High-strength phosphogypoum building block and preparation method

A technology of building blocks and phosphogypsum, which is applied in construction, building components, building structures, etc., can solve the problems that the technology has not been accepted and recognized by enterprises and society, the product strength and quality are unstable, and it has not been put into industrial implementation. , to achieve the effect of protecting land resources and atmospheric environment, high compressive strength, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

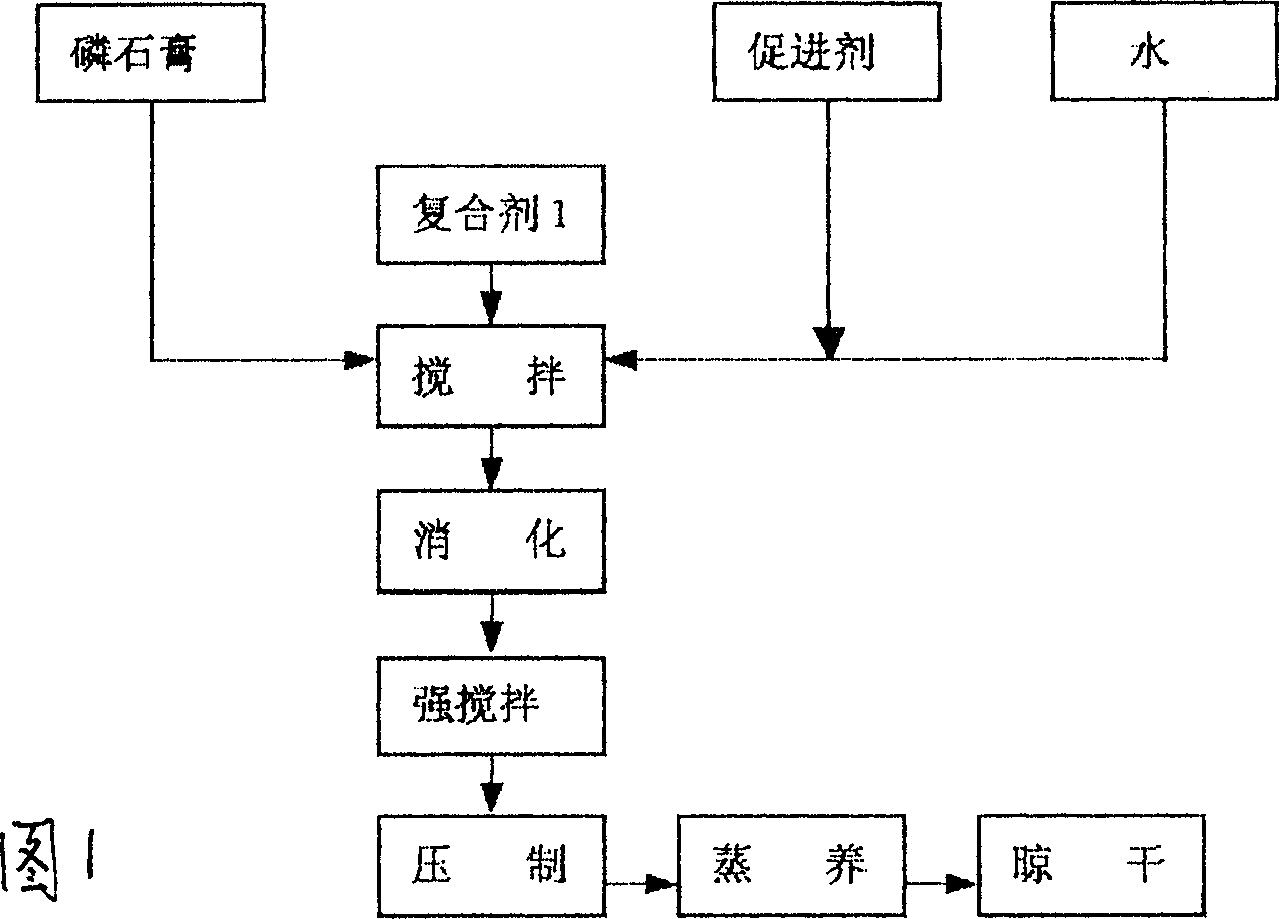

Embodiment 1

[0033] The raw material components of the high-strength phosphogypsum building blocks are: 20 parts of phosphogypsum, 1.5 parts of fly ash, 8.5 parts of sand, 1 part of sodium sulfate, 4.3 parts of calcium oxide, and 8 parts of water. The production and preparation method of the block is as follows: put the above-mentioned solid raw materials into the stirring device, add 1 / 2 of the amount of water to fully stir, after mixing evenly, send the materials into the aging bin, and the materials undergo digestion reaction during the static process, so that It becomes clinker. The digestion reaction time is about 10 hours. Put the matured material into the stirring device and stir, after stirring evenly, put the material into the mold of the block forming press, and press it into the building block of the designed shape. The compression strength of the compression molding is 25MPa. The pressed blocks are left to stand for 8 hours to allow them to fully react, and then sent to the s...

