Sound-absorbing composite and preparation method thereof

A technology of sound-absorbing composite material and polyurethane sponge, which is applied in the fields of noise suppression, chemical instruments and methods, lamination devices, etc., can solve problems such as unfavorable applications, increased vehicle weight, and high density of lead plates, and achieve excellent sound absorption and drop Noise performance, small thermal conductivity, small density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

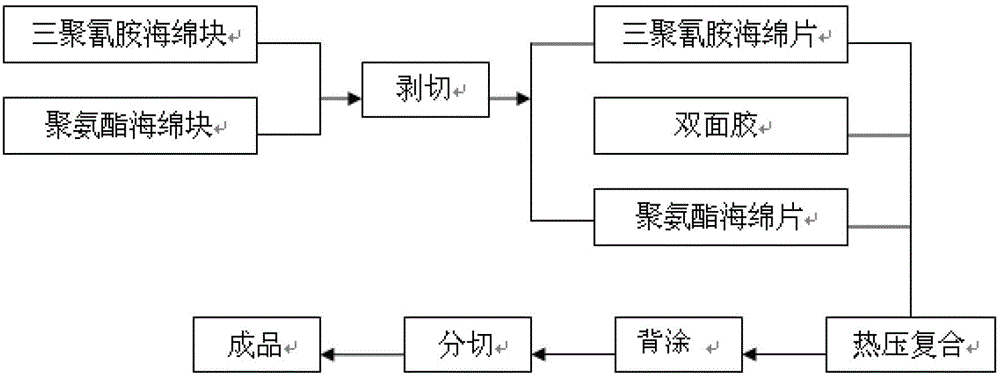

[0043] The present invention also provides a preparation method of the sound-absorbing composite material, comprising the following steps:

[0044] The double-sided adhesive tape is placed between the polyurethane sponge and the melamine sponge, and then hot-pressed and compounded to obtain a semi-finished product of the sound-absorbing composite material, and the thickness ratio of the melamine sponge to the polyurethane sponge is 1:1.5~1:5;

[0045] After coating an adhesive on the melamine sponge of the semi-finished sound-absorbing composite material to form an adhesive layer, the sound-absorbing composite material is obtained.

[0046] In the present invention, double-sided tape is firstly placed between the melamine sponge and the polyurethane sponge with a thickness ratio of 1:1.5 to 1:5, and then hot-pressed composite is performed to obtain a semi-finished product of a sound-absorbing composite material.

[0047] The present invention uses polyurethane sponge as a raw ...

