Patents

Literature

230results about How to "Small average pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming agent for civil construction as well as preparation method and use thereof

The weight percentage of a constructional foaming agent is that the anion surface active agent is 40-70%, the cationic surface active agent is 5-30%, the foam stabilizing agent by 5-15%, and the filling agent by 5-15%. The solid raw material is cracked into particle with the diameter smaller than 100 meshes, and mixed evenly, then liquid raw material spray is agglomerated on the solid raw material which is mixed evenly, stirred evenly and dried, even powder is conformed. The invention has advantages of simple process, and being easy to be shaped, hard to be degenerated and convenient for transportation, which has good water solubility and high stability, with less reduction of concrete strength, low cost etc.

Owner:CHINA RES INST OF DAILY CHEM IND

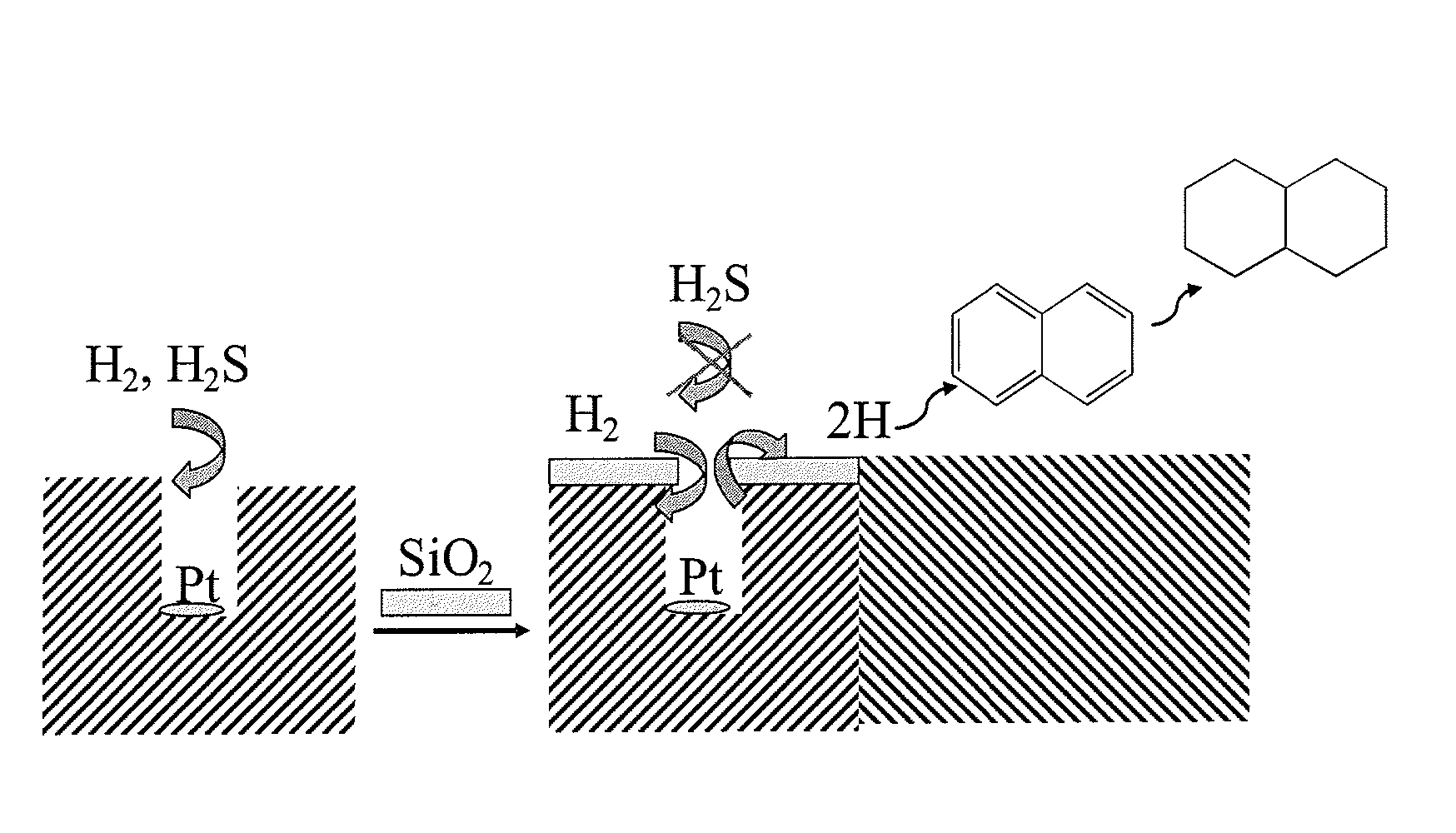

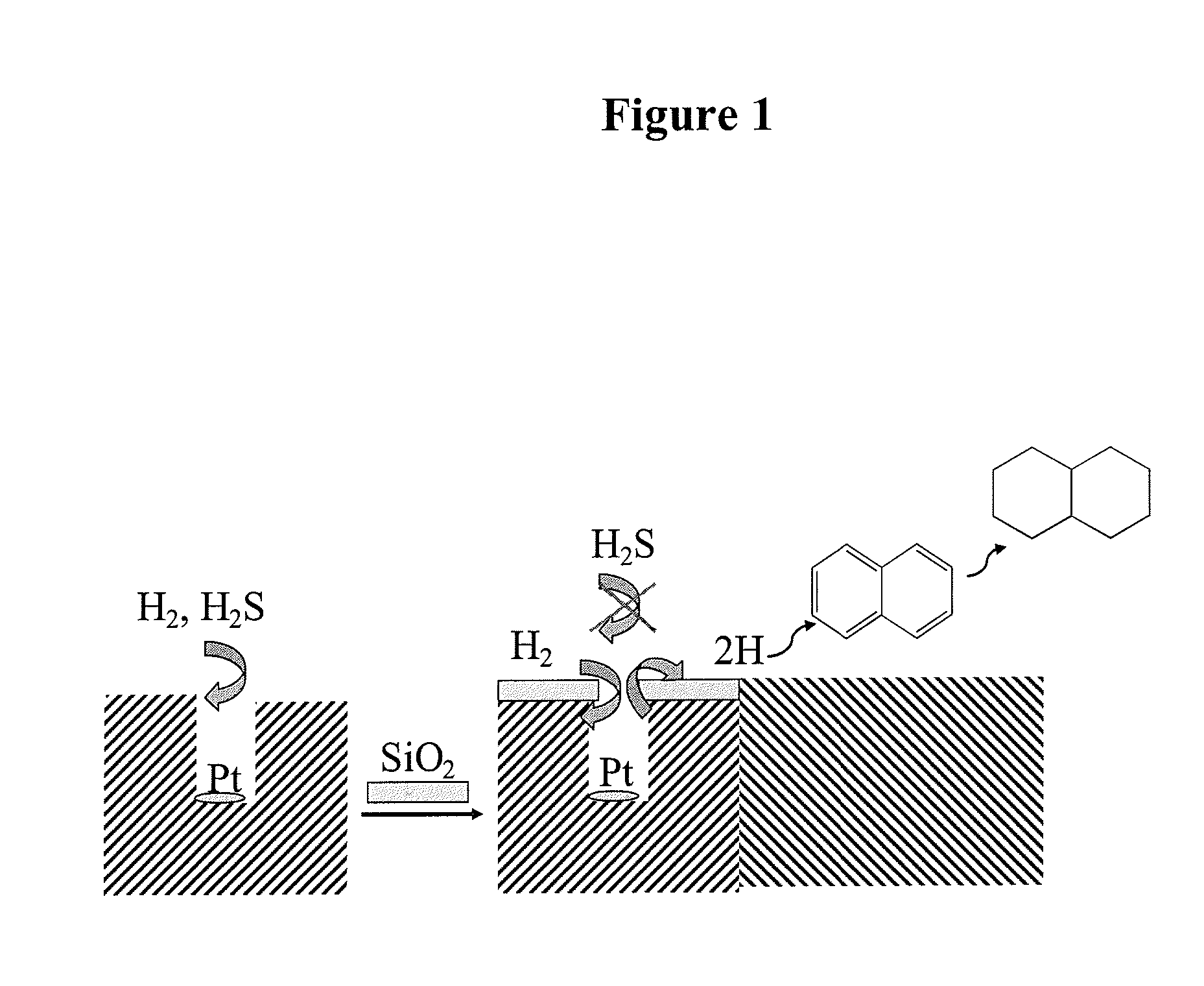

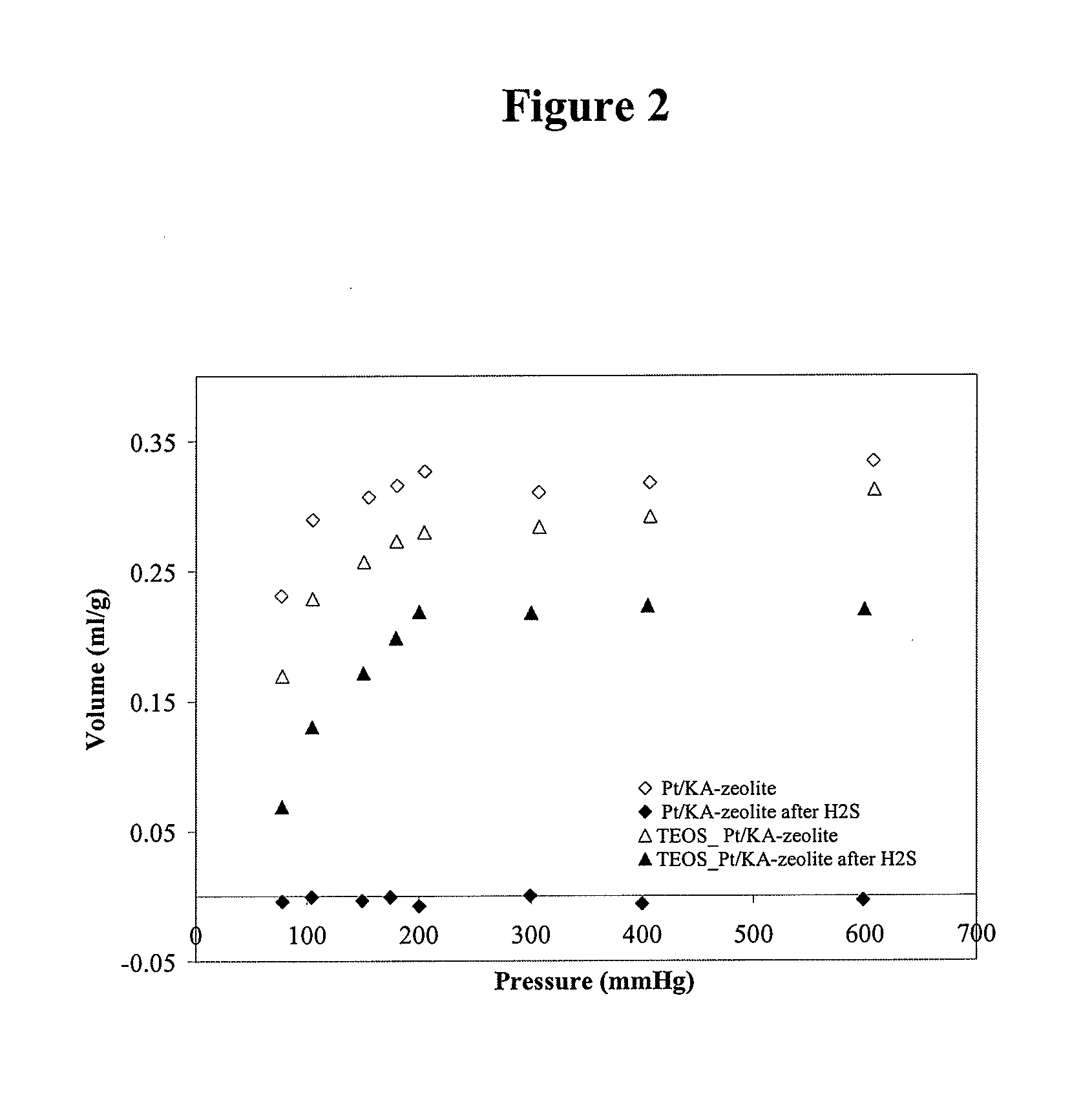

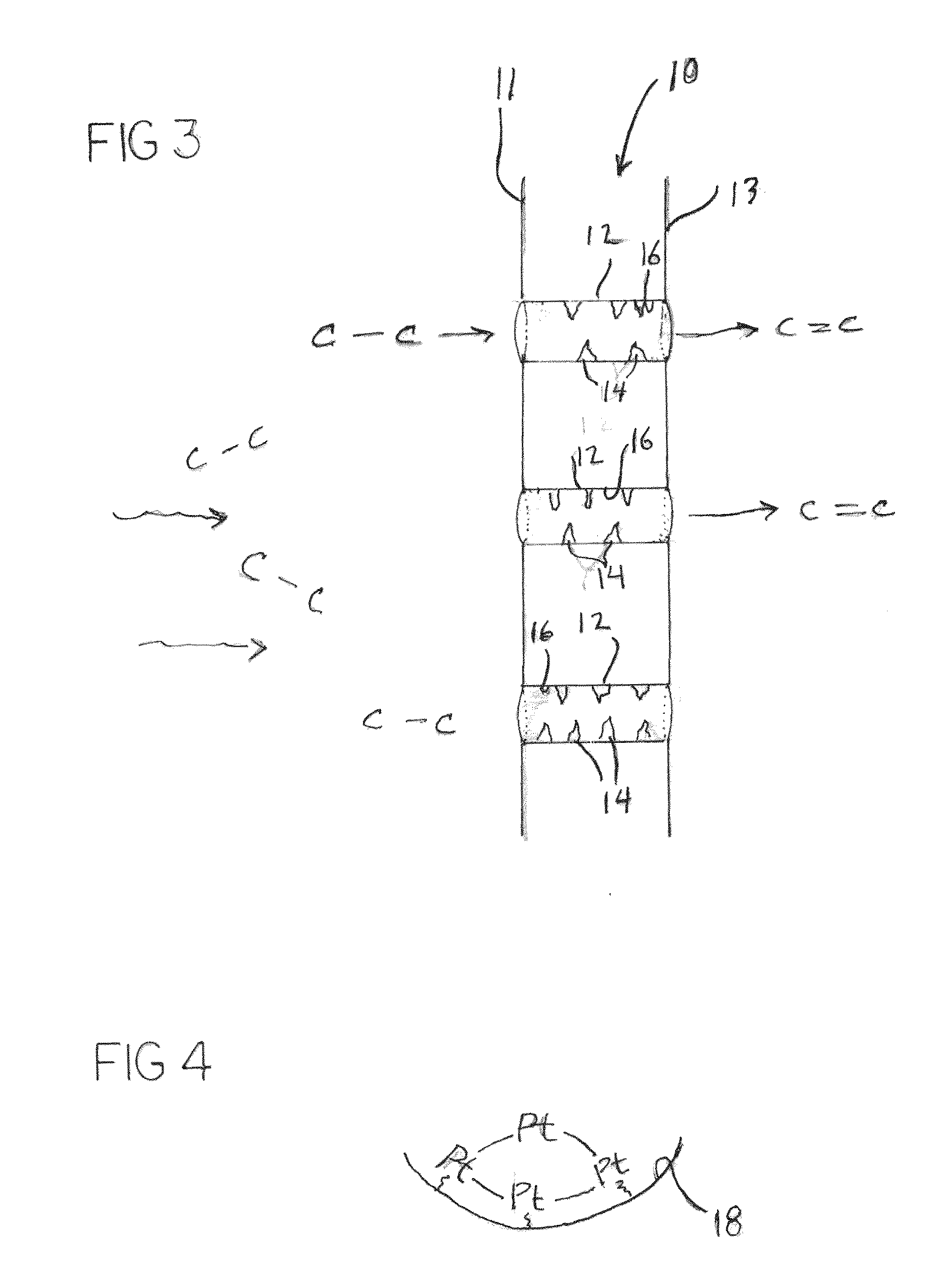

Sulfur-resistant noble metal nano-particles encapsulated in a zeolite cage as a catalyst enhancer

InactiveUS20090048094A1Small average pore sizeMolecular sieve catalystsMolecular sieve catalystHydrogen moleculeChemical vapor deposition

A sulfur resistant catalyst is taught having noble metal nano-particles contained in a zeolite cage having a final pore size of between about 2.9 Å and about 3.5 Å. The zeolite cage is either directly synthesized, or the final pore size of the zeolite cage is reduced by post-treatments selected from chemical vapour deposition, chemical liquid deposition, cation exchange and combinations thereof to allow passage of hydrogen molecules into the cage while excluding organic sulfur molecules. Disassociated hydrogen species from reaction with the noble metal spill over through the zeolite pores to induce hydrogenation and to regenerate neighboring catalyst supports. A method is also taught for producing a sulfur resistant catalyst having noble metal nano-particles. The method involves either synthesizing a zeolite cage having a final pore size of between about 2.9 Å and about 3.5 Å or reducing the size of pores in the zeolite cage by a post treatment selected from chemical vapour deposition, chemical liquid deposition, cation exchange and combinations thereof.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

