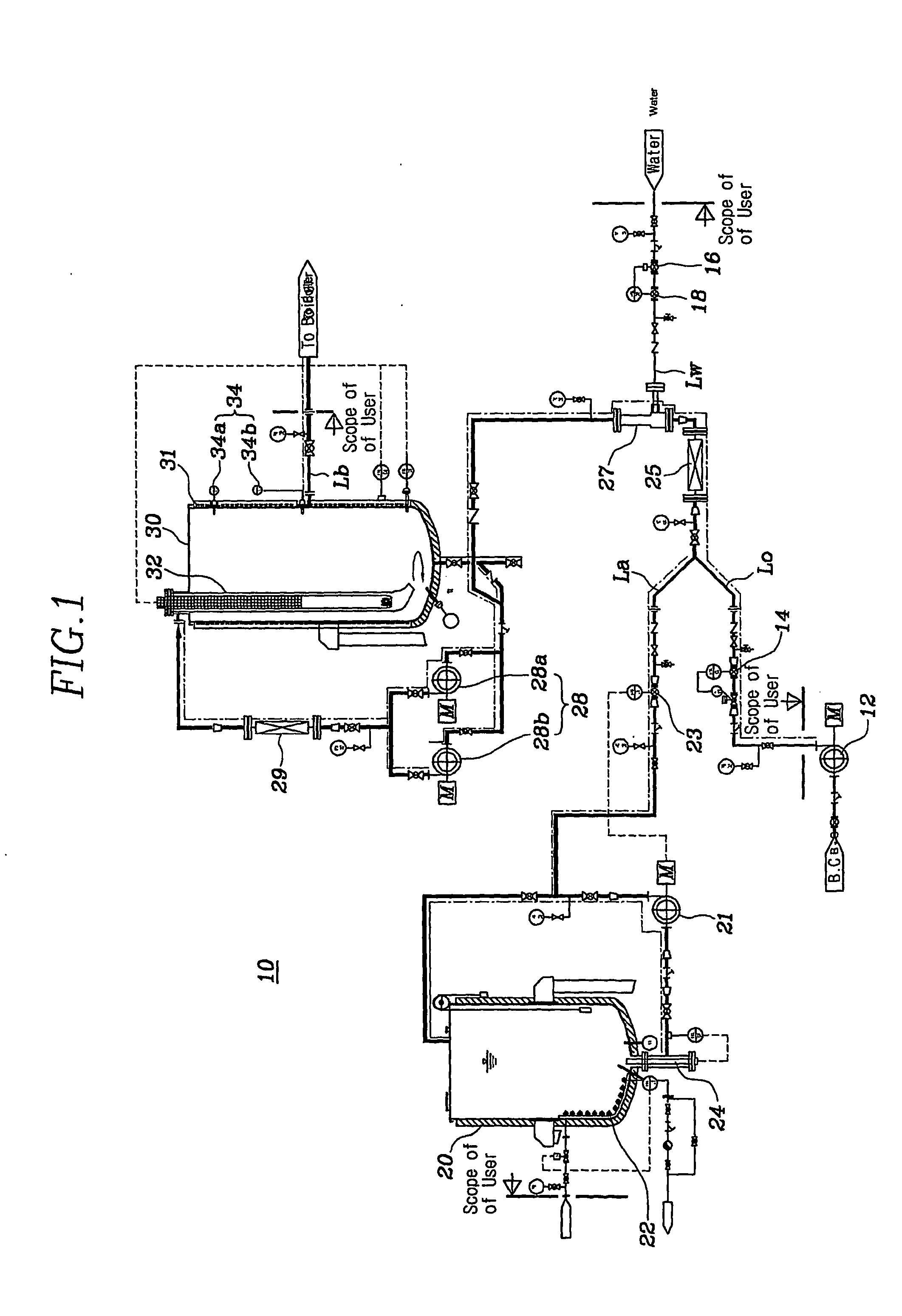

[0046]FIG. 1 is a structural view of an apparatus for producing and supplying water-in-oil emulsified fuel according to the present invention.

