EVA (ethylene vinyl acetate) rubber-plastic composite foaming material used for sole and preparation method

A composite foaming, rubber-plastic technology, applied in soles, applications, footwear, etc., can solve the problems of insufficient mechanical strength, tear resistance and peel resistance, poor low temperature resistance, and poor slip resistance, etc. Wear light and breathable, overcome easy slippage, and improve the effect of anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

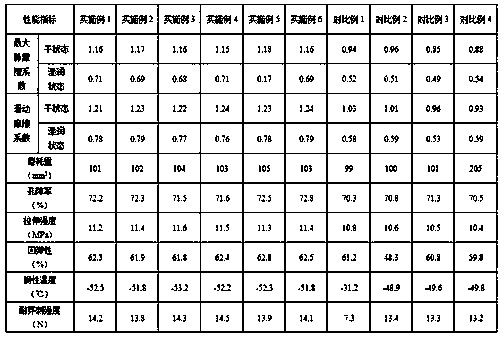

Examples

Embodiment 1

[0044] Raw materials and proportioning are:

[0045] 62 parts by weight of ethylene-vinyl acetate copolymer;

[0046] 13 parts by weight of high styrene rubber;

[0047] 7 parts by weight of random polypropylene;

[0048] 5 parts by weight of tetraacicular zinc oxide whiskers;

[0049] 3 parts by weight of nylon 66 staple fiber;

[0050] 4 parts by weight of calcium carbonate;

[0051] 3 parts by weight of tungsten-cobalt alloy;

[0052] 0.7 parts by weight of crosslinking agent;

[0053] Foaming agent 0.7 parts by weight;

[0054] 0.5 parts by weight of zinc oxide;

[0055] 0.4 parts by weight of stearic acid;

[0056] 0.7 parts by weight of antioxidant;

[0057] In the tungsten-cobalt alloy, 86 parts by weight of tungsten carbide and 14 parts by weight of cobalt; the crosslinking agent is dicumyl peroxide; the foaming agent is azodicarbonamide;

[0058] The preparation process is:

[0059] (1) Spray diamond sand onto the surface of tungsten-cobalt alloy particles at...

Embodiment 2

[0063] Raw materials and proportioning are:

[0064] Ethylene-vinyl acetate copolymer 65.4 parts by weight;

[0065] 12 parts by weight of high styrene rubber;

[0066] 6 parts by weight of random polypropylene;

[0067] 5 parts by weight of tetraacicular zinc oxide whiskers;

[0068] 3 parts by weight of nylon 66 staple fiber;

[0069] 3 parts by weight of calcium carbonate;

[0070] 3 parts by weight of tungsten-cobalt alloy;

[0071] 0.6 parts by weight of crosslinking agent;

[0072] Foaming agent 0.6 parts by weight;

[0073] Zinc oxide 0.4 parts by weight;

[0074] 0.4 parts by weight of stearic acid;

[0075] 0.6 parts by weight of antioxidant;

[0076] In the tungsten-cobalt alloy, 82 parts by weight of tungsten carbide and 18 parts by weight of cobalt; the crosslinking agent is benzoyl peroxide; the foaming agent is azobisisobutyronitrile;

[0077] The preparation process is:

[0078] (1) Spray diamond sand onto the surface of tungsten-cobalt alloy particle...

Embodiment 3

[0082] Raw materials and proportioning are:

[0083] Ethylene-vinyl acetate copolymer 65.3 parts by weight;

[0084] 14 parts by weight of high styrene rubber;

[0085] 8 parts by weight of random polypropylene;

[0086] 7 parts by weight of tetraacicular zinc oxide whiskers;

[0087] 4 parts by weight of nylon 66 staple fiber;

[0088] 5 parts by weight of calcium carbonate;

[0089] 3 parts by weight of tungsten-cobalt alloy;

[0090] 0.8 parts by weight of crosslinking agent;

[0091] Foaming agent 0.9 parts by weight;

[0092] 0.6 parts by weight of zinc oxide;

[0093] 0.5 parts by weight of stearic acid;

[0094] 0.9 parts by weight of antioxidant;

[0095] In the tungsten-cobalt alloy, 88 parts by weight of tungsten carbide and 12 parts by weight of cobalt; the crosslinking agent is dicumyl hydroperoxide; the foaming agent is urea;

[0096] The preparation process is:

[0097] (1) Spray diamond sand onto the surface of tungsten-cobalt alloy particles at high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com