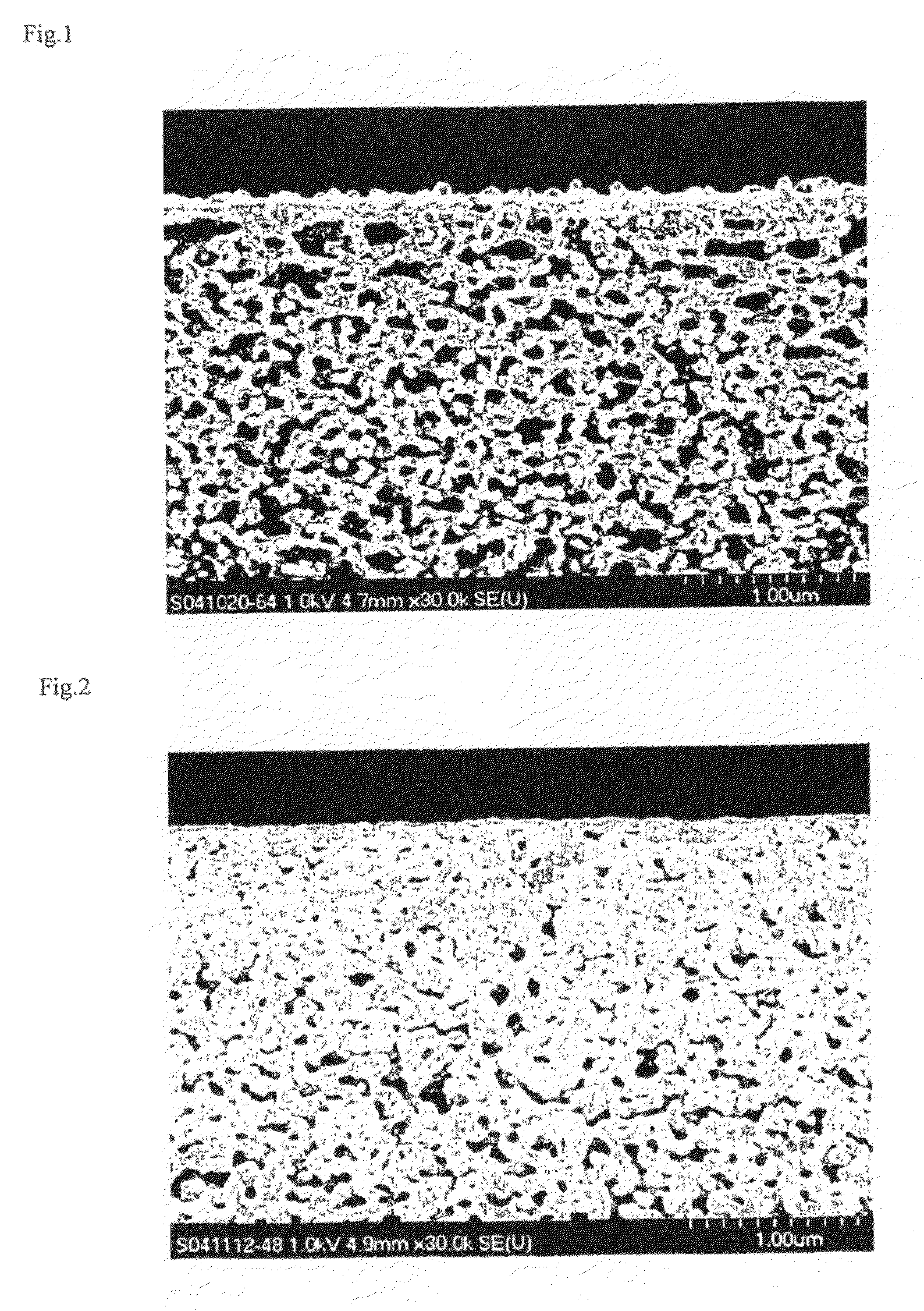

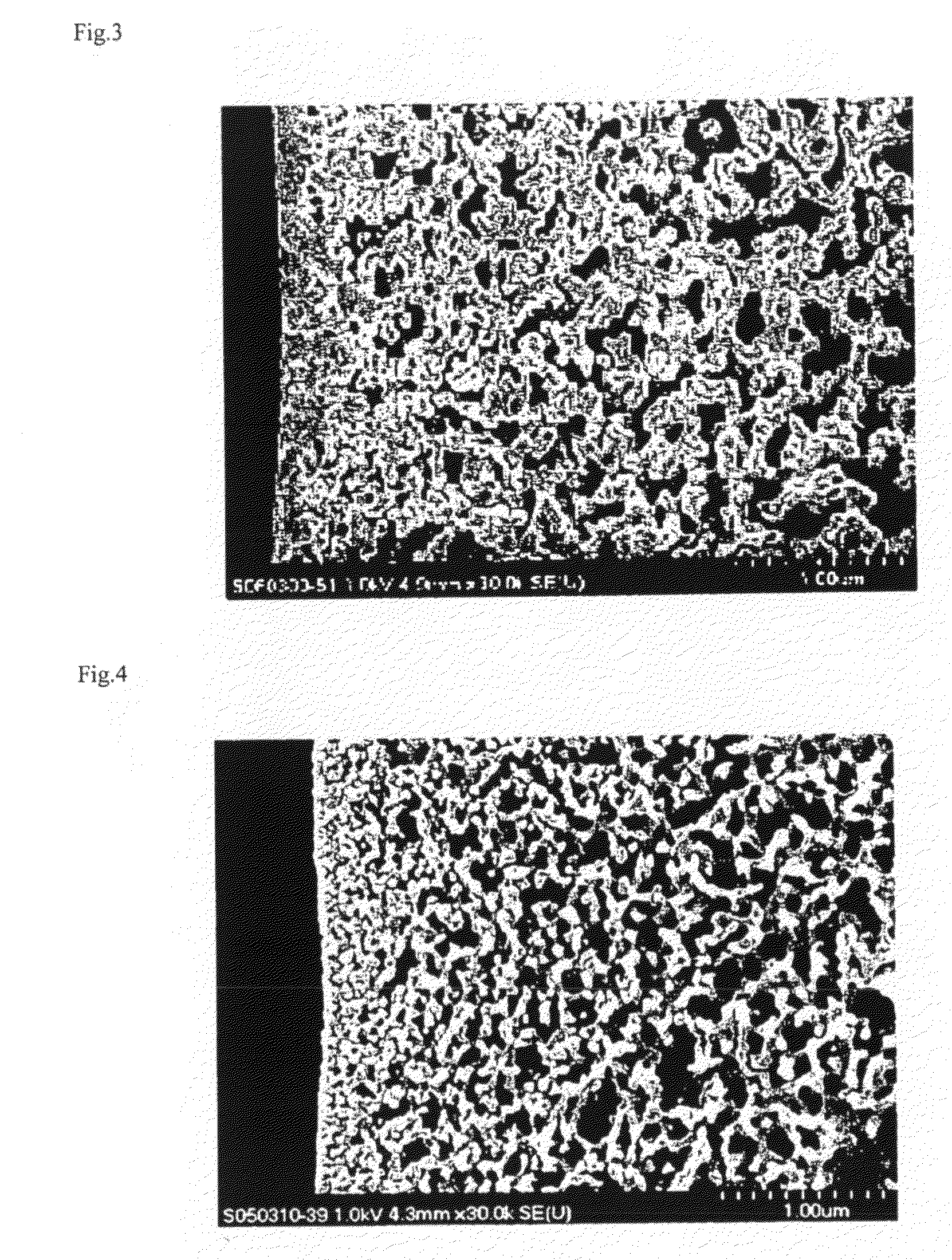

Separation Membrane for Use in Treatment of Liquid Comprising Aromatic Ether Polymer Hydrophilized with Hydrophilizing Agent

InactiveUS20090127186A1Less deteriorationSmall average pore sizeMembranesSemi-permeable membranesChemistryHydrophilization

[Problems] To provide a novel hydrophilized separation membrane for use in the treatment of a liquid, which comprises an aromatic ether polymer, is less likely to be degraded by sterilization with a high energy ray and has a controlled pore size and a high water permeability.[Means for Solving Problems] A porous separation membrane for use in the treatment of a liquid which is produced by a wet film formation process using an aromatic ether polymer and a hydrophilizing agent. The separation membrane can be used for medical purposes or in a pharmaceutical of food.

Owner:ASAHI KASEI KK

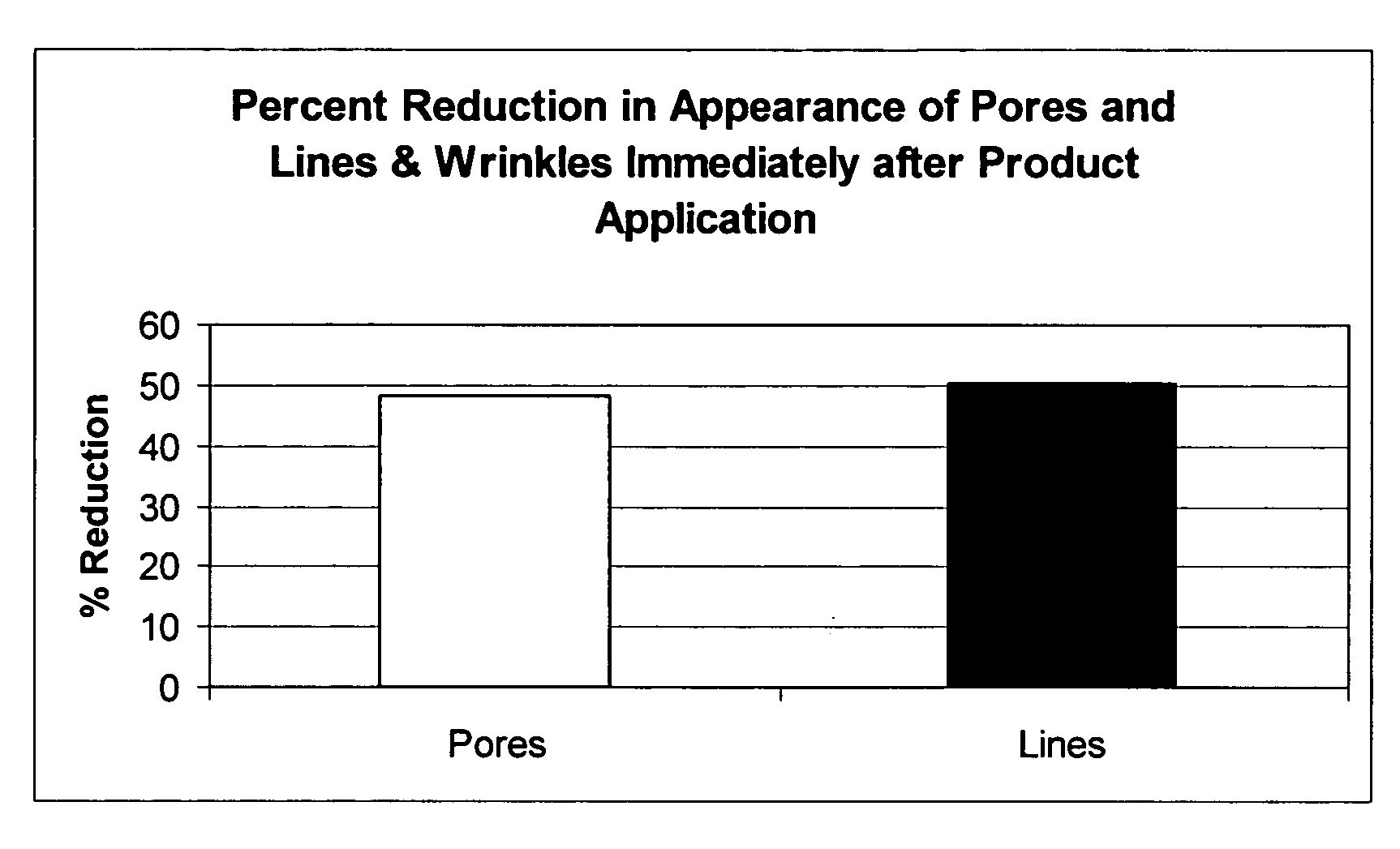

Cosmetic composition for diminishing the appearance of lines and pores

InactiveUS20060257346A1Smoother and more youthful appearanceReduce appearanceCosmetic preparationsHair cosmeticsWrinkle skinCore component

A cosmetic composition for reducing the appearance of lines, wrinkles and the size of pores in the skin is provided. The composition comprises a silica component, a silicon resin-coated elastomeric core component, and a cosmetic patch component, comprising algin / serine / atelocollagen, in a cosmetically acceptable aqueous vehicle.

Owner:ELC MANAGEMENT LLC

High temperature resistance basalt fiber composite filter material and preparation method thereof

