Preparation method of hydrophobic foamed cement composite silicon aerogel material

A technology of foamed cement and silica airgel, which is applied in the direction of chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problems of low operating temperature, unbearable shear stress, high thermal conductivity, etc., and achieve the improvement of mechanical High strength, shortened preparation time, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

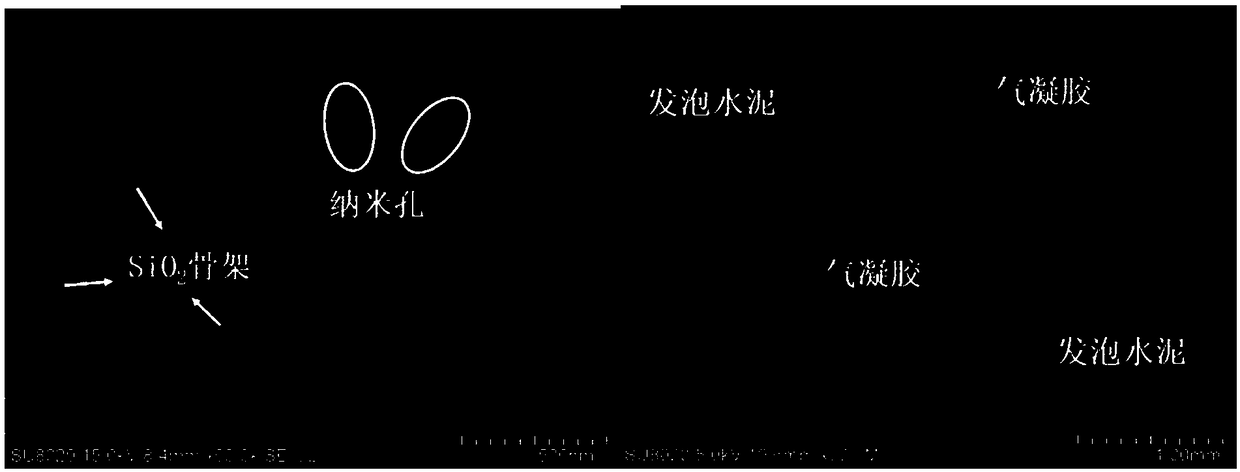

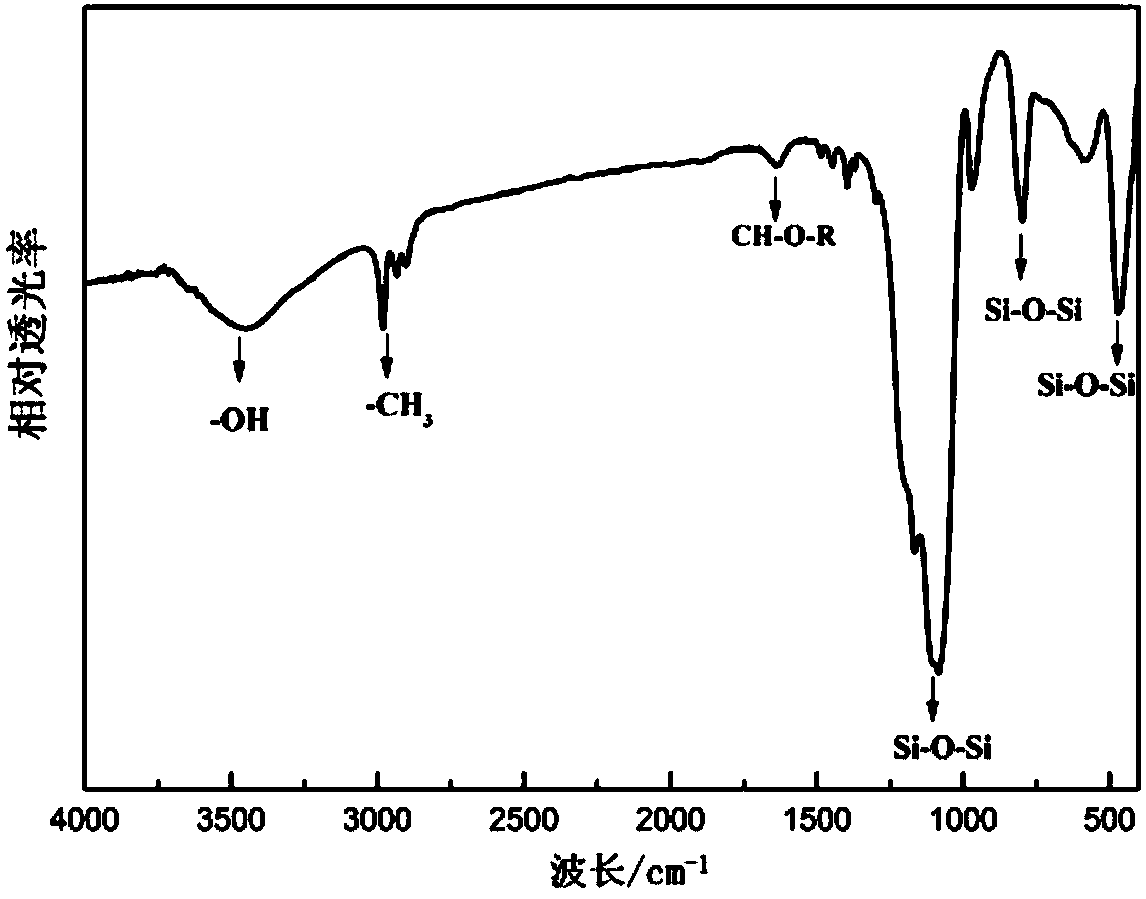

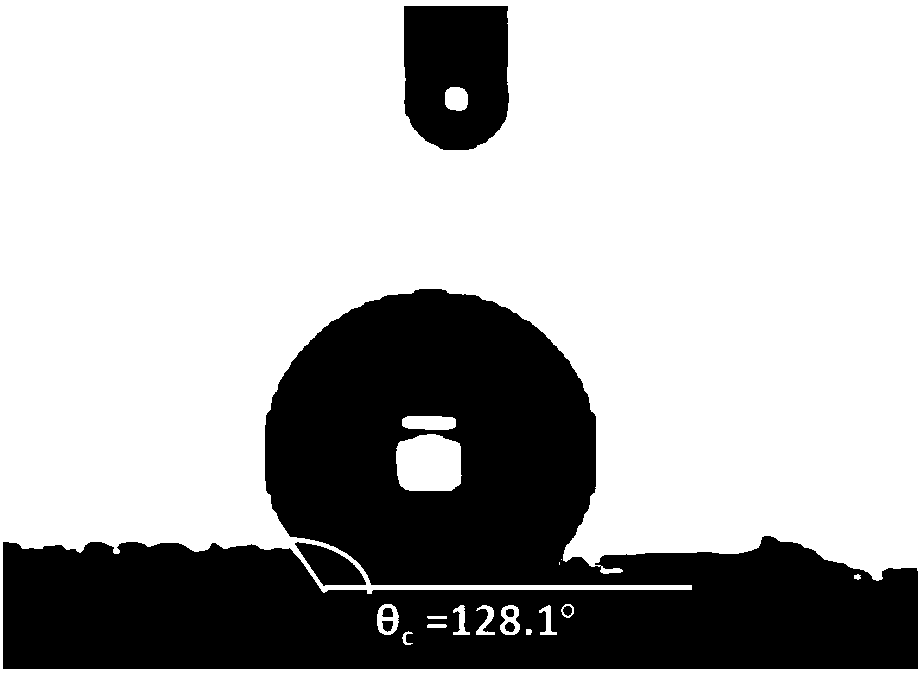

[0034] Add 44.7ml tetraethyl orthosilicate, 12.5ml deionized water, 186.3ml ethanol and 20ml MTES into the beaker, stir the mixed solution for 1h30min, then add 8mol / L ammonia solution dropwise, adjust the pH of the solution to 8 and stir well . Set the density to 0.47g / cm 3 , the thermal conductivity at room temperature is 0.152W·m -1 ·K -1 The hard foam cement material is placed in the mold, and the newly prepared hydrophobic silica sol is poured into the container, whichever is submerged in the base material. Vacuum impregnation of the composite foamed cement was carried out in a vacuum drying oven, the temperature of the vacuum drying oven was set at 20°C, and the vacuum degree was set at 10KPa. Vacuum twice and add sol in time to fully infiltrate the foamed cement matrix. No need to wait for its gel, directly put the sample and the container into the reaction kettle for ethanol supercritical drying. The drying temperature is set at 270°C. After the temperature rises, ...

example 2