Embodiment 2

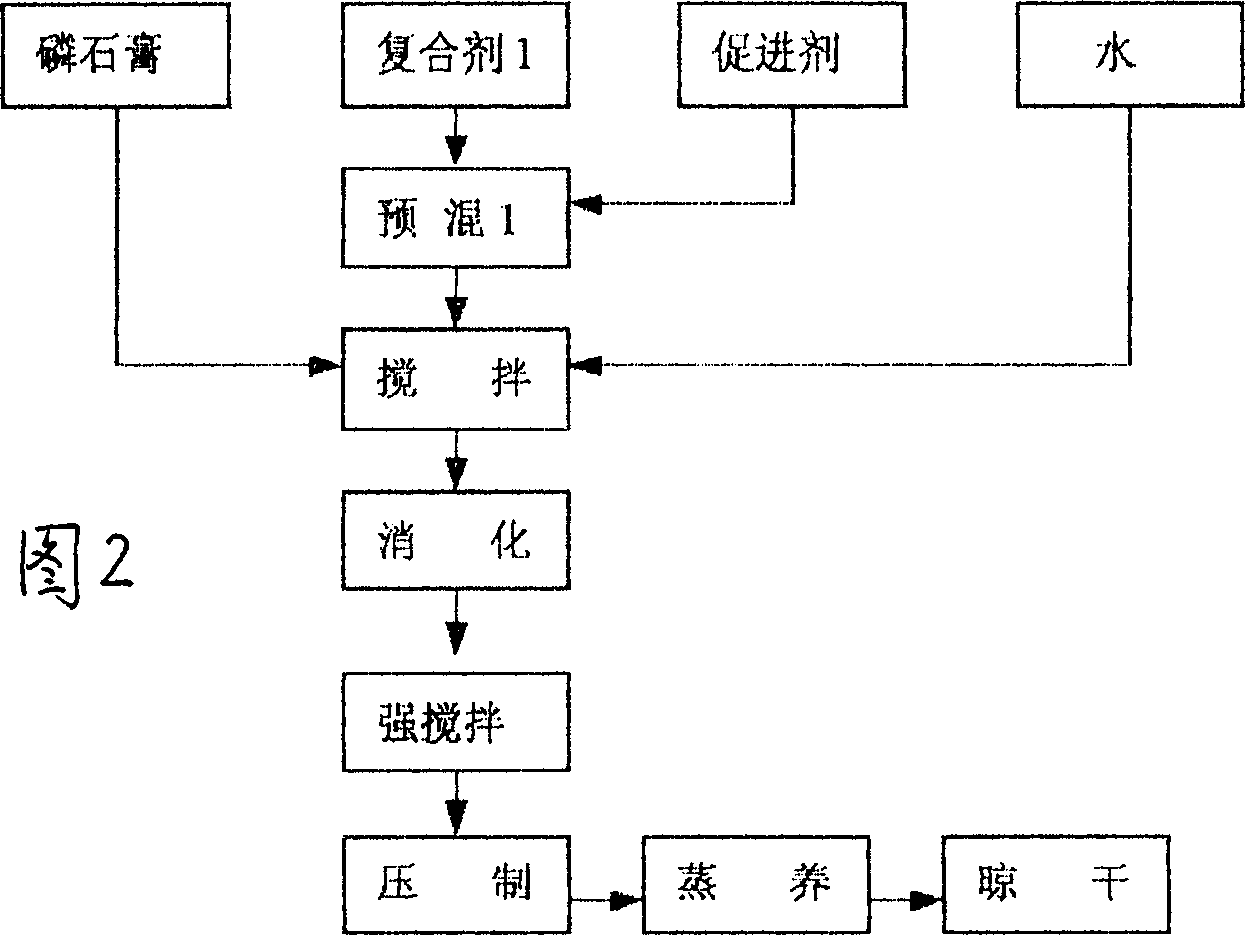

[0035]The raw material components of the high-strength phosphogypsum building blocks are: 40 parts of phosphogypsum, 6.8 parts of fly ash, 1.2 parts of phosphorus slag, 5.2 parts of calcium oxide, and 5.6 parts of water. The process for preparing building blocks from the above raw materials is as follows: first mix fly ash, phosphorus slag and calcium oxide in a dry state, and then put them into the stirring device together with phosphogypsum, and add half of the amount of The water is stirred and mixed, and after the materials are evenly mixed, they are sent to the aging bin for digestion reaction, and the subsequent technological process is the same as that of Example 1. In this embodiment, the process conditions of each process are: the time of digestion reaction is about 10 hours, the compression strength of compression molding is about 50MPa, the block is left to stand for about 6 hours after compression molding, and the pressure of the steam curing room is about 5MPa. Pr...

