Low-density high-noise-reducing polypropylene nano-composite material and preparation method thereof

A technology of nanocomposite materials and polypropylene, which is applied in the field of polymer material modification and processing, can solve the problems of limited noise reduction effect, achieve excellent sound absorption and noise reduction performance, reduce dosage, and the method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

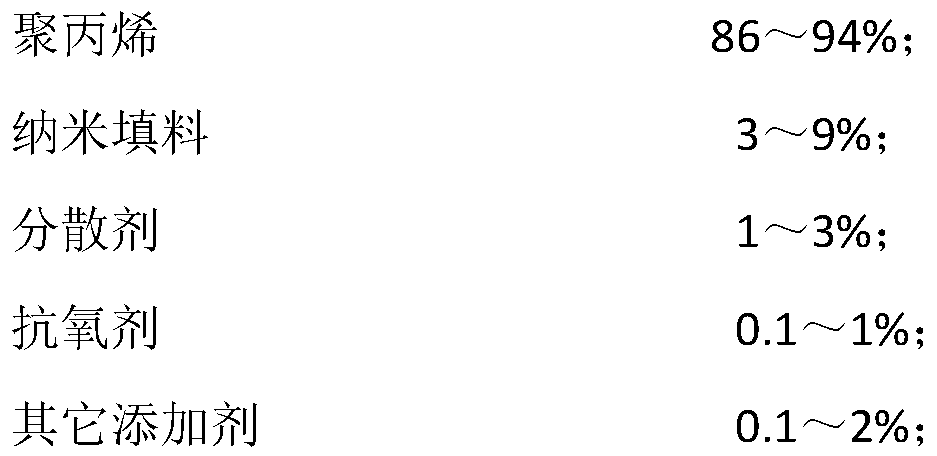

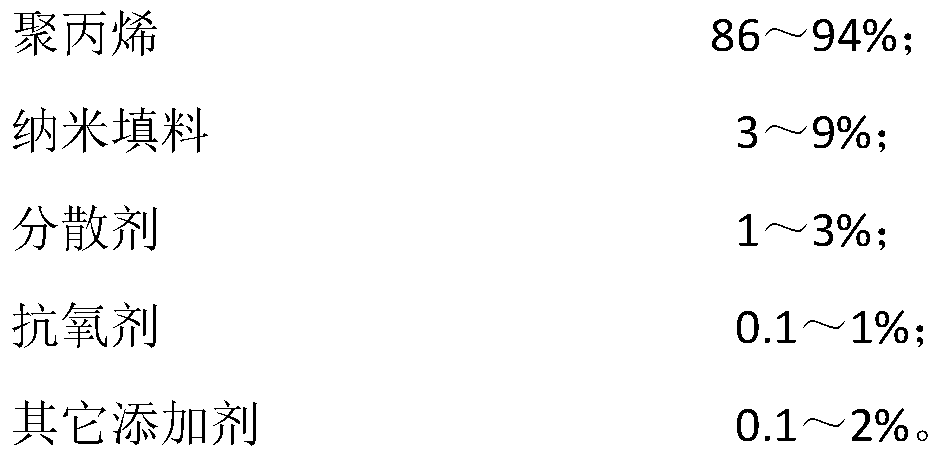

Method used

Image

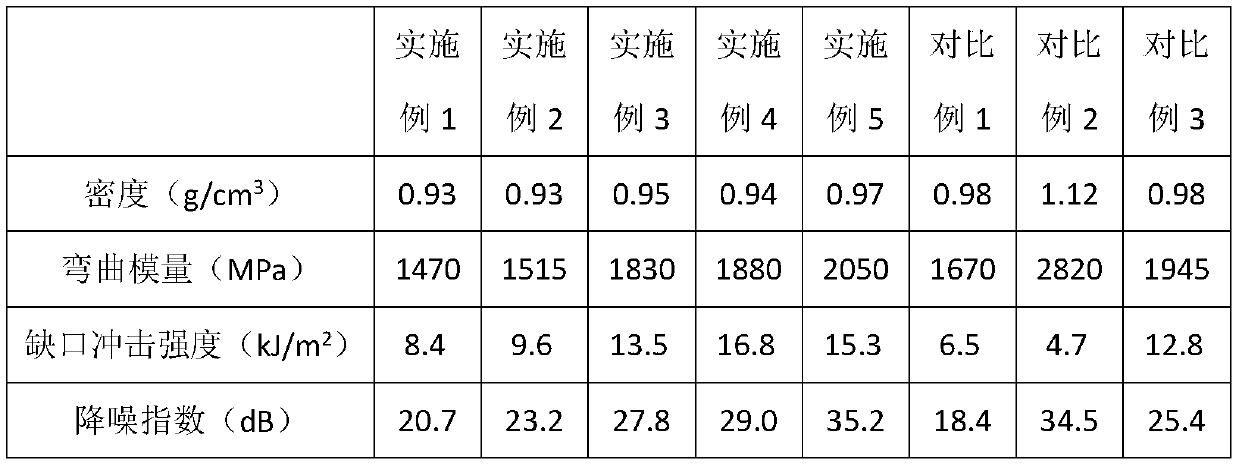

Examples

Embodiment 1

[0025] Weigh 94% of polypropylene, 1% of dispersant, 0.1% of 1010, 0.2% of DSTP, 0.2% of 168 and 1.5% of black masterbatch by weight, and dry mix them in a high-speed mixer for 8 minutes from the main feeding port Added into twin-screw extruder, and weighed 3% of the nano-filler in the second half of the extruder through side feeding, melted, extruded, cooled and granulated to obtain polypropylene nanocomposites, wherein the screw speed was 300 rev / min, the barrel temperature is 190-230°C.

Embodiment 2

[0027] Weigh 93% of polypropylene, 2% of dispersant, 0.1% of 1010, 0.2% of DSTP, 0.2% of 168 and 1.5% of black masterbatch by weight, and dry mix it in a high-speed mixer for 8 minutes from the main feeding port Added into twin-screw extruder, and weighed 3% of the nano-filler in the second half of the extruder through side feeding, melted, extruded, cooled and granulated to obtain polypropylene nanocomposites, wherein the screw speed was 300 rev / min, the barrel temperature is 190-230°C.

Embodiment 3

[0029] Weigh 90% of polypropylene, 2% of dispersant, 0.1% of 1010, 0.2% of DSTP, 0.2% of 168 and 1.5% of black masterbatch by weight, and dry mix it in a high-speed mixer for 8 minutes from the main feeding port Added into twin-screw extruder, and weighed 6% of the nano-filler in the second half of the extruder by side feeding, melted, extruded, cooled and granulated to obtain a polypropylene nanocomposite material, wherein the screw speed was 300 rev / min, the barrel temperature is 190-230°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com