Melt-blown nonwoven fabric comprising ultra-fine fibers, production method therefor, and device for producing same

A technology of melt-blown non-woven fabrics and ultra-fine fibers, which is applied in the directions of melt-spinning, fiber processing, textiles and papermaking, etc., can solve the problems of inability to obtain particle capture and breathable melt-blown non-woven fabrics, and achieve particle capture. Excellent properties and air permeability, inhibition of wire breakage and entanglement, and high particle capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

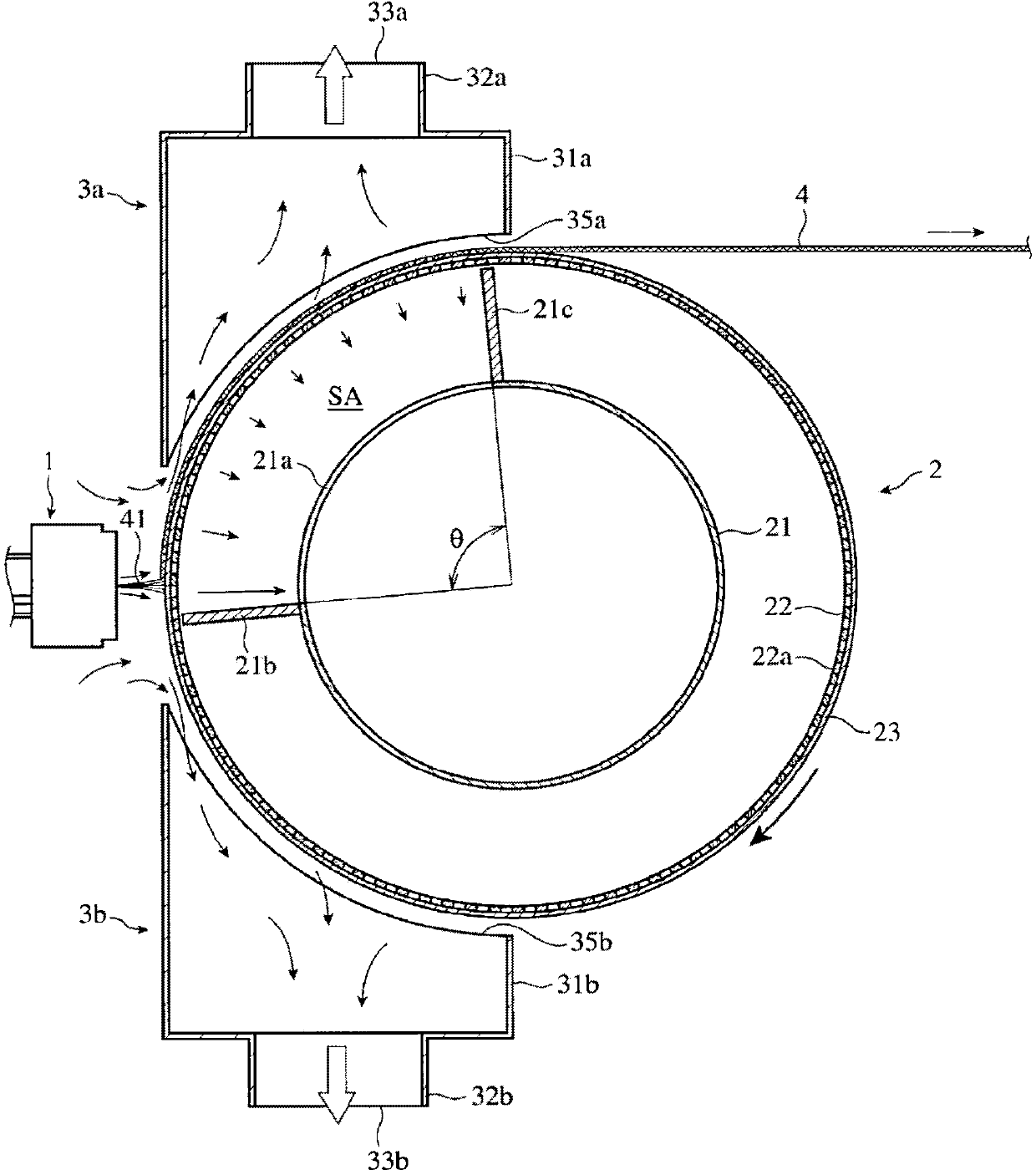

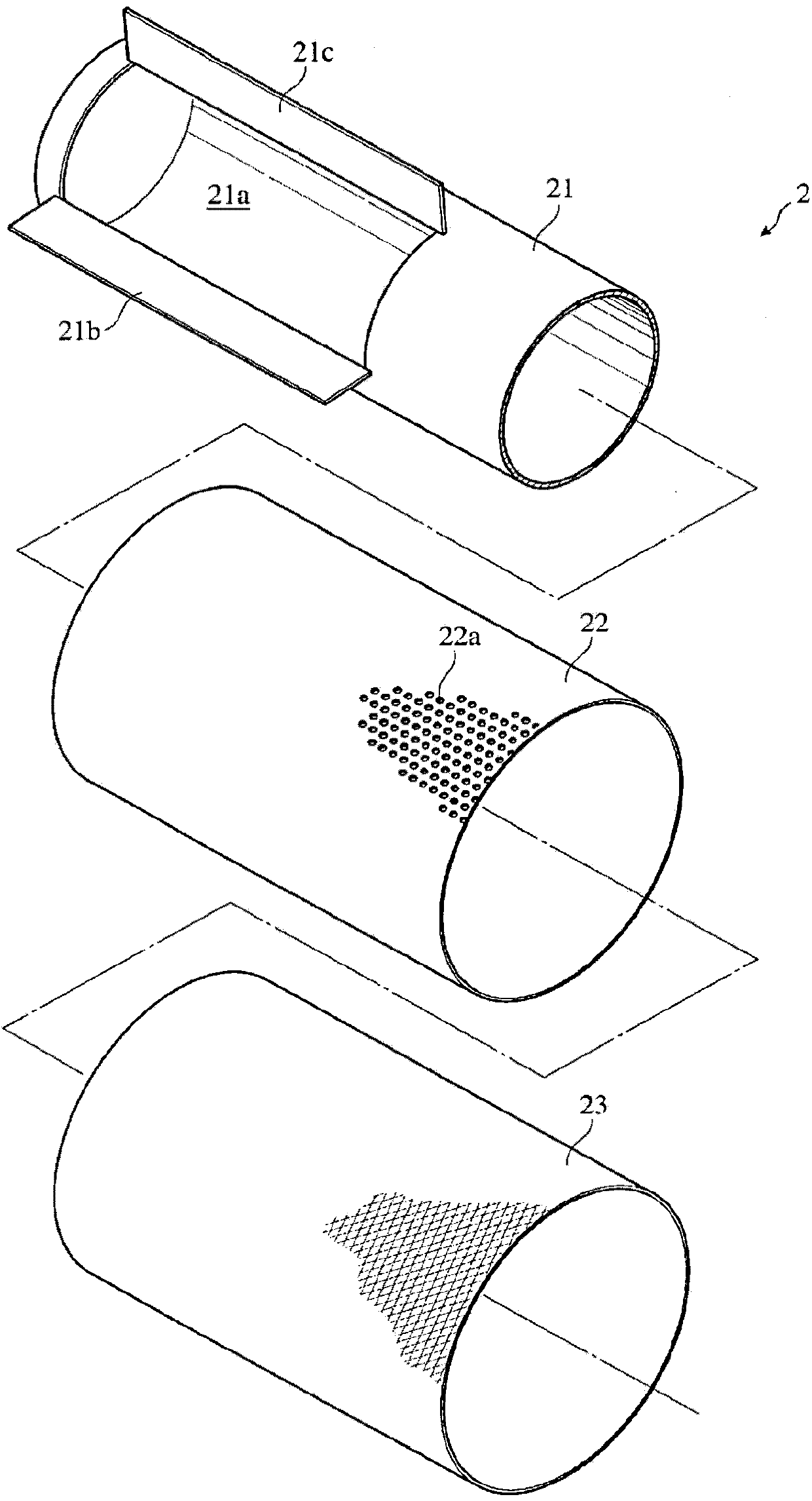

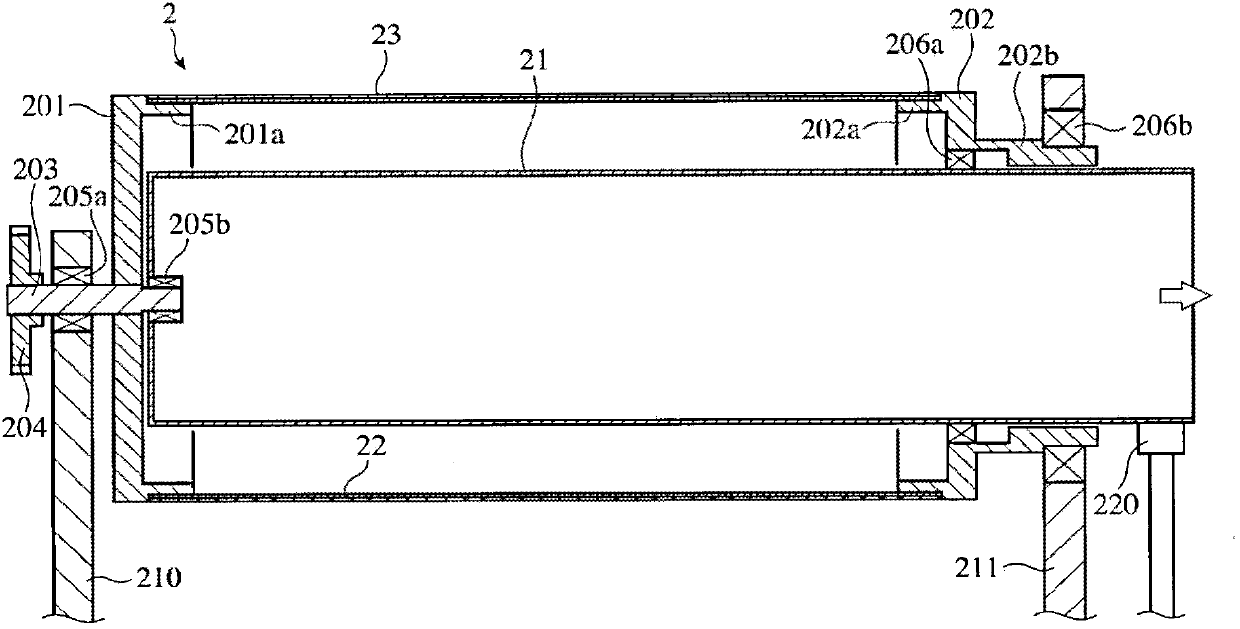

[0125] Polypropylene PP [MFR (JISK7210, 2.16kg, 230°C): 1,550g / 10min, weight-average molecular weight (Mw): 7×10 prepared using a metallocene-based polymerization catalyst 4 , molecular weight distribution (Mw / Mn): 2.5, melting point: 155°C] as raw material, use Figure 1 to Figure 10 The shown apparatus produced a melt-blown nonwoven fabric with a width of 300 mm under the conditions shown in Table 1. It should be noted that the suction covers 3a, 3b are Image 6 in (S 1 +S 2 +S 3 ) are arranged symmetrically on the upstream side and the downstream side of the guide nozzle 1 in such a way that the half circumference of the suction drum 2 is drawn.

Embodiment 2

[0127] A melt-blown nonwoven fabric was produced in the same manner as in Example 1 except that the total gap TG was 0.7 mm (see Table 1).

Embodiment 3

[0129] A melt-blown nonwoven fabric was produced in the same manner as in Example 1 except that the polypropylene discharge amount per spinning nozzle was 6.7 mg / min and the rotational speed of the suction drum was 7.2 m / min (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com