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

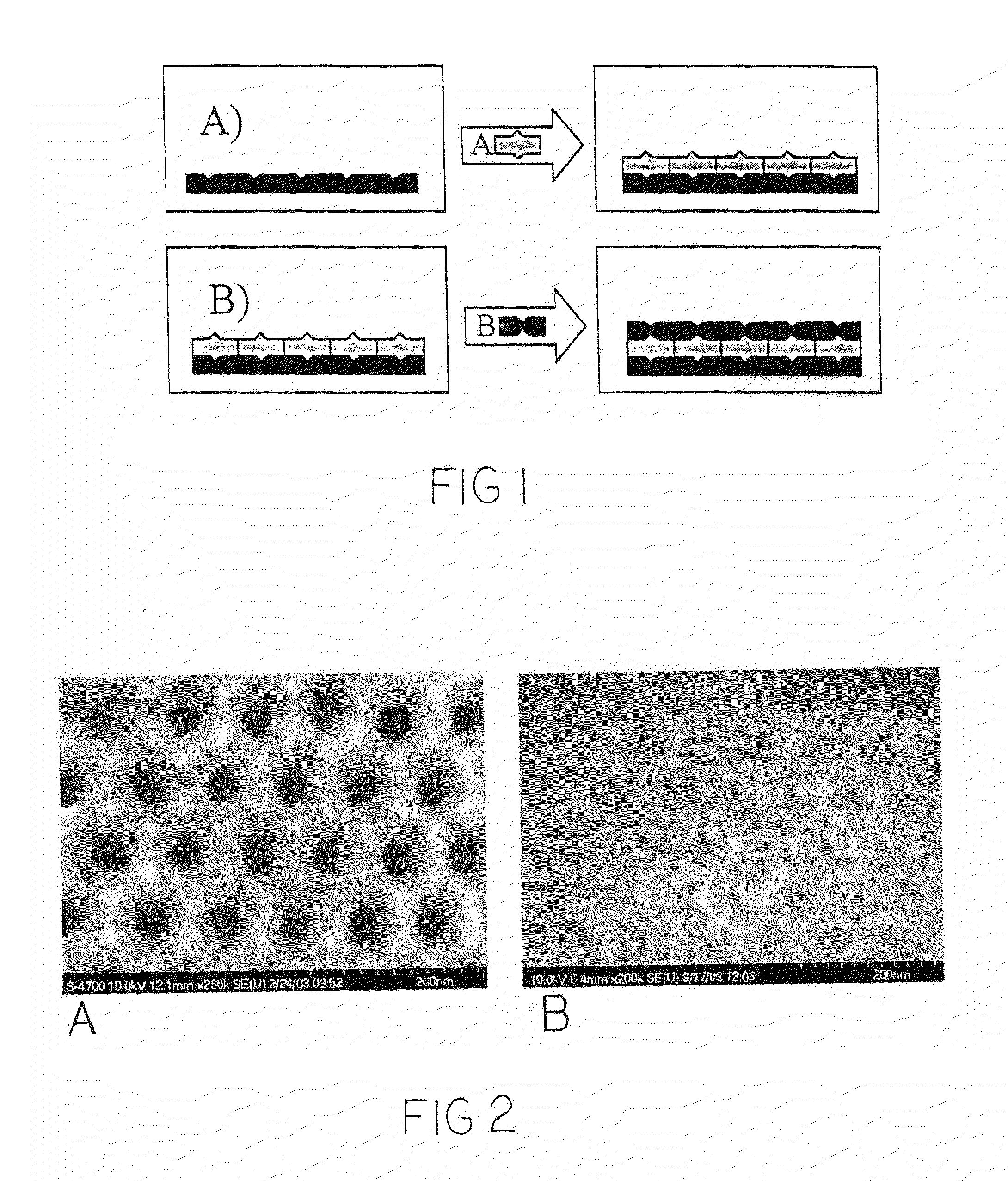

Catalytic nanoporous membranes

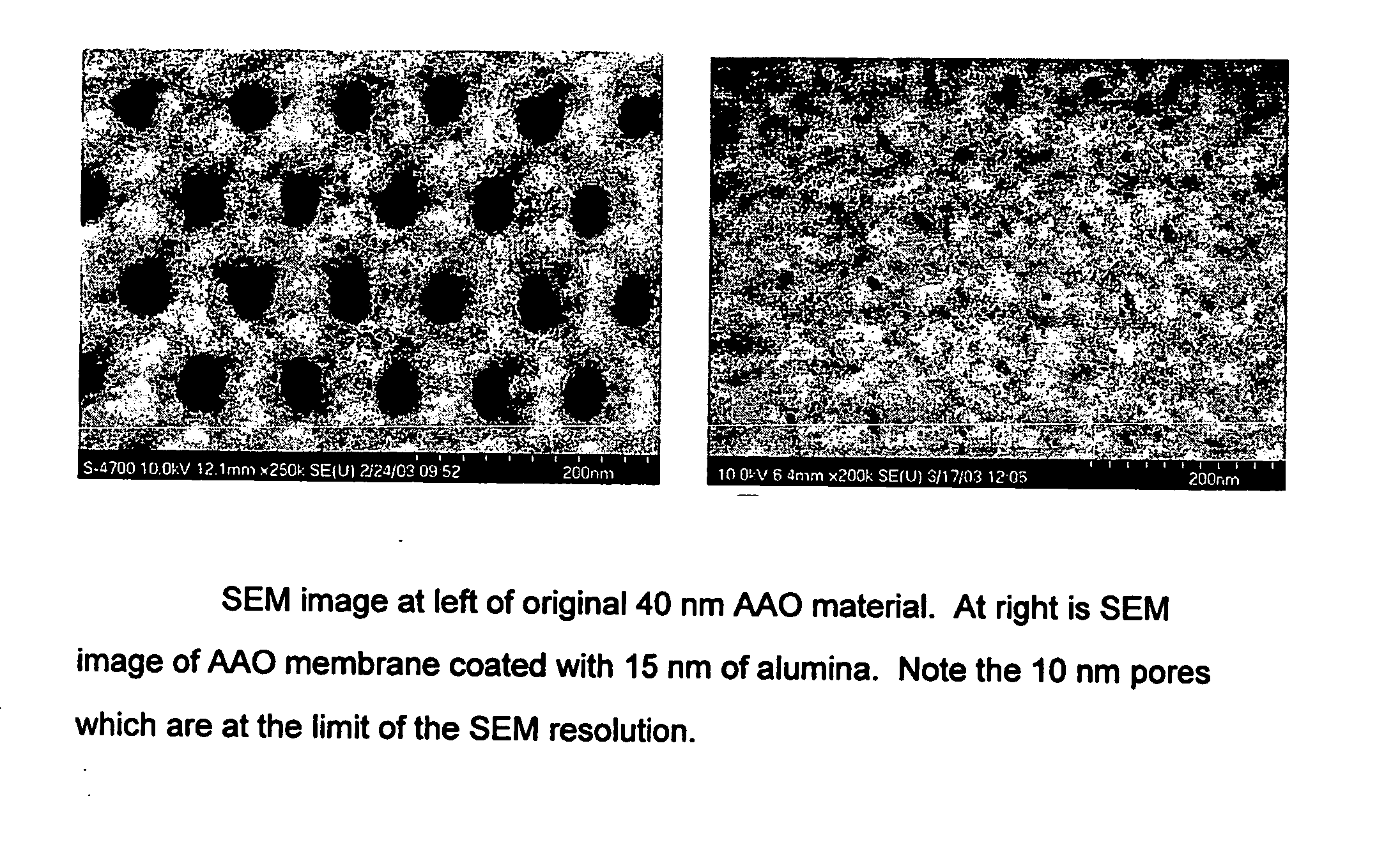

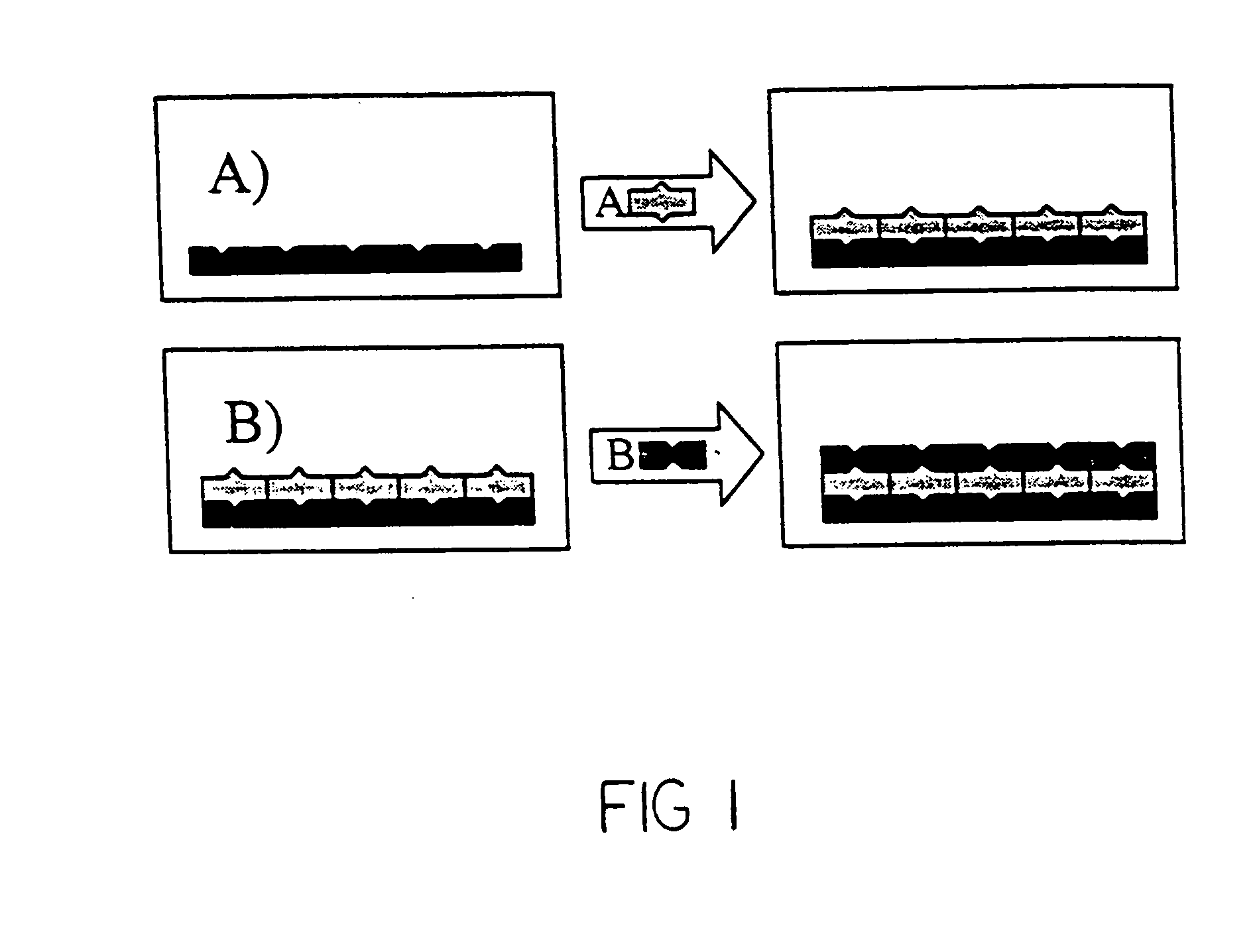

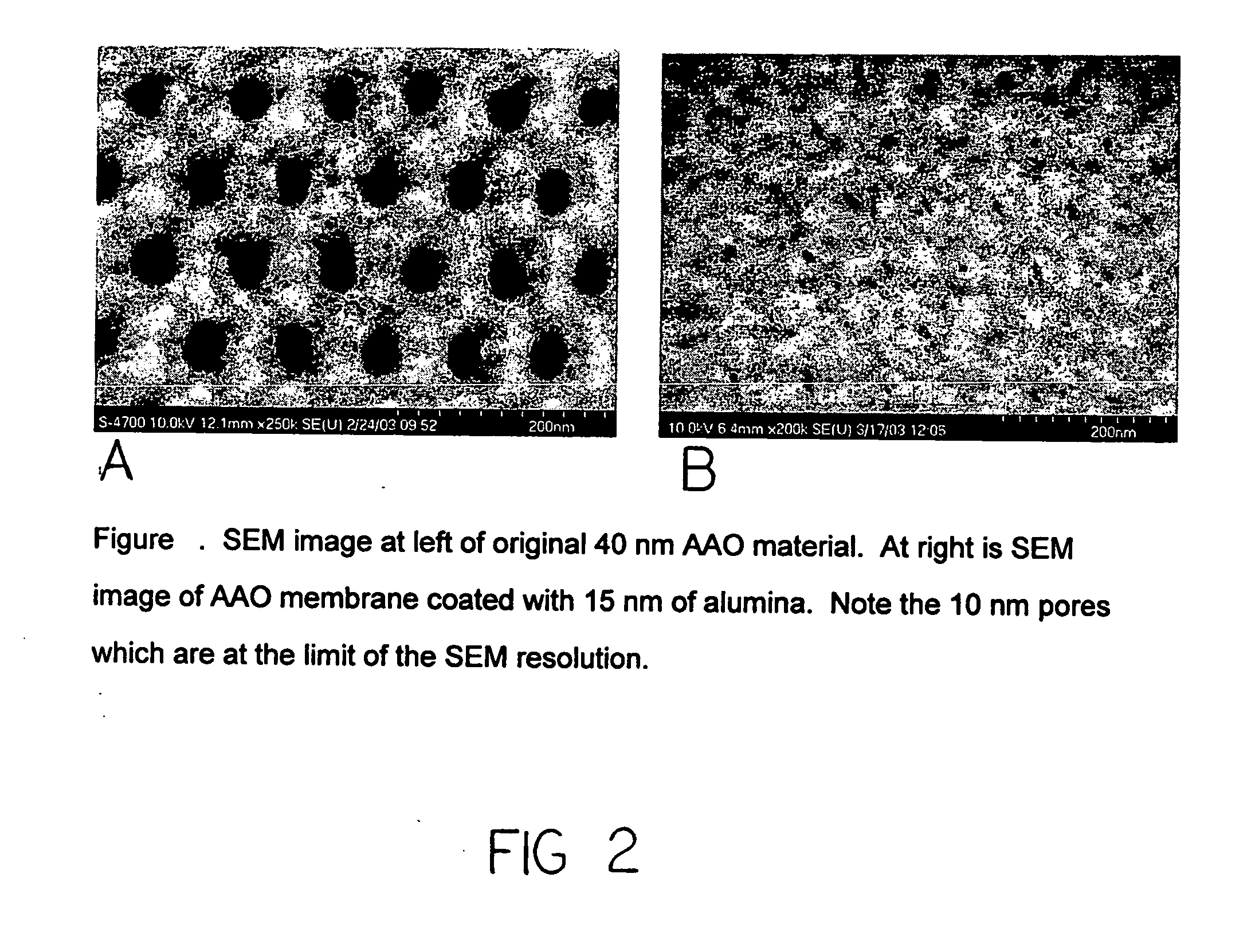

InactiveUS20050065028A1Unique catalyst environmentUniform coatingNanotechOther chemical processesPartial oxidationNanoporous membrane

A nanoporous catalytic membrane which displays several unique features including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity.

Owner:UCHICAGO ARGONNE LLC

Ceramic material of porous spinel, and preparation method

InactiveCN1915903ASmall average pore sizeHigh purityCeramic shaping apparatusCeramicwarePericlasePore distribution

This invention relates to a method for preparing porous spinel ceramic material. The method comprises: (1) mixing magnesite powder 10-90 wt.%, Al(OH)3 powder 10-90 wt.%, water 2-10 wt.% and adhesive 0-3 wt.%; (2) molding; (3) drying the green bodies at 110 deg.C for 4-24 h; (4) sintering at 1600-1800 deg.C, and keeping the temperature for 1-8 h. The porous spinel ceramic material mainly contains MgO and Al2O3, and has main crystal phase of periclase-spinel, spinel or spinel-corundum. The porous spinel ceramic material can be directly contacted with flame retardant magmesium and spinel materials, and is a lightweight heat-insulating flame retardant with uniform pore distribution and high strength.

Owner:WUHAN UNIV OF SCI & TECH

Melt-blown nonwoven fabric comprising ultra-fine fibers, production method therefor, and device for producing same

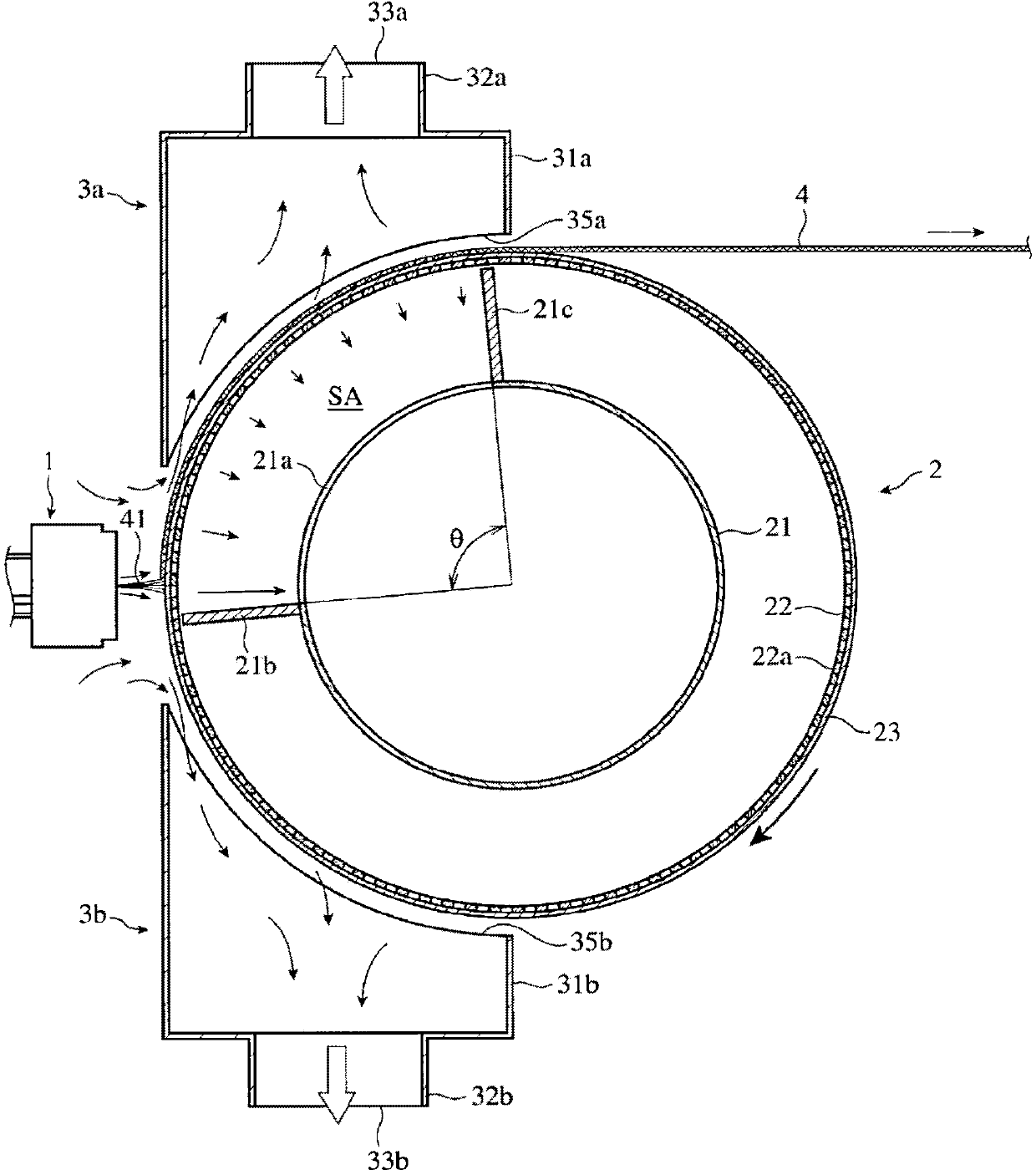

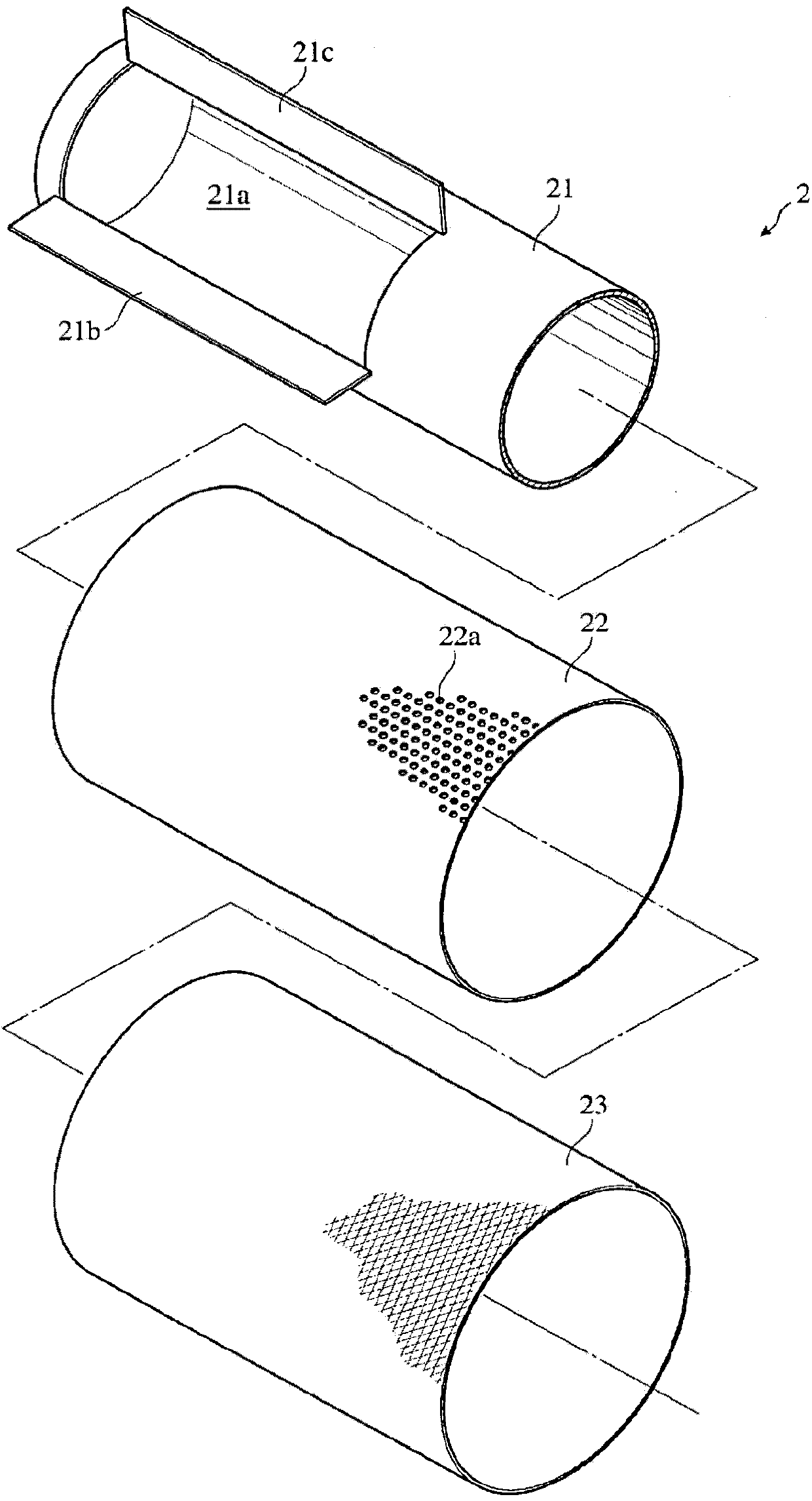

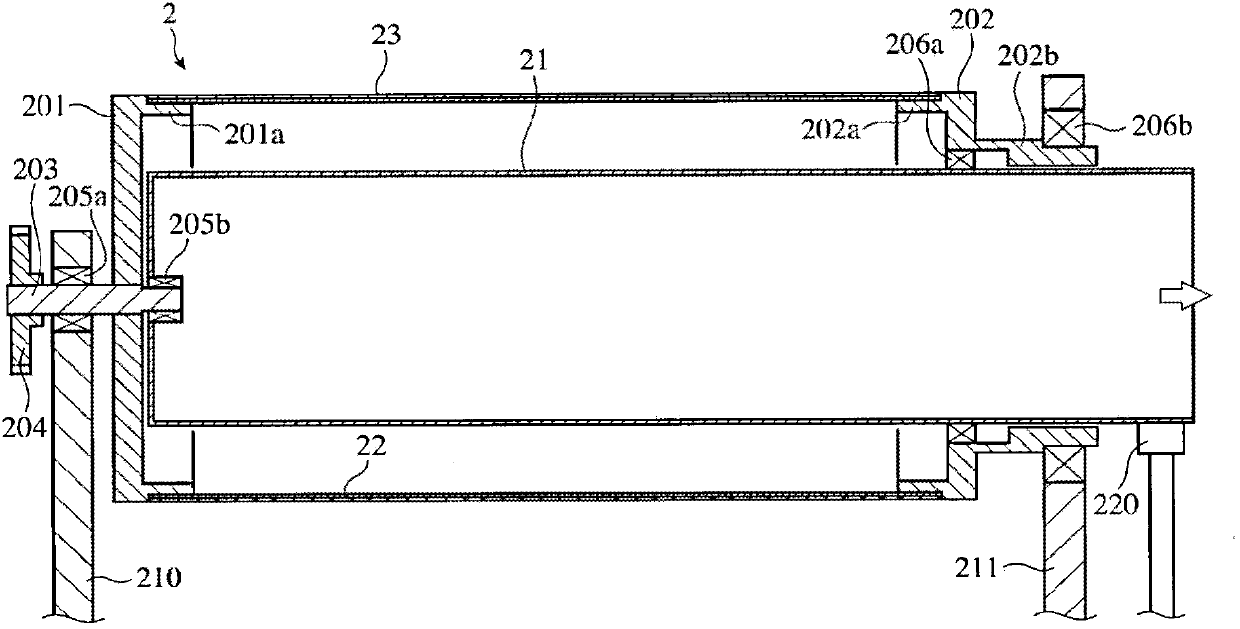

ActiveCN103380242AImprove the capture effectImprove ventilationMelt spinning methodsNon-woven fabricsPolymer scienceSpinning

An ultra-fine fiber melt-blown nonwoven fabric having excellent fine-particle trapping characteristics and air permeability is obtained by a melt-blowing method using: a die (1) having a plurality of ultra-fine spinning nozzles and an air nozzle; a rotating suction roll (2) having a porous outer peripheral surface and which sucks from the inside thereof; and a pair of upper and lower suction hoods (3a, 3b) covering the suction roll (2). In said melt-blow method: the interval between the die (1) and the suction roll (2) is set such that polymer fiber breakage or twisting is suppressed, within a range wherein the stretching of a molten polymer is completed and vibration of the obtained polymer fiber substantially does not occur; and the intervals between the outer peripheral surface of the suction roll (2) and the die-side end section of suction hoods (3a, 3b) are set such that fibers that have broken and attached or fused to the surface of the melt-blown nonwoven fabric can be removed by suction.

