Heat insulation, sound absorption and noise reduction TPU film and production method thereof

A heat insulation and noise reduction technology, applied in the field of polymer materials, can solve the problems of not having sound absorption and noise reduction performance, and achieve good heat insulation, good mechanical properties, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

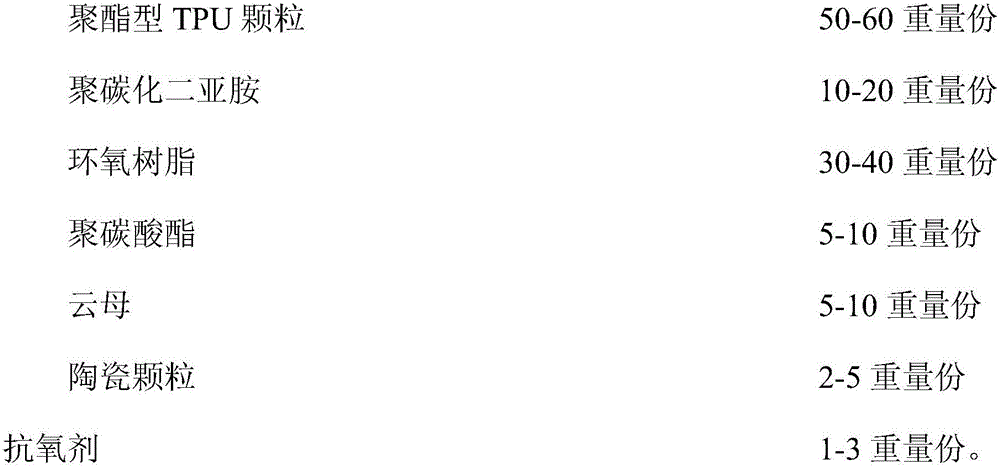

[0032] In the present embodiment, the TPU film is prepared from the following raw materials:

[0033]

[0034] The preparation method is as follows:

[0035] The perlite is pulverized to 150 mesh, and each raw material component is pre-dried at 75 ° C for 3 hours, mixed evenly, and extruded through a casting machine. The temperature of each section of the casting machine is set as follows: the temperature of the barrel is 150 ° C; the temperature of the filter screen The temperature of the elbow is 180°C; the temperature of the connection is 190°C; the temperature of the die head is 190°C, and the TPU film is obtained.

Embodiment 2

[0037] In the present embodiment, the TPU film is prepared from the following raw materials:

[0038]

[0039]

[0040] The preparation method is as follows:

[0041] The perlite is pulverized to 200 mesh, and each raw material component is pre-dried at 80 °C for 1 hour, mixed evenly, and extruded through a casting machine. The temperature of each section of the casting machine is set as follows: the temperature of the barrel is 210 °C; the temperature of the filter screen The temperature of the elbow is 190°C; the temperature of the elbow is 220°C; the temperature of the connection is 210°C; the temperature of the die head is 230°C to obtain a TPU film.

Embodiment 3

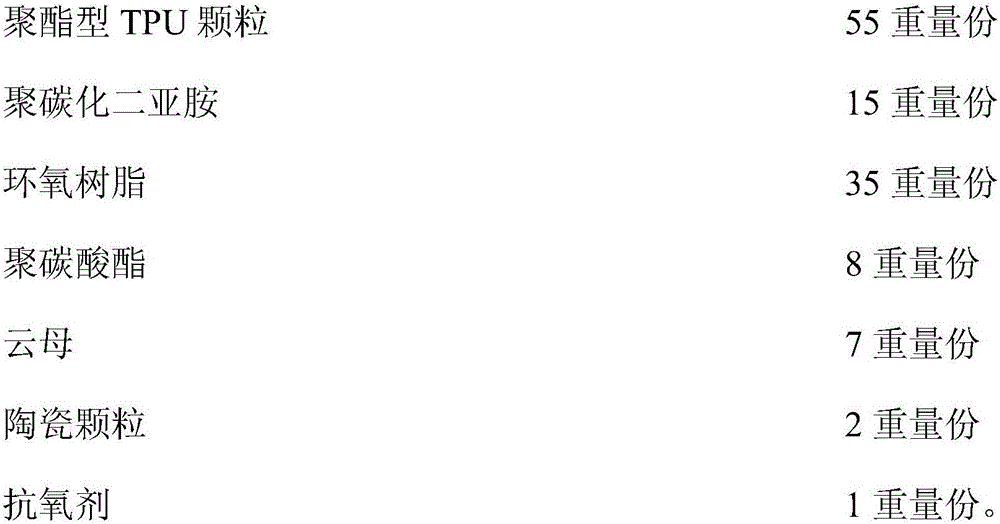

[0043] In the present embodiment, the TPU film is prepared from the following raw materials:

[0044]

[0045] The preparation method is as follows:

[0046] The perlite is pulverized to 180 mesh, and each raw material component is pre-dried at 75 ° C for 2 hours, mixed evenly, and extruded through a casting machine. The temperature of each section of the casting machine is set as follows: the temperature of the barrel is 190 ° C; the temperature of the filter screen The temperature of the elbow is 150°C; the temperature of the elbow is 200°C; the temperature of the connection is 180°C; the temperature of the die head is 220°C, and the TPU film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com