Circulating fluidized bed boiler operation optimizing method based on consumption difference analysis

A circulating fluidized bed, optimized operation technology, applied in the direction of instrumentation, adaptive control, control/regulation system, etc., can solve the problems of large furnace temperature fluctuations, low combustion efficiency, high carbon content in fly ash, etc., to improve boiler efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The technical scheme that the present invention solves technical problem comprises the following steps:

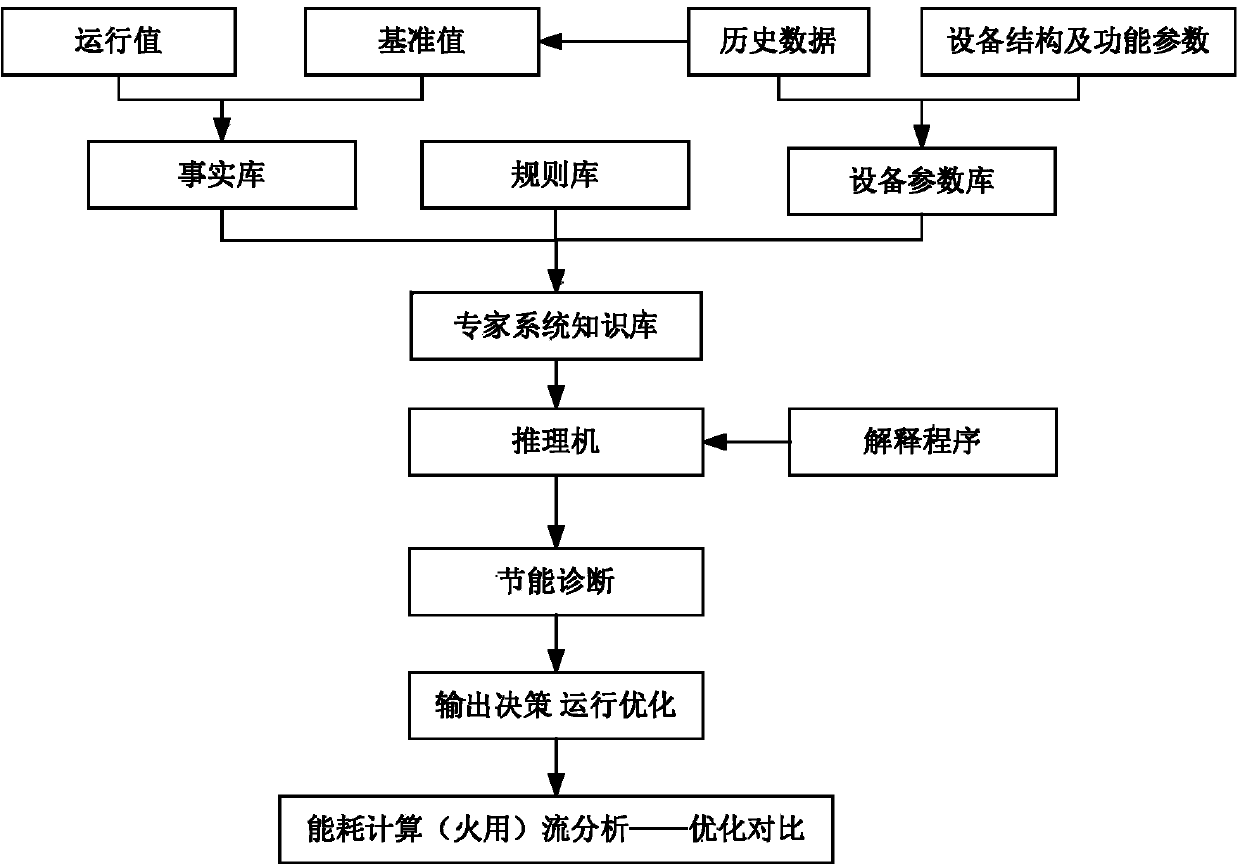

[0047] 1. The creation of an expert system

[0048] Basic parameter library: including structural parameters, design operation parameters and nameplate parameters of each equipment of circulating fluidized bed;

