Metal ultramicropore sound absorption tab

An ultra-microporous, sound-absorbing technology, applied in building components, sound insulation, covering/lining, etc., can solve problems such as increasing engineering costs and reducing decorative effects, achieving stable and reliable performance, improved practical value, and flame retardant materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

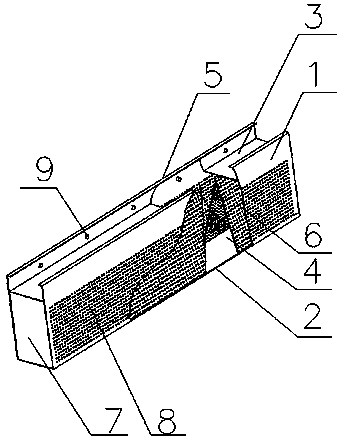

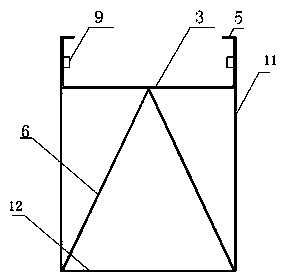

[0039] Taking the metal ultra-microporous sound-absorbing flap set in a science and technology museum as an example, combined with figure 1 with diagram 2-1 To illustrate, the metal ultra-microporous sound-absorbing tabs are made of aluminum alloy, and the cross-sectional shape of the metal ultra-micro-porous sound-absorbing tabs is shown in Figure 2-1. The cross-sectional size used in the exhibition halls and public walkways in the Science and Technology Museum is 50× 100mm (H), the length is 4500㎜, and the installation clearance is 150mm; the section size used in the hall is 50×200mm (H), the length is 3850㎜, and the installation clearance is 200mm; the interior is sound-absorbing partition 6, and the metal super The ultra-micro holes 8 on both sides of the micro-porous sound-absorbing flap have a diameter of 0.2mm, a perforation rate of 0.9%, and a material thickness of 0.6mm; The diameter of the ultra-micro holes 8 of the plate 6 is 0.3 mm, the perforation rate is 1.2%, ...

Embodiment 2

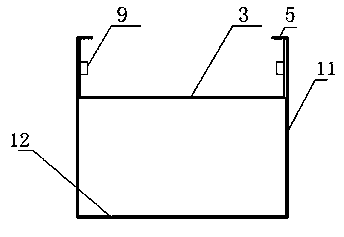

[0041] Taking the metal ultra-microporous sound-absorbing flaps for sound-absorbing and noise-reducing installation on the roof steel grid of a sports center as an example, combined with figure 1 , Figure 2-2 To illustrate, the metal ultra-microporous sound-absorbing tabs of the present invention are used in a total of 28,580 linear meters. The material of the metal ultra-micro-porous sound-absorbing tabs is aluminum alloy, the cross-sectional size is 100×50mm (H), and the installation clearance is 125mm , there is no sound-absorbing partition 6 inside; it is divided into two different perforation methods, one is the ultra-micro-hole 8 on the two side panels 1 of the metal ultra-micro-porous sound-absorbing tab 1. The aperture is 0.2mm, and the perforation rate is 0.9%. The thickness of the material is 0.6㎜; one kind of ultra-micro-hole 8 on both sides of the metal ultra-micro-porous sound-absorbing flap has an aperture diameter of 3mm, a perforation rate of 20%, and is fille...

Embodiment 3

[0043] Taking the metal ultra-microporous sound-absorbing flap set in a sports convention and exhibition center as an example, combining Figure 1, Figure 2-2 and image 3 To illustrate, the material of the metal ultra-microporous sound-absorbing sag is aluminum alloy, the cross-sectional size is 150×50mm, and the length is 3800~4500㎜. Micro-hole 8 has a diameter of 0.2 mm, a perforation rate of 0.9%, and a material thickness of 0.6 mm; the micro-perforation 3 on the supporting top plate 3 and the sealing cover plate 5 at both ends has an aperture of 0.3 mm, a perforation rate of 0.6%, and a material thickness of 0.5 mm. The top of the external corridor is made of metal ultra-microporous sound-absorbing flaps made of aluminum alloy, with a wedge-shaped cross-section, a height of 100mm, and a width of 75mm. The ratio is 1.1%, and the thickness of the material is 0.6mm; it is installed vertically and parallel, and the net spacing is 150mm. It is hung on the exhibition hall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com