Modified coarse aggregate, fiber nano recycled concrete prepared from modified coarse aggregate and preparation method of fiber nano recycled concrete

A technology of recycled concrete and coarse aggregate, applied in the field of building materials, can solve the problems of difficult separation and rare application of nanomaterials, and achieve the effects of alleviating demand, improving pore structure and surface morphology, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

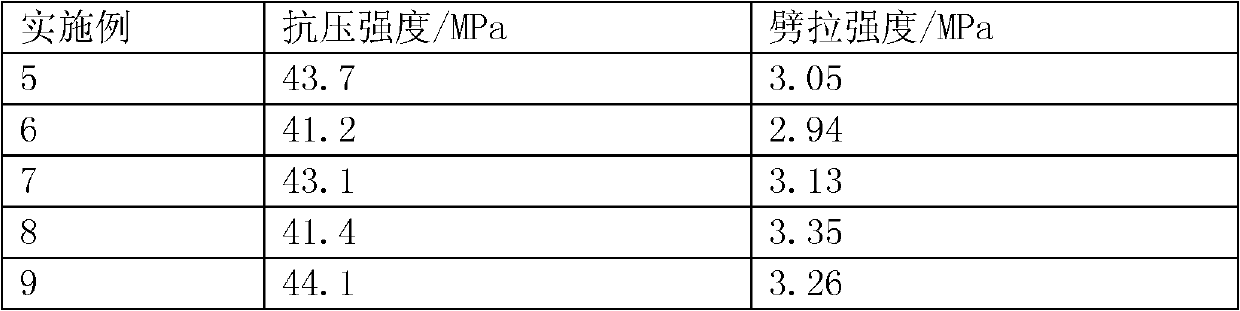

Examples

Embodiment 1

[0055] (1) The waste sintered bricks were crushed and screened to obtain regenerated coarse aggregate, and the coarse aggregate with a particle size range of 4-20 mm was selected, soaked in a nano-silica sol solution with a concentration of 1% for 72 hours, then fished out and dried. , to obtain modified brick coarse aggregate;

[0056] (2) The waste concrete test block was crushed and sieved to obtain recycled coarse aggregate, and the coarse aggregate with a particle size range of 4-20 mm was selected, and then soaked in a nano-silica sol solution with a concentration of 1% for 72 hours, then fished out and dried processing to obtain modified concrete coarse aggregate;

[0057] (3) Mix modified brick coarse aggregate and modified concrete coarse aggregate according to a certain volume ratio of 3:7 to obtain modified coarse aggregate A.

Embodiment 2

[0059] (1) The waste sintered bricks are crushed and screened to obtain regenerated coarse aggregate, and the coarse aggregate with a particle size range of 4-20 mm is selected, soaked in a nano-silica sol solution with a concentration of 2% for 48 hours, then fished out and dried. , to obtain modified brick coarse aggregate;

[0060] (2) The waste concrete test block was crushed and screened to obtain recycled coarse aggregate, and the coarse aggregate with a particle size range of 4-20mm was selected, and then soaked in a nano-silica sol solution with a concentration of 2% for 48 hours, then fished out and dried processing to obtain modified concrete coarse aggregate;

[0061] (3) Mix modified brick coarse aggregate and modified concrete coarse aggregate according to a certain volume ratio of 4:6 to obtain modified coarse aggregate B.

Embodiment 3

[0063] (1) The waste sintered bricks are crushed and screened to obtain regenerated coarse aggregate, and the coarse aggregate with a particle size range of 4-20 mm is selected, soaked in a nano-silica sol solution with a concentration of 3% for 24 hours, then fished out and dried. , to obtain modified brick coarse aggregate;

[0064] (2) The waste concrete test block was crushed and screened to obtain recycled coarse aggregate, and the coarse aggregate with a particle size range of 4-20mm was selected, and then soaked in a nano-silica sol solution with a concentration of 3% for 24 hours, then fished out and dried processing to obtain modified concrete coarse aggregate;

[0065] (3) Mix modified brick coarse aggregate and modified concrete coarse aggregate according to a certain volume ratio of 5:5 to obtain modified coarse aggregate C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com