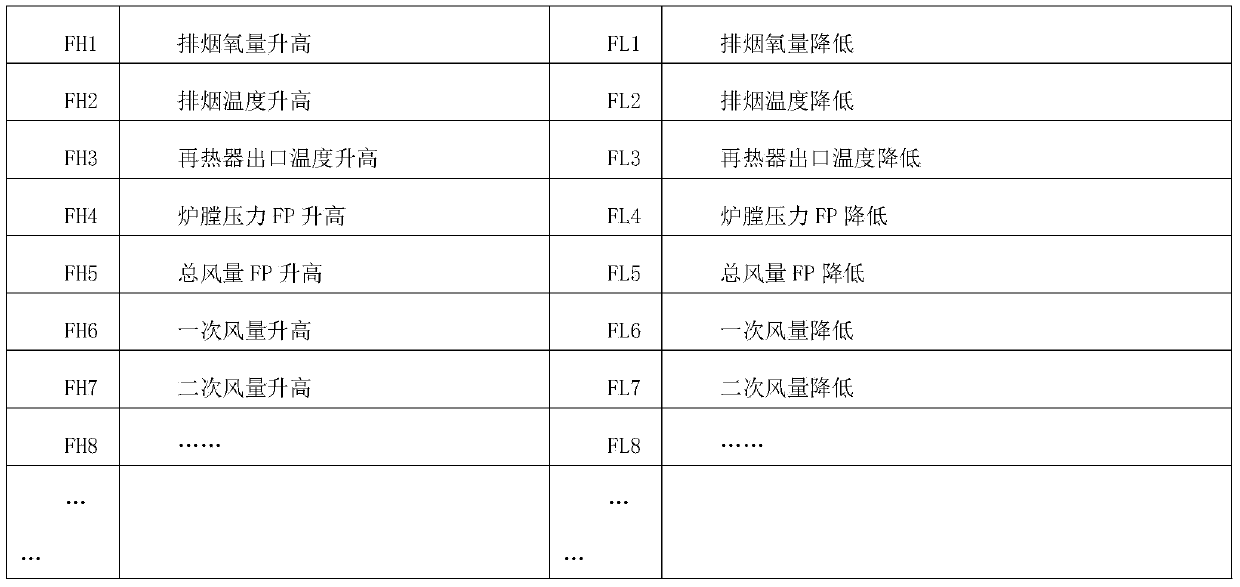

[0049] Fact library: including the fact that the operating values of the measurable parameters of the boiler combustion system, flue gas system and auxiliary system are higher or lower than the reference value;

[0050] Rule base: Including the rules of boiler efficiency reduction caused by different operating facts of the boiler system, that is, the form of the rule is [IF(), THEN()], and the premise of the rule is the fact set that different combinations of boiler system parameters deviate from the reference value ;