Owner:TAPYRUS

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum-magnesium series lightweight pouring material and manufacturing method thereof

The invention discloses a making method of aluminium-magnesium systemic light-quality casting material, which comprises the following steps: adopting 40-70% aluminium-magnesium porous ceramic particle and 0-20% aluminium-magnesium particle as aggregate; selecting 15-55% fine aluminium-magnesium powder, 2-15% pure calcium aluminate and 2-8% active alpha-aluminium micropowder as substrate; blending the mass; adding 8-25% water, 0.1-0.8% silica powder and 0-3% dehydragent to stir evenly; casting; vibrating; moulding; drying for 8-48h under 110 deg.c.

Owner:WUHAN UNIV OF SCI & TECH

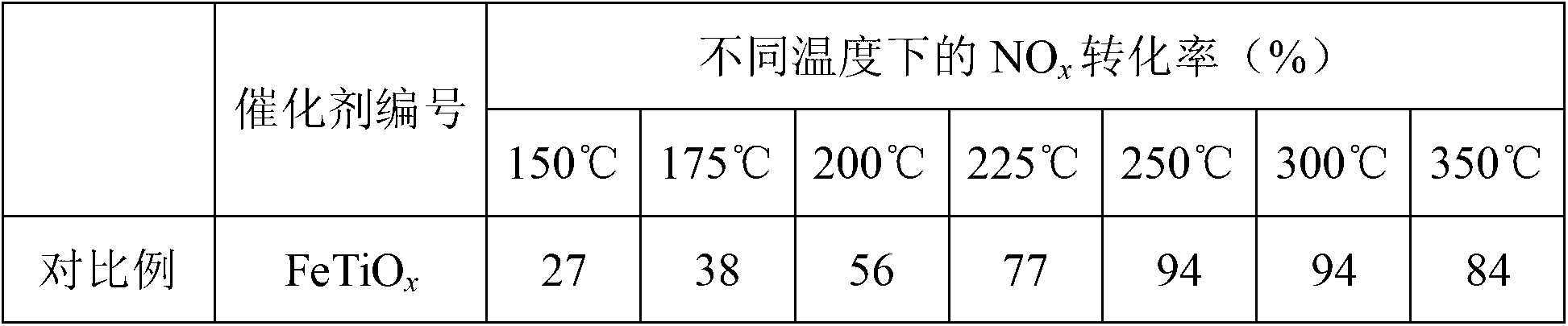

Ferrum-cerium-titanium composite oxide catalyst, preparation method and application of ferrum-cerium-titanium composite oxide catalyst

InactiveCN103071506AImprove purification efficiencyWith water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationCerium

The invention relates to a ferrum-cerium-titanium composite oxide catalyst. A chemical formula of the catalyst is FeCeaTiOx, wherein a is greater than 0 but less than or equal to 1.6. The invention further discloses a preparation method of the catalyst. The method comprises the following steps of (1) preparing and uniformly mixing an Fe source solution, a Ce source solution, and a Ti source solution to obtain a mixed solution, and (2) adding excessive urea precipitant in the mixed solution, precipitating Fe, Ce and Ti ions, conducting suction filtration on an obtained precipitation product, washing, drying, roasting, and obtaining the ferrum-cerium-titanium composite oxide catalyst. The low-temperature activity of the catalyst is improved obviously, the preparation method is simple and practicable, and the catalyst is used for a purification process of selective catalyctic reduction of nitric oxide (NH3-SCR).

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Micro closed-cell light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a micro closed-cell light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: by using 45-65 wt% of gamma-Al2O3 fine powder, 30-50 wt% of alpha-Al2O3 micropowder and 1-10 wt% of nano aluminum oxide micropowder as raw materials, adding water accounting for 40-80 wt% of the raw materials, and carrying out wet milling with a planet ball mill for 0.5-3 hours; putting the slurry subjected to wet milling in a mold, standing at room temperature for 12-24 hours, and stripping; and drying at 110-200 DEG C for 12-36 hours, and keeping the temperature at 1750-1900 DEG C for 1-8 hours to obtain the micro closed-cell light-weight corundum refractory aggregate. The micro closed-cell light-weight corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, low volume density, small average pore size, lower heat conductivity and high molten slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

