High temperature resistance basalt fiber composite filter material and preparation method thereof

A basalt fiber and composite filtration technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of low filtration efficiency, poor softness, loose structure, etc. distribution concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

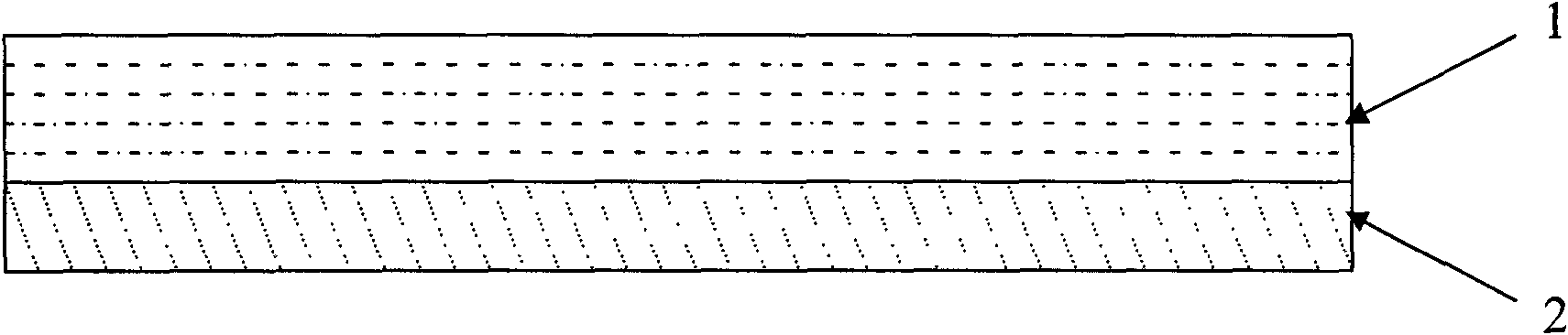

[0024] The polytetrafluoroethylene fiber web (150g / m 2 ), spread on basalt fiber base cloth (350g / m 2 ), the weight ratio of polytetrafluoroethylene fiber mesh and basalt fiber base cloth is 1:2.3, which is strengthened and compounded by spunlace, the net conveying speed is 15m / min, and the spunlace pressure is 180bar. After drying, it is hot-rolled by a hot-rolling mill at a temperature of 230°C and a speed of 10m / s, then impregnated with PTFE emulsion with a concentration of 15%, and then set at 230°C for 18 minutes.

[0025] The specification of the obtained high temperature resistant basalt spunlace composite filter material is 530g / m 2 , Strong: longitudinal strength 1800N (5cm), transverse strength 1400N (5cm), average pore size 0.72μm, air permeability 1.18m / min, filtration resistance 18.14pa.

Embodiment 2

[0027] The polyimide fiber web (170g / m 2 ), spread on basalt fiber base cloth (450g / m 2 ), the weight ratio of polyimide fiber net and basalt fiber base cloth is 1:4.3, which is strengthened and compounded by spunlace, the net conveying speed is 18m / min, and the spunlace pressure is 200bar. After drying, it is hot-rolled by a hot-rolling mill at a temperature of 230°C and a speed of 17m / s, then impregnated with PTFE emulsion with a concentration of 24%, and then set at 250°C for 23 minutes.

[0028] The specification of the obtained high temperature resistant basalt spunlace composite filter material is 650g / m 2 , Strength: longitudinal strength 2100N (5cm), transverse strength 1600N (5cm), average pore size 0.89μm, air permeability 1.52m / min, filtration resistance 16.73pa.

Embodiment 3

[0030] The polyphenylene sulfide fiber web (200g / m 2 ), spread on basalt fiber base cloth (750g / m 2 ), the weight ratio of polyphenylene sulfide fiber net and basalt fiber base cloth is 1:6.8, which is strengthened and compounded by spunlace, the net conveying speed is 23m / min, and the spunlace pressure is 230bar. After drying, it is hot-rolled by a hot-rolling mill at a temperature of 210°C and a speed of 12m / s, then impregnated with PTFE emulsion with a proportion concentration of 18%, and then set at 230°C for 16 minutes.

[0031] The specification of the obtained high temperature resistant basalt spunlace composite filter material is 1000g / m 2 , Strong: longitudinal strength 2400N (5cm), transverse strength 2000N (5cm), average pore size 0.69μm, air permeability 1.04m / min, filtration resistance 20.58pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com