Preparation method of phenol-formaldehyde resin-based carbon molecular sieve for adsorbing and separating methane and nitrogen gas

A phenolic resin, adsorption and separation technology, applied in adsorption purification/separation, carbon preparation/purification, nitrogen purification/separation, etc., can solve the problem of not specifying the suitable pore size range of phenolic resin-based carbon molecular sieve precursor, and the pore size structure of the adsorbent. The gas adsorption performance has not been described, nor the method of adjusting the pore size of the precursor is pointed out, so as to achieve the effect of being beneficial to the kinetic separation, promoting the kinetic separation performance and reducing the heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dry the phenolic resin waste at 170°C for 12 hours, mix evenly according to the weight ratio of phenolic resin waste: coal tar, water and starch is 1:0.35:0.7:0.15, and extrude it. The diameter of the columnar material is 1.5mm. Drying was performed at 105°C for 2 hours. Under the protection of nitrogen, according to a certain heating rate of 4 ° C / min to 650 ° C for 60 minutes, then according to the heating rate of 20 ° C / min to a high temperature of 800 ° C, the carbonization holding time is 60 minutes, and the carbon molecular sieve precursor sample Q-1 can be obtained , the pore diameter characteristics are: less than 0.6nm pore volume is 0.043ml / g; It is 0.04ml / g.

[0022] Under nitrogen protection, the temperature of Q-1 was directly raised to the deposition temperature of 850°C without cooling and discharging treatment, and the deposition time was kept at 40 minutes. The mixed gas of nitrogen and methane was used as the deposition gas, and the volume fracti...

Embodiment 2

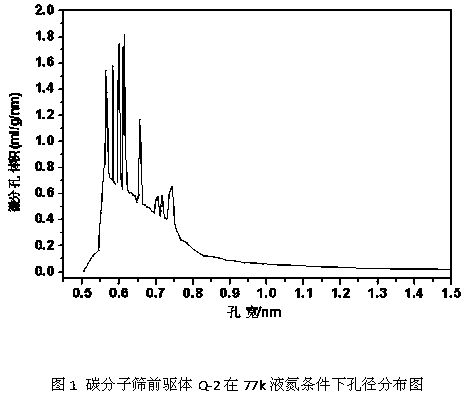

[0024] Dry the phenolic resin waste at 170°C for 12 hours, mix evenly according to the weight of phenolic resin waste: coal tar, water and starch in the ratio of 1:0.35:0.7:0.1, and extrude into strips. The diameter of the columnar material is 1.5mm. °C for 2 hours. Under the protection of nitrogen, according to a certain heating rate of 4 ° C / min to 650 ° C for 60 minutes, then according to the heating rate of 20 ° C / min to a high temperature of 850 ° C, the carbonization holding time is 30 minutes, and the carbon molecular sieve precursor sample Q-2 can be obtained. ;The pore diameter characteristics are: the pore volume of micropores less than 0.6nm is 0.057ml / g, the pore volume of 0.6nm~0.7nm micropores is 0.065ml / g, the pore volume of 0.7nm~0.8nm micropores is 0.025ml / g, 0.8 The pore volume of nanometer ~ 1.5nm micropore is 0.03ml / g.

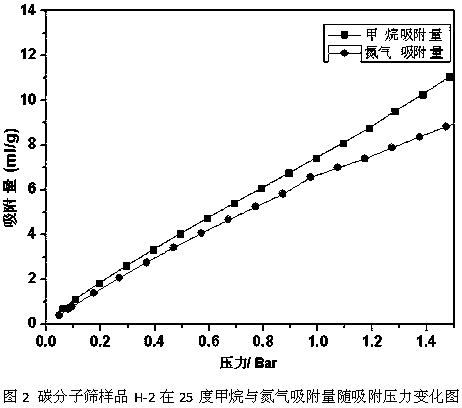

[0025] Q-2 was kept under the nitrogen protection state without cooling and discharging treatment, and the deposition temperature was...

Embodiment 3

[0027]Dry the phenolic resin waste at 170°C for 12 hours, mix evenly according to the weight ratio of phenolic resin waste: coal tar, water and starch is 1:0.3:0.6:0.1, and extrude it. The diameter of the columnar material is 1.5mm. Drying was performed at 105°C for 2 hours. Under the protection of nitrogen, according to a certain heating rate of 4°C / min to 700°C for 30 minutes, then according to the heating rate of 20°C / min to a high temperature of 900°C, the carbonization holding time is 20min, and the carbon molecular sieve precursor sample Q-3 can be obtained The pore size characteristics are: less than 0.6nm pore volume is 0.042ml / g, 0.6nm~0.7nm pore volume is 0.070ml / g, 0.7nm~0.8nm pore volume is 0.02ml / g, 0.8nm~1.5nm pore volume It is 0.04ml / g.

[0028] Under the protection of nitrogen, the temperature of Q-3 was directly lowered to the deposition temperature of 850°C without cooling and discharging treatment, and the deposition time was kept at 20 minutes. The mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com