Method for preparing metal micro-nano fibers through centrifugal melt electrostatic spinning

A melt electrospinning, micro-nano fiber technology, applied in textile/flexible product manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of small fiber breaking strength and elongation, poor fiber surface quality, fiber Large diameter and other problems, to achieve the effect of fast heating speed, smooth inner wall and high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

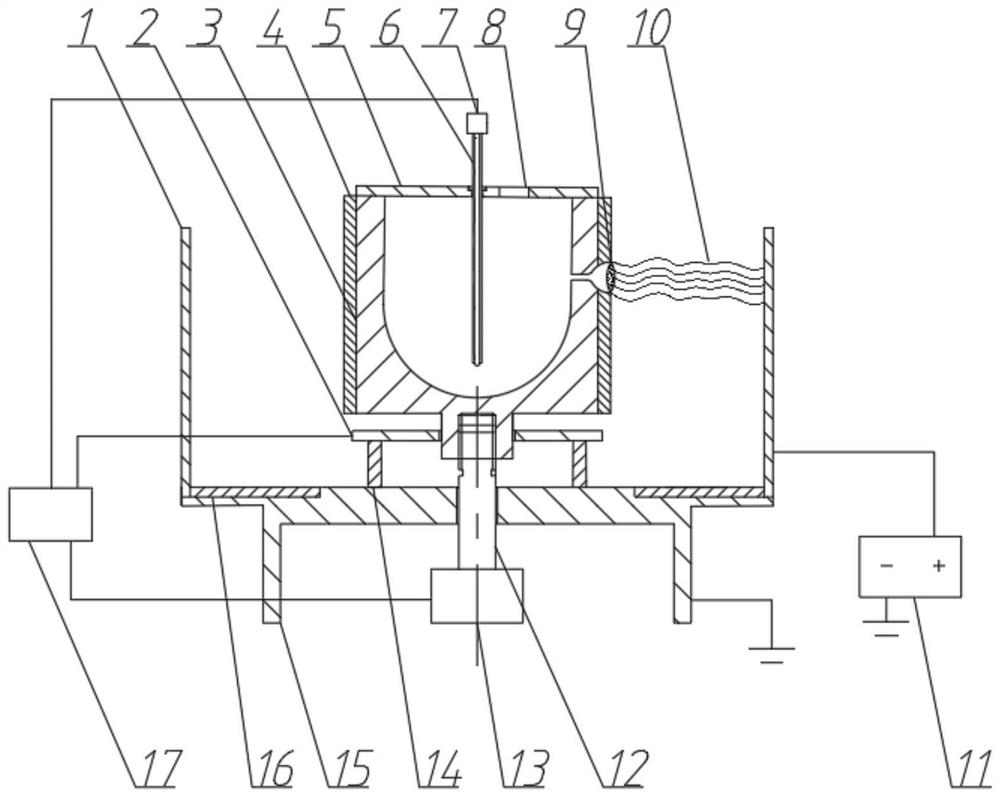

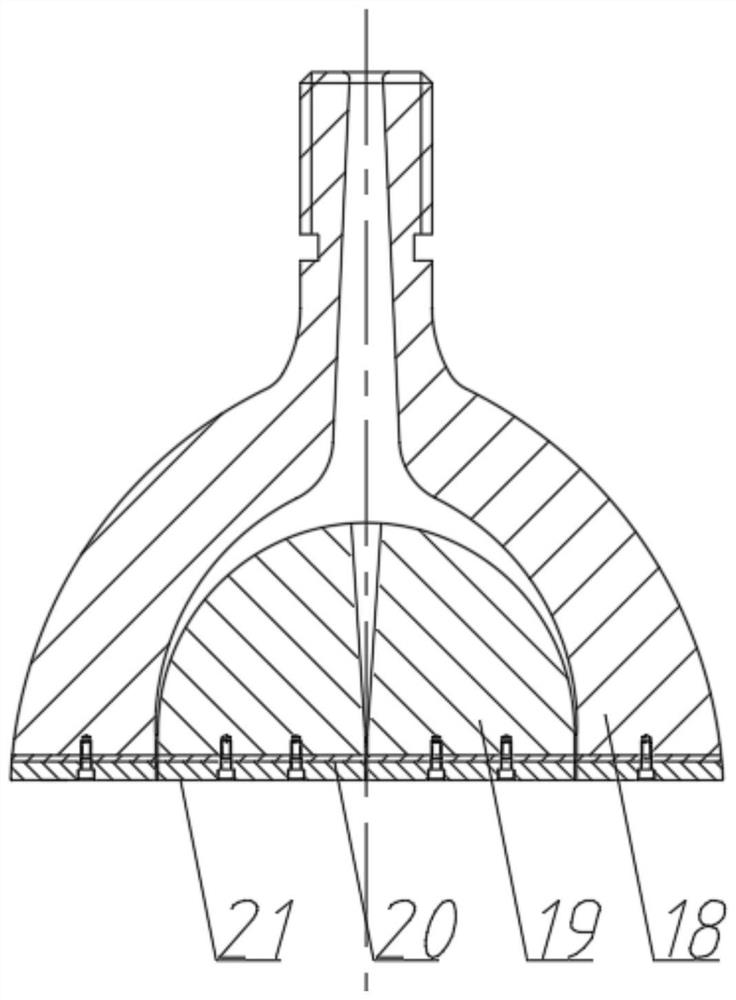

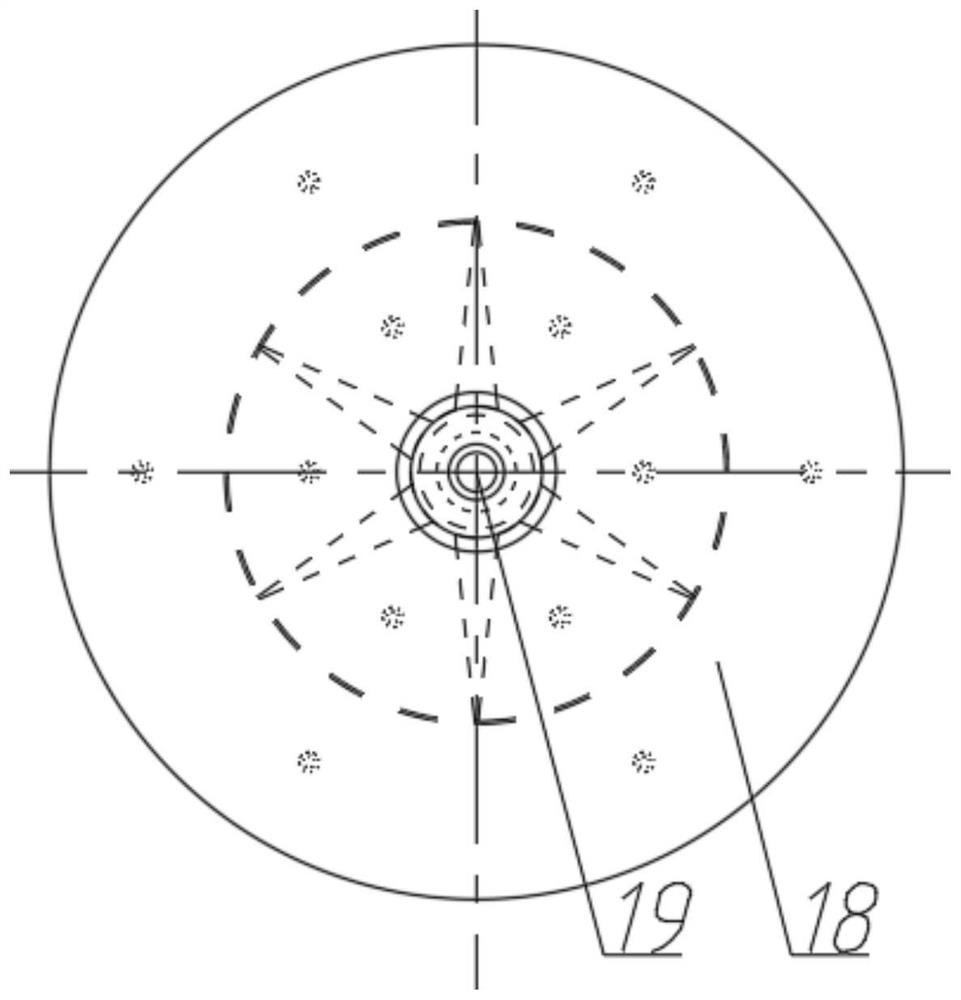

[0029] in as figure 1 In the device, add 30g metal block to the customized crucible 3, cover the end cap 5, install and fix the K-type thermocouple 7, and then turn on the power of the integrated console 17, and the metal in the customized crucible 3 is adjusted by the electromagnetic induction coil 2. The block is heated, and the real-time temperature monitoring is carried out through the K-type thermocouple 7. The signal is fed back to the integrated console 17, and observation is carried out through the observation port on the end cover 5. After the pure metal block is completely melted into a melt, the temperature is maintained again. 10min, then start the high-voltage power supply 11 and the high-speed motor 13, set the rotating speed to 1000r / min, and drive the customized crucible 3 to rotate through the rotating shaft 12. The nozzles 9 evenly fall on the collecting plate 1 in the form of fibers, so as to obtain long metal fibers 10 with multiple advantages such as small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com