Environment-friendly composite partition board and preparation method thereof

A kind of composite partition wall, environmental protection technology, applied in the direction of walls, sound insulation, building components, etc., can solve the problem of reducing the overall strength, and achieve the effect of increasing bond strength, high density, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

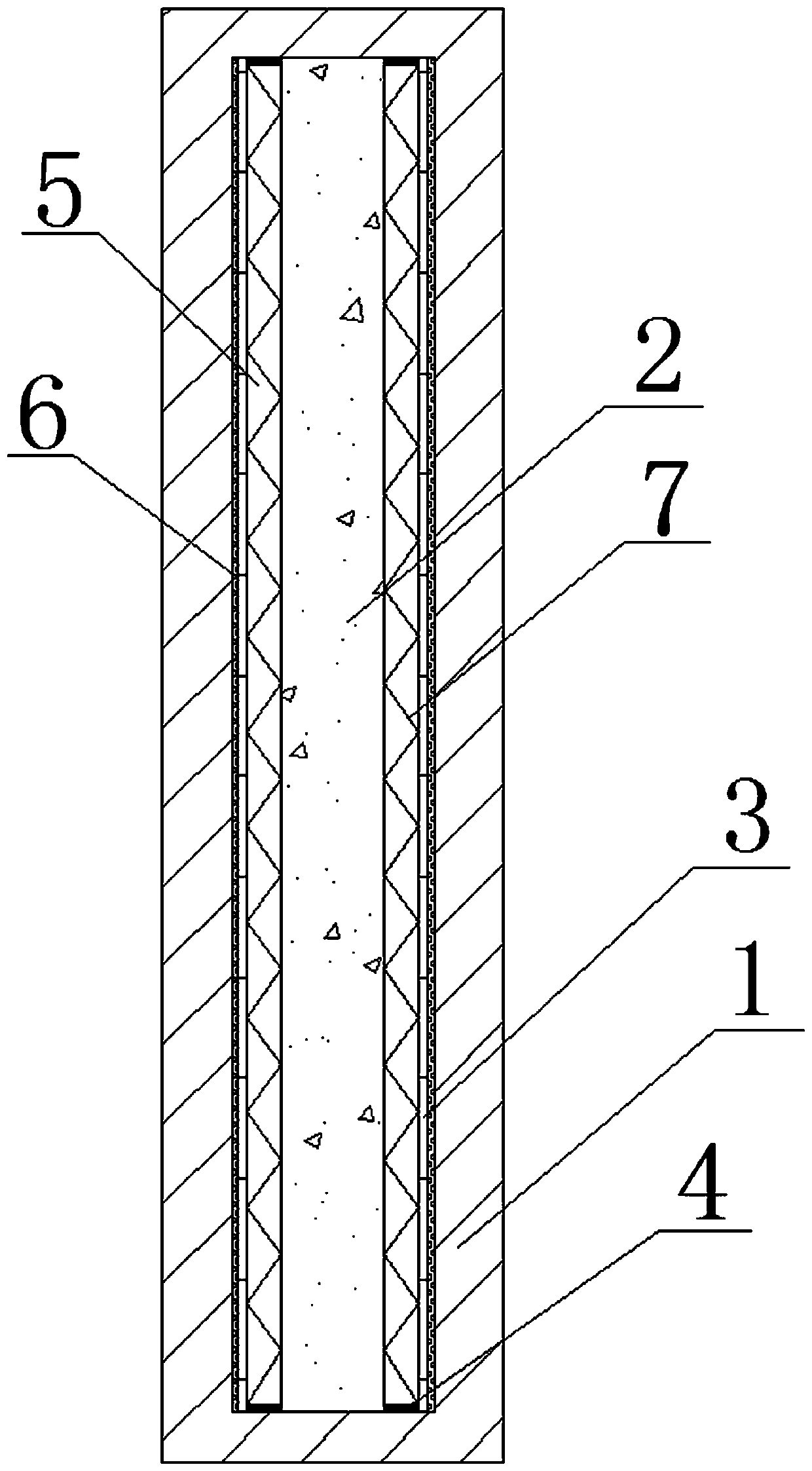

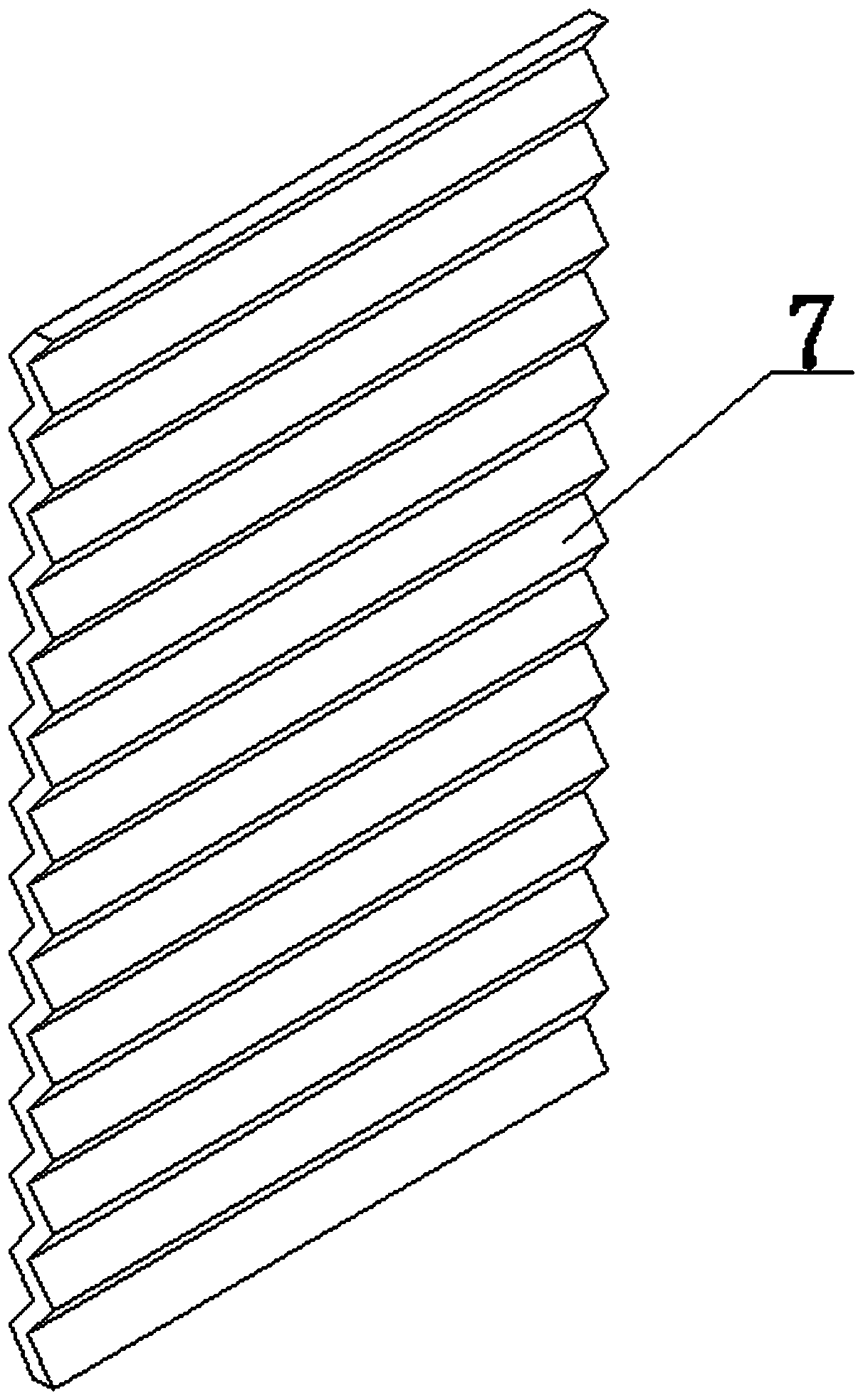

[0032] An environmentally friendly composite partition board, such as figure 1 As shown, it includes the surface layer 1 on both sides and the sandwich layer 2 in the middle, wherein the two sides of the sandwich layer 2 are respectively fixed with a perforated plate 3, and the surrounding wall 4 is fixed around the perforated plate 3. An air layer 5 is formed between them, and a corrugated plate 7 is arranged in the air layer 5, wherein the surface of the corrugated plate 7 is a zigzag structure, such as figure 2 As shown, the outer side of the perforated plate 3 is laid with multiple layers of non-woven fabrics 6, and the surface layers 1 on both sides of the sandwich layer 2 are connected up and down.

[0033] Wherein the non-woven fabric 6 is a polyester non-woven fabric, and the non-woven fabric in this embodiment has two layers; the thickness of the perforated plate is 2 mm, the aperture is 1.5 mm, and the perforation rate is 4%.

[0034] The surface layer 1 is made of...

Embodiment 2

[0044] The structure and preparation method of the environment-friendly composite partition wall panel in Example 2 are the same as in Example 1, except that the non-woven fabric 6 is polypropylene non-woven fabric, and the non-woven fabric in this embodiment has 3 layers; the perforated plate The plate thickness is 2mm, the hole diameter is 1.6mm, and the perforation rate is 3%.