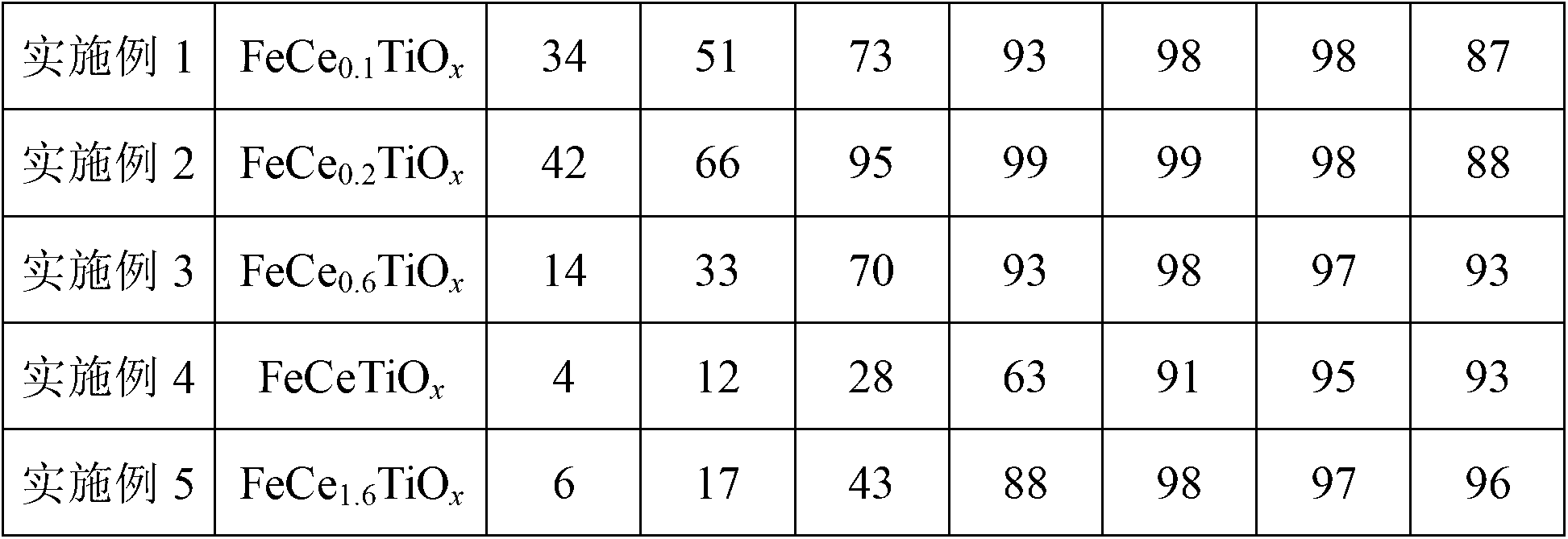

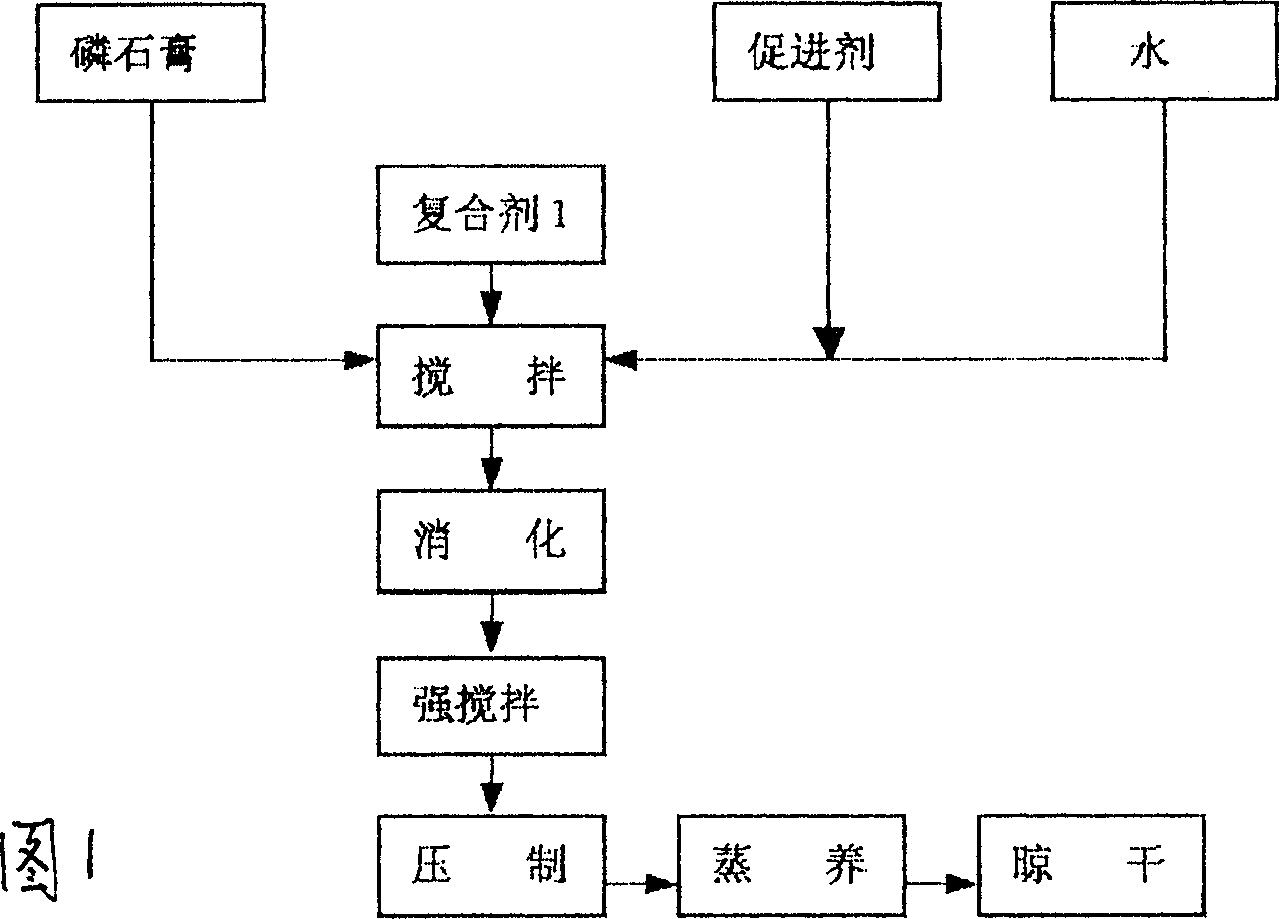

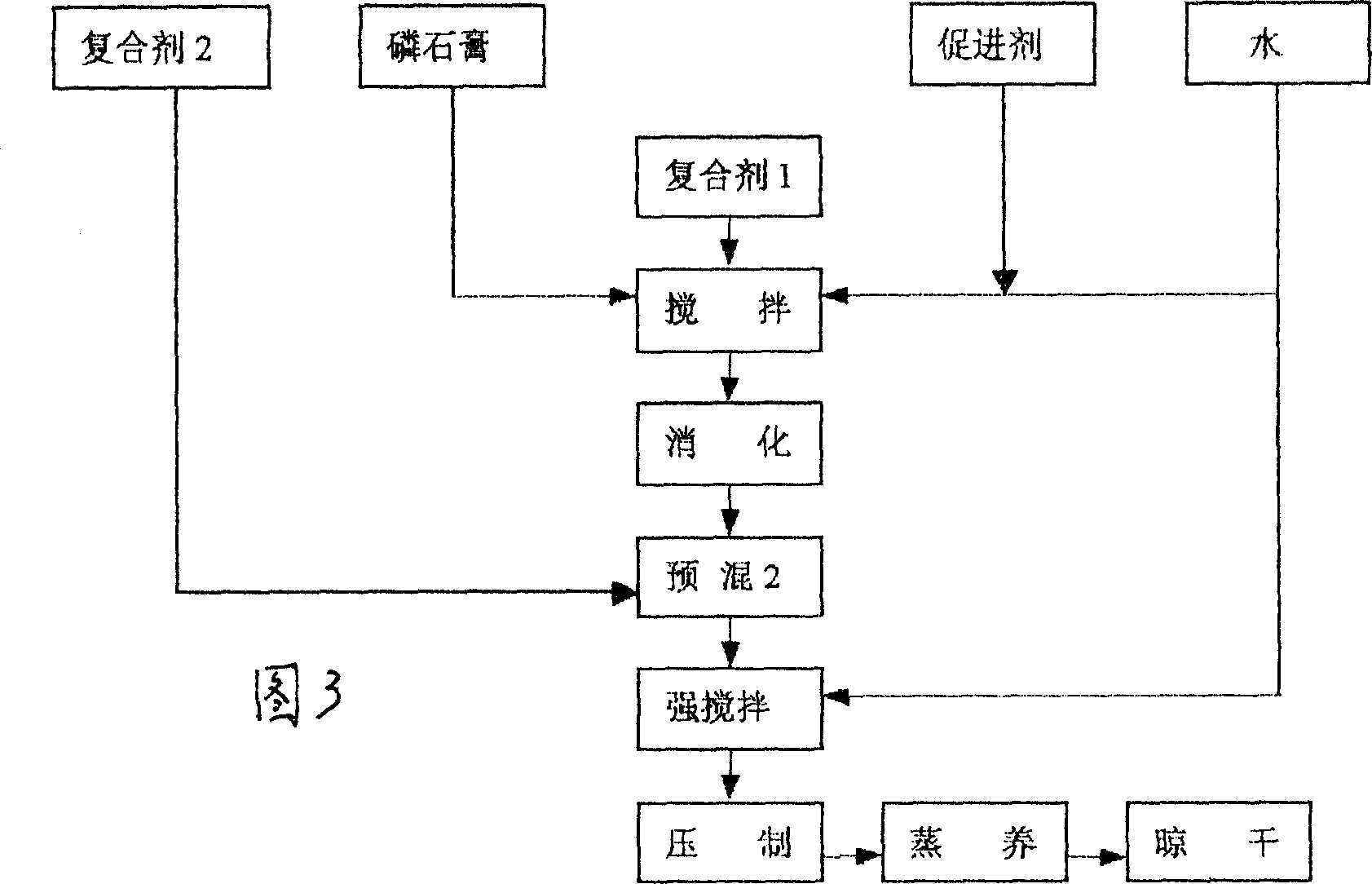

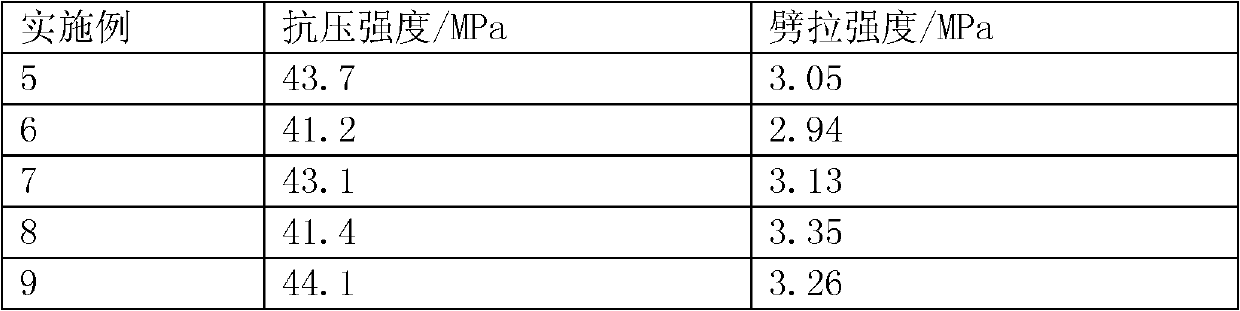

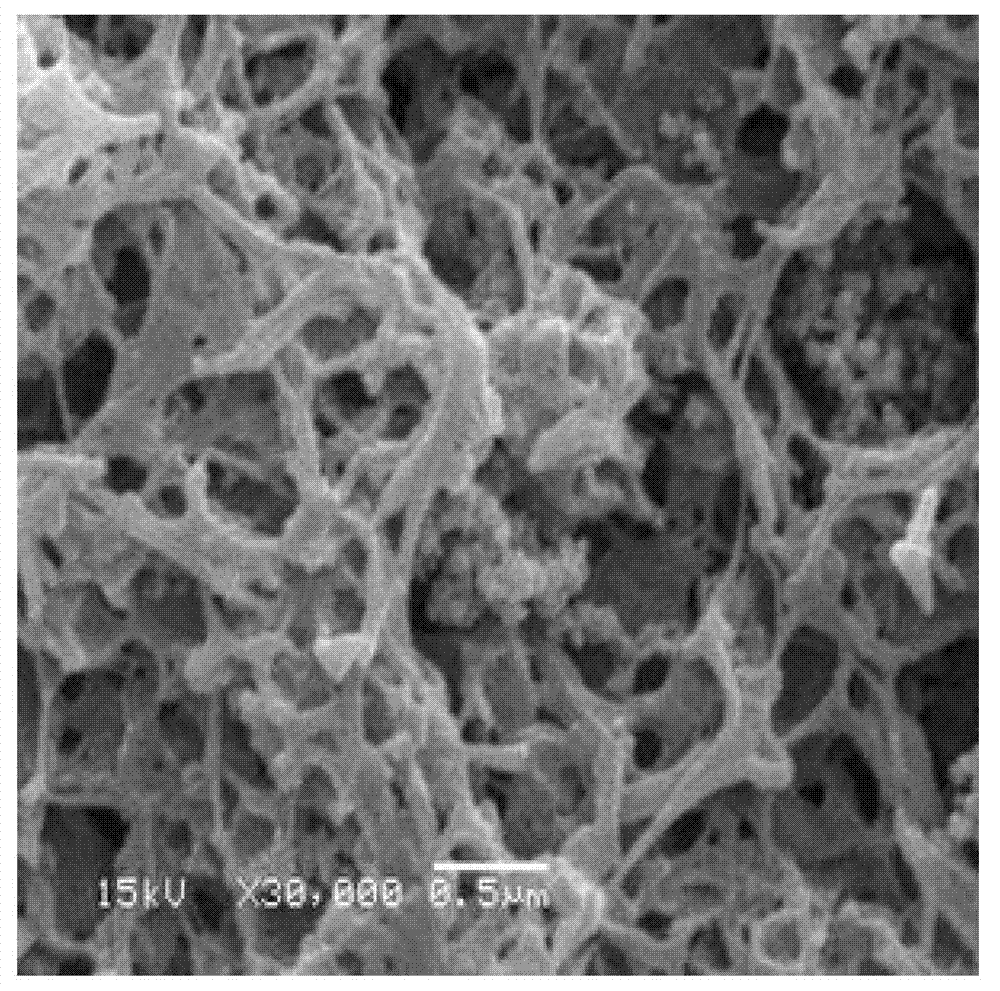

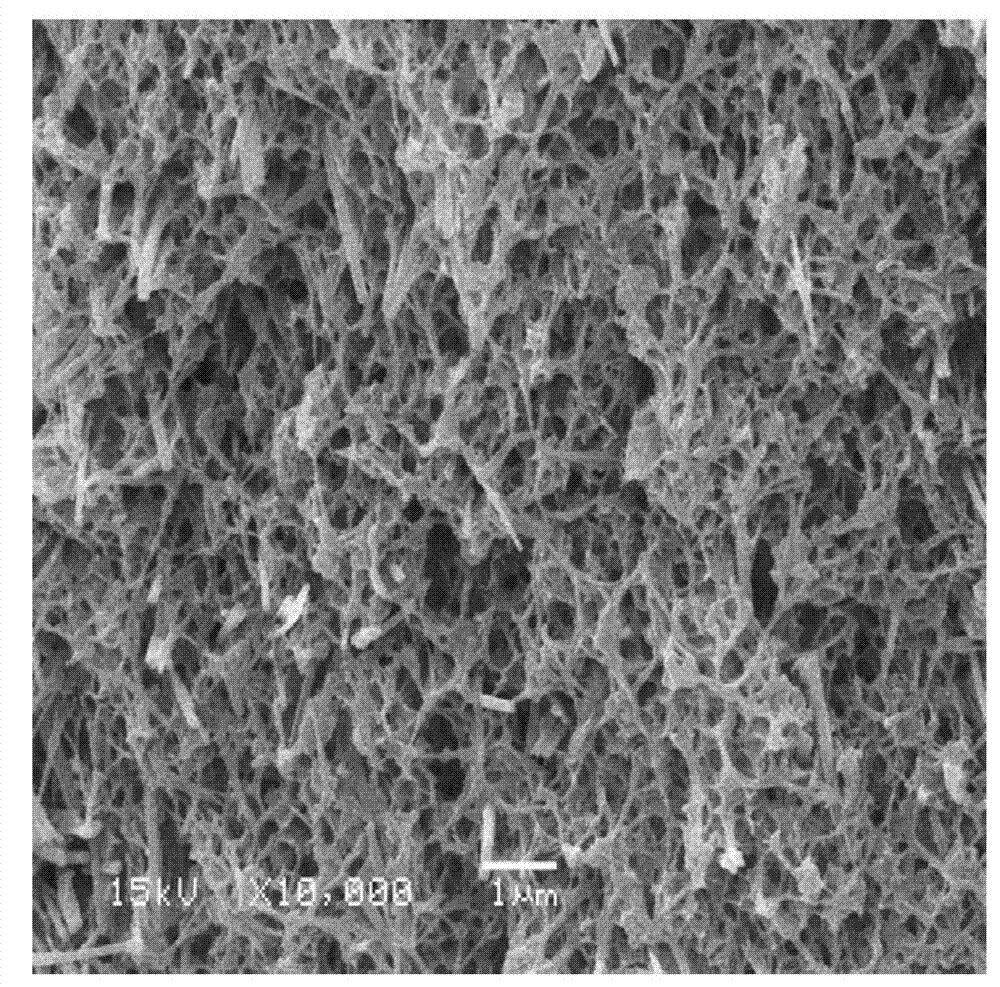

High-strength phosphogypoum building block and preparation method

InactiveCN1433989AHigh compressive strengthHigh strengthSolid waste managementSolid waste disposalBrickPhosphogypsum

The prsent invention relates to a high-strength phosphogypsum building block and its preparation method. The raw material component of said block mainly is waste material phosphogypsum produced in the course of production of phosphate fertilizer, and other raw material components includes non-activated compound agent, activated compound agent, accelerator and water. Its preparation method includes the following steps: primary mixing of raw materials, digestion reaction, mainly mixing, press-forming, steam-curing and standing for seasoning. Said block is high in compressino strength, low in unit weight and low in production cost.

Owner:SICHUAN UNIV

Lightweight micro closed cell magnesium-containing corundum refractory aggregate and preparation method thereof

The invention relates to lightweight micro closed cell magnesium-containing corundum refractory aggregate and a preparation method of the refractory aggregate. The method comprises the steps of taking 80-95wt% of gamma-Al2O3 fine powder, 1-10wt% of nano alumina powder and 1-10wt% of magnesium oxide micropowder as raw materials, adding water accounting for 40-70wt% of the raw materials, mixing, wet-milling with a planet ball mill for 0.5-3h to form slurry, putting the slurry in a mold, placing under a room temperature condition for 12-24h, removing the mold, drying a demolded green body for 12-36h at 110-200 DEG C, and carrying out heat preservation for 1-8h at 1750-1900 DEG C to form the lightweight micro closed cell magnesium-containing corundum refractory aggregate. The prepared lightweight micro closed cell magnesium-containing corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, lower volume density, small mean pore size, lower heat conductivity, and strong washout and slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Modified coarse aggregate, fiber nano recycled concrete prepared from modified coarse aggregate and preparation method of fiber nano recycled concrete

The invention belongs to the technical field of building materials, and particularly relates to a modified coarse aggregate with improved performance, excellent-performance fiber nano recycled concrete prepared from the modified coarse aggregate and a preparation method of the fiber nano recycled concrete. The preparation method includes the following steps that waste concrete test blocks and waste sintered bricks are crushed and screened to obtain a recycled coarse aggregate, and the recycled coarse aggregate is dried after being soaked with a nano silica sol to obtain a modified concrete coarse aggregate and a modified brick coarse aggregate; water, cement, fine aggregate, the modified concrete coarse aggregate, the modified brick coarse aggregate and polyvinyl alcohol fiber are preparedin proportion; the modified brick coarse aggregate, the modified concrete coarse aggregate, the cement and the fine aggregate are put into a stirrer and pre-stirred, the polyvinyl alcohol fiber is evenly dispersed and added, and dry mixing is carried out; water and a water reducer are sequentially added into the stirrer and stirred until the mixture is evenly mixed. Construction waste is effectively utilized to prepare the recycled concrete with certain performance indexes.

Owner:ZHENGZHOU UNIV

Porous mullite ceramic materials and method for preparing same

InactiveCN1884193AHigh porosityHigh strengthCeramic shaping apparatusCeramicwareChemical compositionMetallurgy

The invention discloses a porous mullite ceramic material and preparing method, which comprises the following steps: dispensing 10-50 percent coal gangue powder, 50-90 percent Al (OH) 3, 2-10 percent water and 0-10 percent addictive; stirring; moulding; drying the mould at 110 deg.c for 4-24 h; sintering at 1400-1600 deg.c for 1-8 h. The chemical component of product is SiO2 and Al2O3, wherein the main crystal phase is mullite or mullite-alumina, which can be high-strength and light-quality insulating flame-proof material.

Owner:WUHAN UNIV OF SCI & TECH

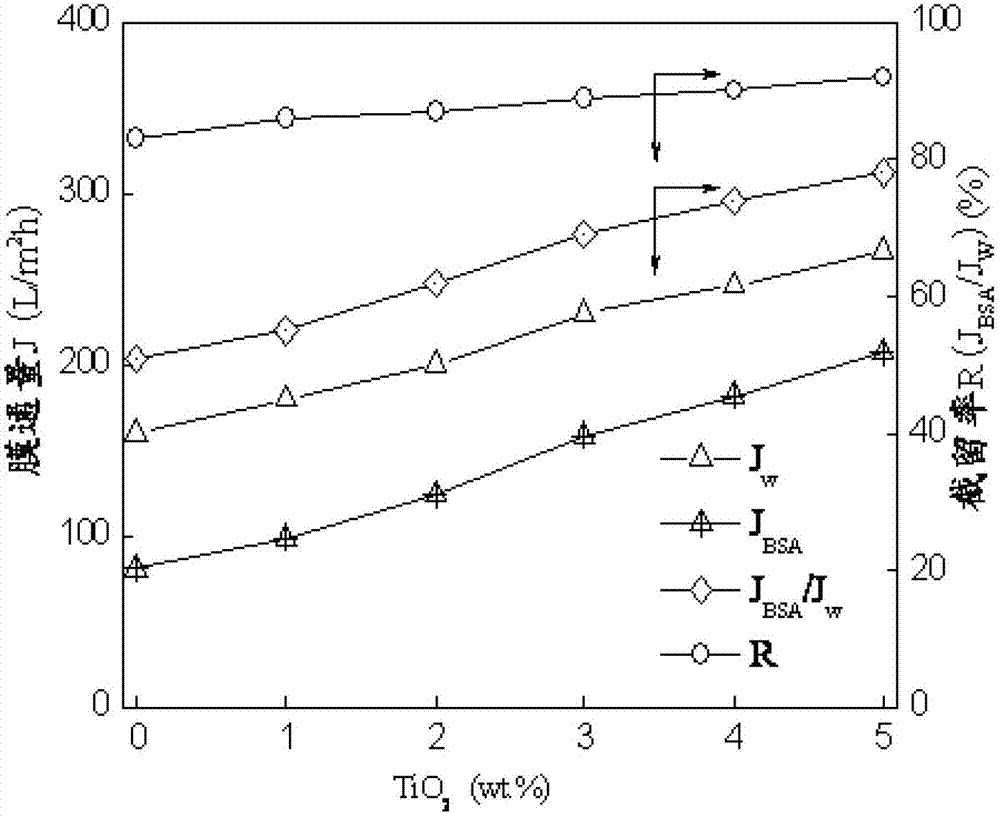

Novel polyvinylidene fluoride film as well as preparation method and application thereof

InactiveCN102728240AEasy reunionEasy to drainSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOrganic solventNanowire

The invention relates to a titanium oxide nanowire modified polyvinylidene fluoride separation film and a preparation method of the film. The titanium oxide nanowire modified polyvinylidene fluoride separation film comprises polyvinylidene fluoride (PVDF) accounting for 18-25wt% of the total mass, organic solvent accounting for 70-80wt% of the total mass, porogen accounting for 3-5wt% of the total mass, dispersing agent accounting for 0.1-1wt% of the total mass and titanium oxide nanowire accounting for 1-5wt% of PVDF. The modified film solves the problem that the PVDF-TiO2 nanoparticles are easily agglomerated and can easily run away, and has stability and durability.

Owner:CHANGZHOU UNIV

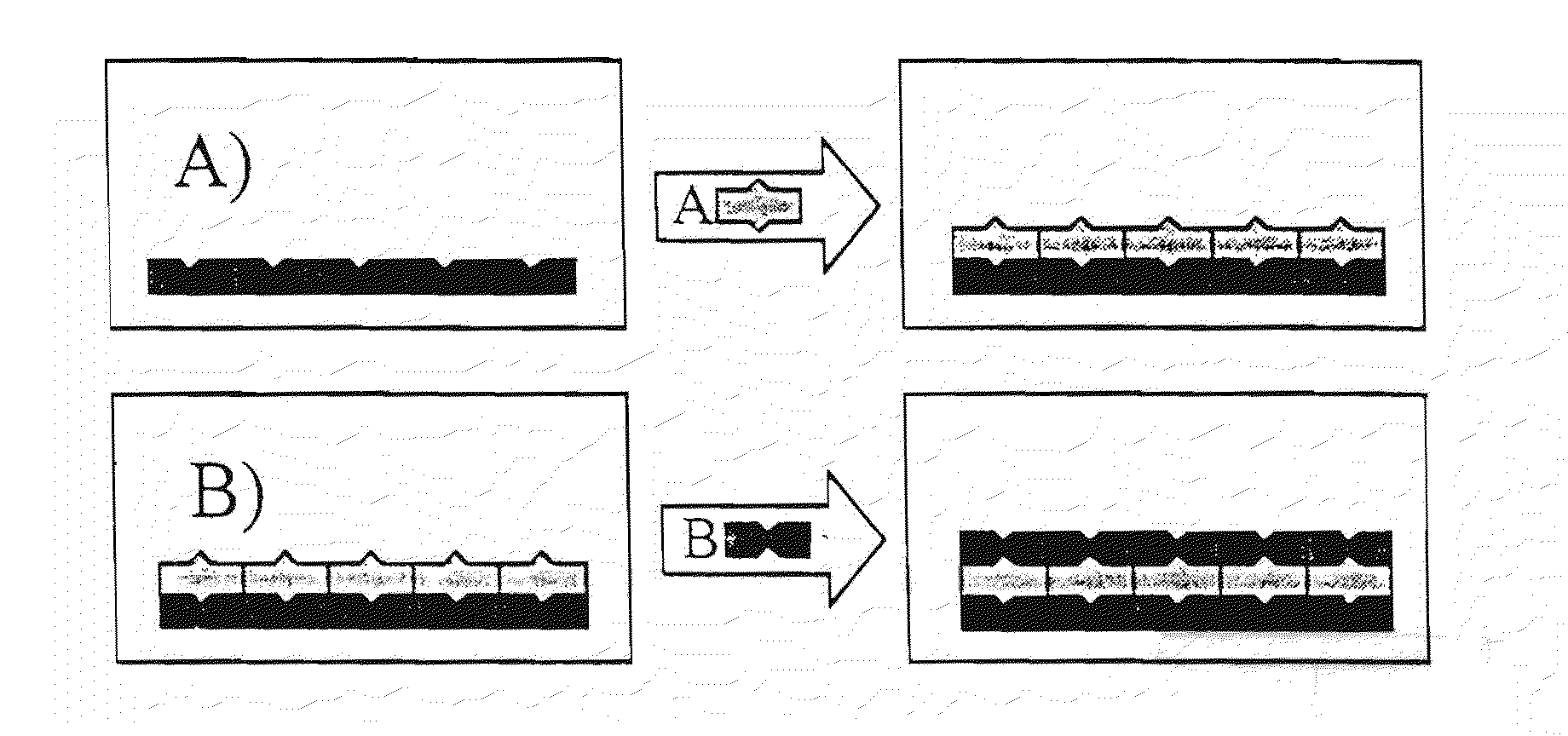

Catalytic nanoporous membranes

InactiveUS20100075827A1Unique catalyst environmentUniform coatingOther chemical processesCatalyst activation/preparationPartial oxidationGas phase

A nanoporous catalytic membrane which displays several unique features Including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity. Also provided is a method for producing a catalytic membrane having flow-through pores and discreet catalytic clusters adhering to the inside surfaces of the pores.