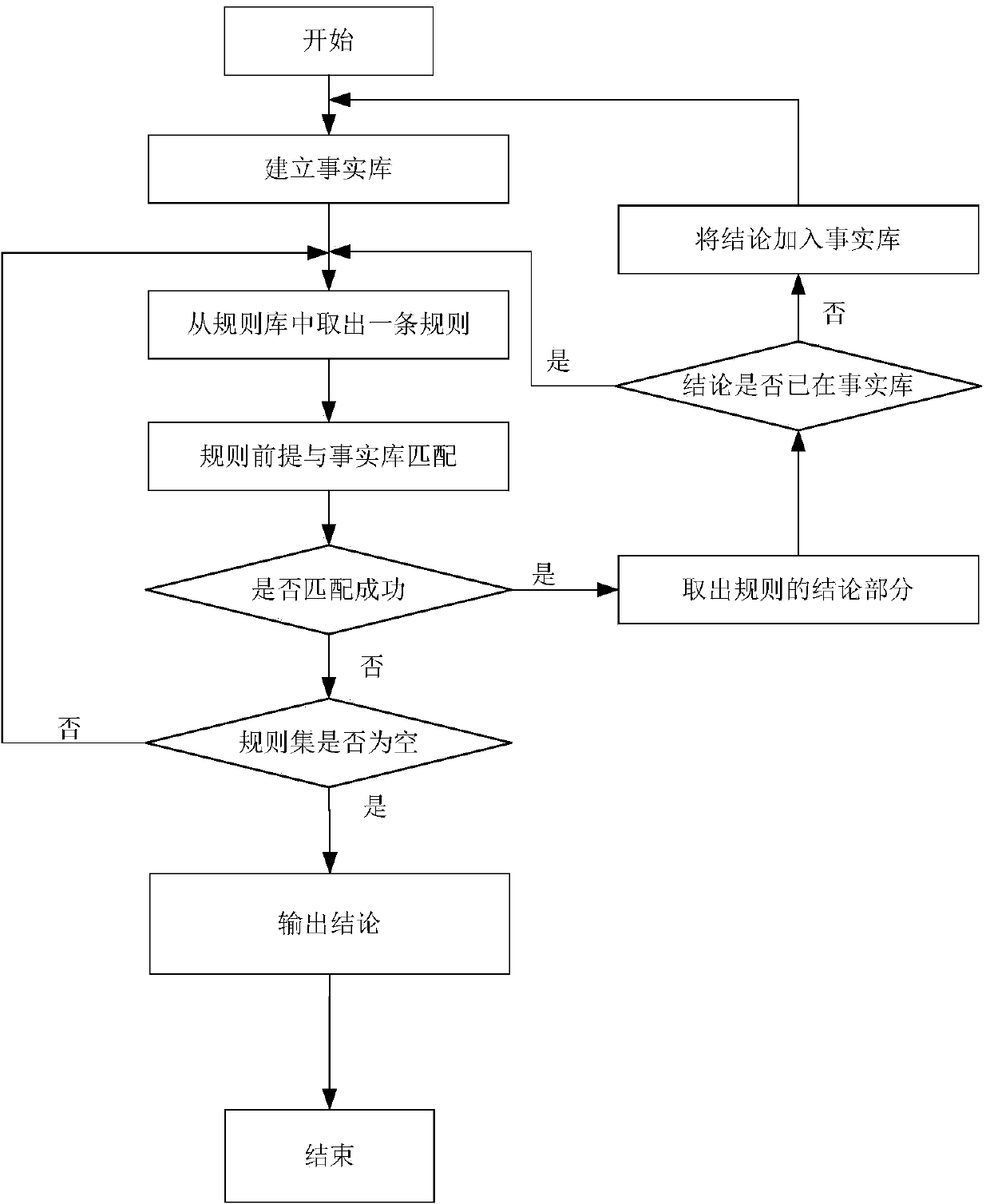

[0051] Reasoning engine: reasoning based on the forward reasoning strategy;

[0052] Interpretation module: output the matching [fact]...

Embodiment 2

[0068] This embodiment describes the present invention in more detail in conjunction with the energy efficiency optimization of two circulating fluidized bed boiler systems in a certain power plant.

[0069] 1. Establishment of expert system knowledge base

[0070] The circulating fluidized bed boiler optimization operation system is a typical plant level optimization system of circulating fluidized bed power plant based on expert system. The establishment of expert system knowledge base includes:

[0071] 1) Establishment of equipment parameter library

[0072] The equipment parameter library includes the structure and design parameters of the main equipment and auxiliary equipment of the boiler system of the power plant; it includes the operation history data from October 2013 to March 2014 after the overhaul of the unit, which is imported from the SIS system.

[0073] 2) Establishment of fact database

[0074] The fact base contains all the facts needed and generated whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com