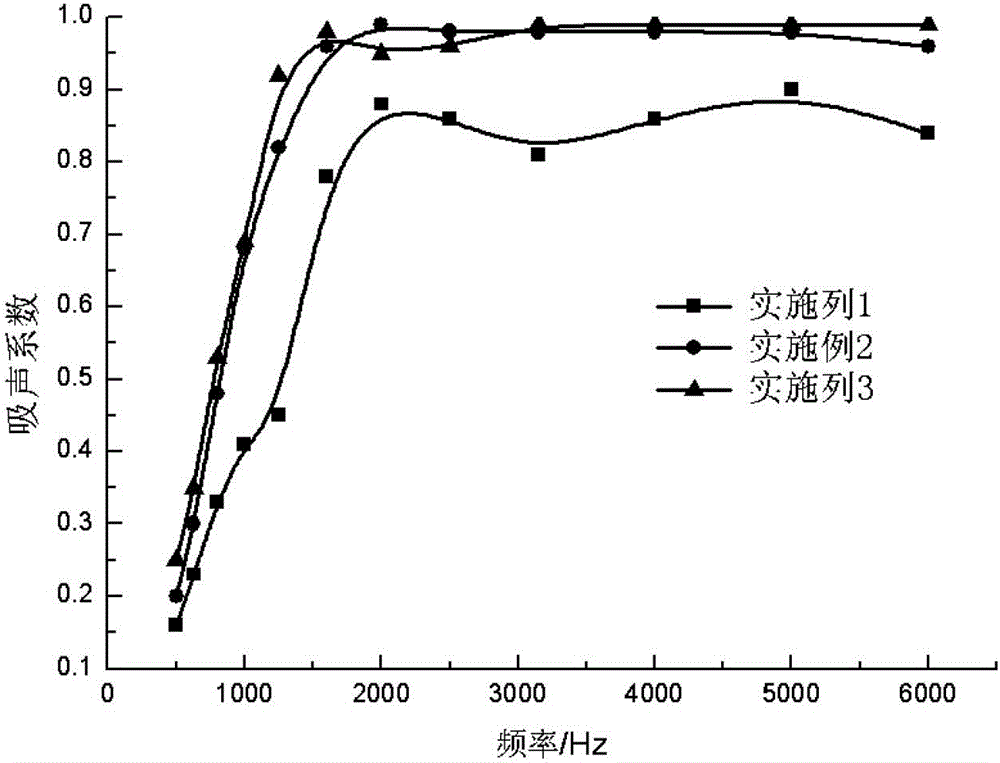

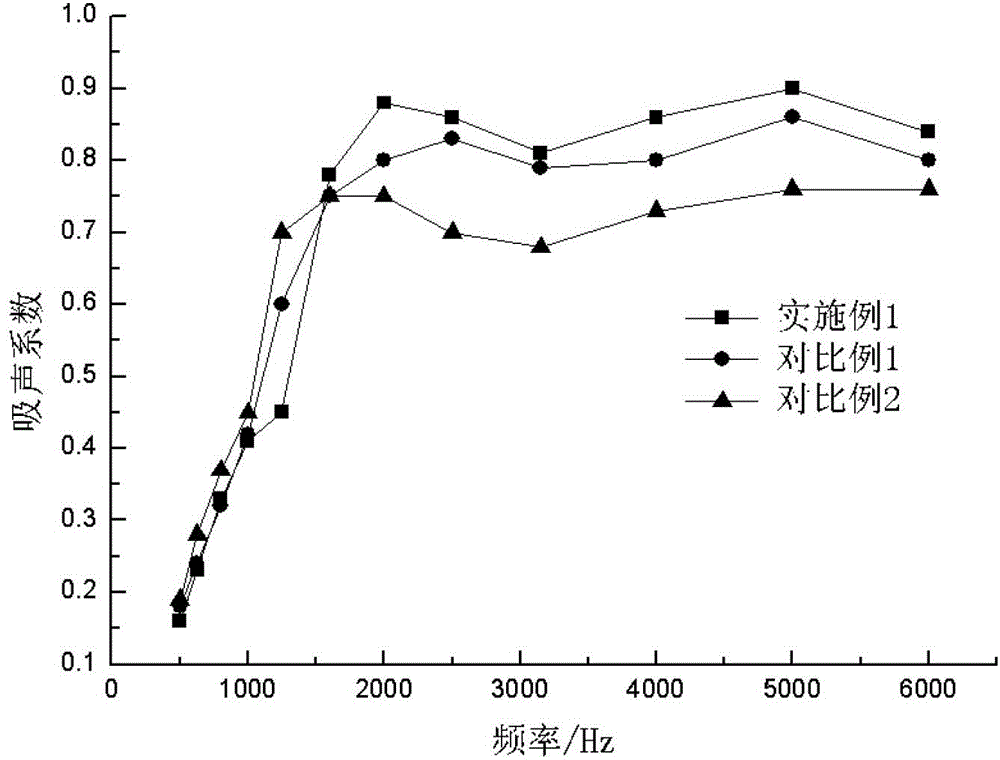

Embodiment 1

[0064] figure 1 The flow chart of the preparation of the sound-absorbing composite material provided in Example 1 of the present invention. see figure 1 , peel the melamine sponge block into a melamine sponge sheet with a thickness of 10mm, peel the polyurethane sponge block into a polyurethane sponge sheet with a thickness of 15mm, place the double-sided tape between the polyurethane sponge sheet and the melamine sponge sheet, and then Carry out hot-pressing compounding to obtain a semi-finished product of the sound-absorbing composite material; the temperature of the hot-pressing compounding is 50°C, the pressure is 5MPa, and the time is 60s;

[0065] The semi-finished melamine sponge of the sound-absorbing composite material is back-coated with adhesive to form an adhesive layer with a thickness of 0.05mm, which is then slit and trimmed by a slitting machine to obtain a finished sound-absorbing composite material, melamine sponge The thickness ratio to polyurethane sponge...

Embodiment 2

[0073] Peel the melamine sponge block into a melamine sponge sheet with a thickness of 10mm, peel the polyurethane sponge block into a polyurethane sponge sheet with a thickness of 25mm, place the double-sided tape between the polyurethane sponge sheet and the melamine sponge sheet, and then carry out Hot-pressing and compounding to obtain a semi-finished product of the sound-absorbing composite material; the temperature of the hot-pressing compounding is 80°C, the pressure is 1MPa, and the time is 20s;

[0074] The semi-finished melamine sponge of the sound-absorbing composite material is back-coated with adhesive to form an adhesive layer with a thickness of 0.05mm, which is then slit and trimmed by a slitting machine to obtain a finished sound-absorbing composite material, melamine sponge The thickness ratio to polyurethane sponge is 1:2.5.

[0075] After the sound-absorbing composite material is obtained, its sound-absorbing performance is tested according to the method de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com