Owner:UCHICAGO ARGONNE LLC

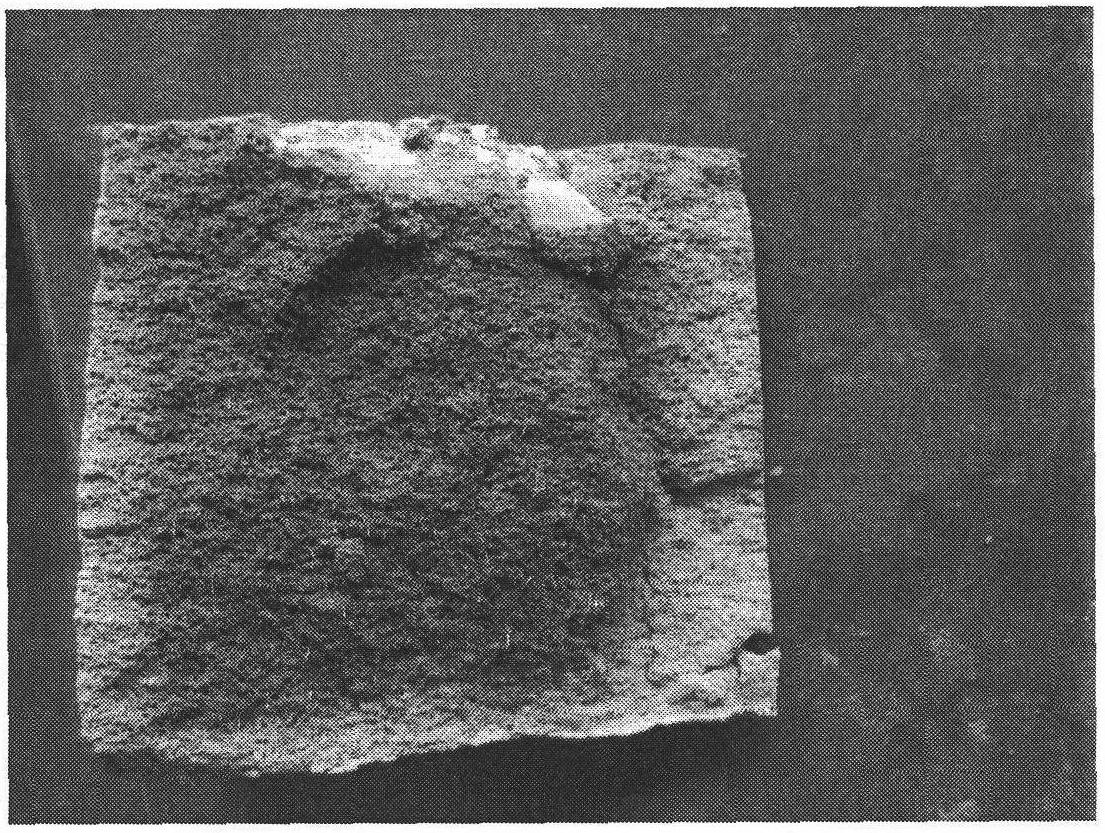

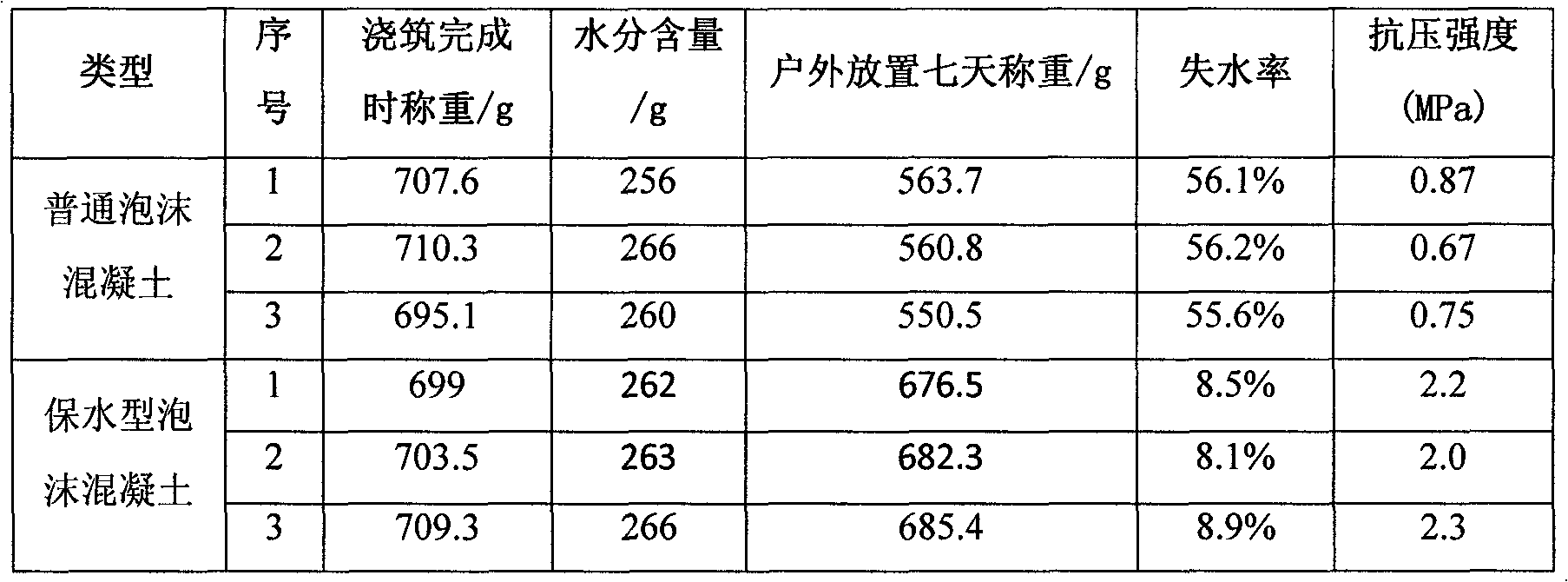

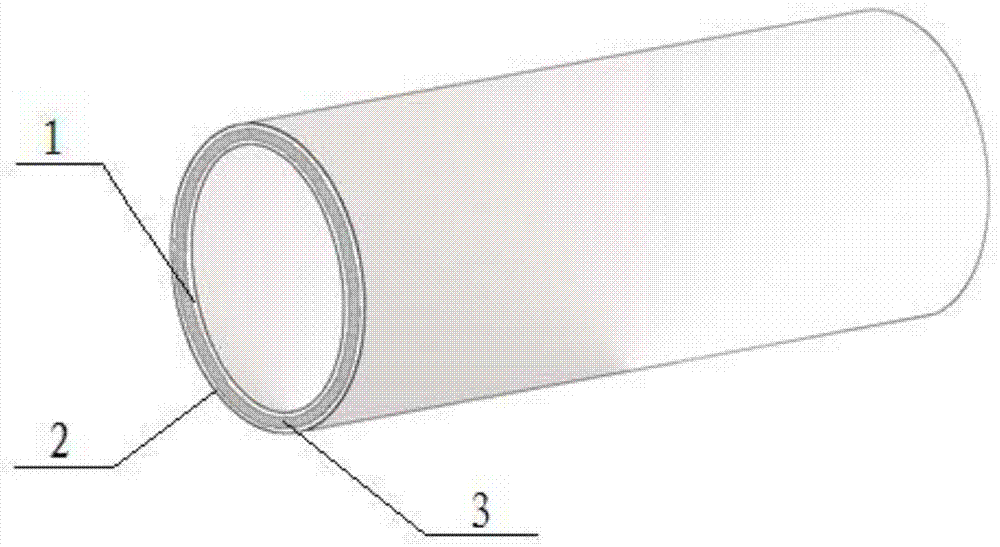

Foaming agent for preparation of Water-retaining foam concrete

InactiveCN102659445AEnhanced interactionHigh mechanical strengthCeramicwareWater useMaterials science

The invention provides a foaming agent for preparation of water-retaining foam concrete. The foaming agent comprises, by weight percent, 10-30% of anionic surfactant, 5-10% of foam stabilizer, 1-10% of water-retaining agent, and 50-80% of water. The anionic surfactant, the foam stabilizer, the water-retaining agent and the water are added into a reaction container according to the specified weight percentage, the temperature is adjusted to 50-90 DEG C for reaction for 1-3 hours, and uniform and transparent liquid is obtained. The water-retaining foam concrete made of the foaming agent has outstanding water retaining effect and unchanged mechanical strength, and is especially suitable for placement of foam concrete in areas with difficulty in water use or subsequent foam concrete maintenance.

Owner:HUBEI UNIV

Method for preparing composite ceramic membrane on surface of magnesium alloy intravascular stent by micro-arc oxidation

InactiveCN103882497AFast growthImprove fracture toughnessAnodisationStentsElectrolytic agentMicro arc oxidation

The invention discloses a method for preparing a composite ceramic membrane on the surface of a magnesium alloy intravascular stent by micro-arc oxidation. The method comprises the following steps: 1) preparing an electrolyte; 2) performing micro-arc oxidation treatment by taking the magnesium alloy intravascular stent as an anode, taking a stainless steel plate as a cathode and taking a stainless steel wire with the surface coated with an insulating plastic membrane as an auxiliary cathode so as to in-situ grow a layer of uniform composite ceramic membrane on the surface of the magnesium alloy intravascular stent. Micron-grade holes which are uniformly distributed in the prepared composite ceramic membrane can be used as carriers for directly transporting a medicament to a lesion part in a tubular cavity. When the composite ceramic membrane is not subjected to hole sealing post-treatment, the resistance to corrosion of neutral NaCl salt mist can be up to 500h, the resistance to corrosion of a simulated body fluid environment can be up to 2400h, and the fracture toughness is obviously improved. The preparation process disclosed by the invention has the advantages of high efficiency and energy conservation.

Owner:CHANGAN UNIV

EVA (ethylene vinyl acetate) rubber-plastic composite foaming material used for sole and preparation method

The invention belongs to the technical field of rubber-plastic composite sole materials and provides an EVA (ethylene vinyl acetate) rubber-plastic composite foaming material used for a sole and a preparation method. The EVA rubber-plastic composite foaming material is prepared from raw materials in parts by weight as follows: 59.8-71.9 parts of an EVA copolymer, 10-15 parts of high styrene rubber, 5-10 parts of atactic polypropylene, 4-8 parts of tetrapod-like zinc oxide whiskers, 2-4 parts of nylon 66 staple fiber, 3-5 parts of calcium carbonate, 2-4 parts of a tungsten-cobalt alloy, 0.5-1 part of a crosslinking agent, 0.5-1 part of a foaming agent, 0.3-0.7 parts of zinc oxide, 0.3-0.5 parts of stearic acid and 0.5-1 part of an anti-ageing agent. The prepared rubber-plastic composite foaming material effectively overcomes the defects that EVA foaming materials easily slide, get hard at the low temperature and are not stab-proof, has high porosity and smaller average pore sizes whilehaving higher elasticity, strength, slip resistance and wear resistance, is light and breathable to wear and can be widely used in the sole materials.

Owner:广东恒骏工贸发展有限公司

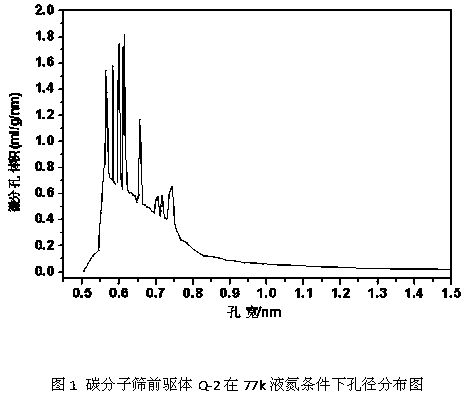

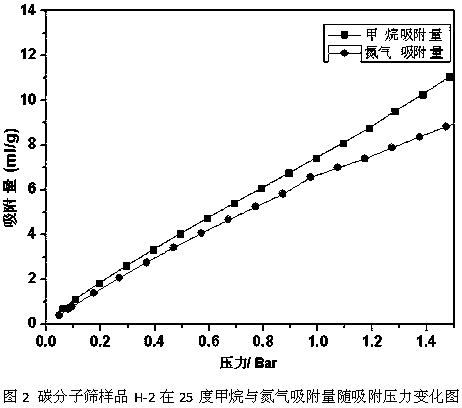

Preparation method of phenol-formaldehyde resin-based carbon molecular sieve for adsorbing and separating methane and nitrogen gas

ActiveCN109179369AReduce lossesReduce the amount of adsorptionNitrogen purification/separationCarbon preparation/purificationCarbonizationNitrogen gas

The invention discloses a preparation method of a phenol-formaldehyde resin-based carbon molecular sieve for adsorbing and separating methane and nitrogen gas. The preparation method mainly includes the following steps: (1) mixing phenol-formaldehyde resin waste, coal tar, water and a pore-forming agent in a certain proportion evenly, carrying out strip extrusion moulding and drying at low temperature; (2) carbonizing at high temperature under the protection of nitrogen gas to prepare a pre-deposition matrix with suitable pore size; and (3) directly introducing a methane depositing agent and depositing without cooling of the matrix, and adjusting the pore size of the matrix to prepare the carbon molecular sieve sample. The raw materials have low cost, carbonization and deposition are integrated in the preparation process, the energy loss is reduced, more energy is saved, the influence of heat on the pore size change of the matrix during carbonization cooling and deposition heating is reduced, and the pore size is relatively stable; the pore size of the matrix prepared by the method is small, the deposition time is reduced, and the sample after deposition has the adsorption capacityof nitrogen gas of 6.5-7.5 ml / g and the adsorption capacity of methane of 7-10 ml / g at 25 DEG C / 1 atmospheric pressure.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

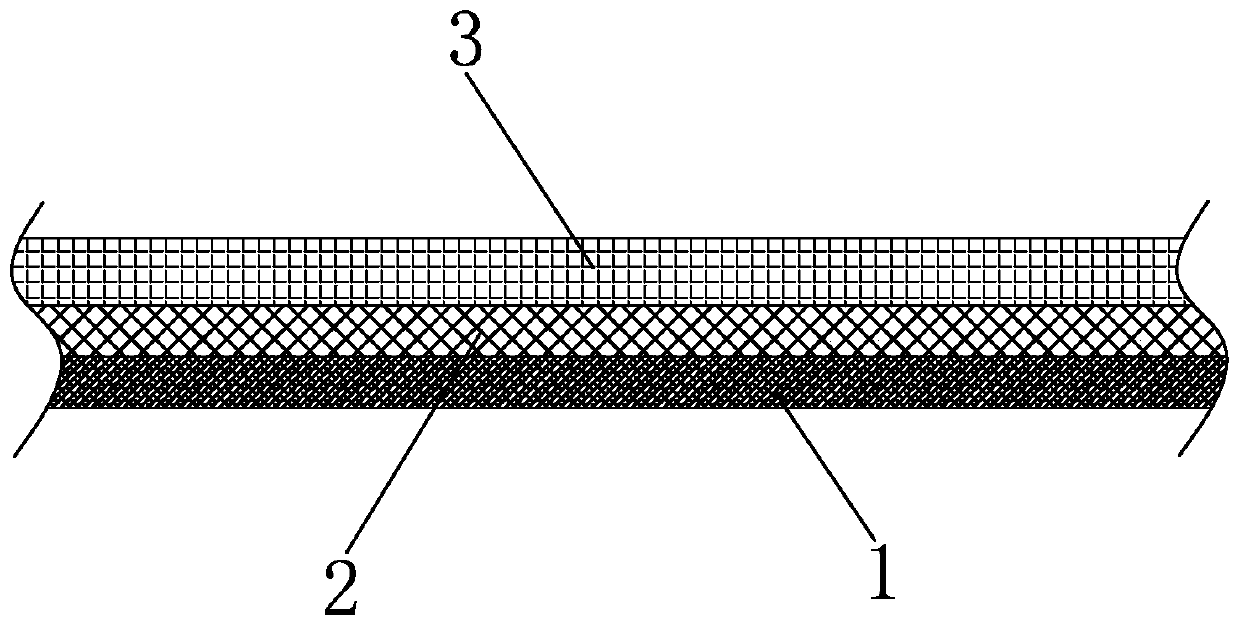

Highly-waterproof highly-breathable nanofiber membrane and preparation method thereof

PendingCN110258021AImprove yieldGood flexibilityLiquid repellent fibresAbrasion resistant fibresPolyvinyl butyralFiber

The invention discloses a highly-waterproof highly-breathable nanofiber membrane and a preparation method thereof. The highly-waterproof highly-breathable nanofiber membrane comprises a PVB electrospun membrane, a PVDF electrospun membrane and a FPU electrospun membrane which are stacked and composited from inside to outside, the PVB electrospun membrane is formed by interweaving polyvinyl butyral nanofiber of 150-400nm in average diameter, the PVDF electrospun membrane is formed by interweaving polyvinylidene fluoride nanofiber of 400-600nm in average diameter, and the FPU electrospun membrane is formed by interweaving fluorosilane modified polyurethane nanofiber of 200-300nm in diameter. The preparation method is simple and reasonable in process and low in manufacturing cost, and the highly-waterproof highly-breathable nanofiber membrane prepared by the method is high in strength, waterproofness and one-way breathability.