Embodiment 3

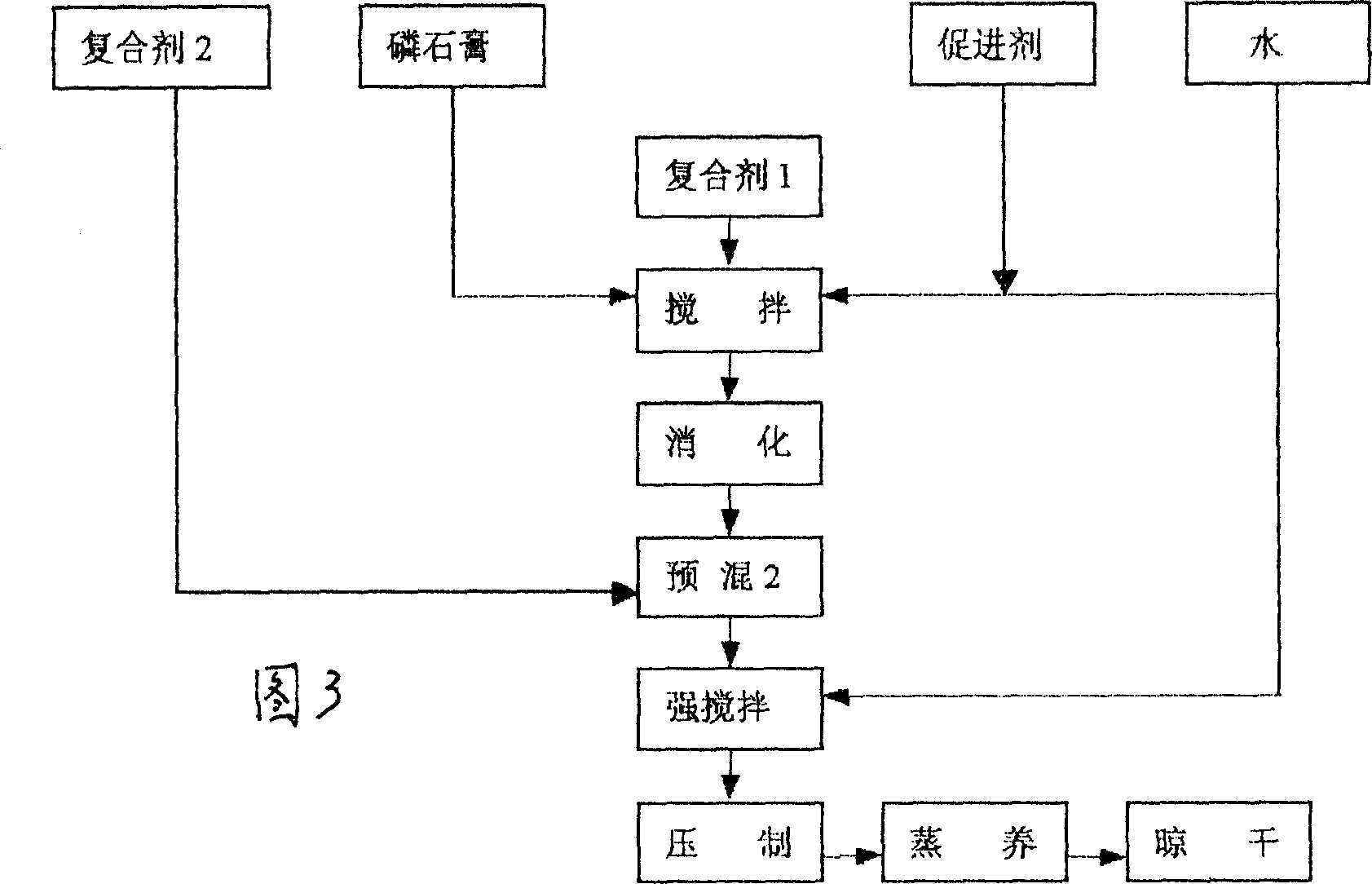

[0037] The raw material components of high-strength phosphogypsum building blocks are: 23 parts of phosphogypsum, 4.5 parts of fly ash, 1.2 parts of titanium slag, 3 parts of sand, 4.2 parts of cement, 0.5 parts of 5% polyacrylamide resin solution, calcium oxide 4.2 parts, 1 part of sodium chloride and 5 parts of water. The process of preparing building blocks from the above raw materials is as follows: put phosphogypsum, fly ash, titanium slag, calcium oxide and sodium chloride into the stirring device together, add half of the amount of water for stirring, and mix well , sent to the aging bin for digestion and reaction, and reacted for about 12 hours, and the material reacted and matured. The cured material is mixed with cement and polyacrylamide resin solution first, and then the remaining water is added for stirring and mixing, and then sent to the pressing molding process after mixing evenly. The subsequent technological process is identical with embodiment 1. In the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com