Foaming agent for preparation of Water-retaining foam concrete

A technology of foam concrete and foam agent, which is applied in the field of civil engineering, can solve the problems of unsatisfactory foam stability, uniformity and dispersibility, lack of foam agent for water-retaining foam concrete, and poor cement bonding, so as to ensure the follow-up water Effects of chemicalization, enhanced interaction, and increased mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

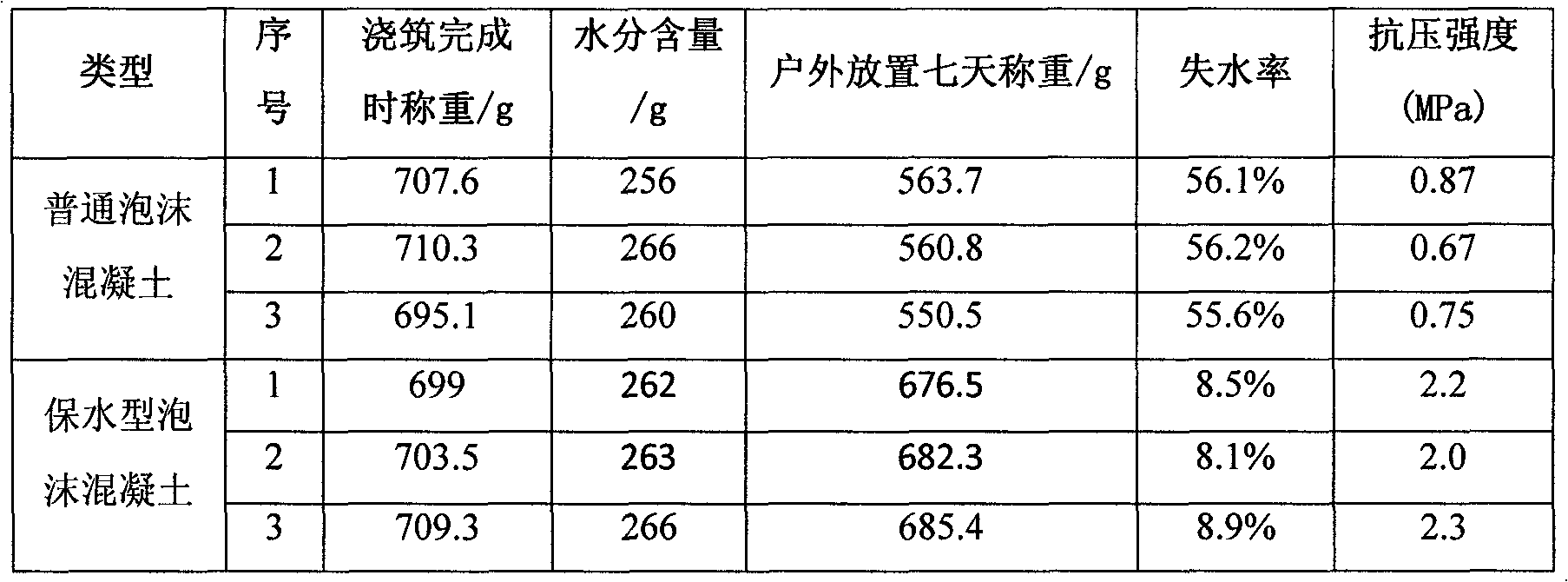

Image

Examples

preparation example Construction

[0019] The foaming agent for preparing water-retaining foam concrete of the present invention, its weight percent consists of:

[0020]

[0021] The anionic surfactants are: alkyl sulfonate, alkyl sulfate, α-alkenyl sulfonate, soap with a carbon chain length of 8-20, and a carbon chain length of 12-18 and EO adduct number Among fatty alcohol ether sulfates with a carbon chain length of 2-9, fatty alcohol ether carboxylates with a carbon chain length of 12-15 and an EO adduct number of 3-9, and fatty acid methyl ester sulfonates with a carbon chain length of 10-18 one or more of.

[0022] The foam stabilizer is: one or more of triethanolamine, gum arabic, gelatin, polymethylcellulose sodium.

[0023] The water retaining agent is: polyvinyl alcohol 1799, polyvinyl alcohol 2488, hydroxypropyl methylcellulose, polyacrylate, polyacrylamide, sodium polyacrylate, potassium polyacrylate, ammonium polyacrylate.

[0024] Foam preparation method of the present invention is as follow...

Embodiment 1

[0030] The foaming agent of the present invention can be obtained by compounding α-alkenyl sulfonate, sodium lauryl polyoxyethylene ether sulfate, triethanolamine, polyacrylamide, and polyvinyl alcohol 1799, and its weight percentage is:

[0031]

[0032] Add the above-mentioned anionic surfactant, foam stabilizer, water-retaining agent, and water into the reaction vessel according to the weight percentage described in Example 1, adjust the temperature to 50-90° C., and the reaction time is 1-3 hours to form a uniform transparent liquid.

[0033] Adopt this invention foaming agent to prepare water-retaining type foam concrete, concrete operation is as follows:

[0034] 1) Portland cement is used as the cementitious material, mixed with an appropriate amount of fly ash, and mixed and stirred uniformly according to the mass ratio of cement: fly ash: water = 1:0.1~1:0.4~0.6 to prepare cement concrete slurry.

[0035] 2) Dilute the invented foam agent with water by 50-70 times ...

Embodiment 2

[0037]

[0038]Add the above-mentioned anionic surfactant, foam stabilizer, water-retaining agent, and water into the reaction vessel according to the weight percentages described in Example 2, adjust the temperature to 50-90°C, and the reaction time is 1-3 hours to form a uniform transparent liquid.

[0039] Adopt this invention foaming agent to prepare water-retaining type foam concrete, concrete operation is as follows:

[0040] 1) Portland cement is used as the cementitious material, mixed with an appropriate amount of fly ash, and mixed and stirred uniformly according to the mass ratio of cement: fly ash: water = 1:0.1~1:0.4~0.6 to prepare cement concrete slurry.

[0041] 2) Dilute the invented foam agent with water by 50-70 times and prepare foam with a foaming machine, mix the foam into the above-mentioned cement concrete slurry, mix evenly and pour to form water-retaining foam concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com