Owner:江苏三丰特种材料科技有限公司

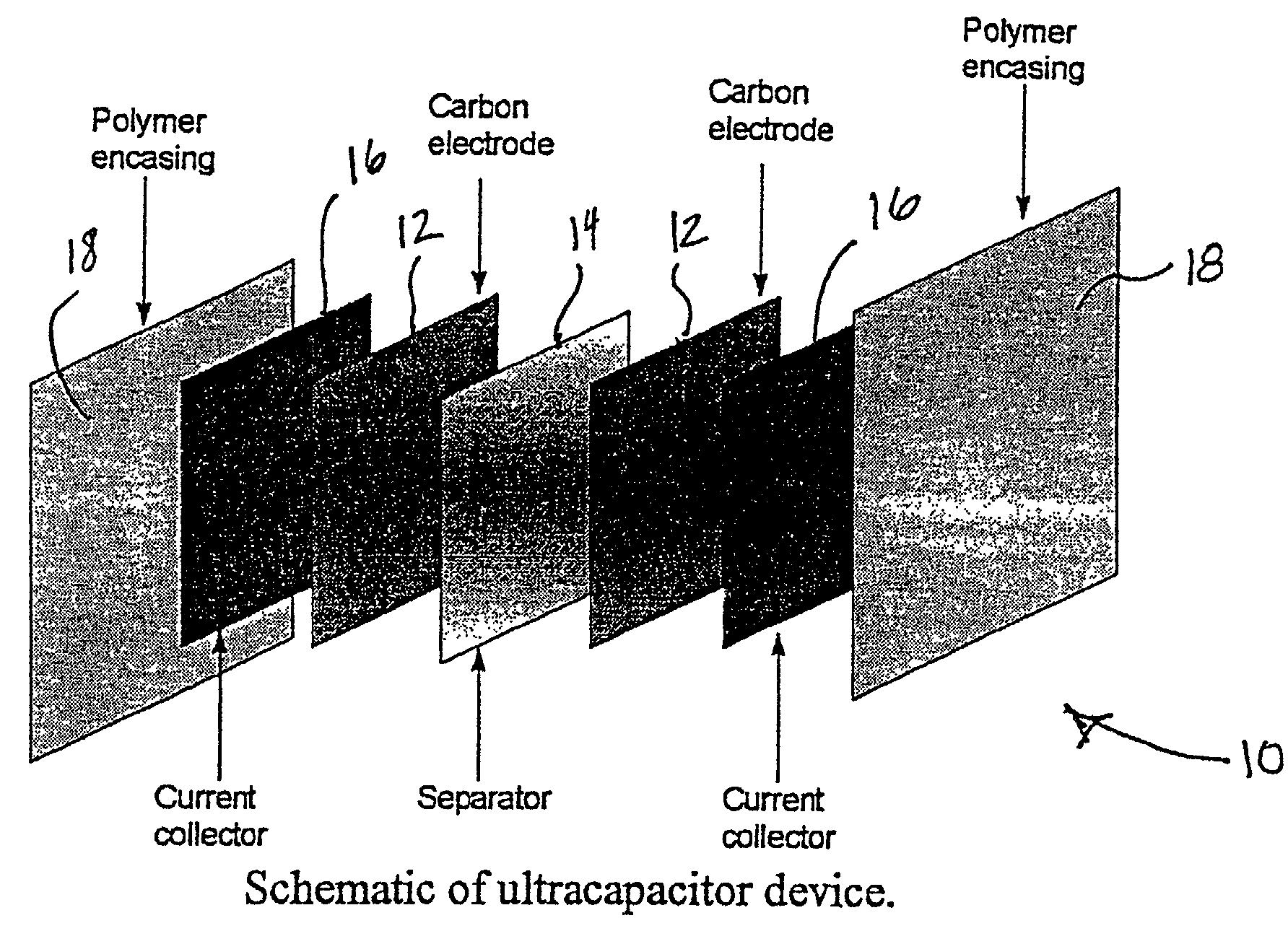

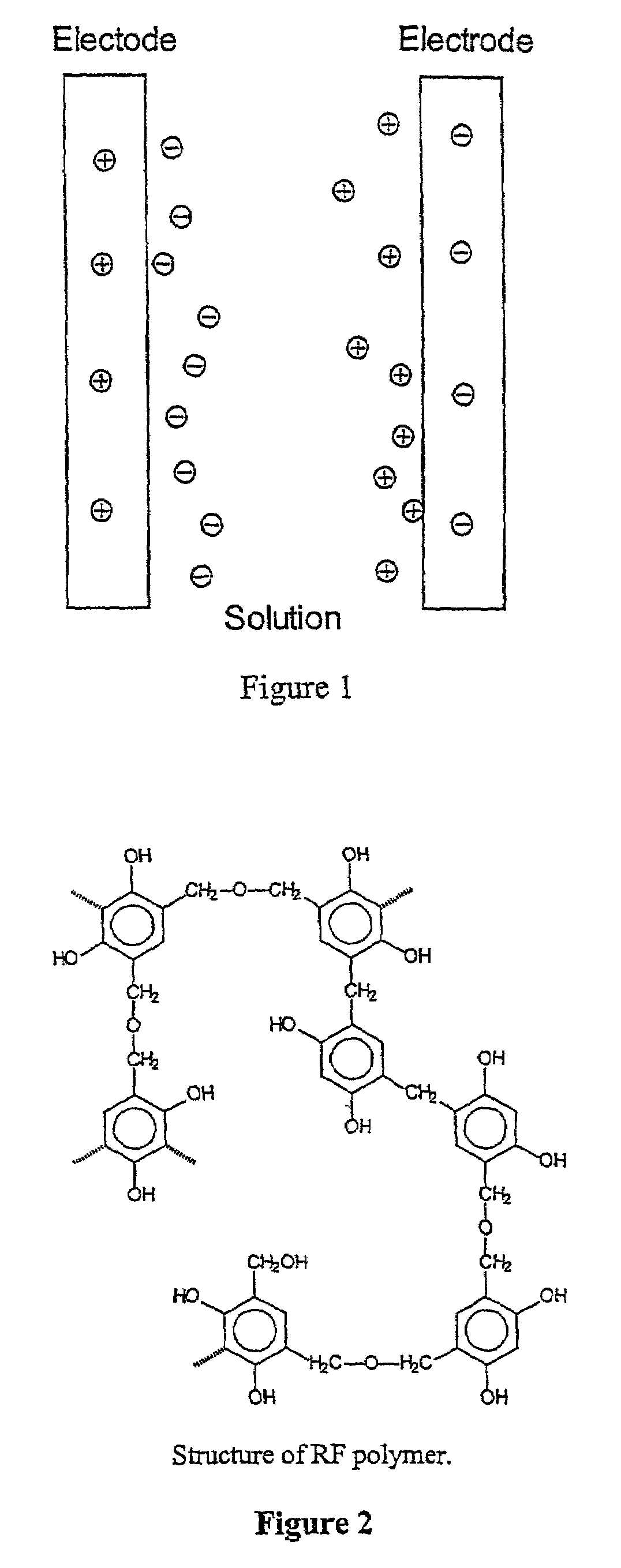

Mesoporous carbons and polymers from hydroxylated benzenes

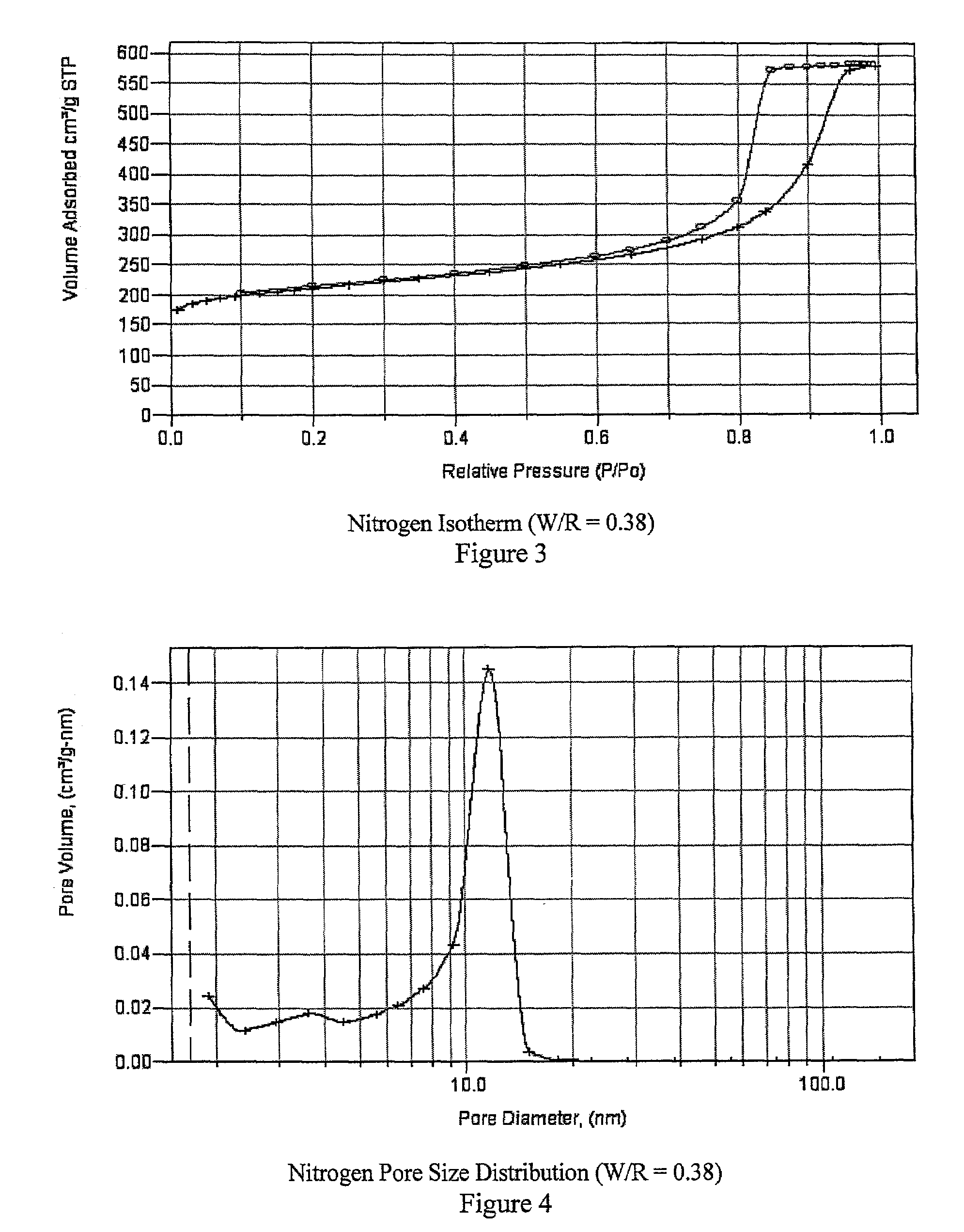

InactiveUS7167354B2High mesoporositySimple and inexpensive to manufactureHybrid capacitor electrolytesPhysical/chemical process catalystsPolymer scienceSorbent

A mesoporous polymer and method of preparing a mesoporous polymer whose polymerization kinetics are dependent upon pH and whose pore size is controlled by pH and solvent concentration are disclosed. The polymer is optionally pyrolyzed to form a primarily carbonaceous solid. The material has an average pore size in the mesopore range and is suitable for use in liquid-phase surface limited applications including chromatographic, sorbent, catalytic, and electrical applications.

Owner:TDA RES

Preparation method of nano tourmaline modified dust removal filter material

ActiveCN107261641AHigh pyroelectric coefficientImprove charging capacityDispersed particle filtrationMembrane filtersEmulsionTest sample

The invention discloses a preparation method of a nano tourmaline modified dust removal filter material, which belongs to the technical field of high-temperature smoke dust removal. The preparation method comprises the following steps: carrying out heat treatment for nano tourmaline powder; weighing sodium hexametaphosphate and sodium polyacrylate, and mixing the sodium hexametaphosphate and sodium polyacrylate with water; weighing nano tourmaline powder, adding water, and mixing with PTFE emulsion; adding the sodium hexametaphosphate and sodium polyacrylate into a mixed solution of the nano tourmaline powder and PTFE emulsion, and obtaining a nano tourmaline treatment solution; soaking a filter material test sample in the nano tourmaline treatment solution, and obtaining a nano tourmaline filter material; and polarizing the nano tourmaline filter material by virtue of electrets, and obtaining the nano tourmaline modified dust removal filter material. By adopting the preparation method, not only is electrets performance high, small dust can be trapped, the dust filter efficiency can be improved, the dust removing rate can be increased, and the equipment resistance is reduced.

Owner:南京际华三五二一环保科技有限公司

Bonding agent of baking-free bricks prepared from drilling well solid waste materials

ActiveCN101805161AIncreased contact surface areaHigh strengthSolid waste managementBrickPhosphogypsum

The invention relates to a bonding agent of baking-free bricks prepared from drilling well solid waste materials, which is applied to the field of treating petroleum drilling well solid waste materials into resources for preparing baking-free bricks. The bonding agent comprises the following ingredients in parts by weight: 3.3 to 8 of polyaluminium chloride, 6 to 25 of phosphogypsum, 10 to 26 of lime, 20 to 60 of fly ash and 4.4 to 12 of ferrous sulfate. A method for using drilling well solid waste materials for preparing the baking-free bricks comprises the following steps that: the baking-free bricks are prepared from the following ingredients in parts by weights: 10 to 22 of bonding agents of baking-free bricks prepared from drilling well solid waste materials, 30 to 55 of drilling well solid waste materials and 35 to 45 of crude aggregate; and the ingredients are uniformly mixed, are extruded and formed through a baking-free brick machine, and are maintained for 14 to 21 days to prepare the baking-free bricks. The invention has the advantages that the baking-free bricks can be prepared, and through the analysis via the sampling and the water soaking experiments on the baking-free bricks, all contaminant indexes reach the primary standard. Through the examination according to the standard JC422-1991, the detected items of the samples reach the requirements of the standard.

