Variable cross-section perforated double-layer sandwich broadband sound-absorbing panel

A sound-absorbing board and variable-section technology, applied in layered products, paper/cardboard layered products, chemical instruments and methods, etc., can solve problems such as narrow sound-absorbing frequency bands, widen the sound-absorbing frequency band, and improve sound-absorbing performance. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

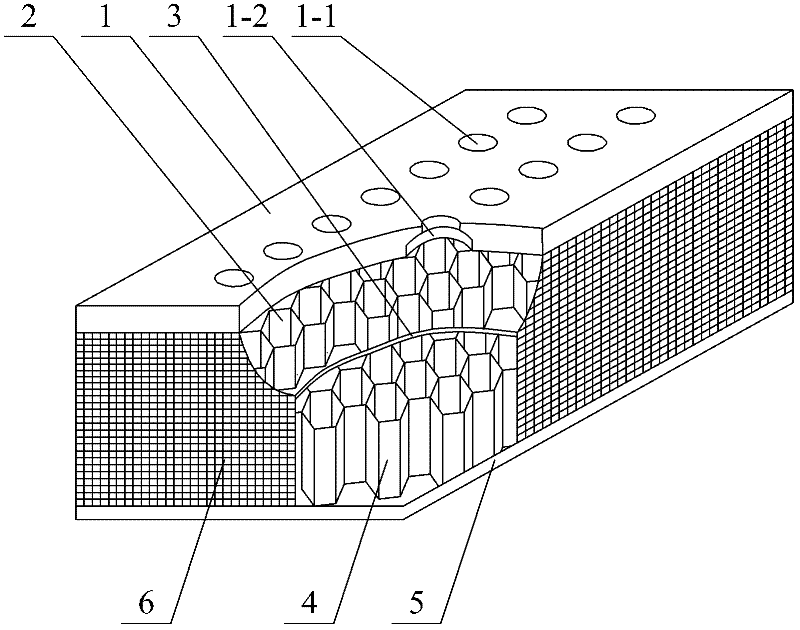

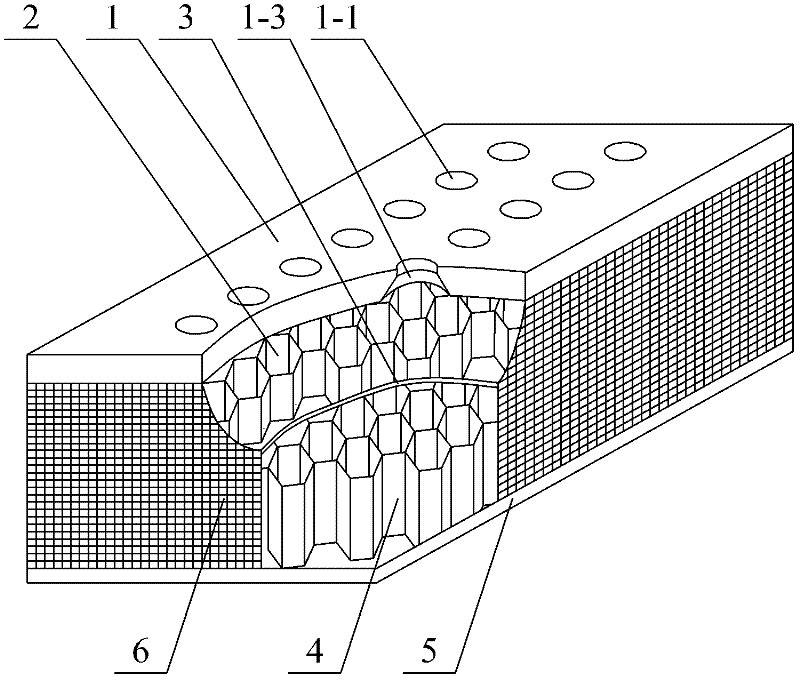

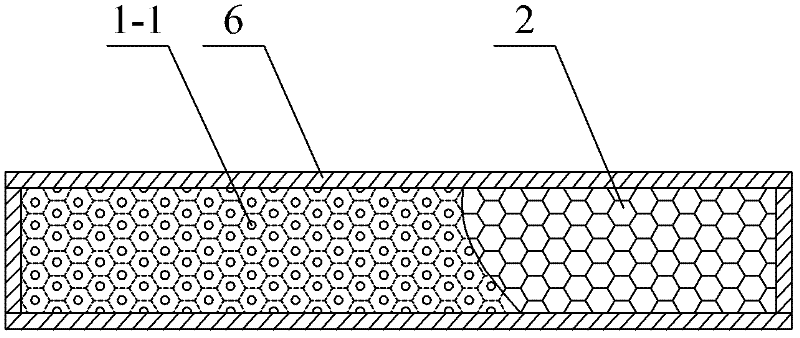

[0016] Specific implementation mode one: combine Figure 1 to Figure 5 Explain that the variable cross-section perforated double-layer sandwich broadband sound-absorbing panel of this embodiment includes a panel 1, an upper core layer 2, a paper thin layer 3, a lower core layer 4, and a back plate 5. The panel 1, the upper core layer 2, the paper thin layer 3, the lower core layer 4 and the back plate 5 are bonded together from top to bottom in sequence; the panel 1 is uniformly processed with a plurality of through holes along the thickness direction, each A through hole is made up of small-diameter circular hole 1-1 and large-diameter circular hole 1-2 or conical hole 1-3, and described small-diameter circular hole 1-1 is offered on the front of panel 1, and described large-diameter circular hole 1-2 or conical hole 1-3 is provided on the back side of panel 1, and the aperture diameter of described small-diameter circular hole 1-1 is equal to the small end aperture of conica...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 , figure 2 and Image 6 Note that the perforation rate of the panel 1 in this embodiment is 3-10%, and the perforation rate is the percentage of the sum of the areas of all through holes on the panel to the panel area. The panel 1 with a perforation rate of 3-10%, the core layer 2 with a chamber volume ratio of 0.8-0.9, and the core layer 4 with a chamber volume ratio of 0.8-0.9 are combined to greatly improve the absorption. sound rate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 1 to Figure 5 Note that, in this embodiment, the diameter of each small-diameter circular hole 1-1 is 1-10 mm; the diameter of each large-diameter circular hole 1-2 is 3-20 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com