[0045] The surface layer 1 is made of the following raw materials in parts by weight: 32 parts of 32.5 Portland cement, 8 parts of vermiculite powder, 11 parts of diatomaceous earth, 2.5 parts of glass fiber, 8 parts of activated carbon, 11 parts of wheat husk powder, and 11 parts of water , 1.2 parts of glass microspheres, 11 parts of rubber powder, 1.5 parts of rosin powder and 8 parts of polyurethane emulsion.

[0046] The sandwich layer 2 is made of the following raw materials in parts by weight: 22 parts of tobacco stem fiber, 11 parts of aluminum silicate fiber, 14 parts of polyurethane sponge...

Embodiment 3

[0052] The structure and preparation method of the environment-friendly composite partition wall panel in Example 3 are the same as in Example 1, except that the non-woven fabric 6 is polyester non-woven fabric, and the non-woven fabric in this embodiment has 3 layers; The plate thickness is 2mm, the hole diameter is 1.6mm, and the perforation rate is 2%.

[0053] The surface layer 1 is made of the following raw materials in parts by weight: 35 parts of 32.5 Portland cement, 9 parts of vermiculite powder, 10 parts of diatomaceous earth, 3 parts of glass fiber, 10 parts of activated carbon, 10 parts of wheat husk powder, and 12 parts of water , 1.5 parts of glass microspheres, 10 parts of rubber powder, 2 parts of rosin powder and 10 parts of polyurethane emulsion.

[0054] The sandwich layer 2 is made of the following raw materials in parts by weight: 25 parts of tobacco stem fiber, 12 parts of aluminum silicate fiber, 13 parts of polyurethane sponge and 5 parts of adhesive ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com