Novel thermal insulation building coating

A technology for thermal insulation and architectural coatings, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of new thermal insulation coatings that have not yet been discovered with ferric oxide fine powder, and achieve good energy-saving effects, low density, and inhibition Effects of thermal radiation and heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

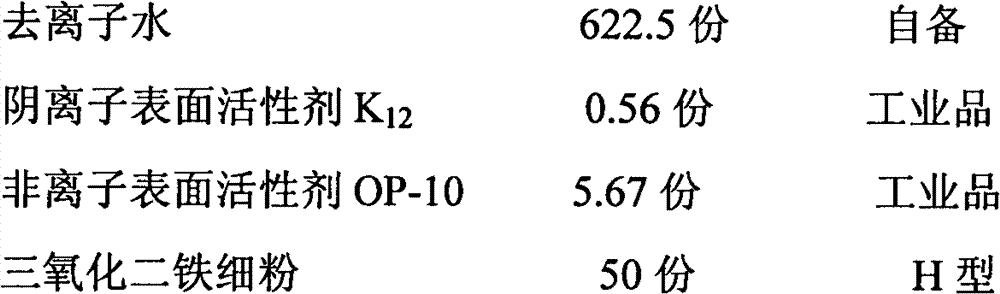

[0034] (1) The raw materials and their specifications and dosages selected for the prefabricated emulsion are as follows:

[0035] Item Material name Quantity Specification

[0036] (1) Class emulsion:

[0037]

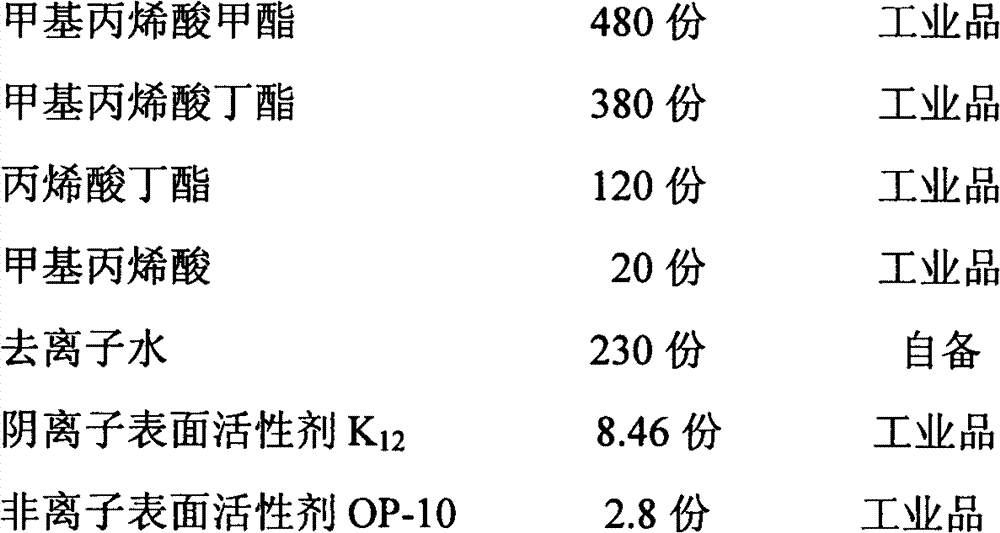

[0038] (2) Monomer pre-emulsion:

[0039]

[0040] (3) Initiator:

[0041] 130 parts of deionized water

[0042] Potassium persulfate 4 parts chemically pure

[0043] (4) Oxidation-reduction initiator:

[0044] 8 parts of deionized water

[0045] Potassium persulfate 0.45 part chemically pure

[0046] Sodium hyposulfite 0.45 part chemically pure

[0047] (5) Other components:

[0048] 10 parts deionized water

[0049] 6 parts of tributyl phosphate industrial product

[0050] (2) The emulsion preparation process is as follows:

[0051] (1) Fe2O3 fine powder pretreatment

[0052] Use 200# solvent gas oil and silane coupling agent KH550 to prepare a diluent in a ratio of 1:1 (v), soak 50 parts of ferric oxide fine powder with the diluted coupling agent,...

Embodiment 2

[0064] For the preparation of thermal insulation exterior wall architectural coatings, the selected raw materials and their specifications, dosage and preparation methods are as follows:

[0065] (1) Raw materials and their specifications and dosage

[0066] (1) Deionized water (medium), 473 parts, self-prepared;

[0067] (2) Benzyl bromide acetate (preservative), 1.36 parts, industrial product;

[0068] (3) 1.36 parts of octylisothiazolinone (antifungal agent), industrial product;

[0069] (4) Trimethylpentanediol monoisobutyrate (film-forming aid), 9.52 parts, industrial product;

[0070] (5) 2.5% cellulose glycolate (protective colloid), 95.2 parts, self-prepared;

[0071] (6) polyvinyl alcohol (colloidal protective agent), 34 parts, self-provided;

[0072] (7) Sodium hexametaphosphate (dispersant), 2.04 parts, industrial product;

[0073] (8) tributyl phosphate (defoamer), 1.36 parts, industrial product;

[0074] (9) OP-10 (wetting agent), 0.17 parts, industrial prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com