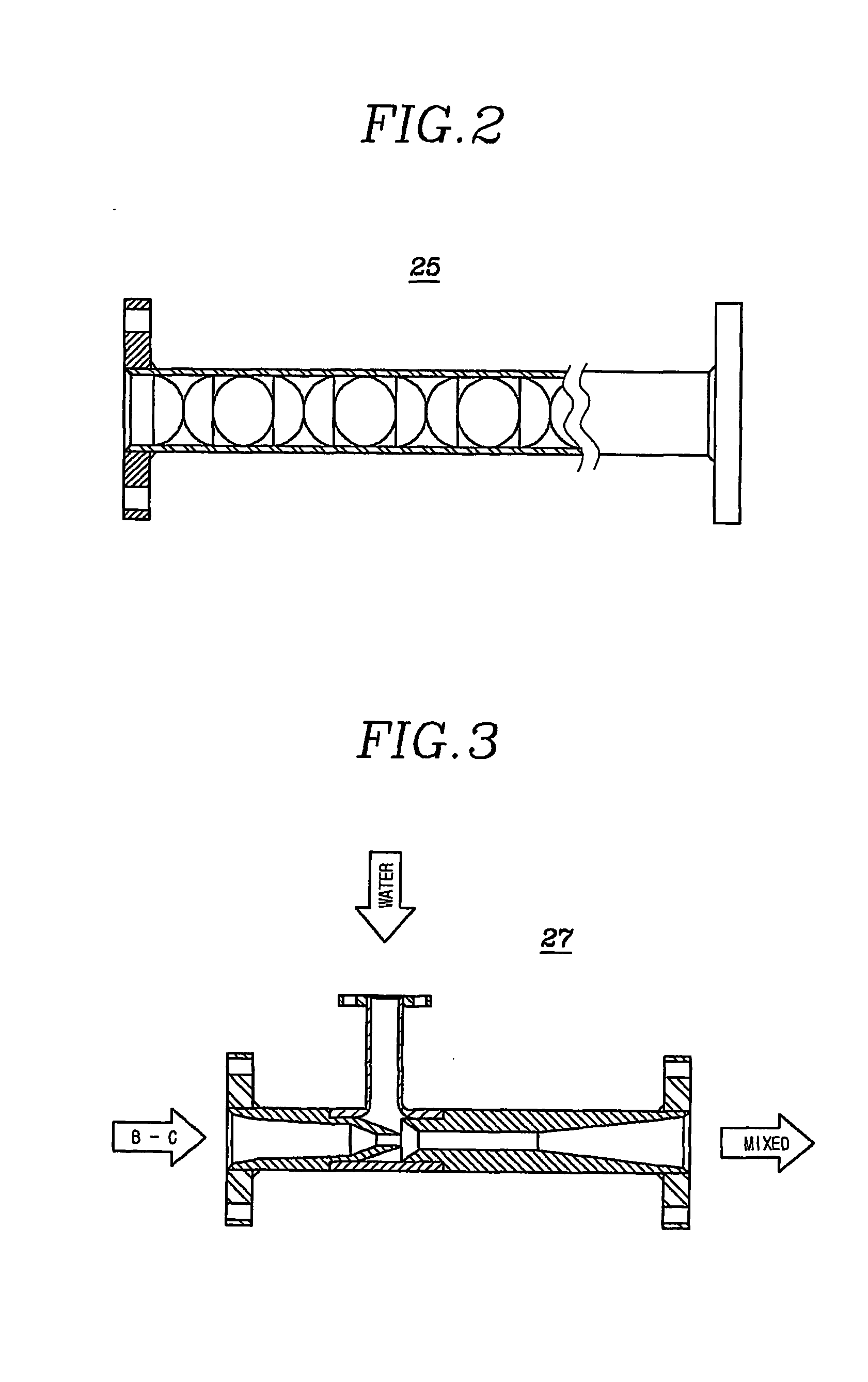

[0047] With reference to FIG. 1, an apparatus 10 for producing and supplying water-in-oil emulsified fuel includes an additive storage tank 20 for storing an emulsifier; an emulsion tank 30 for storing water-in-oil emulsified fuel; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion.

[0048] The emulsifier stored in the additive storage tank 20 is an additive that acts to prevent the separation of water and oil when a high temperature state of the water-in-oil emulsified fuel is maintained. ...

second embodiment

[0081]FIG. 5 is a structural view of an apparatus for producing and supplying water-in-oil emulsified fuel according to the present invention.

[0082] With reference to FIG. 5, an apparatus 40 for producing and supplying water-in-oil emulsified fuel includes an additive storage tank 41 for storing an emulsifier; an emulsion tank 43 for storing water-in-oil emulsified fuel; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion. The apparatus also includes a service tank 45 that stores water-in-oil emulsified fuel before the same is supplied to a boiler.

[0083] It is preferable that the emulsion tank 43 is manufactured having a capacit...

third embodiment

[0088]FIG. 6 is a structural view of an apparatus for producing and supplying water-in-oil emulsified fuel according to the present invention.

[0089] With reference to FIG. 6, an apparatus 60 for producing and supplying water-in-oil emulsified fuel includes an additive storage tank 61 for storing an emulsifier; an emulsion tank 63 for storing water-in-oil emulsified fuel; a raw material supplier for supplying at a predetermined ratio and according to predetermined values B-C oil, an emulsifier, and water, which become the raw materials for water-in-oil emulsified fuel; a first mixing section for consecutively and uniformly mixing the supplied raw materials; and a second mixing section for mixing the primarily mixed raw material oil with pre-emulsified fuel to perform emulsion.

[0090] In the apparatus 60 for producing and supplying water-in-oil emulsified fuel according to the third embodiment, a circulation electric heater 70 and a third mixer 69 are mounted in this sequence on a cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com