Ferrum-cerium-titanium composite oxide catalyst, preparation method and application of ferrum-cerium-titanium composite oxide catalyst

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of insignificant improvement in purification efficiency and overcome corrosion Volatility and volatility, improve fluidity, promote highly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

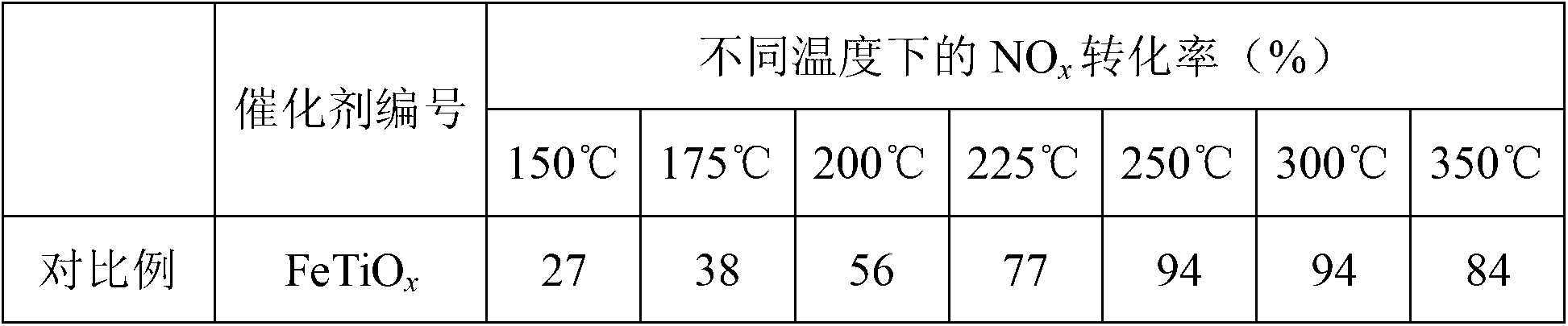

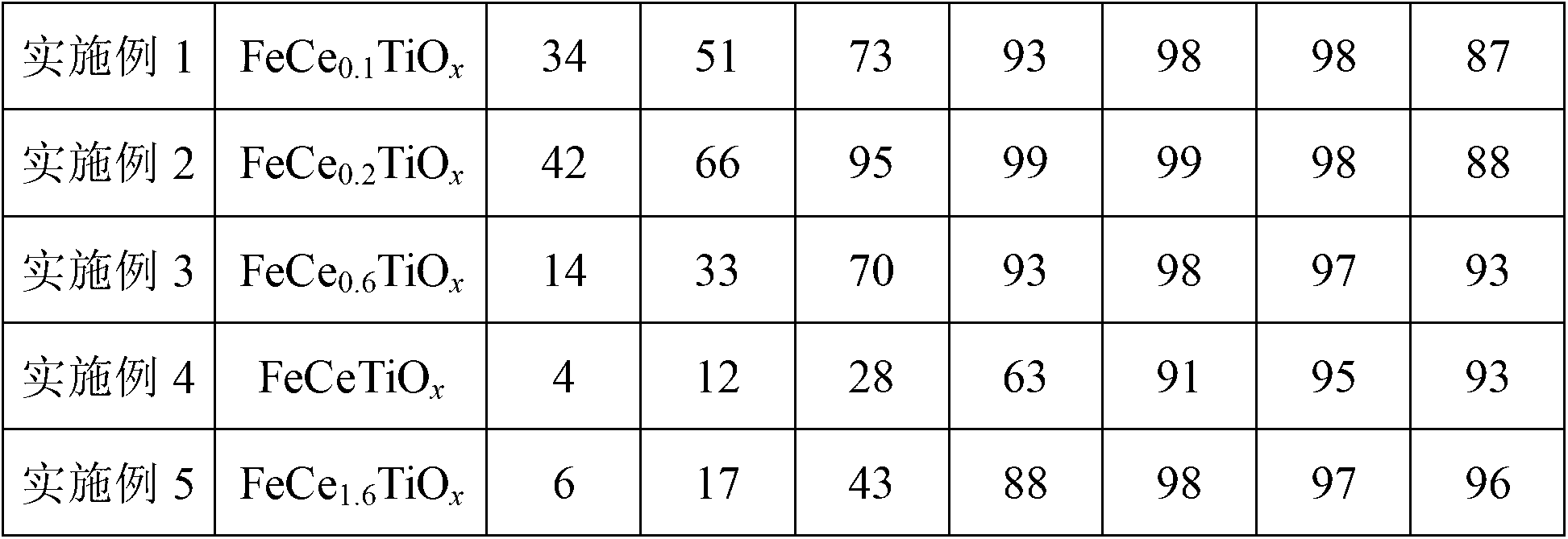

Examples

Embodiment 1

[0042] An iron-cerium-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeCe a TiO x , where a is 0.1.

[0043] The preparation method of above-mentioned catalyst comprises the steps:

[0044] (1) Prepare ferric nitrate, cerium nitrate and titanium sulfate solutions, mix ferric nitrate, cerium nitrate and titanium sulfate solutions evenly to obtain a mixed solution, control the molar ratio of Fe element to Ti element in the mixed solution to be 1:1, Ce element The molar ratio with Fe element is 0.1:1;

[0045] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + Ce source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, Ce and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 100°C for 5h, and then calcined in a muffle furnace at 500°C for 3h in an air atmosphere to obtain the iron-cerium-titani...

Embodiment 2

[0047] An iron-cerium-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeCe a TiO x , where a is 0.2.

[0048] The preparation method of above-mentioned catalyst comprises the steps:

[0049] (1) Prepare ferric nitrate, cerium nitrate and titanium sulfate solutions, mix ferric nitrate, cerium nitrate and titanium sulfate solutions evenly to obtain a mixed solution, control the molar ratio of Fe element to Ti element in the mixed solution to be 1:1, Ce element The molar ratio with Fe element is 0.2:1;

[0050] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + Ce source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, Ce and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 100°C for 5h, and then calcined in a muffle furnace at 500°C for 3h in an air atmosphere to obtain the iron-cerium-titani...

Embodiment 3

[0052] An iron-cerium-titanium composite oxide catalyst, the catalyst has the following chemical composition: FeCe a TiO x , where a is 0.6.

[0053] The preparation method of above-mentioned catalyst comprises the steps:

[0054] A method for preparing an iron-cerium-titanium composite oxide catalyst, the method comprising the steps of:

[0055] (1) Prepare ferric nitrate, cerium nitrate and titanium sulfate solutions, mix ferric nitrate, cerium nitrate and titanium sulfate solutions evenly to obtain a mixed solution, control the molar ratio of Fe element to Ti element in the mixed solution to be 1:1, Ce element The molar ratio with Fe element is 0.6:1;

[0056] (2) Add excess urea precipitant to the mixed solution, the molar ratio of urea / (Fe source + Ce source + Ti source) is 10:1, and stir continuously for 12 hours in a water bath at 90°C to precipitate Fe, Ce and Ti ions Completely, the obtained precipitated product was suction-filtered, washed, dried in an oven at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com