Owner:PETROCHINA CO LTD

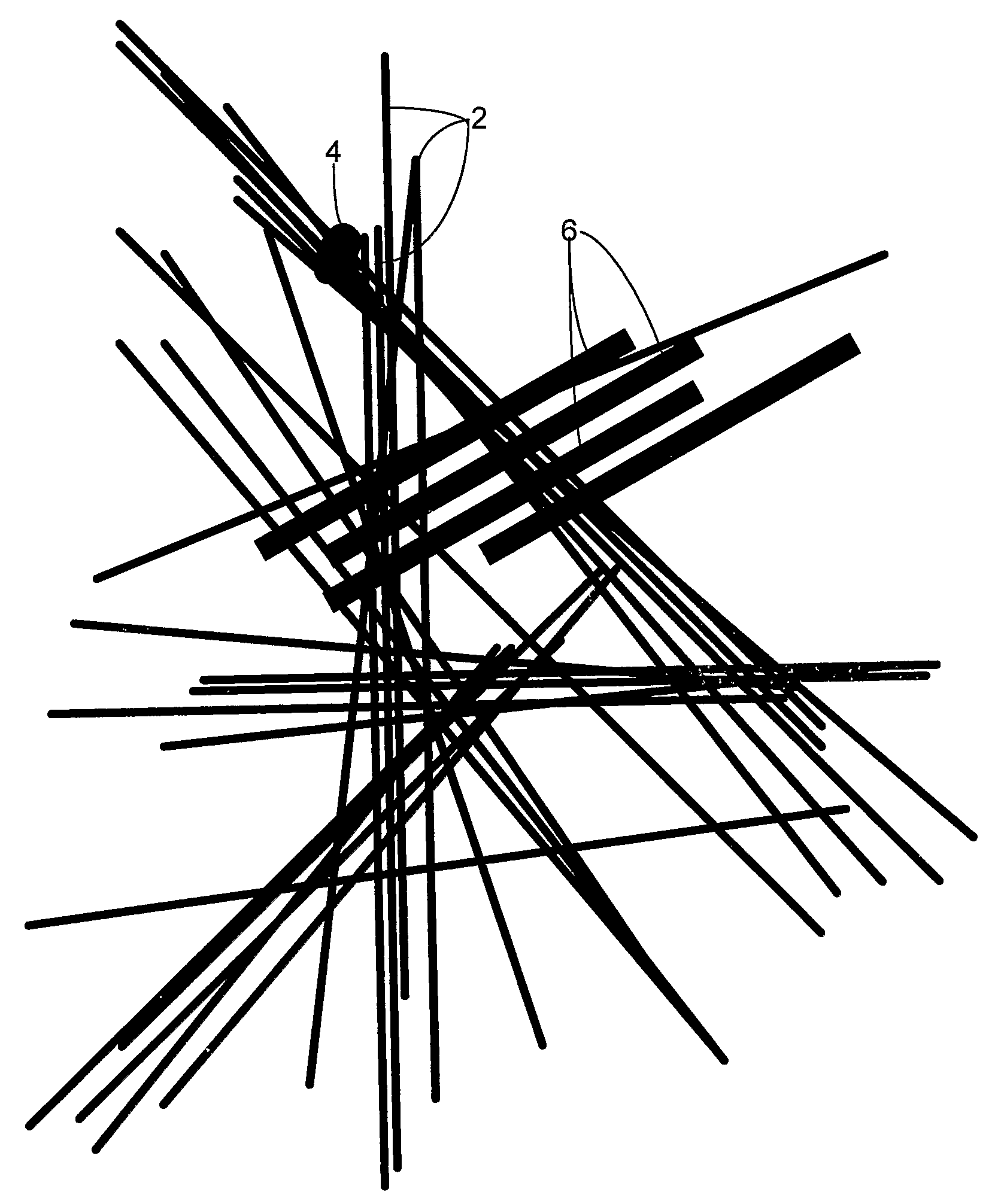

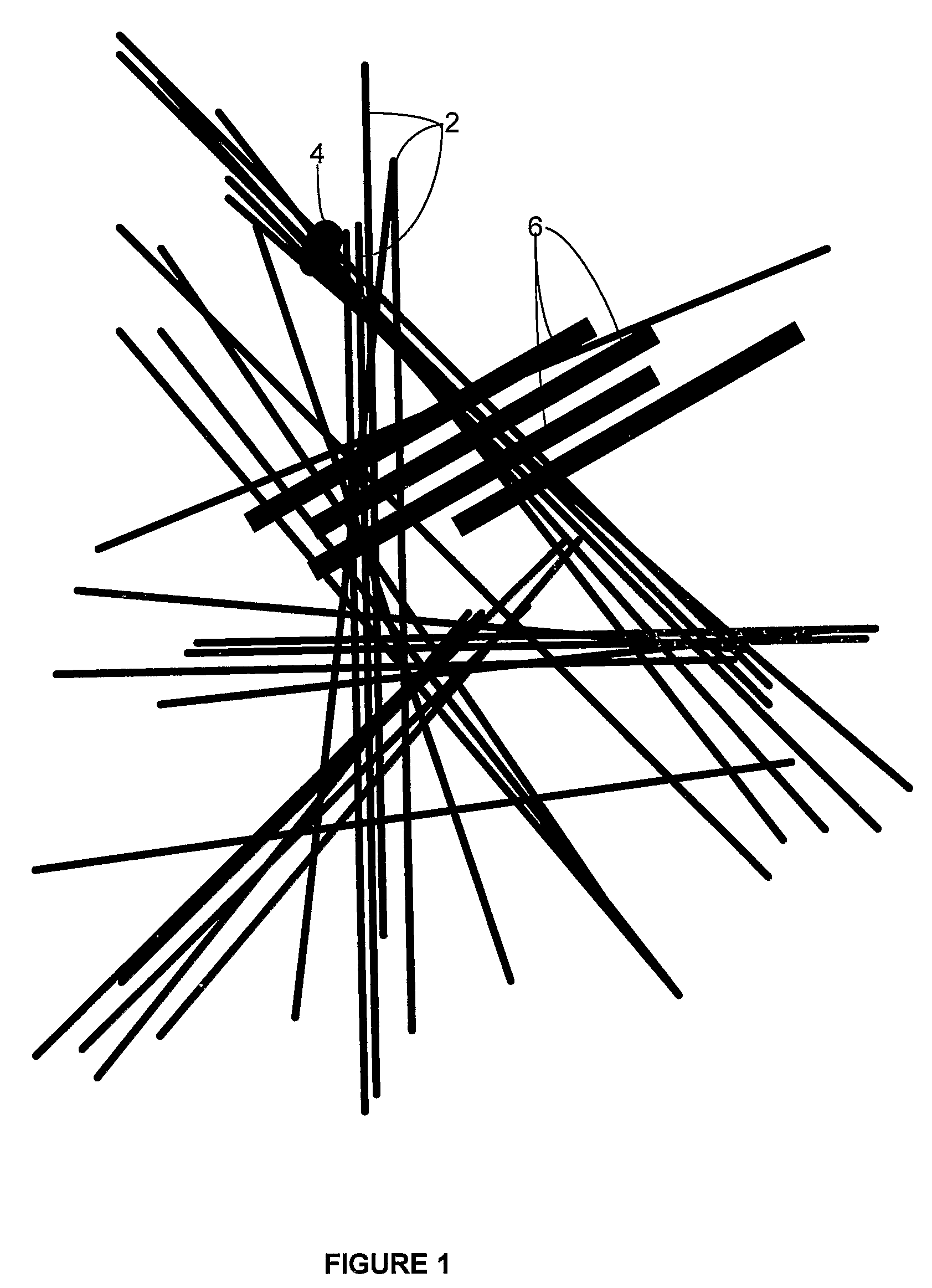

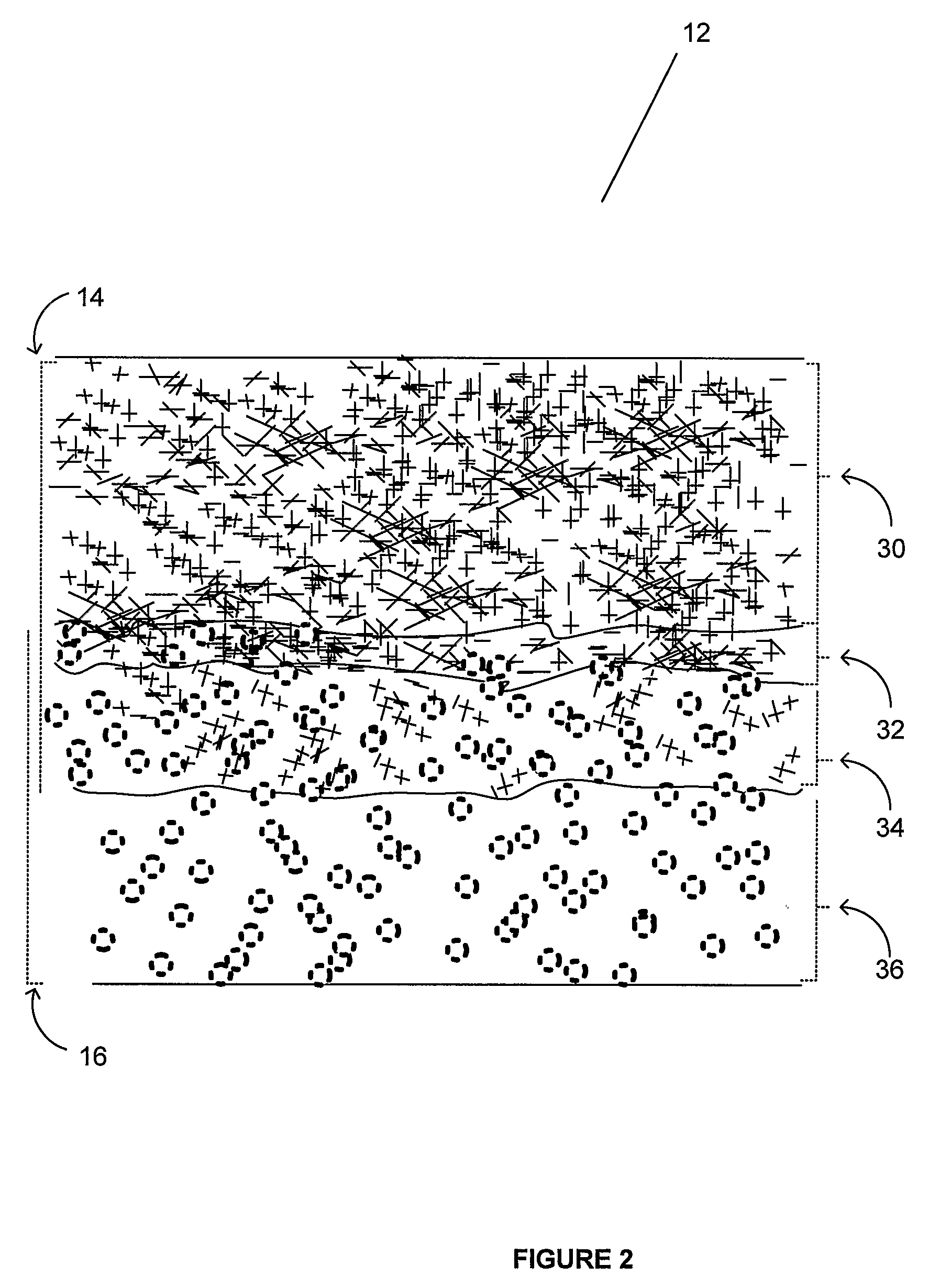

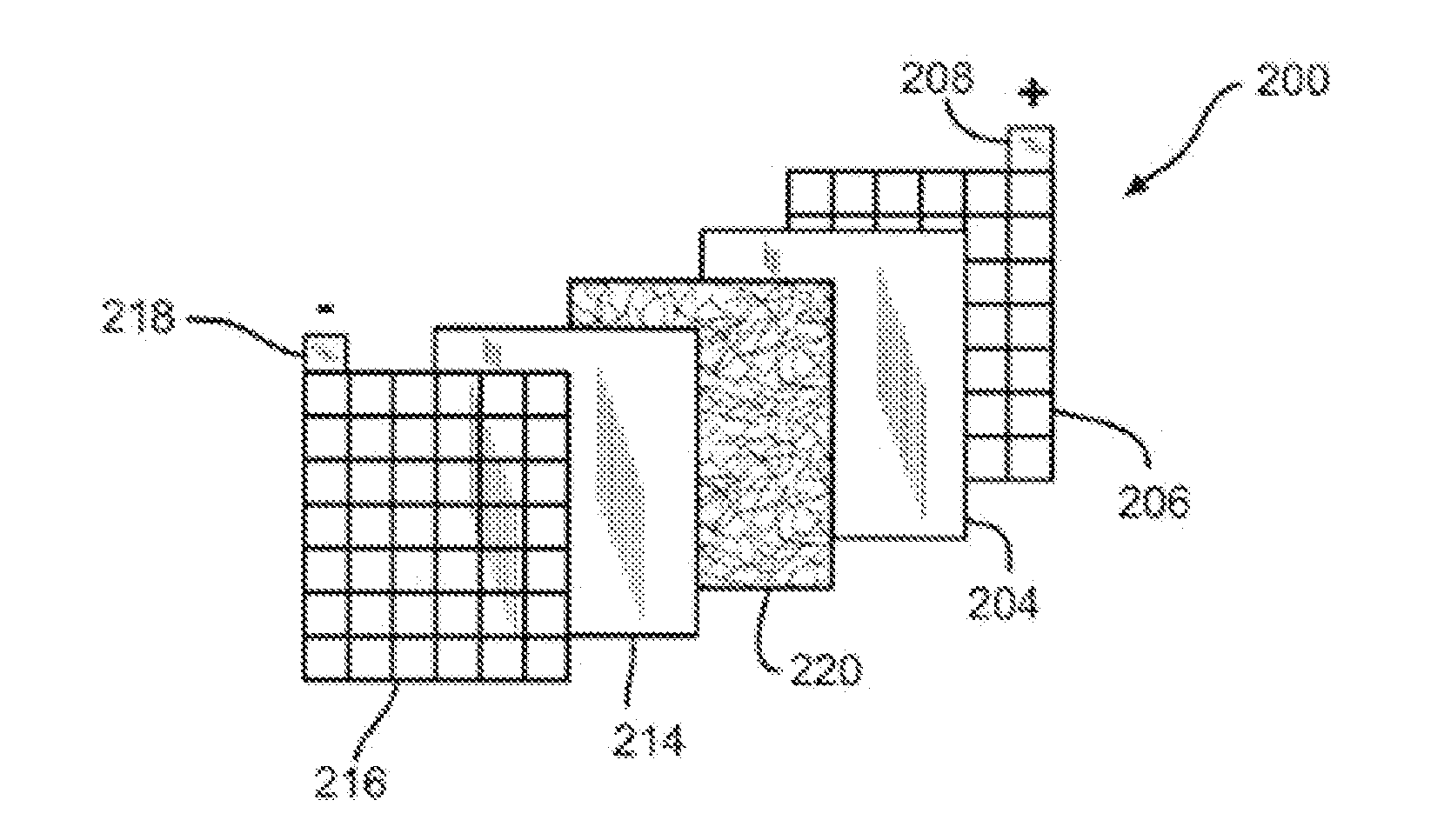

Blood Separator and Method of Separating a Fluid Fraction from Whole Blood

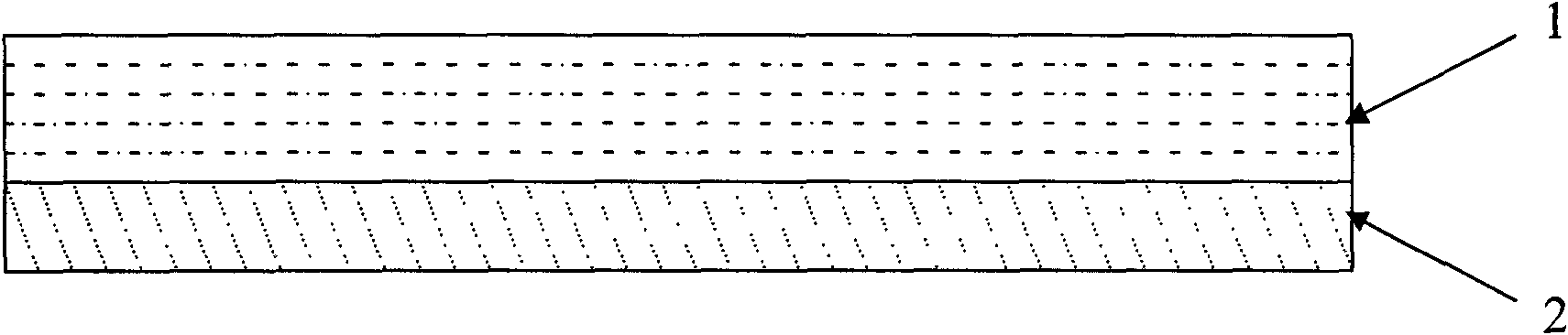

InactiveUS20080210644A1Small average pore sizeIncrease stiffnessSynthetic cellulose/non-cellulose material pulp/paperLoose filtering material filtersBi modalBlood separation

A novel composite of glass fiber paper and reinforcing material that is useful for high speed manufacturing of devices comprising it is disclosed. The composite is formed by pressing into a glass fiber paper, having multimodal (at least bi-modal) composition, a hydrophilic reinforcing material. The composite has anisotropic separation properties that are particularly useful for preparing a fluid fraction from whole blood. The preferred glass fiber paper comprises glass fibers such that there are a plurality of short fibers (6) having large diameters and long fibers (2) with smaller diameters. The preferred glass fiber paper also exhibits partial ordering. There are many more of the long fibers (2) with smaller diameters than of the short fibers (6) having large diameters. Also disclosed are several blood separator device designs for efficiently separating the fluid fraction of blood from whole blood using the composite.

Owner:AKERS BIOSCI

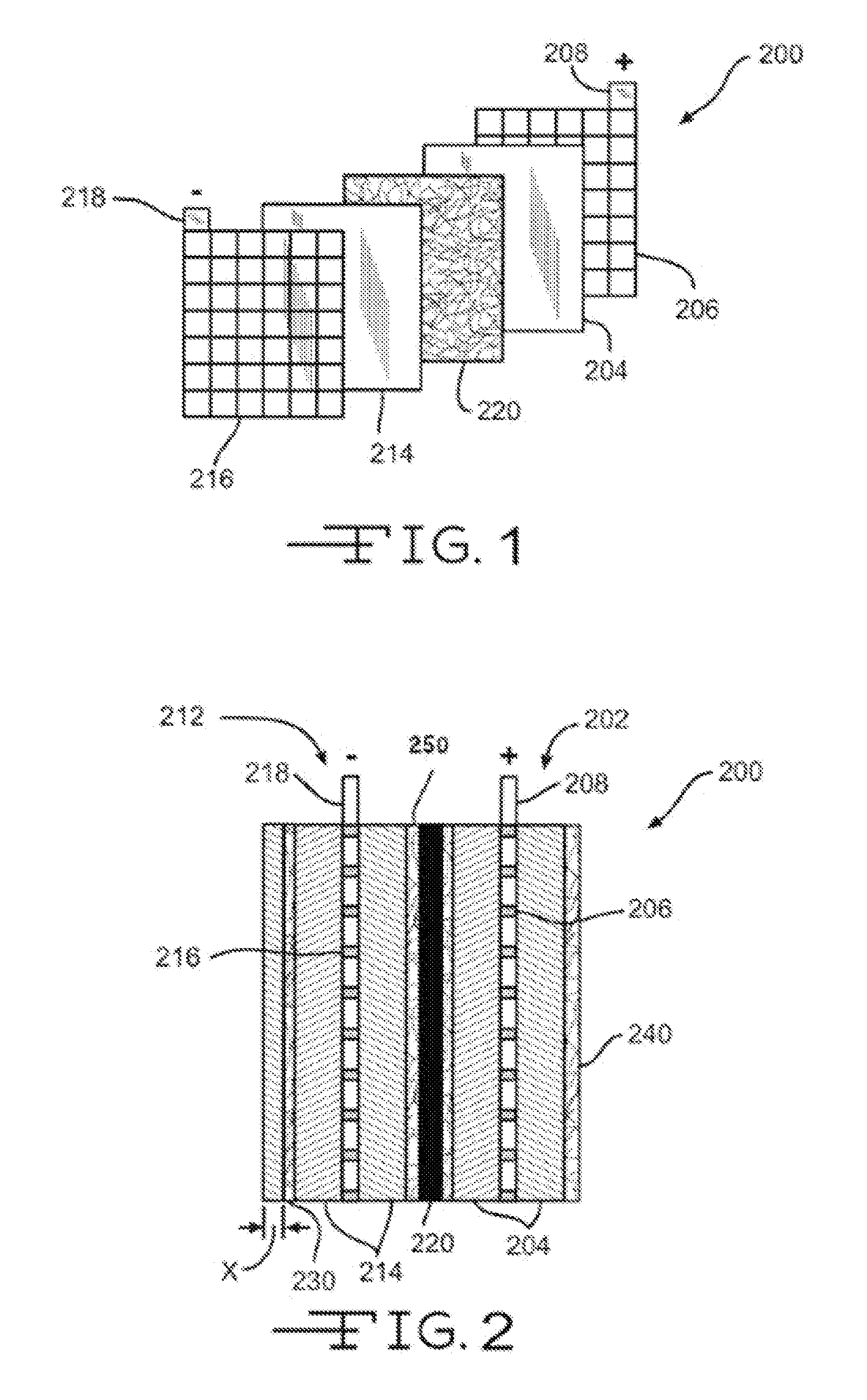

Small pore size nonwoven mat with hydrophilic/acid resistant filler used in lead acid batteries and applications therefor

ActiveUS20160268567A1Reduce air permeabilitySmall average pore sizeLead-acid accumulatorsCell component detailsFiberGlass fiber

According to one embodiment, a nonwoven fiber mat includes between 10% and 50% by weight of a plurality of first glass fibers having an average diameter of less than 5 μm and between 50% and 90% by weight of a plurality of second glass fibers having an average diameter of greater than 6 μm. The nonwoven fiber mat also includes an acid resistant binder that binds the first and second glass fibers together. The nonwoven fiber mat has an average pore size of between 1 and 100 μm and exhibits an air permeability of below 100 cubic feet per minute per square foot (cfm / ft2) as measured by the Frazier test at 125 Pa according to ASTM Standard Method D737.

Owner:JOHNS MANVILLE CORP

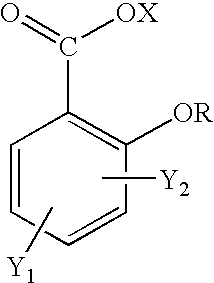

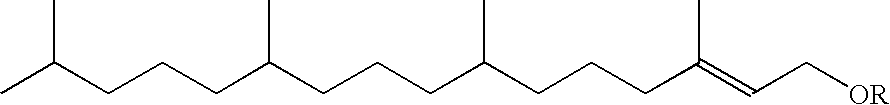

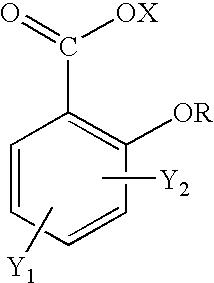

Topical use of halosalicylic acid derivatives

InactiveUS20050136015A1Accelerated sebumAccelerated acne controlAntibacterial agentsBiocideDiseaseSkin callus

Halosalicylic acid compounds of the present invention, having at least one halogen substituent on the aromatic ring, are employed to produce desquamation of skin, treat nail disorders or dandruff, remove calluses, control acne and excess sebum production, reduce skin pore size or control blackheads. Topical compositions containing the halosalicylic acid compound and a cosmetically acceptable vehicle are disclosed.

Owner:AVON PROD INC

Blood filter material and process for preparing same

The invention relates to a blood filtering material and its preparation method. The material is formed from filtration substrate and surface modified layer, wherein the filtration substrate is macromolecular nonwoven material processed by using melt-blowing method with density of 10-1000g / cm2, mean pore size of 0.1-100 mu m, thickness of 0.01-50mm, fiber diameter of 0.01-50 mu m; surface modified layer is formed from fibroin protein and polyurethane blended aqueous solution in 90-10:10-90 by weight; Conventional coating method is adopted, comprising blending medical polyurethane aqueous solution and self-made fibroin protein, applying the above blend on the surface of filtration substrate, drying, bonding, and curing. In the invention, the price of raw materials is low, and the products are provided with excellent blood compatibility, wettability, permeability and high filter efficiency which can be used as blood filtering materials.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com