Sound-insulating aluminum plastic composite plate with high heat-dissipating property

An aluminum-plastic composite board with high heat dissipation technology, which is applied in coatings, layered products, buildings, etc., can solve the problems affecting the heat dissipation of the building area of the computer room, the heat dissipation function of the composite board is not high, and the threat to life and property safety, etc., to achieve excellent Anti-wind erosion performance, excellent sound absorption and noise reduction performance, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

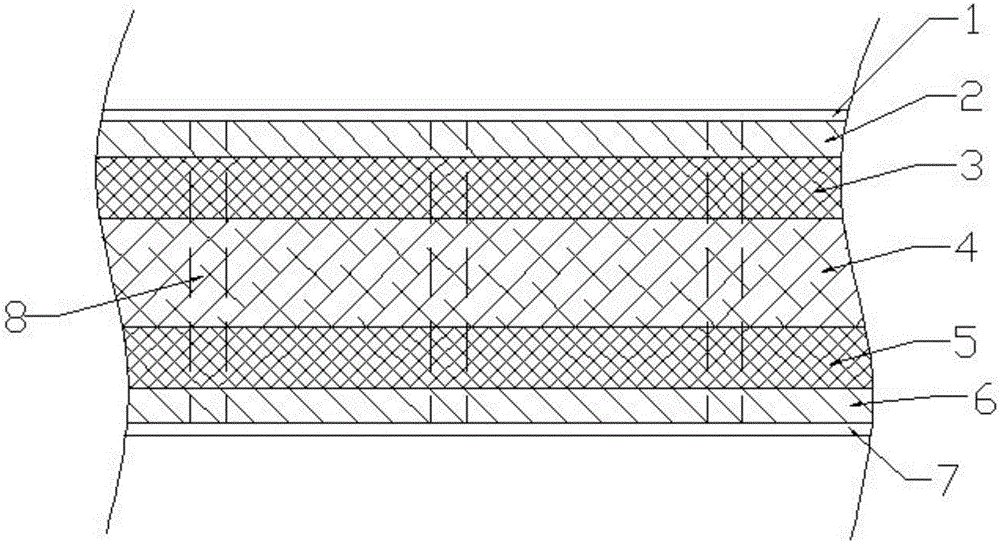

[0019] A high heat dissipation and sound-insulating aluminum-plastic composite board, its cross-sectional structure from outside to inside is ETFE (ethylene-tetrafluoroethylene copolymer) coating 1, aluminum alloy board upper layer 2, polyethylene (PE) board upper layer 3, silicic acid Aluminum fiber board layer 4, polyethylene board lower layer 5, aluminum alloy board lower layer 6, PVDF (polyvinylidene fluoride) coating 7, the aluminum alloy board upper layer 2, polyethylene board upper layer 3, aluminum silicate fiber board layer 4, The lower layer 5 of the polyethylene board and the lower layer 6 of the aluminum alloy board are bonded between each layer;

[0020] The upper layer 2 of the aluminum alloy plate and the lower layer 6 of the aluminum alloy plate are threadedly connected with an aluminum heat conduction column 8, and the aluminum heat conduction column 8 runs through the upper layer 3 of the polyethylene plate, the layer 4 of the aluminum silicate fiber board, an...

Embodiment 2

[0027] A high heat dissipation and sound-insulating aluminum-plastic composite board, its cross-sectional structure from outside to inside is ETFE (ethylene-tetrafluoroethylene copolymer) coating 1, aluminum alloy board upper layer 2, polyethylene (PE) board upper layer 3, silicic acid Aluminum fiber board layer 4, polyethylene board lower layer 5, aluminum alloy board lower layer 6, PVDF (polyvinylidene fluoride) coating 7, the aluminum alloy board upper layer 2, polyethylene board upper layer 3, aluminum silicate fiber board layer 4, The lower layer 5 of the polyethylene board and the lower layer 6 of the aluminum alloy board are bonded between each layer;

[0028] The upper layer 2 of the aluminum alloy plate and the lower layer 6 of the aluminum alloy plate are bolted with an aluminum heat conduction column 8, and the aluminum heat conduction column 8 runs through the upper layer 3 of the polyethylene plate, the layer 4 of the aluminum silicate fiber plate, and the lower la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com