[0037] Add 53.7ml tetraethyl orthosilicate, 9.7ml deionized water, 183.7ml ethanol and 19.9ml MTES into the beaker, stir the mixed solution for 1 hour, then add 9mol / L ammonia solution dropwise, adjust the pH of the solution to 8 and stir uniform. Set the density to 0.52g / cm 3 , the thermal conductivity at room temperature is 0.183W·m -1 ·K -1 The hard foam cement material is placed in the mold, and the newly prepared hydrophobic silica sol is poured into the container, whichever is submerged in the base material. Vacuum impregnation of composite foamed cement was carried out in a vacuum drying oven, the temperature of the vacuum drying oven was set at 40°C, and the vacuum degree was set at 30KPa. Vacuum 3 times and add sol in time to fully infiltrate the foamed cement matrix. No need to wait for the gel, directly put the sample and the container into the reaction kettle for ethanol supercritical drying. The drying temperature is set at 260°C. After the temperature rises, ...

example 3

[0040] Add 39.3ml tetraethyl orthosilicate, 11.0ml deionized water, 163.8ml ethanol and 20.8ml MTES into the beaker, stir the mixed solution for 2 hours, then add 13mol / L ammonia solution dropwise, adjust the pH of the solution to 9 and then stir uniform. Set the density to 0.32g / cm 3 , the thermal conductivity at room temperature is 0.098W·m -1 ·K -1 The hard foam cement material is placed in the mold, and the newly prepared hydrophobic silica sol is poured into the container, whichever is submerged in the base material. Vacuum impregnation of composite foamed cement was carried out in a vacuum drying oven, the temperature of the vacuum drying oven was set at 30°C, and the vacuum degree was set at 20KPa. Vacuum twice and add sol in time to fully infiltrate the foamed cement matrix. No need to wait for the gel, directly put the sample and the container into the reaction kettle for ethanol supercritical drying. The drying temperature is set at 290°C. After the temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com